Preparation method of cobalt lithium silicate anode material for lithium ion battery

A lithium ion battery, lithium cobalt silicate technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problem of poor electrochemical performance of silicate cathode materials, unsuitable for large-scale industrial production, and silicate cathodes. The problem of poor reproducibility of materials can achieve the effect of high practical use value, good electrochemical performance and controllable morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

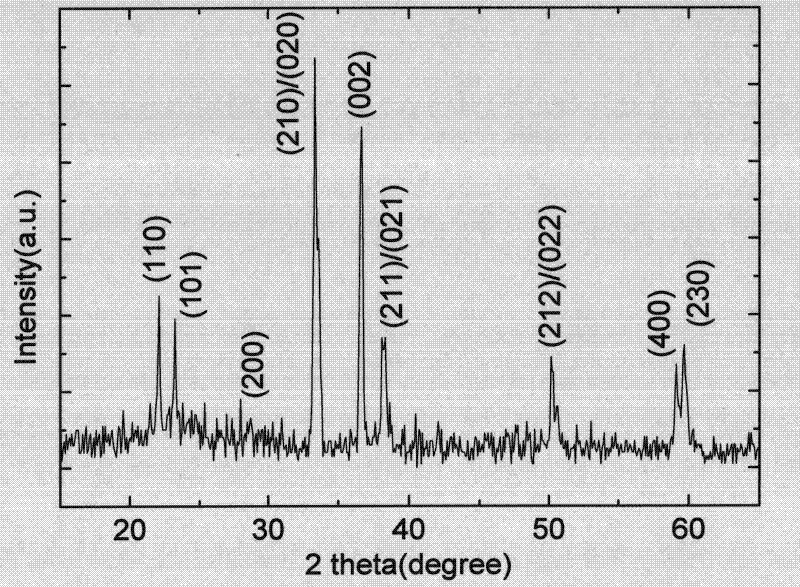

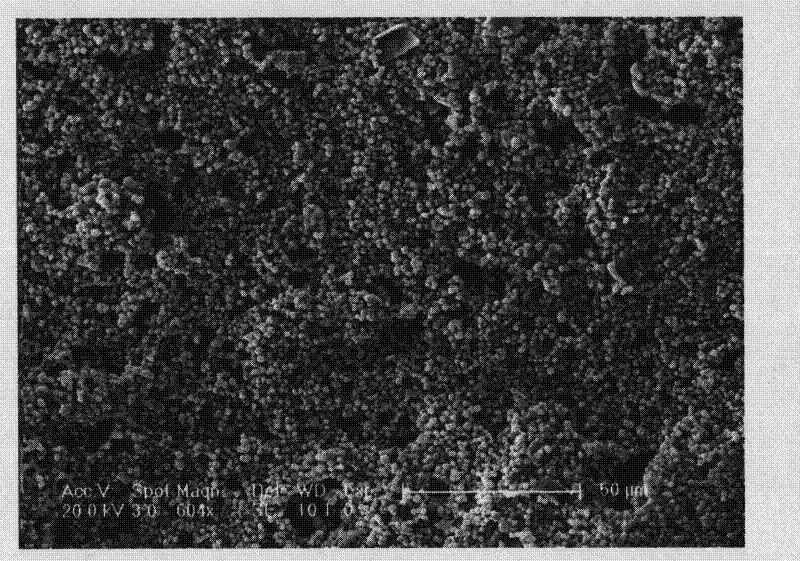

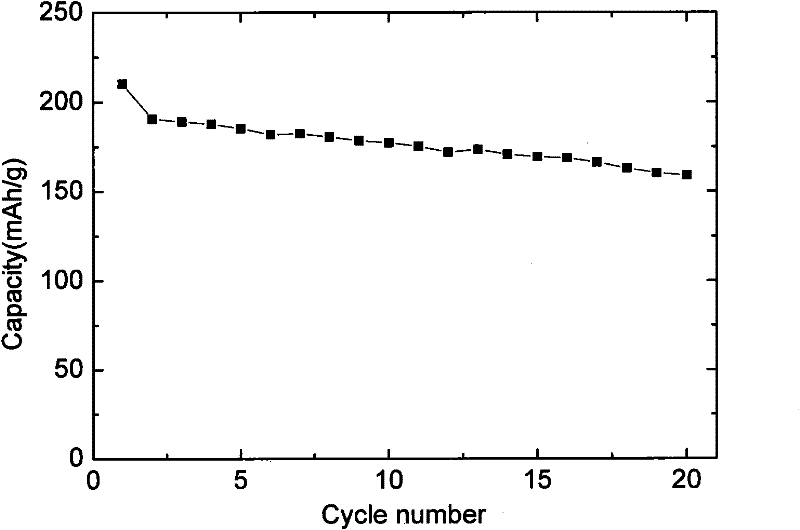

[0022] The present invention proposes a method for preparing a lithium cobalt silicate positive electrode material for lithium ion batteries, which is to prepare the lithium cobalt silicate positive electrode material at a low temperature (120-200°C) liquid phase by using the existing ion thermal synthesis method Specifically, it includes the following steps: ① adding 0.02 mol of lithium hydroxide to 100 ml of imidazole ionic liquid, and then stirring; ② adding 0.01 mol of silicon dioxide with a particle size of 1 μm after stirring for 30 minutes, and continuing to stir; ③After stirring for 5 hours, add 0.01mol of cobalt acetate, and continue to stir for 2 hours, so that lithium hydroxide, silicon dioxide, and cobalt acetate are evenly mixed in the imidazole ionic liquid; ④Pour the mixed substance obtained after uniform mixing into high pressure In the reaction kettle, react at a reaction temperature of 200 ° C for 2 days; ⑤ After the autoclave is naturally cooled to room tempe...

Embodiment 2

