Core-shell solid fertilizer rich in mineral substance and preparation method thereof

A solid fertilizer and mineral technology, applied in the directions of organic fertilizers, inorganic fertilizers, fertilizer mixtures, etc., can solve the problems of inability to supplement trace elements, environmental pollution, etc., to improve the utilization rate of the season, control the release time, and reduce land fertilization. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

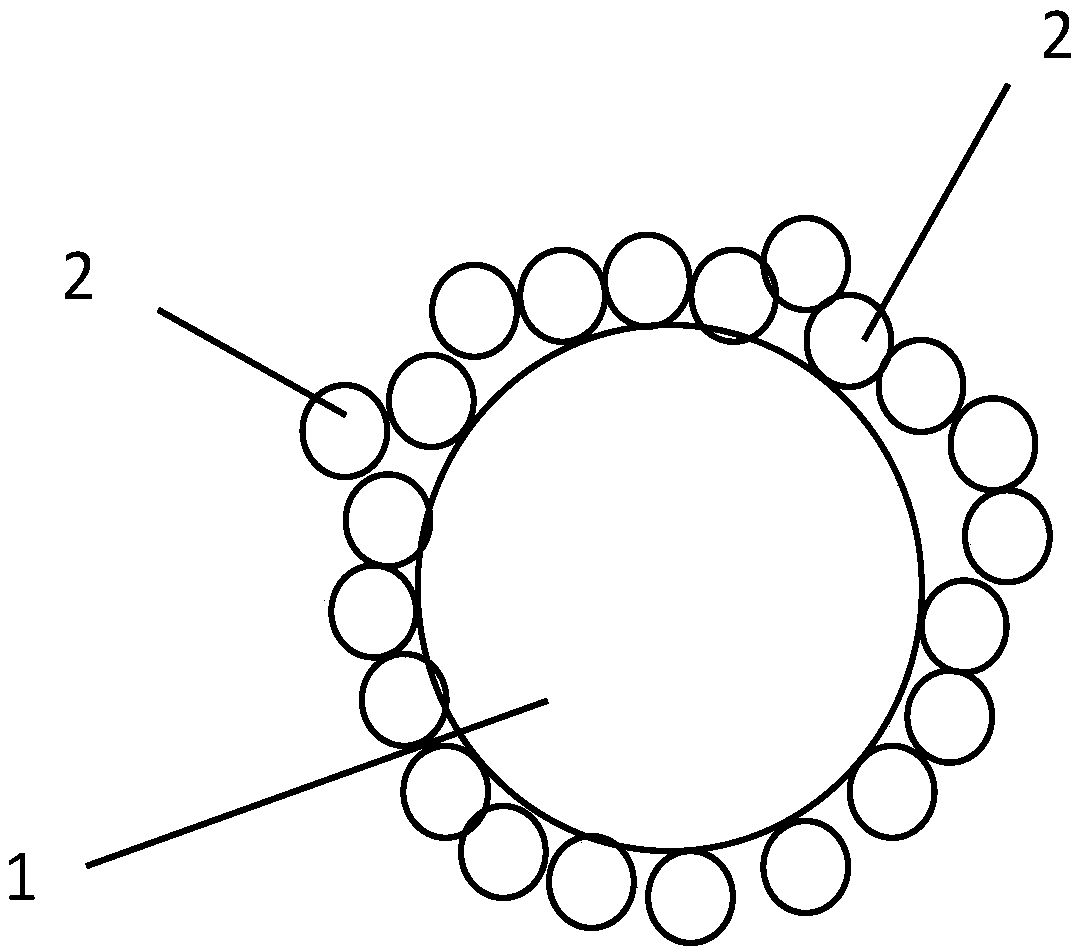

[0045] The first step, getting diameter is 55 parts by weight of urea granules of 8mm;

[0046] The second step is to take 40 parts by weight of ultrafine mineral particles containing medium and trace elements with a particle size of 400 microns obtained by coal and gangue through micro-mineral separation technology, and dissolve 5 parts by weight of polycarboxymethyl cellulose into an aqueous solution , disperse the mineral particles in the aqueous solution and mix uniformly to obtain a coating solution.

