Silk fibroin/octacalcium phosphate composite bone scaffold material and preparation method

A technology of silk fibroin and octacalcium phosphate, applied in the field of materials, to achieve good degradation performance and mechanical properties, increase strength, and enhance osteogenic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Dissolve silk fibroin in 50 mL of calcium nitrate 40 mM solution to prepare a solution with a silk fibroin concentration of 0.1 wt%.

[0029] 2. Prepare 50 mL of sodium dihydrogen phosphate solution with a concentration of 40 mM.

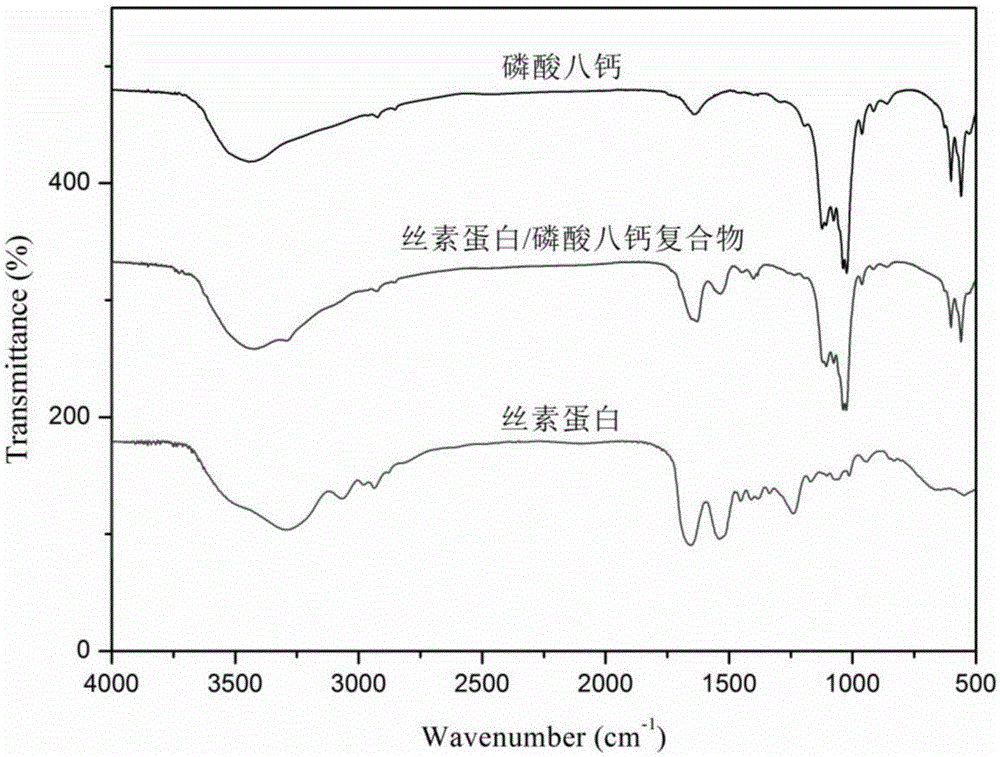

[0030] 3. Slowly add the silk fibroin-containing calcium nitrate solution prepared in step 1) to the sodium dihydrogen phosphate solution prepared in step 2) under stirring conditions at 68°C, and continue stirring for 1 hour to finally obtain a white precipitate things. After the white precipitate was centrifuged and washed three times, it was placed at -80°C for 1 day, and after 2 days of freeze-drying, the silk fibroin / octacalcium phosphate complex was obtained. Its infrared spectrum is as follows: figure 1 shown;

[0031] 4. Grind the silk fibroin / octacalcium phosphate compound obtained in step 3) into powder with a mortar, weigh 20 mg of powder, mix it with 1 mL of silk fibroin solution with a concentration of 6 wt%, and inject it i...

Embodiment 2

[0034] 1. Dissolve silk fibroin in 50 mL of calcium nitrate 80 mM solution to prepare a solution with a silk fibroin concentration of 0.5 wt%.

[0035] 2. Prepare 50 mL of sodium dihydrogen phosphate solution with a concentration of 80 mM.

[0036] 3. Slowly add the silk fibroin-containing calcium nitrate solution prepared in step 1) to the sodium dihydrogen phosphate solution prepared in step 2) under stirring conditions at 70°C, and continue to stir for 1.5 hours to finally obtain a white precipitate things. The white precipitate was centrifuged and washed three times, placed at -80°C for 1 day, and freeze-dried for 2 days to obtain the silk fibroin / octacalcium phosphate complex;

[0037] 4. Grind the silk fibroin / octacalcium phosphate compound obtained in step 3) into powder with a mortar, weigh 50 mg of powder, mix it with 1 mL of silk fibroin solution with a concentration of 10 wt%, and inject it into a cylindrical mold. Placed at -80°C for 1 day and freeze-dried for 2 ...

Embodiment 3

[0040] 1. Dissolve silk fibroin in 120 mL of calcium nitrate 40 mM solution to prepare a solution with a silk fibroin concentration of 2 wt%.

[0041] 2. Prepare 120 mL of sodium dihydrogen phosphate solution with a concentration of 40 mM.

[0042] 3. Under the condition of heating and stirring at 68°C, slowly add the calcium nitrate solution containing silk fibroin prepared in step 1) to the sodium dihydrogen phosphate solution prepared in step 2), and continue stirring for 1.5 hours, and finally a white precipitate is obtained things. The white precipitate was centrifuged and washed three times, placed at -80°C for 1 day, and freeze-dried for 2 days to obtain the silk fibroin / octacalcium phosphate complex;

[0043] 4. Grind the silk fibroin / octacalcium phosphate compound obtained in step 3) into powder with a mortar, weigh 100 mg of powder, mix it with 1 mL of silk fibroin solution with a concentration of 10 wt%, and inject it into a cylindrical mold. Placed at -80°C for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com