Preparation method of silicate positive electrode material for lithium ion battery

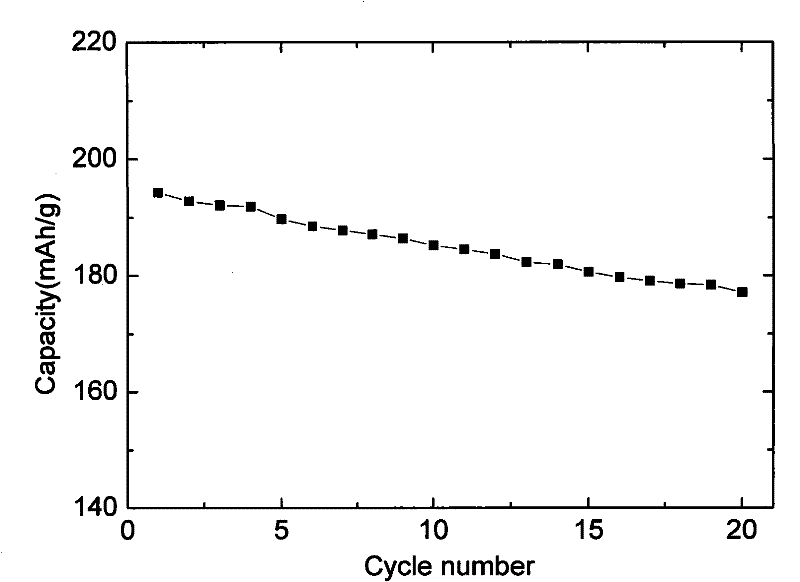

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problem of poor electrochemical performance of silicate positive electrode materials, uneven particles of silicate positive electrode materials, and unsuitability for large-scale Industrial production and other issues, to achieve high practical value, good electrochemical performance, and high reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

