Buffer tripod for pulling flat car

A technology of tripod and flatbed truck is applied in the field of buffer tripod, which can solve the problems of tripod cracking, hidden danger and breakage, and achieve the effect of prolonging the service life, ensuring safe production and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

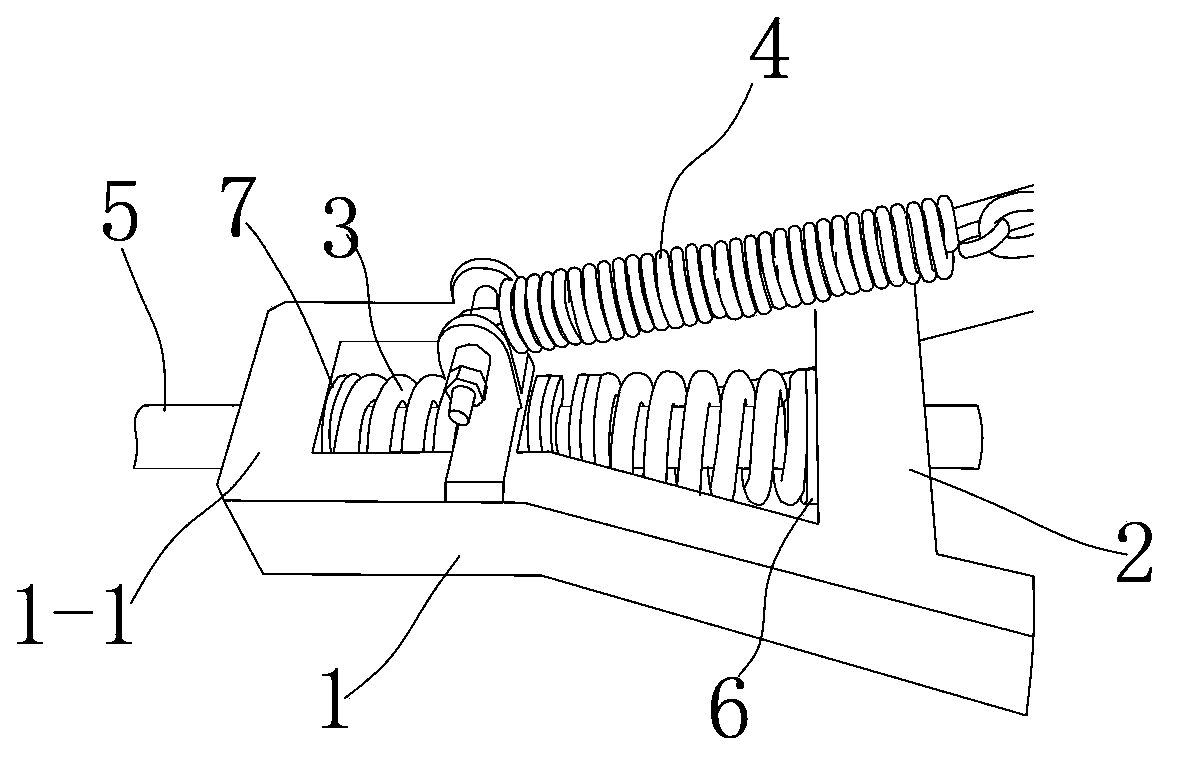

[0022] Below with reference to accompanying drawing, the present invention is described in further detail:

