Patents

Literature

36results about How to "Suppression of poor appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

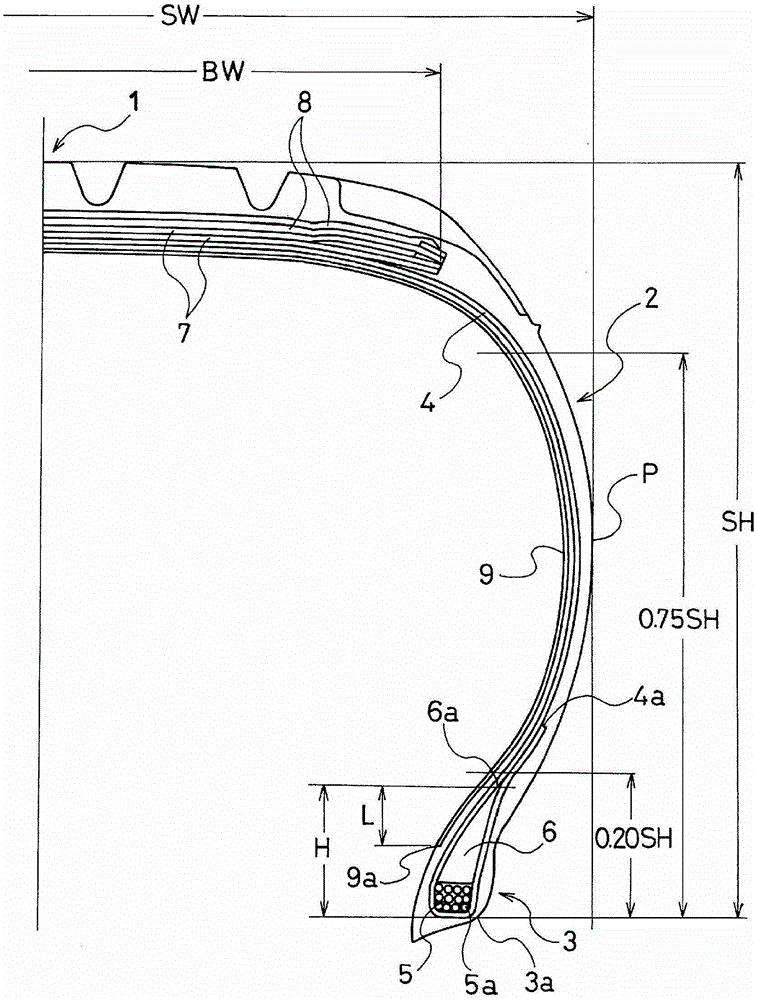

Pneumatic tire

InactiveCN103221233AModerate Rigidity VariationsMake up for driving stabilityWithout separate inflatable insertsSpecial tyresElastomerThermoplastic elastomer