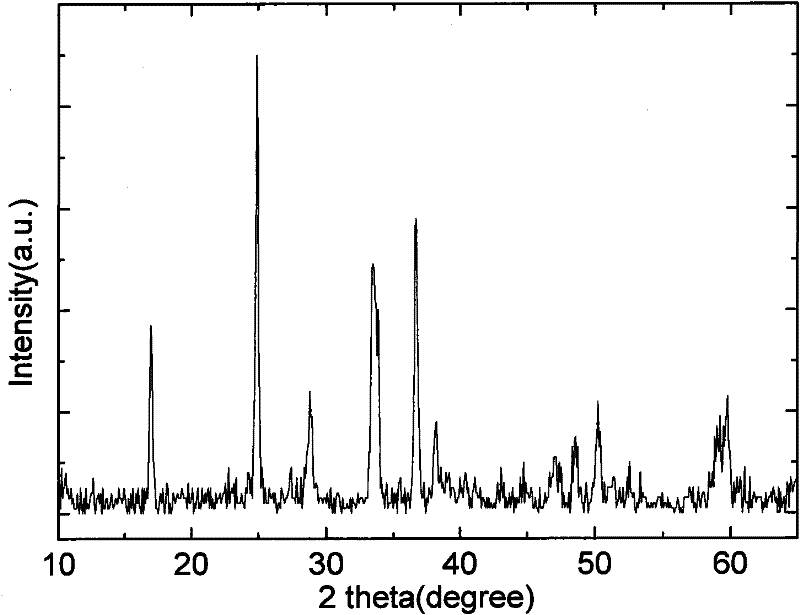

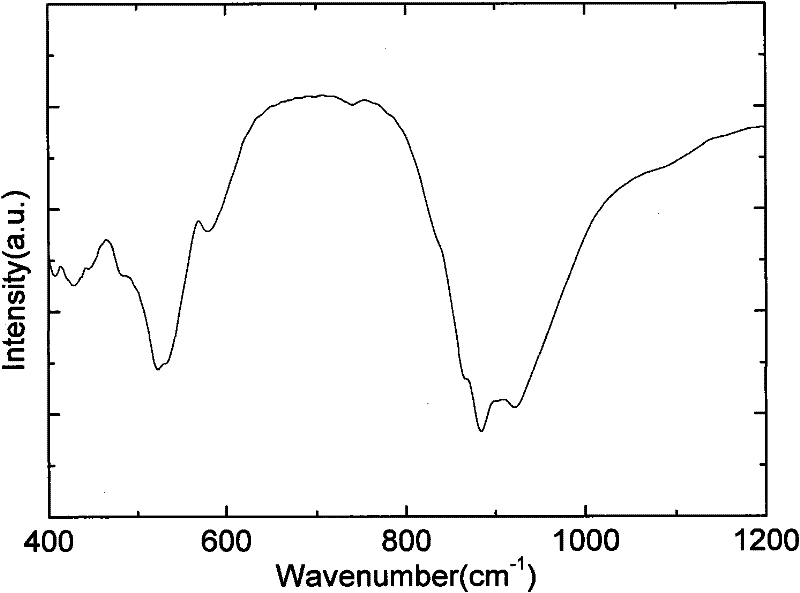

[0023] The present invention proposes a method for preparing a silicate cathode material for lithium ion batteries, which uses a one-step sintering process to prepare a silicate cathode material at medium and low temperatures (550-600°C), which specifically includes the following steps: ① Dissolve 0.09 mol of manganous sulfate and 0.01 mol of ferrous sulfate in distilled water, and then stir; ② After stirring until manganous sulfate and ferrous sulfate are completely dissolved in distilled water, add 4 mol / L hydrogen while stirring Sodium oxide solution, until the pH value of the mixture of manganous sulfate, ferrous sulfate, sodium hydroxide solution and distilled water is 12, which promotes the complete precipitation of manganese ions and iron ions; ③Use existing filtration methods to filter out Precipitate, and then wash the precipitate with distilled water or / and ethanol at least once; ④ Mix the cleaned precipitate with 0.1 mol of silica, 0.08 mol of lithium hydroxide, and 0...

Embodiment 2

[0030] The process of preparing the silicate cathode material in this embodiment is as follows: ① Dissolve 0.1 mol of manganous sulfate in distilled water, and then stir; ② After stirring until the manganous sulfate is completely dissolved in distilled water, add 3 mol / L dropwise while stirring Until the pH of the mixed solution of manganous sulfate, sodium hydroxide solution and distilled water is 13 to promote the complete precipitation of manganese ions; ③Use the existing filtration method to filter out the precipitate, and then use distilled water Or / and ethanol to clean the precipitate at least once; ④ Mix the cleaned precipitate with 0.1 mol of silica, 0.08 mol of lithium hydroxide, and 0.12 mol of lithium nitrate; ⑤ Put the mixed material in an inert gas (argon gas) (Or nitrogen) for one step sintering under the protection of 550℃, and the sintering time is 12 hours to obtain Li 2 MnSiO 4 Powder, will Li 2 MnSiO 4 The powder is used as a silicate cathode material.

[0031]...

Embodiment 3

[0034] The process of preparing the silicate cathode material in this embodiment is as follows: ① Dissolve 0.08 mol of manganous sulfate and 0.02 mol of ferrous sulfate in distilled water, and then stir; ② Stir until the manganous sulfate and ferrous sulfate are completely dissolved in After distilling the water, add 5mol / L sodium hydroxide solution dropwise while stirring until the pH of the mixed solution of manganese sulfate, ferrous sulfate, sodium hydroxide solution and distilled water is 11, which promotes manganese ions and iron The ions are completely precipitated; ③Use the existing filtration method to filter the precipitate, and then wash the precipitate with distilled water or / and ethanol at least once; ④The cleaned precipitate is mixed with 0.1 mol of silica, 0.08 mol of lithium hydroxide, and 0.12 mol Lithium nitrate is fully mixed; ⑤The mixed materials are sintered under the protection of inert gas (argon or nitrogen) at a sintering temperature of 600℃ and a sinter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com