[0030] The process of preparing lithium cobalt silicate cathode material in this example is as follows: ①Add 0.05mol of lithium hydroxide to 100ml of imidazole-based ionic liquid, and then stir; ②Add 0.01mol of lithium hydroxide with a particle size of 10μm after stirring for 20 minutes Silicon dioxide, continue to stir; ③ after stirring for 7 hours, then add 0.01mol of cobalt acetate, and continue to stir for 1 hour, so that lithium hydroxide, silicon dioxide, and cobalt acetate are evenly mixed in the imidazole ionic liquid; The mixed substance obtained after mixing is poured into the autoclave, and reacted for 7 days at a reaction temperature of 150 ° C; ⑤ After the autoclave is naturally cooled to room temperature, take out the product in the autoclave; ⑥ Use distilled water or / and ethanol Wash the product several times; ⑦Put the cleaned product in an oven and dry it at a temperature of 80°C. The powder obtained after drying is the lithium cobalt silicate cathode material. ...

Embodiment 3

[0034] The process of preparing lithium cobalt silicate cathode material in this example is as follows: ①Add 0.04mol of lithium hydroxide to 100ml of imidazole ionic liquid, and then stir; ②Add 0.01mol of lithium hydroxide with a particle size of 10nm after stirring for 50 minutes. Silica, continue to stir; ③ After stirring for 2 hours, then add 0.01mol of cobalt acetate, and continue to stir for 5 hours, so that lithium hydroxide, silicon dioxide, and cobalt acetate are evenly mixed in the imidazole ionic liquid; ④ Mix evenly Pour the obtained mixture into the autoclave and react for 5 days at a reaction temperature of 120°C; ⑤After the autoclave is naturally cooled to room temperature, take out the product in the autoclave; ⑥Wash with distilled water or / and ethanol The product is produced many times; ⑦Put the cleaned product into an oven and dry it at a temperature of 100°C. The powder obtained after drying is the lithium cobalt silicate cathode material.

[0035] In this sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com