High-strength easily degradable modified polyethylene film and preparation method thereof

A polyethylene film and easy-to-degrade technology, which is applied in the field of high-strength and easily-degradable modified polyethylene film and its preparation, can solve the problems that the performance of recycled products cannot meet the requirements, the economic benefits of recycling are not obvious, and the strength is not enough, and achieve green Low energy consumption compatibility, improved thermo-oxidative degradation, good degradation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

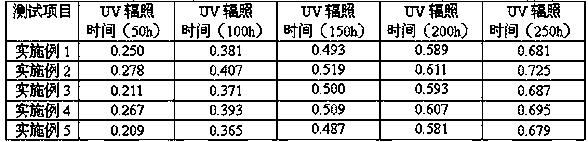

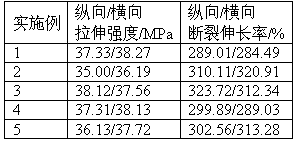

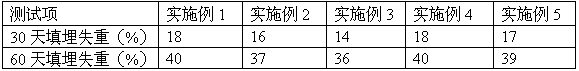

Examples

Embodiment 1

[0021] Example 1 Preparation of high-strength and easily degradable modified polyethylene film

[0022] (1) Preparation of nano-copper oxide mimetic enzyme: according to the molar ratio of copper nitrate: water: sodium citrate is 1: 10: 1, first make a solution of copper nitrate and water, and then add the required molar amount of Saturated sodium citrate solution was added dropwise to the copper nitrate solution while stirring. After the dropwise addition, a complex salt solution was obtained. The complex salt solution was placed in a hydrothermal reaction kettle, and reacted at 100°C for 8h, 6000r / min centrifuged for 20 minutes, washed with water, vacuum-dried at 5kPa and 60°C for 30 minutes to obtain nano-copper oxide mimetic enzyme;

[0023](2) Preparation of nano-copper oxide mimetic enzyme coated with hydrophilic modified polyurea: according to the mass ratio of toluene-2,4-diisocyanate: triethylenetetramine: nano-copper oxide mimetic enzyme: water: acetone is 5:1 ︰5︰3...

Embodiment 2

[0026] Example 2 Preparation of high-strength and easily degradable modified polyethylene film

[0027] (1) Preparation of nano-copper oxide mimetic enzyme: according to the molar ratio of copper nitrate: water: sodium citrate is 1: 15: 1, first make a solution of copper nitrate and water, and then add the required molar amount of Saturated sodium citrate solution was added dropwise to the copper nitrate solution while stirring. After the dropwise addition, a complex salt solution was obtained. The complex salt solution was placed in a hydrothermal reaction kettle and reacted at 120°C for 12h, 8000r / min centrifuged for 40 minutes, washed with water, vacuum-dried at 20kPa and 80°C for 60 minutes to obtain nano-copper oxide mimetic enzyme;

[0028] (2) Preparation of nano-copper oxide mimetic enzyme coated with hydrophilic modified polyurea: according to the mass ratio of toluene-2,4-diisocyanate: triethylenetetramine: nano-copper oxide mimetic enzyme: water: acetone is 8:1 ︰1...

Embodiment 3

[0031] Example 3 Preparation of high-strength and easily degradable modified polyethylene film

[0032] (1) Preparation of nano-copper oxide mimetic enzyme: according to the molar ratio of copper nitrate: water: sodium citrate is 1: 11: 1, first make a solution of copper nitrate and water, and then add the required molar amount of Saturated sodium citrate solution was added dropwise to the copper nitrate solution while stirring. After the dropwise addition, a complex salt solution was obtained. The complex salt solution was placed in a hydrothermal reaction kettle and reacted at 110°C for 9h, 7000r / min centrifuged for 30min, washed with water, vacuum-dried at 8kPa and 70°C for 40min to obtain nano-copper oxide mimetic enzyme;

[0033] (2) Preparation of nano-copper oxide mimetic enzyme coated with hydrophilic modified polyurea: according to the mass ratio of toluene-2,4-diisocyanate: triethylenetetramine: nano-copper oxide mimetic enzyme: water: acetone is 6:1 ︰7︰4︰5 ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com