Bone defect repair material based on modified perovskite quantum dots and preparation method of bone defect repair material

A repair material, perovskite technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve problems such as intensifying halogen vacancies and interstitial metals, poor stability of perovskite quantum dots, and accelerating perovskite structure collapse. Achieve the effect of preventing oxidation, excellent metal chelating properties, improving stability and biological safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A bone defect repair material based on modified perovskite quantum dots, including the following raw materials in mass percentage: hydroxyapatite 20%, octacalcium phosphate 10%, bone morphogenetic protein 0.5%, collagen 1%, chondroitin sulfate 0.5%, carboxymethyl chitosan 3%, modified perovskite quantum dot solution to make up the balance;

[0030] The reaction raw materials and mass parts of the modified perovskite quantum dot solution are as follows: CsPbBr 3 0.5 parts of perovskite quantum dots, 8 parts of dipalmitoylphosphatidylethanolamine, 3 parts of aspartic acid, 1 part of reduced glutathione, 0.5 parts of EDC·HCl, 20 parts of chloroform, and 100 parts of deionized water.

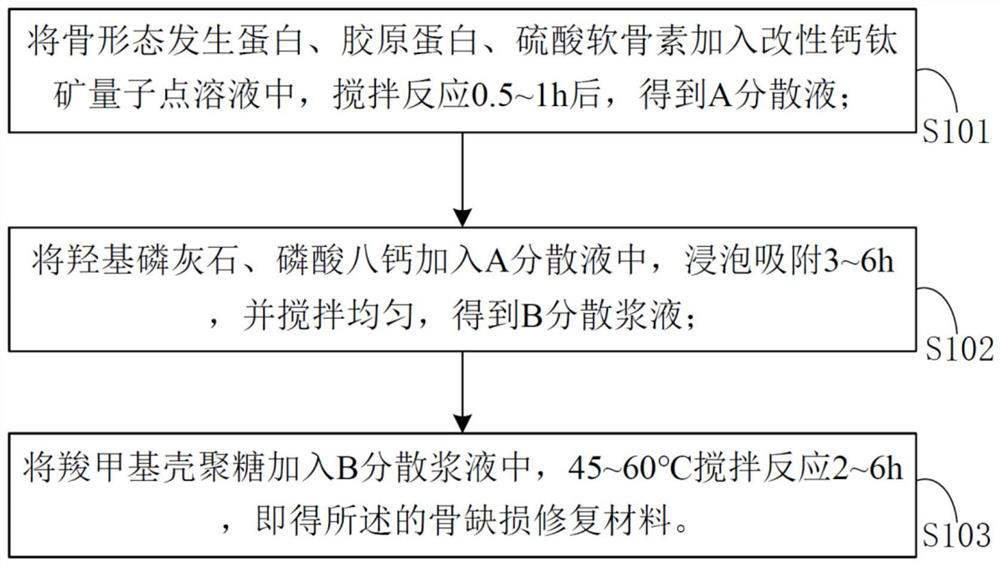

[0031] A method for preparing a bone defect repair material based on modified perovskite quantum dots, comprising the following steps:

[0032] S101: Prepare modified perovskite quantum dot solution:

[0033] i: Add dipalmitoylphosphatidylethanolamine to chloroform solvent, magnetically sti...

Embodiment 2

[0040] A bone defect repair material based on modified perovskite quantum dots, including the following raw materials in mass percentage: hydroxyapatite 25%, octacalcium phosphate 15%, bone morphogenetic protein 1%, collagen 3%, chondroitin sulfate 1%, carboxymethyl chitosan 4%, modified perovskite quantum dot solution to make up the balance;

[0041] The reaction raw materials and mass parts of the modified perovskite quantum dot solution are as follows: 1 part of perovskite quantum dot, 12 parts of dipalmitoylphosphatidylethanolamine, 5 parts of glutamic acid, 2 parts of reduced glutathione, 1 part of EDC·HCl, 25 parts of chloroform, 100 parts of deionized water.

[0042] A method for preparing a bone defect repair material based on modified perovskite quantum dots, comprising the following steps:

[0043] S101: Prepare modified perovskite quantum dot solution:

[0044] i: Add dipalmitoylphosphatidylethanolamine to chloroform solvent, magnetically stir until completely dis...

Embodiment 3

[0051] A bone defect repair material based on modified perovskite quantum dots, including the following raw materials in mass percentage: 30% of hydroxyapatite, 20% of octacalcium phosphate, 2% of bone morphogenetic protein, 5% of collagen, and chondroitin sulfate 2%, carboxymethyl chitosan 5%, modified perovskite quantum dot solution to make up the balance;

[0052] The reaction raw materials and mass parts of the modified perovskite quantum dot solution are as follows: CsSnBr 2.5 I 0.5 1.5 parts of perovskite quantum dots, 16 parts of dipalmitoylphosphatidylethanolamine, 7 parts of aspartic acid, 3 parts of reduced glutathione, 1 part of EDC·HCl, 30 parts of chloroform, and 100 parts of deionized water.

[0053] A method for preparing a bone defect repair material based on modified perovskite quantum dots, comprising the following steps:

[0054] S101: Prepare modified perovskite quantum dot solution:

[0055] i: Add dipalmitoylphosphatidylethanolamine to chloroform solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com