Preparation method of pipe type inorganic-organic compound micro-filtration membrane

A microfiltration membrane and organic technology, which is applied in the field of preparation of tubular inorganic-organic composite microfiltration membranes, can solve the problems of increasing the preparation cost of composite membranes, unfavorable industrialization of the preparation process, and unfavorable large-scale production, etc., and shorten the production process. cycle, avoid high temperature sintering process, simple and fast preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

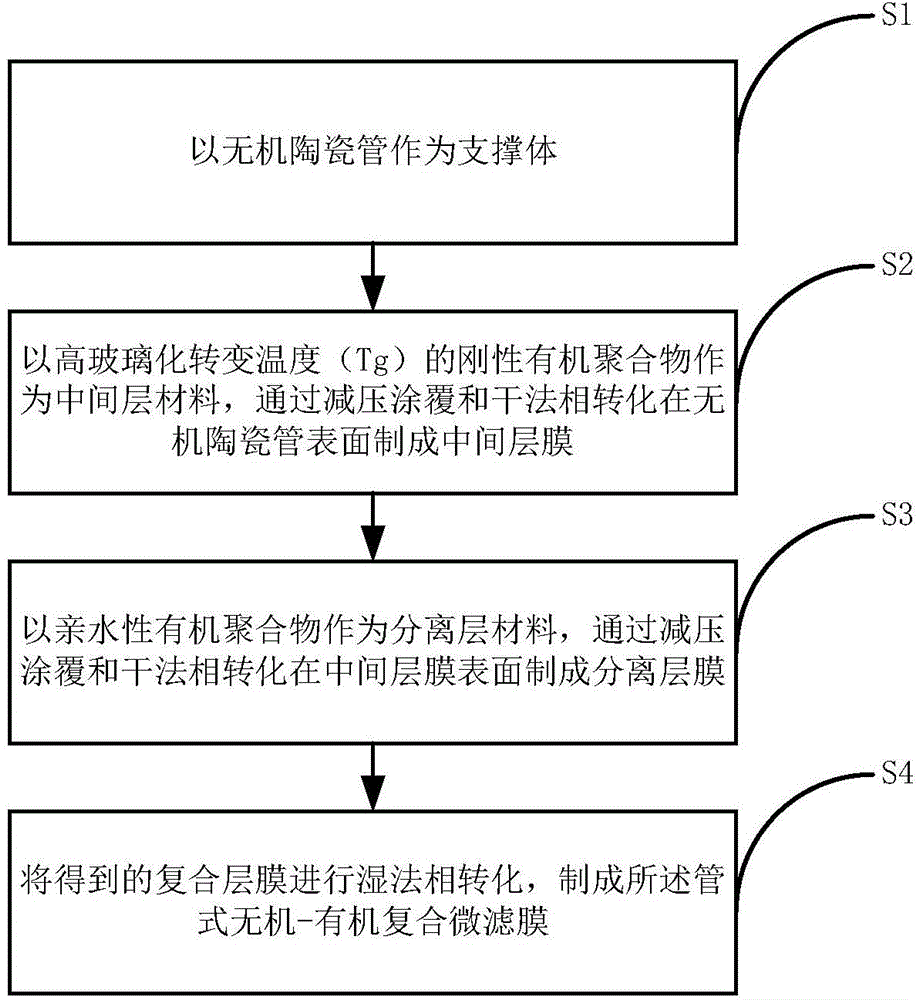

[0041] refer to figure 1 , a method for preparing a tubular inorganic-organic composite microfiltration membrane proposed by the present invention, comprising:

[0042] S1. Use inorganic ceramic tubes as supports.

[0043] S2. A rigid organic polymer with a high glass transition temperature (Tg) is used as an intermediate layer material, and an intermediate layer film is formed on the surface of the inorganic ceramic tube by vacuum coating and dry phase inversion.

[0044] Wherein, Tg≥200°C, more preferably Tg≥210°C, further preferably Tg≥220°C, further preferably Tg≥230°C, further preferably Tg≥240°C, further preferably Tg≥250°C. Specifically, the high glass transition temperature (Tg) rigid organic polymer includes at least one of polyarylsulfone, polyethersulfone, polyetherketone, phenolphthalein-based polyethersulfone or phenolphthalein-based polyetherketone. During the preparation process, a rigid organic polymer with a high glass transition temperature (Tg) is dissolve...

Embodiment 1

[0051] In Example 1 of the present invention: the material of the inorganic ceramic tube is α-Al 2 o 3 , The configuration is a single channel, the pore size is 0.2-2μm; the rigid organic polymer with high Tg is polyaryl sulfone; the hydrophilic organic polymer is cellulose acetate. The vacuum degree of the pump was 0.02 MPa during the decompression coating process, and the temperature and humidity were 20° C. and 60% during the dry phase inversion process.

[0052] A kind of preparation method of the tubular inorganic-organic composite microfiltration membrane that embodiment 1 proposes, comprising:

[0053] S1. Clean the inorganic ceramic tube with deionized water, then soak it in deionized water for 8 hours, and then dry it at 60°C for 12 hours;

[0054] S2. Prepare 10% polyarylsulfone coating solution, the solvent used is N-methylpyrrolidone, use polyarylsulfone coating solution to carry out decompression coating on the inner surface of the inorganic ceramic tube, and th...

Embodiment 2

[0059] In Example 2 of the present invention: the material of the inorganic ceramic tube is α-Al 2 o 3 , The configuration is a single channel, the pore size is 2-10μm; the rigid organic polymer with high Tg is polyaryl sulfone; the hydrophilic organic polymer is cellulose acetate. The vacuum degree of the pump was 0.02 MPa during the decompression coating process, and the temperature and humidity were 40° C. and 70% during the dry phase inversion process.

[0060] A kind of preparation method of the tubular inorganic-organic composite microfiltration membrane that embodiment 2 proposes, comprising:

[0061] S1. Wash the inorganic ceramic tube with deionized water, then soak it in deionized water for 8 hours, and then dry it at 60° C. for 12 hours.

[0062] S2. Prepare 20% polyarylsulfone coating solution, the solvent used is N-methylpyrrolidone, use polyarylsulfone coating solution to carry out decompression coating on the inner surface of the inorganic ceramic tube, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com