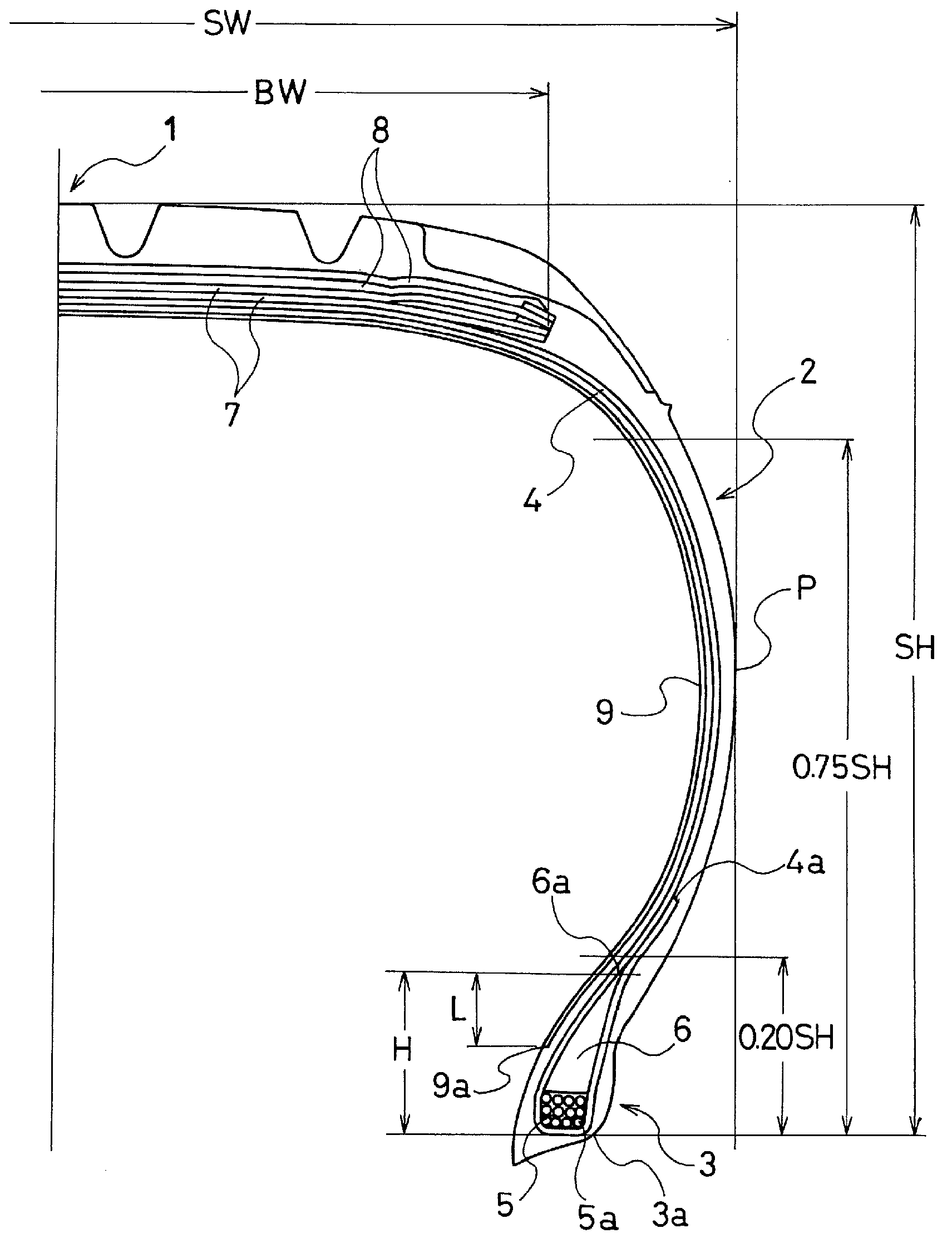

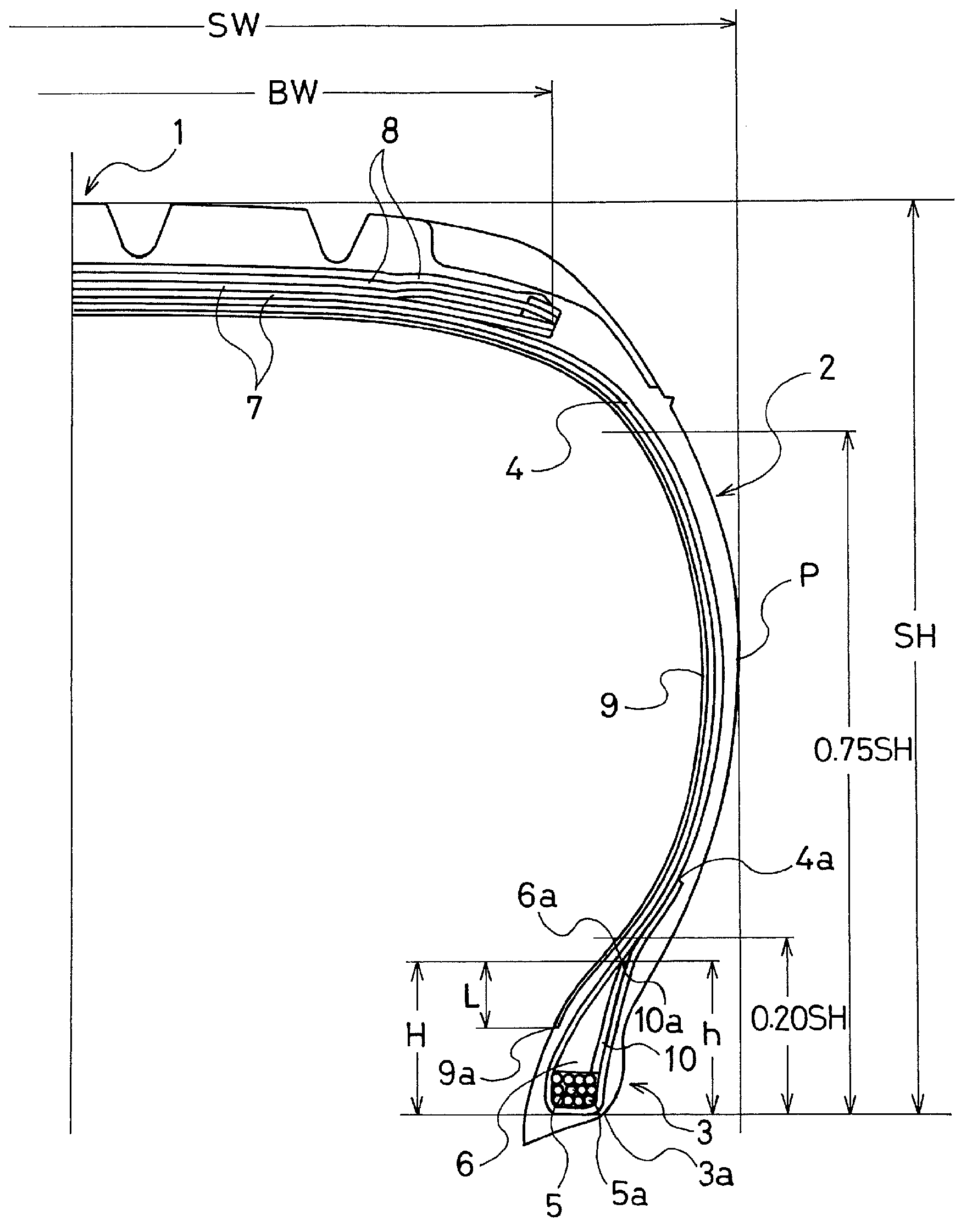

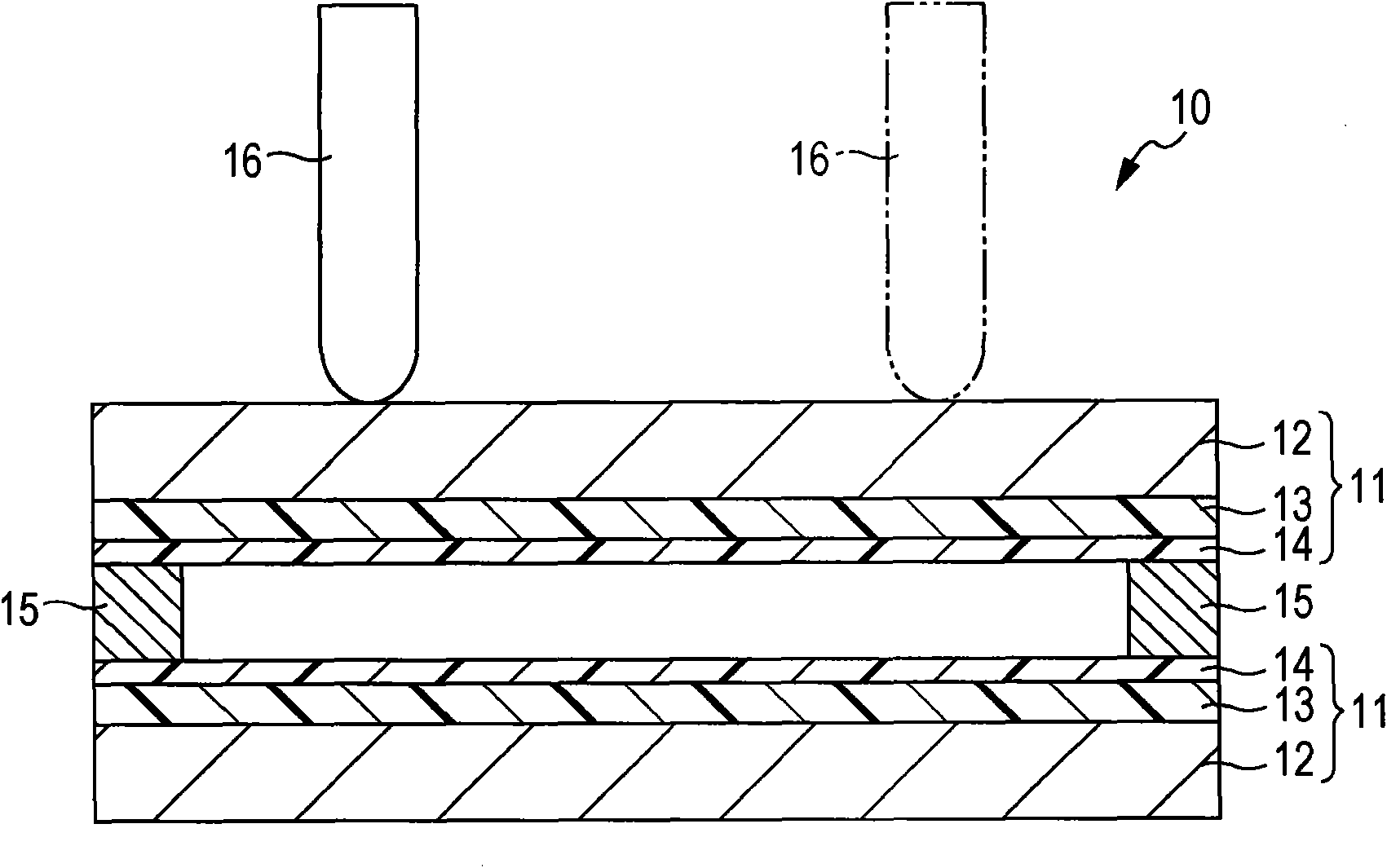

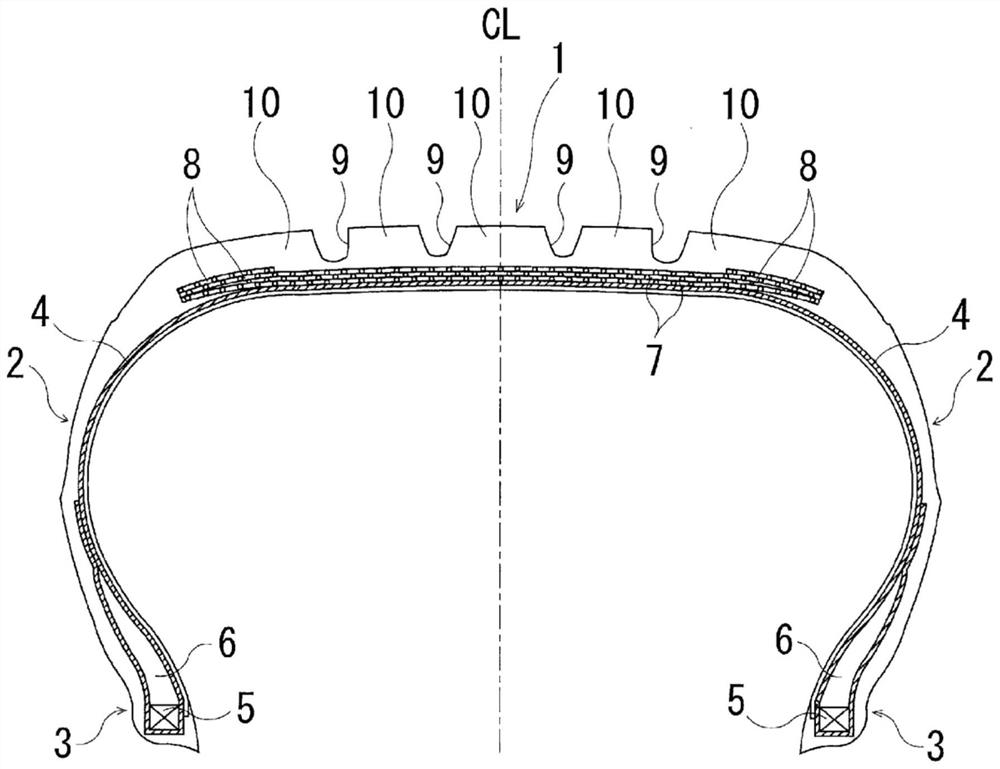

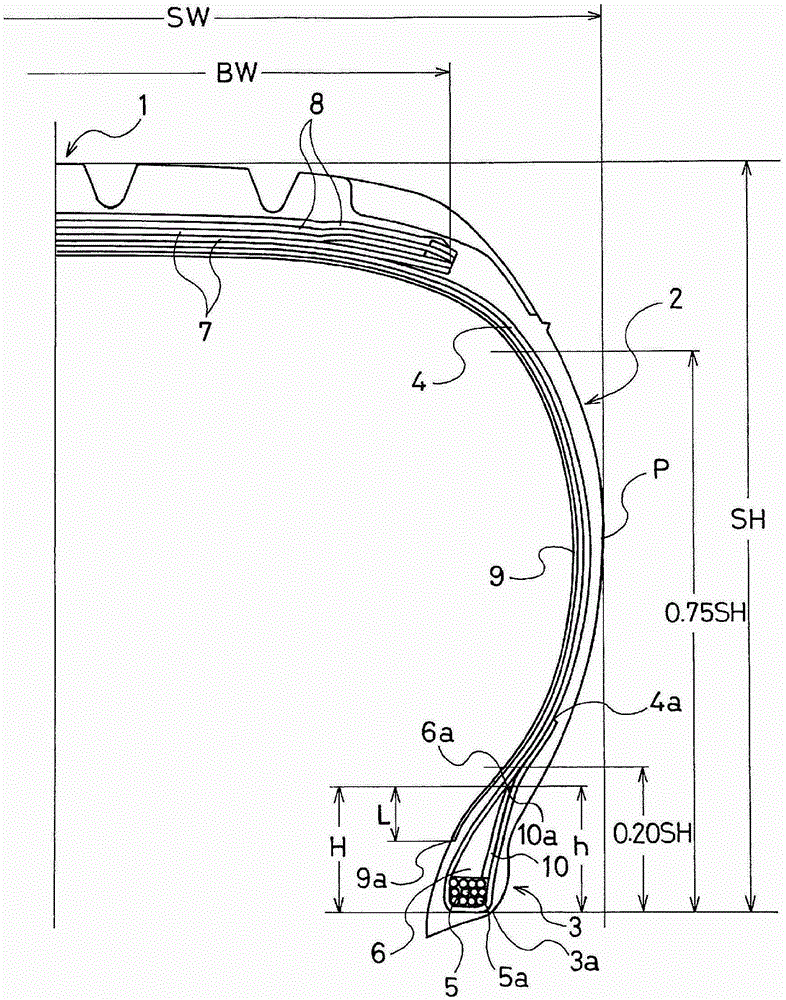