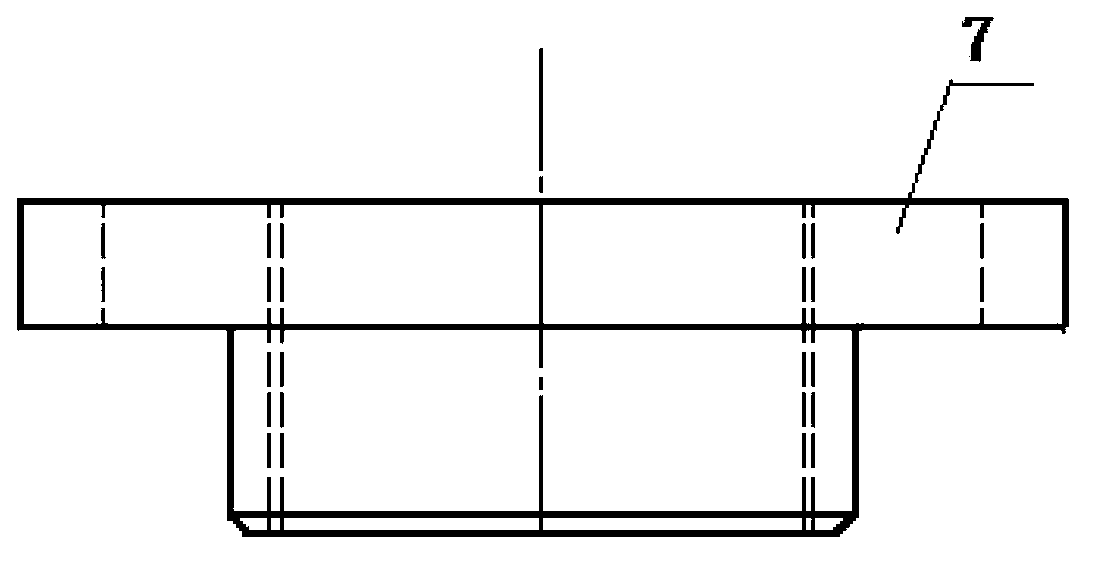

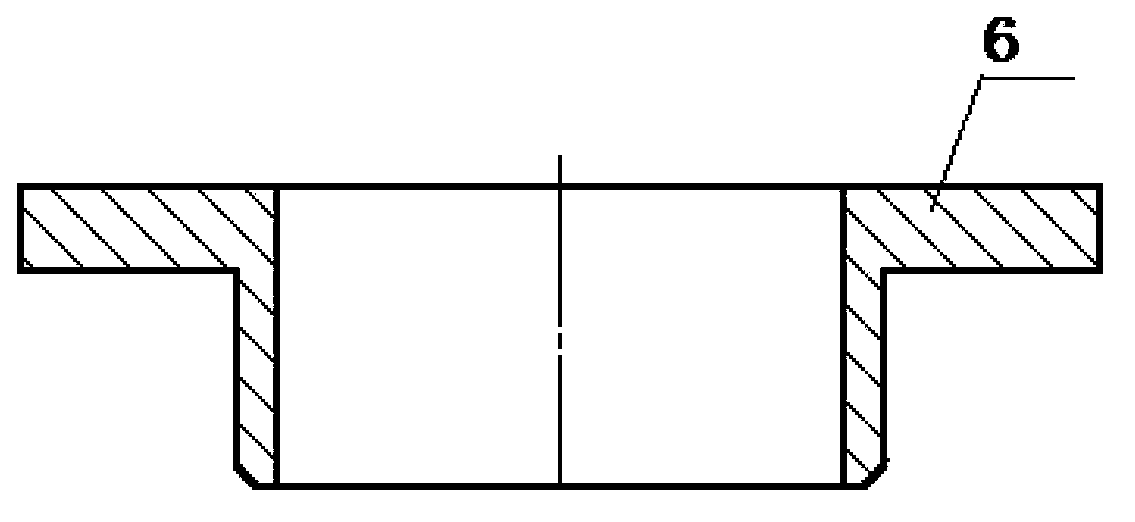

[0023] combine Figure 1 to Figure 3 , a buffer tripod for towing a flatbed vehicle, comprising a frame body 1, a crossbeam 2 is fixed on the frame body, and a movable draw bar 5 is penetrated between the front end 1-1 of the frame body and the crossbeam, During processing, it is realized by opening holes on the front end of the frame body and the beam and passing the draw bar through the two holes. The draw bar is covered with a compression spring 3, and the front end of the draw bar is fixed with a draw bar nut 7 to draw A gasket 6 is sheathed at the rear end of the rod, and the two ends of the compression spring 3 press against the drawbar nut and the gasket respectively.

[0024] With the above-mentioned device, when the tractor starts, turns, stops or goes up and down slopes, the impulse force on the tripod due to the inertia of the vehicle is buffered by the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com