A kind of mineral-rich compound fertilizer and its production process

A mineral and compound fertilizer technology, applied in fertilization devices, organic fertilizers, excretion fertilizers, etc., can solve problems such as environmental pollution, inability to supplement trace elements, and achieve extended release time, improved water lock capacity and carbon replacement capacity, The effect of blocking absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

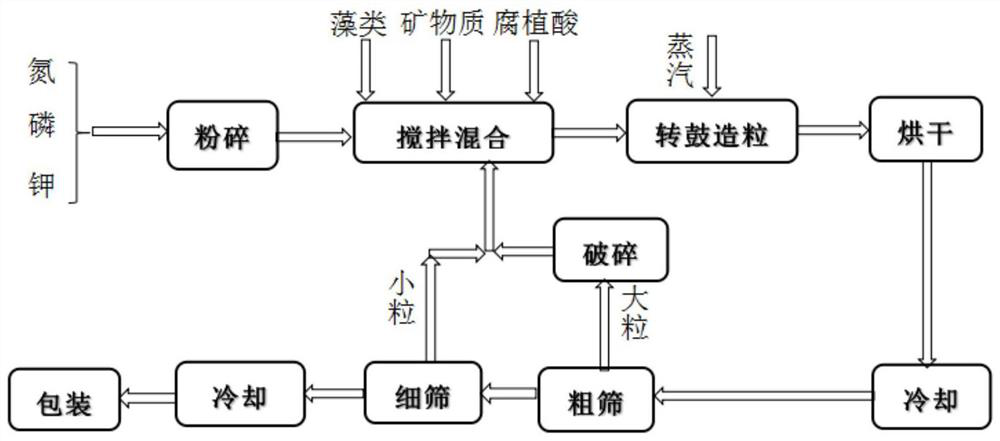

Image

Examples

Embodiment 1

[0048] In the first step, 30 parts by weight, smash, 40 mesh sieve, spare.

[0049] In the second step, 50 parts by weight of superfine mine particles having a particle diameter of 500 microns were added to the first step product, and 2 parts by weight of humic acid, 2 parts by weight of humic acid. 15 parts by weight of the biochemically treated animal feces, mixed fermentation of 100 min, reaction temperature is 40 ° C,

[0050] In the third step, 3 parts by weight of the chemically treated seaweed is added to the second step product, and after stirring mix, the material is sent to the disc granulator for granulation, and the granulated particles finally enter the drum dryer. Drying under temperature conditions at 80 ° C, while the material was frictionally friction in the drying cylinder for secondary granulation.

[0051] In the fourth step, the dry particles are fed into the cooler for cooling, sieving, inspection, metering, packaging, product compound fertilizers.

Embodiment 2

[0053] In the first step, 50 parts by weight, crush, 40 mesh sieve, spare.

[0054] In the second step, 40 parts by weight of the micro-ineralizing substance obtained by coal and coal gangue microallite separation techniques were added to the first step product, 3 parts by weight of yellow rot acid, 3 parts by weight of yellow rot acid, seaweed 7 parts by weight of the activation liquid, staying for 100 min in the fermentator, fermentation temperature 35 ° C.

[0055] In the third step, stir the first product and the second step product, after mixing, the material is sent to the disc granulator for granulation, and the granulated particles finally enter the drum dryer under 80 ° C temperature conditions. Dry, while the material is frictionally rubbed with a dry cylinder.

[0056] In the fourth step, the dry particles are fed into the cooler for cooling, sieving, inspection, metering, packaging, product compound fertilizers.

Embodiment 3

[0058] The first step is to take 35 parts by weight, smash, 40 mesh sieve, spare.

[0059] In the second step, 60 parts by weight of the superfine mine particles having a medium-micrometer particle obtained in the first step of the micrometer separation technique were added to the micrite separation technique, and 3 parts by weight of the organic chelating agent EDTA were mixed. 200min, making it chemically chelated reaction.

[0060] In the third step, the first step product and the second step product are stirred, and 2 parts by weight of the black rot is mixed. After mixing, the granulation is added to the disc granulator, and the granular particles are finally entered into the roller bake. The dryer dried under temperature conditions at 80 ° C while the material was frictionally fed twice with a dry cylinder.

[0061] In the fourth step, the dry particles are fed into the cooler for cooling, sieving, inspection, metering, packaging, product compound fertilizers.

[0062] Speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com