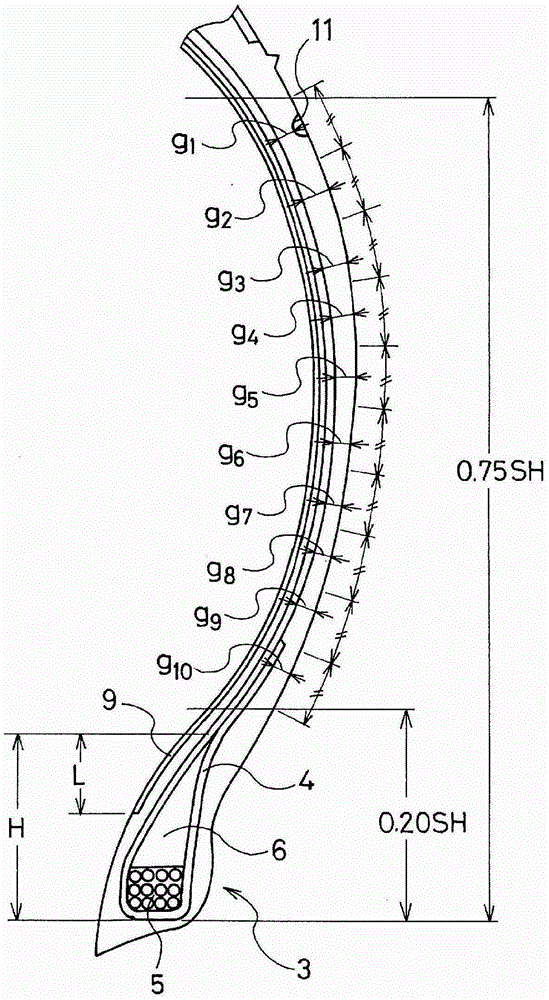

Proposed is a pneumatic tire which has an excellent balance between tire weight reduction and steering stability. The height (H) of a bead filler (6) from a bead heel (3a) is set to 10-30 mm, and an inner liner (9) arranged inside a carcass layer (4) is configured of a thermoplastic resin that has a Young's modulus of 70-1500 MPa and a thickness of 0.05-0.25 mm or a thermoplastic elastomer composition that is obtained by blending a thermoplastic resin component and an elastomer component. An end portion (9a) of the inner liner (9) is positioned inside a radially outer end portion (6a) of the bead filler (6) in the tire radial direction.

