Drug loading biological activity glass complex calcium phosphate bone cement and application thereof

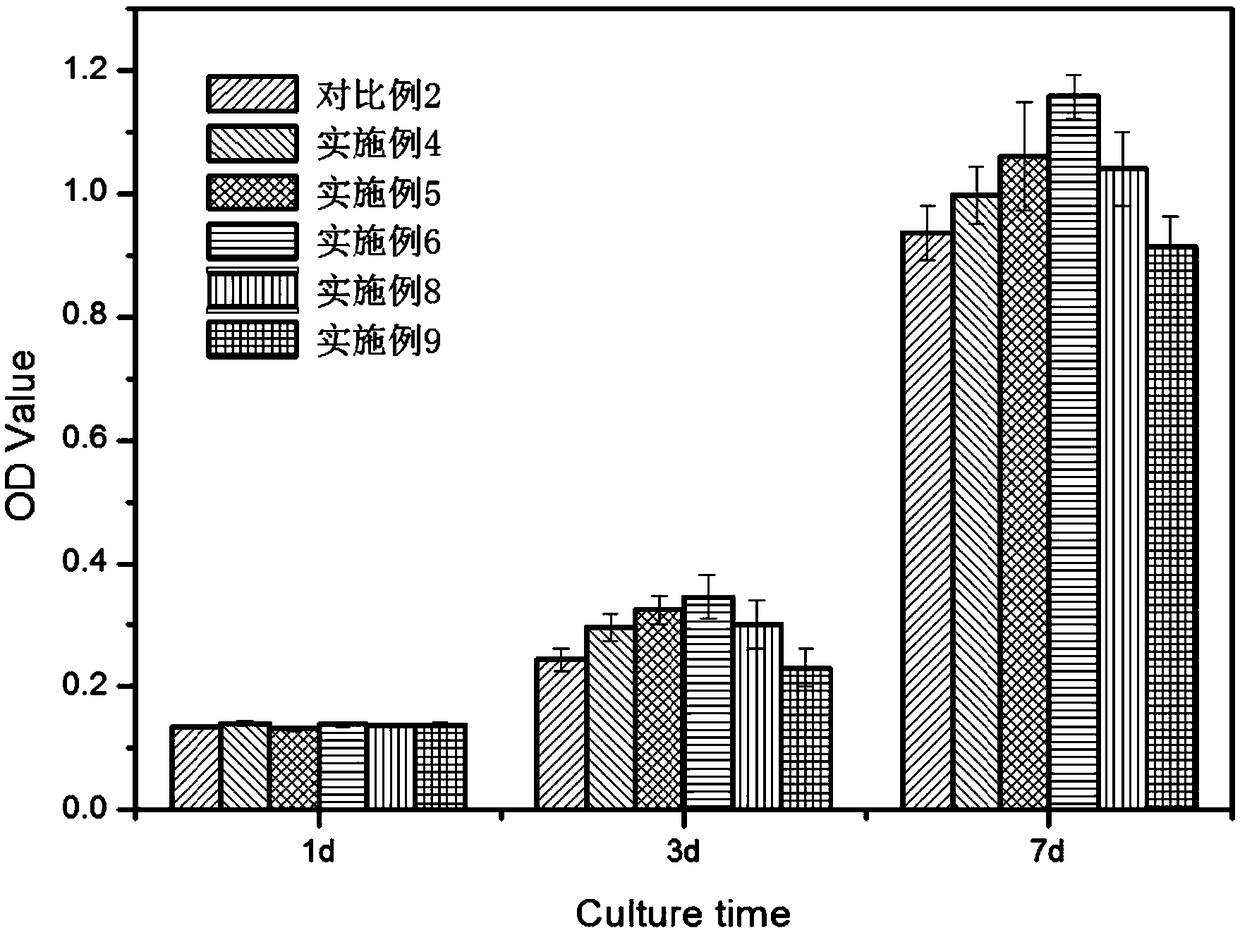

A technology of bioactive glass and calcium phosphate bone cement, which is applied in the fields of medical science, tissue regeneration, prosthesis, etc., can solve the problems of lack of macroporous structure of osteoblasts, slow degradation, low mechanical properties of calcium phosphate bone cement, etc., to achieve Increase porosity, increase compressive strength, and facilitate cell proliferation and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of drug-loaded bioactive glass microspheres described in this embodiment is:

[0037] (1) Dissolve 0.65g of calcium nitrate in a mixed solution of 180mL of deionized water and 70mL of absolute ethanol, mix uniformly to form a water phase solution; dissolve ethyl orthosilicate in cyclohexane to form an oil phase solution;

[0038] (2) Mix the water phase solution and the oil phase solution, then add 0.22g of cetyltrimethylammonium bromide and stir evenly, then add 3mL of ammonia water, stir for 3 hours, then add 0.35g of triethyl phosphate, stir for reaction , to obtain a bioactive glass gel solution, wherein the molar ratio of ethyl orthosilicate, triethyl phosphate and calcium nitrate is 80:5:15;

[0039] (3) Centrifuge the bioactive glass gel solution, wash the precipitate, and dry it at 60°C to obtain a bioactive glass gel powder;

[0040] (4) Heat-treat the obtained bioactive glass gel powder in a high-temperature furnace at 650° C. for 8 hou...

