Injectable calcium sulfate hemihydrate/octacalcium phosphate/sodium hyaluronate sulphate composite artificial bone material and preparation method thereof

A technology of sodium hyaluronate and calcium sulfate hemihydrate, which is applied in the fields of pharmaceutical formula, medical science, prosthesis, etc., can solve the problems of incomplete degradation, influence of new bone growth, long time of body retention, etc., and achieve operation Ease of application, good injectability, good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

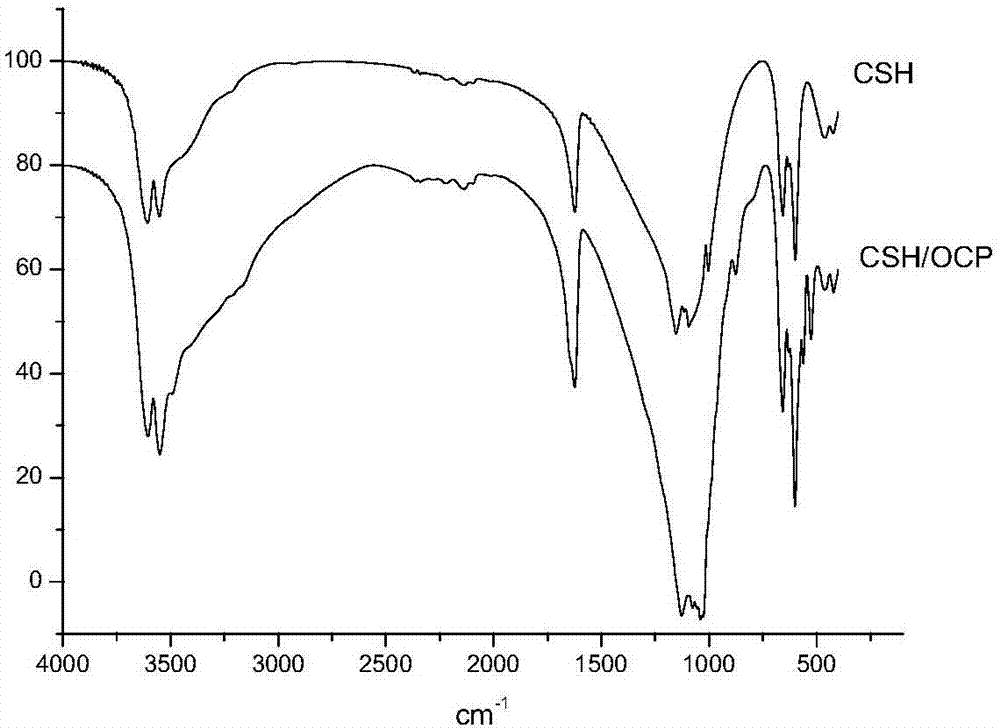

[0030] (1) Preparation of calcium sulfate hemihydrate powder: take analytically pure calcium sulfate dihydrate as raw material, adopt steam heating method to prepare calcium sulfate hemihydrate, at first, add a certain amount of calcium sulfate dihydrate in stainless steel container, then Add the corresponding amount of crystal-transforming agent solution that has been prepared, stir evenly, and react in a closed high-temperature and high-pressure reactor under the conditions of 0.15-0.2MPa pressure and 125-135°C for 4-6 hours, then take it out, and then put it into the temperature setting Dry it in an oven at 125-135°C, and finally take it out, grind it and sieve it to obtain calcium sulfate hemihydrate powder.

[0031] (2) Preparation of octacalcium phosphate powder: prepare a calcium acetate solution with a concentration of 0.04M and a sodium dihydrogen phosphate solution of 0.04M, and then slowly add the prepared calcium acetate solution to the sodium dihydrogen phosphate s...

Embodiment 1

[0037]An injectable calcium sulfate hemihydrate / octacalcium phosphate / sodium hyaluronate sulfate composite artificial bone material is prepared by the following method:

