Two-section type spray-welded coating smooth sucker rod and machining process thereof

A pumping polished rod, two-stage technology, applied in drill pipe, drilling equipment, earth-moving drilling, etc., can solve the problems of little room for composition improvement, increased difficulty, unacceptable cost, etc., to improve the overall toughness and Fatigue resistance, excellent bending and fatigue resistance, the effect of ensuring straightness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

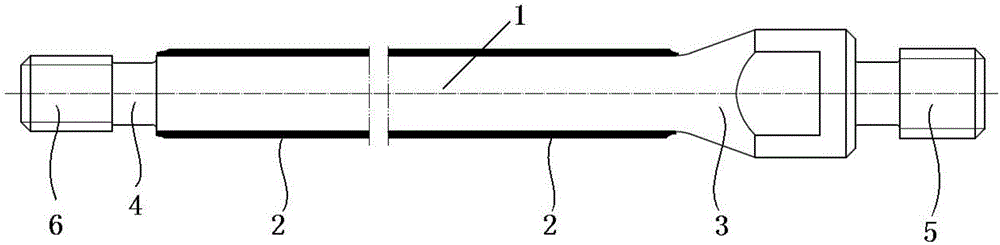

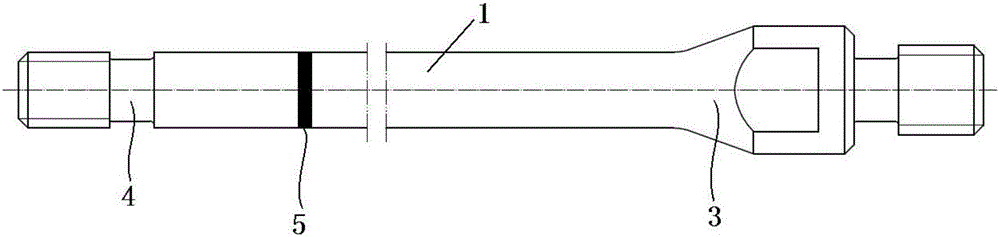

[0033] see figure 1 , according to the embodiment of the two-stage spray welding coating oil pumping polished rod provided by the present invention, comprising a base material 1 and an alloy coating 2 positioned on the surface of the base material 1, the base material 1 is a long straight round rod with one end It is an upsetting section 3, and the other end is an unupsetting section 4. There are external threads that can be connected with the sucker rod coupling on the ends 5 and 6 of the base material. The base material of the unupsetting section 4 is High-strength and tough steel with a length of about 1 to 3 meters, the high-strength and tough steel contains at least two elements in the alloy elements Ni, Co, Mo, Nb, V and Ti, and the base material of the upsetting section 3 is ordinary steel The base material, the high-strength and tough steel base material of the unupset section 4 and the ordinary steel base material of the upsetting section 3 are connected together by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com