[0047] The third step is to completely coat the above-mentioned coating solution on the surface of urea particles by spraying or dipping, and then dry naturally or at a temperature not higher than 80°C to obtain the core of the mineral-rich particles Shell-type solid fertilizer.

Embodiment 2

[0049] The first step, getting diameter is 35 parts by weight of the ammonium phosphate particle of 14mm;

[0050] In the second step, 40 parts by weight of ultrafine mineral particles containing medium and trace elements with a particle size of 400 microns obtained by taking coal and coal gangue through micro-mineral separation technology are added to a paste composed of 25 parts by weight of starch and water, Mix evenly to obtain coating liquid.

[0051] The third step is to coat the above-mentioned coating solution on the surface of ammonium phosphate particles by rolling coating method or dip coating method, and then dry naturally or at a temperature not higher than 80°C to obtain the mineral-rich particles. Core-shell solid fertilizer.

Embodiment 3

[0053] The first step, getting diameter is 80 weight parts of the potassium sulfate particle of 6mm;

[0054] In the second step, 12 parts by weight of ultrafine mineral particles containing medium and trace elements with a particle diameter of 100 microns obtained by taking coal and coal gangue through the micro-mineral separation technology, adding 8 parts by weight of water glass aqueous solution, and mixing uniformly to obtain a package Overlay.

[0055] In the third step, the coating liquid is coated on the surface of ammonium phosphate particles by a dip coating method, and then naturally cooled and dried to obtain the core-shell solid fertilizer rich in minerals.

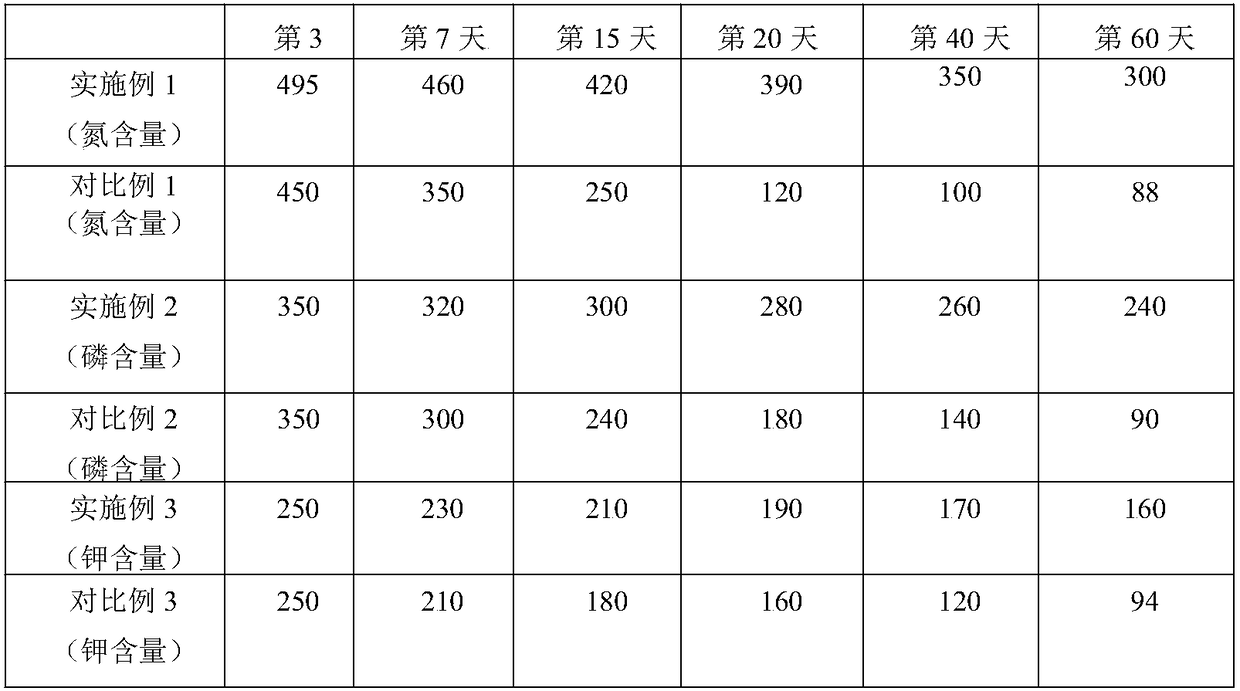

[0056] Specific use case

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com