Embodiment 2

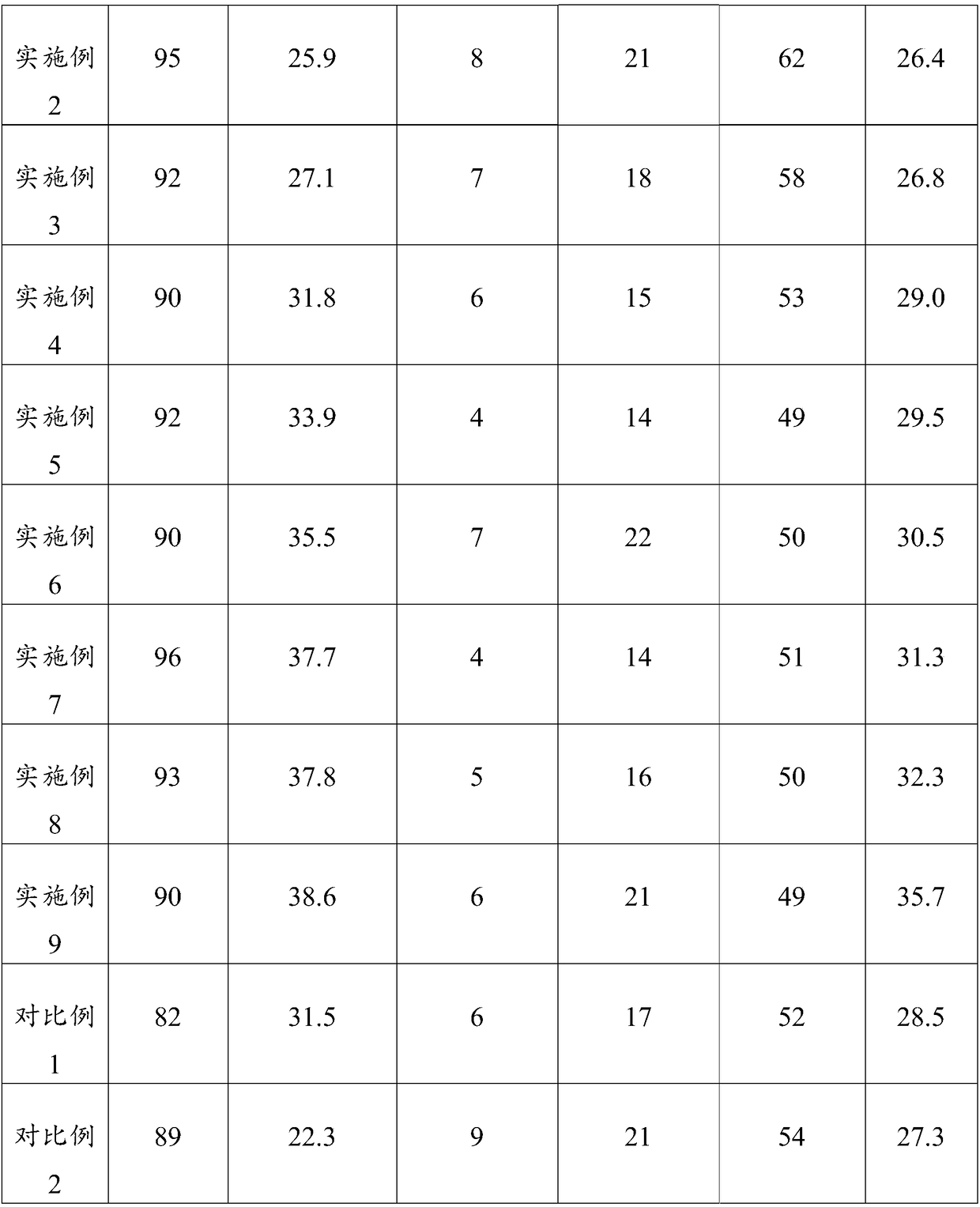

[0044] As an embodiment of the drug-loaded bioactive glass composite calcium phosphate bone cement of the present invention, the drug-loaded bioactive glass composite calcium phosphate bone cement described in this embodiment includes a solid phase powder and a solidification liquid, and the solid phase powder Comprising the drug-loaded bioactive glass microspheres and the calcium phosphate bone cement solid phase powder prepared in Example 1; the mass ratio of the drug-loaded bioactive glass microspheres and the calcium phosphate bone cement solid phase powder is 0.04:1; the calcium phosphate bone The cement solid phase powder comprises α-tricalcium phosphate, calcium carbonate and strontium-doped octacalcium phosphate; in the calcium phosphate bone cement solid phase powder, the molar ratio of strontium to calcium is: strontium:calcium=0.05:1; the calcium The molar ratio of the sum of strontium and phosphorus is: calcium+strontium: phosphorus=1.1:1; the degree of substitution o...

Embodiment 3

[0048] As an embodiment of the drug-loaded bioactive glass composite calcium phosphate bone cement of the present invention, the drug-loaded bioactive glass composite calcium phosphate bone cement described in this embodiment includes a solid phase powder and a solidification liquid, and the solid phase powder Comprising the drug-loaded bioactive glass microspheres and the calcium phosphate bone cement solid phase powder prepared in Example 1; the mass ratio of the drug-loaded bioactive glass microspheres and the calcium phosphate bone cement solid phase powder is 0.04:1; the calcium phosphate bone The cement solid phase powder comprises α-tricalcium phosphate, calcium carbonate and strontium-doped octacalcium phosphate; in the calcium phosphate bone cement solid phase powder, the molar ratio of strontium to calcium is: strontium:calcium=0.1:1; the calcium The molar ratio of the sum of strontium and phosphorus is: calcium+strontium: phosphorus=1.2:1; the degree of substitution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com