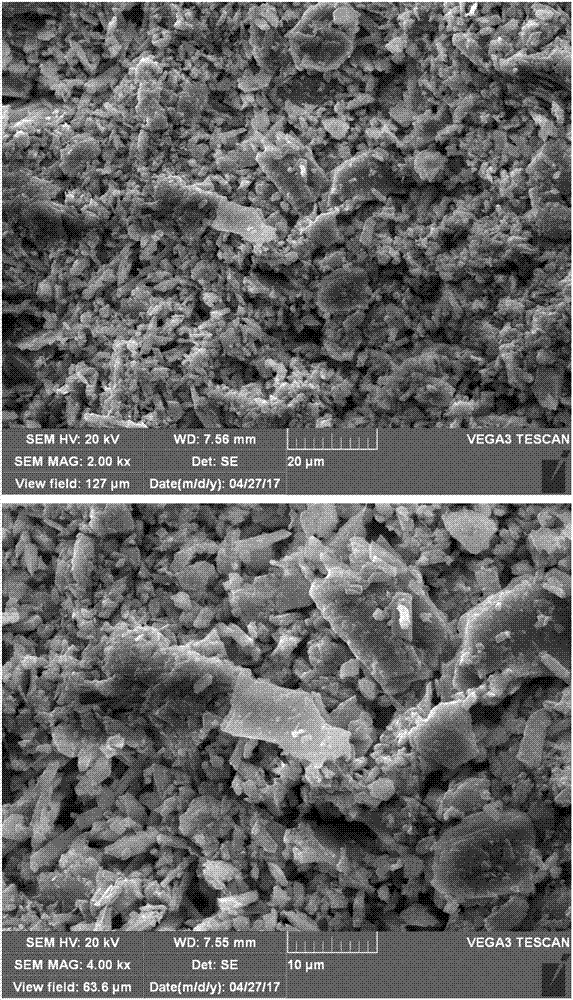

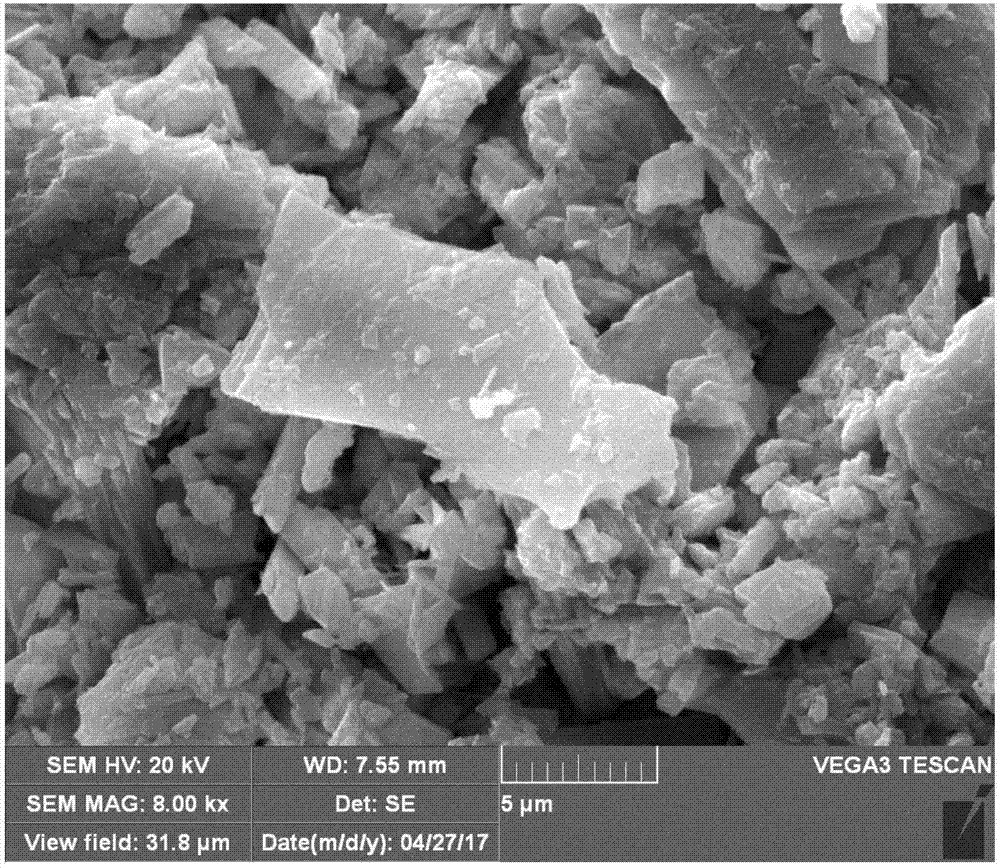

[0038] (1) Preparation of calcium sulfate hemihydrate / octacalcium phosphate composite powder: Mix 2 g of α-calcium sulfate hemihydrate (CSH) with a particle size of 1 to 200 μm and 2 g of octacalcium phosphate with a particle size of 1 to 200 μm, and add to Ultrasonic dispersion in absolute ethanol, followed by drying to make calcium sulfate hemihydrate / octacalcium phosphate composite powder;

[0039] (2) Preparation of sodium hyaluronate sulfate solidified solution: dissolve sodium hyaluronate sulfate with a particle size of 1 to 100 μm in deionized water, and stir magnetically to obtain a 1 wt% sodium hyaluronate sulfate solidified solution;

[0040] (3) Mix sodium hyaluronate sulfate solidified liquid with calcium sulfate hemihydrate / octacalcium phosphate composite powder at a ratio of 0.5ml / g for 0.5 to 2...

Embodiment 2

[0043] An injectable calcium sulfate hemihydrate / octacalcium phosphate / sodium hyaluronate sulfate composite artificial bone material is prepared by the following method:

[0044] (1) Preparation of calcium sulfate hemihydrate / octacalcium phosphate composite powder: mix 2 g of α-calcium sulfate hemihydrate (CSH) with a particle size of 1 to 300 μm and 1 g of octacalcium phosphate with a particle size of 1 to 200 μm, and add to Ultrasonic dispersion in absolute ethanol, followed by drying to make calcium sulfate hemihydrate / octacalcium phosphate composite powder;

[0045] (2) Preparation of sodium hyaluronate sulfate solidified solution: dissolve sodium hyaluronate sulfate with a particle size of 1 to 100 μm in deionized water, and stir magnetically to obtain a 1 wt% sodium hyaluronate sulfate solidified solution;

[0046] (3) Mix the sodium hyaluronate sulfate solidified solution with calcium sulfate hemihydrate / octacalcium phosphate composite powder at a ratio of 0.4ml / g for 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com