Test structure for monitoring source and drain polycrystalline silicon etching

A technology for testing structure and polysilicon, applied in semiconductor/solid-state device testing/measurement, electrical components, electrical solid-state devices, etc., can solve problems such as loss, etching residue, etc., and achieve the effect of reducing the risk of subsequent losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

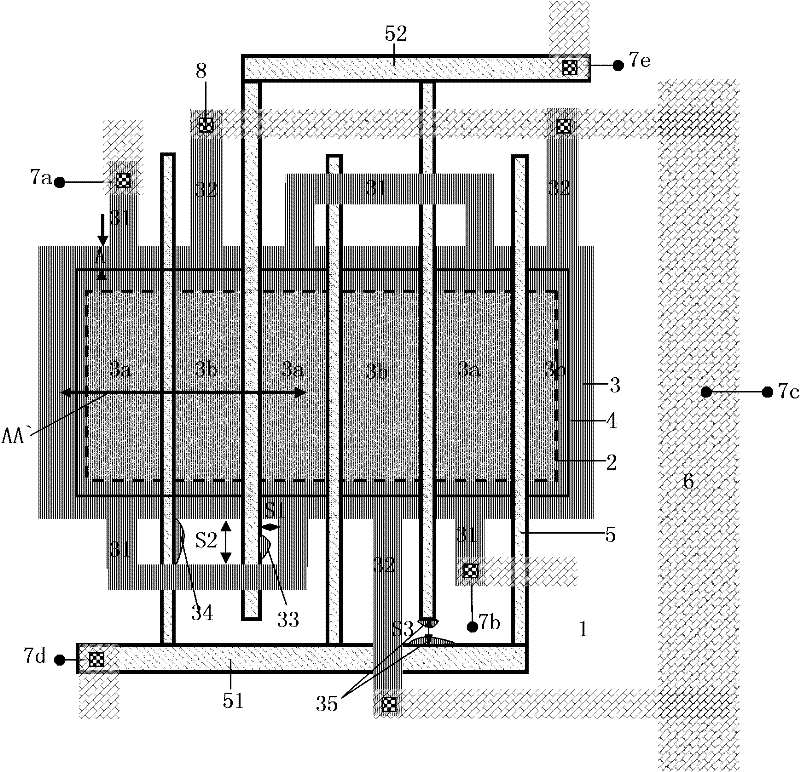

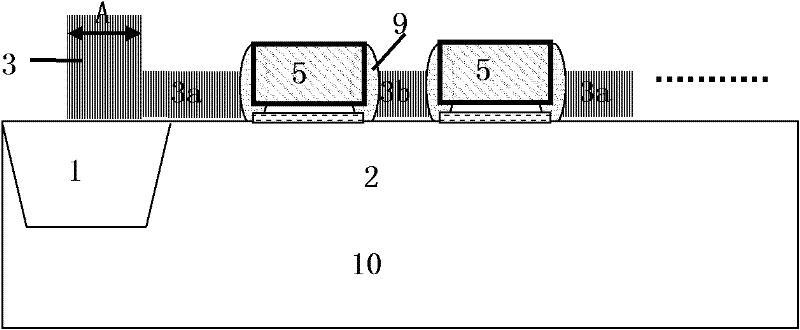

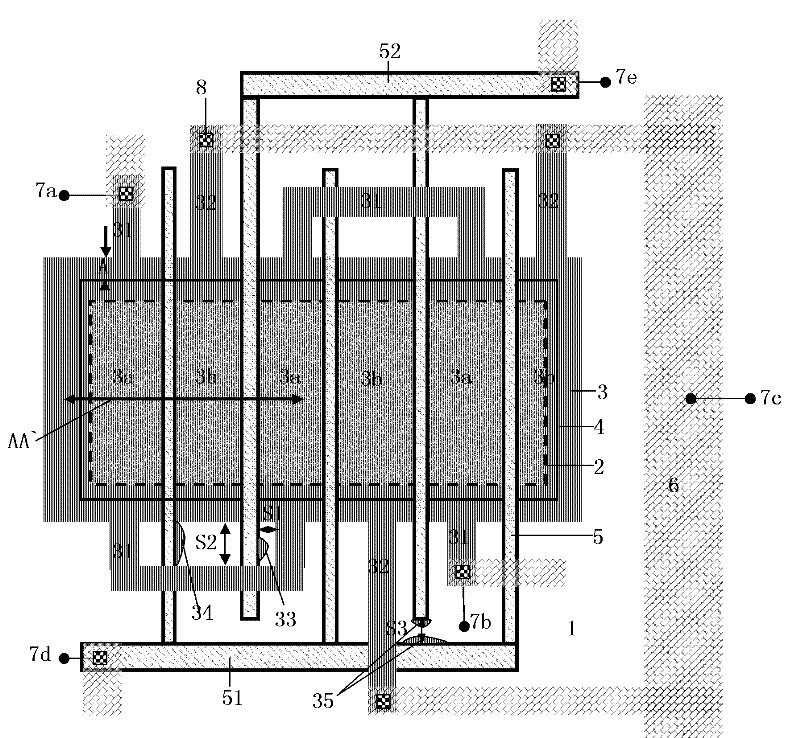

[0019] Such as figure 1 As shown, it is a schematic diagram of the layout of the test structure used to monitor the source-drain polysilicon etching according to the embodiment of the present invention; figure 2 shown, is figure 1 Schematic diagram of the cross-section of the AA` axis. The embodiment of the present invention is used to monitor the source-drain polysilicon etching test structure, which is formed on the scribe groove area of the silicon substrate 10, and the active area 2 is isolated by the shallow trench isolation 1, including:

[0020] Multiple rows of gate polysilicon 5 are arranged in parallel on the active region 2 , and the long side direction of the gate polysilicon 5 is perpendicular to the long side direction of the active region 2 .

[0021] The source-drain polysilicon 3 covering the active region 2 and the gate polysilicon 5, the source-drain polysilicon 3 includes multiple rows of source-drain regions 3a, 3b arranged in parallel and a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com