Preparation method of composite coating with excellent biocompatibility and antibacterial property on surface of medical implant

A biocompatible and composite coating technology, applied in coatings, prostheses, medical science, etc., can solve problems such as high cost, lack of antibacterial properties of coatings, loose implants, etc., to achieve optimized surface morphology, Suitable for cell growth and enhanced antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Composite films of octacalcium phosphate and ε-polylysine were prepared by electrochemical co-deposition. The pure titanium foil was cut into a size of 1cm×1cm, ultrasonically cleaned in acetone, ethanol and deionized water for 15min, and then air-dried. Preparation solution: HF and HNO 3 The volume ratio is 1:10, and the pretreated titanium foil is immersed in the mixed acid solution for 2 minutes, rinsed with deionized water, and dried in the air. After removal, the deposition solution contained 10 mg / mL ε-polylysine, 0.014M Ca(NO 3 ) 2 and 0.04M NH 4 h 2 PO 4 , the treated titanium foil was used as the cathode, the graphite rod was used as the anode, and the constant current mode (0.5mA / cm 2 ) was electrodeposited on the surface of titanium foil to obtain a composite film of octacalcium phosphate and ε-polylysine, and the deposition time was 10 min.

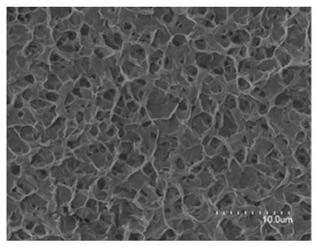

[0030] figure 1 The scanning electron microscope images of the octacalcium phosphate and ε-polylysine composi...

Embodiment 2

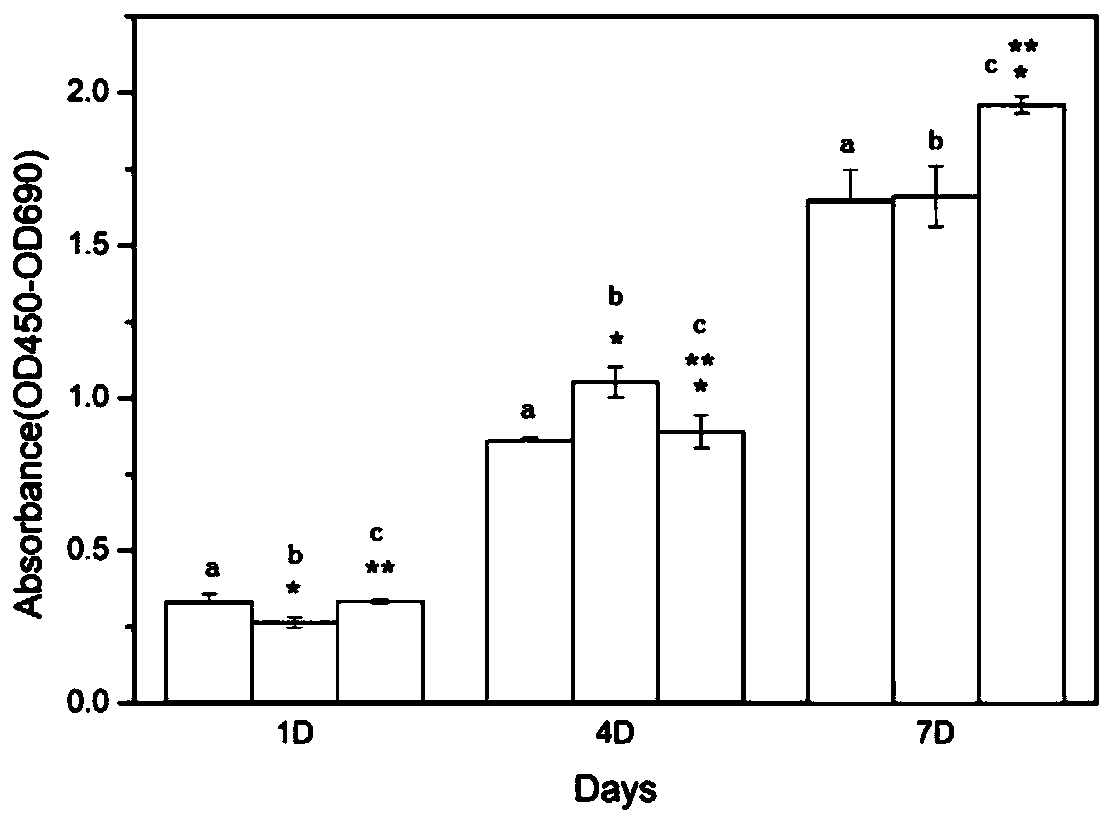

[0032] Prepare the octacalcium phosphate and ε-polylysine composite film layer in Example 1 on the surface of pure titanium foil, and use the octacalcium phosphate film layer without ε-polylysine prepared under the same conditions as a comparison sample with WST -1 detection kit for cell proliferation test, using MC3T3-E1 cells, cell density 2×10 4 / cm 2 , and incubated for 1 day, 4 days, and 7 days. The result is as figure 2 As shown, the cells grow and adhere well on the surface of the octacalcium phosphate and ε-polylysine composite film, and have a certain ability to promote cell proliferation. When the cells were cultured for 7 days, the octacalcium phosphate and ε-polylysine composite film The cell proliferation rate is even higher than that of the octacalcium phosphate film layer, indicating that the composite film layer of octacalcium phosphate and ε-polylysine has good biocompatibility and biological activity.

Embodiment 3

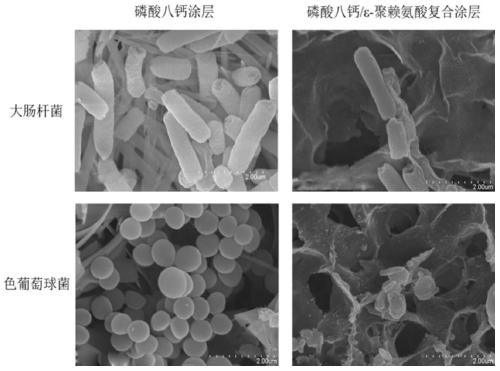

[0034] Prepare the octacalcium phosphate and ε-polylysine composite film layer in Example 1 on the surface of pure titanium foil, and use the octacalcium phosphate film layer without ε-polylysine prepared under the same conditions as a comparison sample Pyridine orange staining was used for antibacterial experiments, using Escherichia coli and Staphylococcus aureus, cultured for 24 hours. The result is as image 3 and 4 As shown, due to the presence of ε-polylysine, the composite film layer of octacalcium phosphate and ε-polylysine significantly enhanced the inhibitory effect of the material surface on Escherichia coli and Staphylococcus aureus, making the implant have a strong Antibacterial properties.

[0035] The invention uses titanium, titanium alloy, tantalum alloy, stainless steel and other medical implants as the substrate, and constructs a composite film layer of octacalcium phosphate and ε-polylysine on the surface. Compared with the octacalcium phosphate film lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com