Preparation method of high-performance modified tetracalcium phosphate 3D (three-dimensional) printing material for biomedicine

A tetracalcium phosphate, biomedical technology, applied in the field of 3D printing materials, can solve the problems of difficult to achieve chemical balance, low porosity and mechanical strength, slow chemical reaction, etc., to reduce energy consumption, cost reduction, mechanical The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

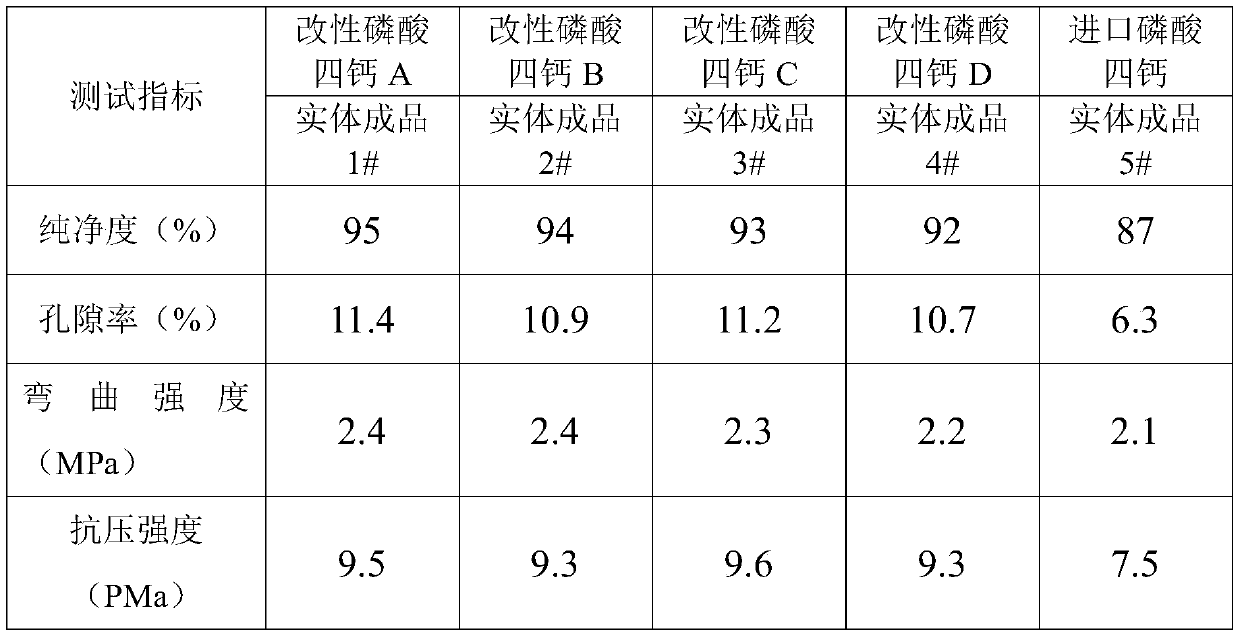

Examples

Embodiment 1

[0035] Prepare modified tetracalcium phosphate 3D printing material, the steps are:

[0036] (1) First, 1 part of Ce(NO 3 ) 3 , Add 50 parts of magnesium chloride to 500 parts of pure water and stir well; then slowly add 0.1moL·L -1 NaOH solution until the system pH ≥ 10, then add 30 parts of silica sol (SiO 2 Colloid concentration is 20%) and slowly add 0.1moL·L -1 Dilute sulfuric acid solution until the pH of the system is less than or equal to 7; then raise the temperature to 160°C and keep it warm for 2 hours; then stop the reaction and discharge the material, filter the reaction solution and wash it thoroughly, and then fully dry the filter cake at 80°C to obtain positively charged silicon Acid magnesium aluminum additive;

[0037] (2) Next, mix calcium carbonate and calcium hydrogen phosphate dihydrate according to the molar ratio of Ca:P=2:1, and then add the positively charged magnesium aluminum silicate auxiliary agent prepared in step (1) (the dosage is calcium c...

Embodiment 2

[0039] Prepare modified tetracalcium phosphate 3D printing material, the steps are:

[0040] (1) First, 2 copies of Ce 2 (SO 4 ) 3 , 3 copies of Dy(NO3 ) 3 , 40 parts of magnesium sulfate and 40 parts of magnesium nitrate are added to 500 parts of pure water and fully stirred evenly; then slowly add 0.5moL·L -1 KOH+0.5moL·L -1 Mix dilute alkali solution with NaOH until the system pH ≥ 10, then add 30 parts of silica sol (SiO 2 Colloid concentration is 20%) and 30 parts of silica sol (SiO 2 Colloid concentration is 30%), and slowly add 0.5moL·L -1 Sulfuric acid+0.5moL·L -1 Mix dilute acid solution with hydrochloric acid until the pH of the system is less than or equal to 7; then raise the temperature to 200°C and keep it warm for 4 hours; then stop the reaction and discharge the material, filter the reaction solution and wash it thoroughly, and then fully dry the filter cake at 95°C to obtain positive Charged magnesium aluminum silicate additive;

[0041] (2) Next, cal...

Embodiment 3

[0043] Prepare the modified tetracalcium phosphate 3D printing material, the steps are:

[0044] (1) First, 1 part of CeCl 3 , 1 Dy 2 (SO 4 ) 3 , 1 part of Sr(NO 3 ) 2 , 20 parts of magnesium chloride, 15 parts of magnesium sulfate, and 30 parts of magnesium nitrate are added to 500 parts of pure water and fully stirred evenly; then slowly add 0.2moL·L -1 KOH+0.3moL·L -1 NaOH+0.1moL·L -1 Mix ammonia water with dilute alkali solution until the pH of the system is ≥ 10, then add 10 parts of silica sol (SiO 2 Colloidal concentration is 20%), 10 parts of silica sol (SiO 2 Colloid concentration is 23%), 10 parts of silica sol (SiO 2 Colloid concentration is 25%), and slowly add 0.2moL·L -1 Sulfuric acid+0.3moL·L -1 Hydrochloric acid+0.1moL·L -1 Mix dilute acid solution with phosphoric acid until the pH of the system is less than or equal to 7; then raise the temperature to 170°C and keep it warm for 3 hours; then stop the reaction and discharge the material, filter the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com