Composite bioceramic material and preparation method thereof

A technology of composite bioceramics and ceramics, used in medical science, prosthesis and other directions, can solve the problems of low strength, changes in surrounding biological tissues, toxic metal ions in the human body, etc., and achieve the effect of good mechanical properties and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

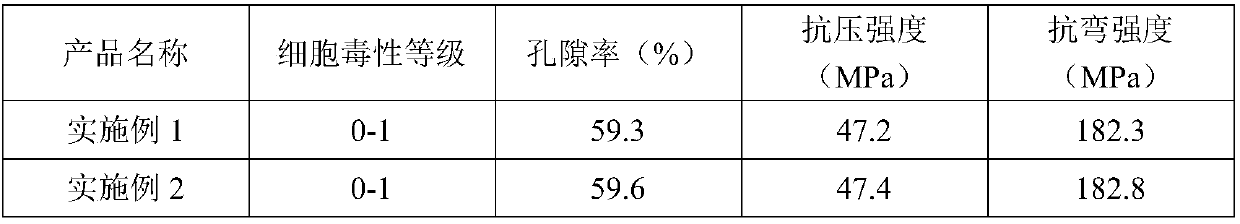

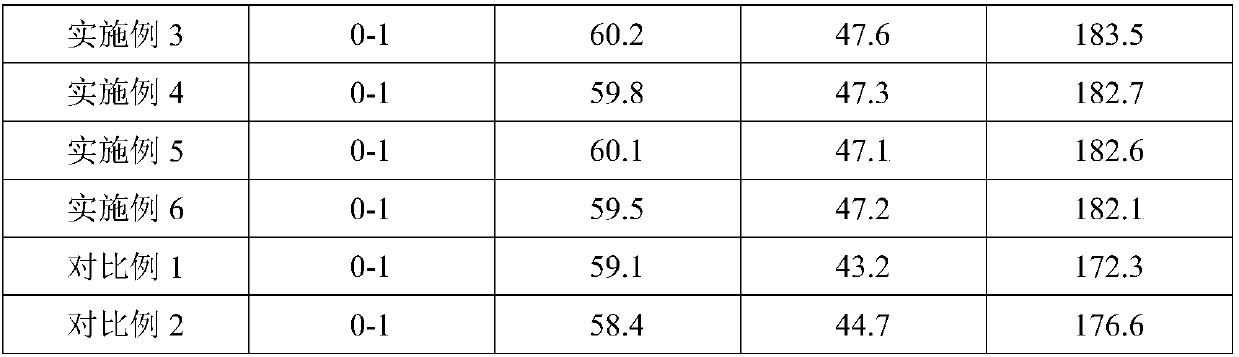

Examples

Embodiment 1

[0016] A composite bioceramic material, prepared from the following components in parts by weight: 20 parts of porous hydroxyapatite, 10 parts of biphasic calcium phosphate ceramics, 5 parts of octacalcium phosphate, 1 part of calcium pyrophosphate, 2 parts of polylactic acid, 1 part of phenolic epoxy resin, 0.6 parts of calcium nitrate, 1 part of ramie seed gum, 0.3 parts of carbon spheres, 0.2 parts of chitosan, 0.4 parts of nano-zinc oxide, 1 part of polyoxyethylene-polyoxypropylene copolymer, 0.5 parts of nano-titanium dioxide 0.4 parts of strontium carbonate, 1 part of polyoxyethylene polyoxypropylene pentaerythritol ether, 2 parts of 3,3'-diaminodipropylamine, 2 parts of polyethylene glycol, and 80 parts of distilled water.

[0017] The preparation method of the composite bioceramic material is as follows: S1: Porous hydroxyapatite, biphasic calcium phosphate ceramics, octacalcium phosphate, calcium pyrophosphate, calcium nitrate, ramie seed gum, carbon spheres, nano-tita...

Embodiment 2

[0019] A composite bioceramic material, prepared from the following components in parts by weight: 22 parts of porous hydroxyapatite, 12 parts of biphasic calcium phosphate ceramics, 6 parts of octacalcium phosphate, 1.2 parts of calcium pyrophosphate, 2.5 parts of polylactic acid, 1.5 parts of phenolic epoxy resin, 0.7 parts of calcium nitrate, 1-2 parts of ramie seed gum, 0.4 parts of carbon balls, 0.24 parts of chitosan, 0.5 parts of nano-zinc oxide, 1.2 parts of polyoxyethylene-polyoxypropylene copolymer, nano 0.6 parts of titanium dioxide, 0.48 parts of strontium carbonate, 1.2 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, 2.5 parts of 3,3'-diaminodipropylamine, 2.8 parts of polyethylene glycol, and 90 parts of distilled water.

[0020] The preparation method of the composite bioceramic material is as follows: S1: Porous hydroxyapatite, biphasic calcium phosphate ceramics, octacalcium phosphate, calcium pyrophosphate, calcium nitrate, ramie seed gum, car...

Embodiment 3

[0022] A composite bioceramic material, prepared from the following components in parts by weight: 25 parts of porous hydroxyapatite, 15 parts of biphasic calcium phosphate ceramics, 7.5 parts of octacalcium phosphate, 1.5 parts of calcium pyrophosphate, 3 parts of polylactic acid, 2 parts of phenolic epoxy resin, 0.9 parts of calcium nitrate, 1.7 parts of ramie seed gum, 0.5 parts of carbon spheres, 0.3 parts of chitosan, 0.6 parts of nano-zinc oxide, 1.4 parts of polyoxyethylene-polyoxypropylene copolymer, 0.8 parts of nano-titanium dioxide 0.6 parts of strontium carbonate, 1.6 parts of polyoxyethylene polyoxypropylene pentaerythritol ether, 4 parts of 3,3'-diaminodipropylamine, 3.5 parts of polyethylene glycol, and 130 parts of distilled water.

[0023] The preparation method of the composite bioceramic material is as follows: S1: Porous hydroxyapatite, biphasic calcium phosphate ceramics, octacalcium phosphate, calcium pyrophosphate, calcium nitrate, ramie seed gum, carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com