Owner:THE YOKOHAMA RUBBER CO LTD

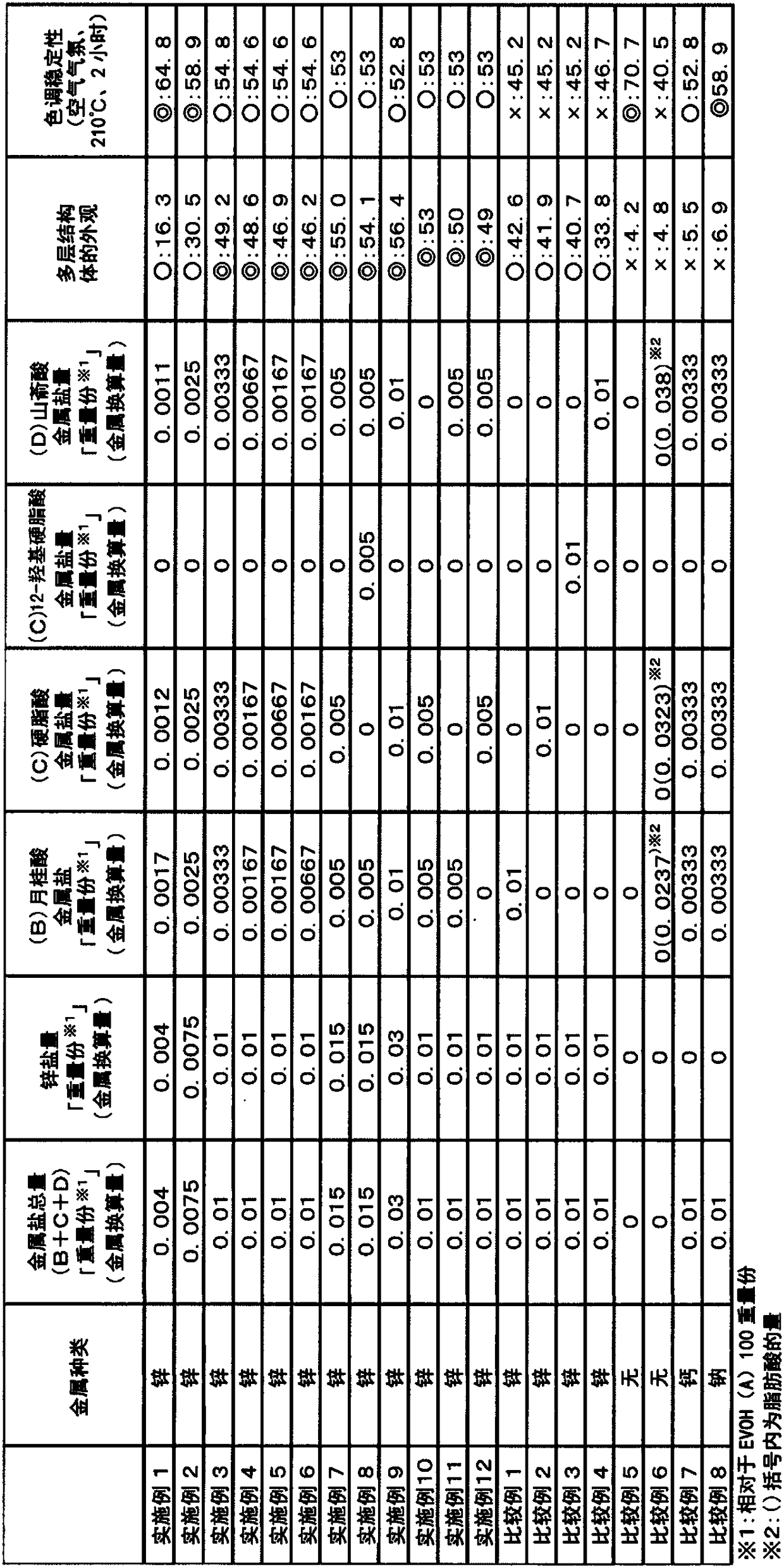

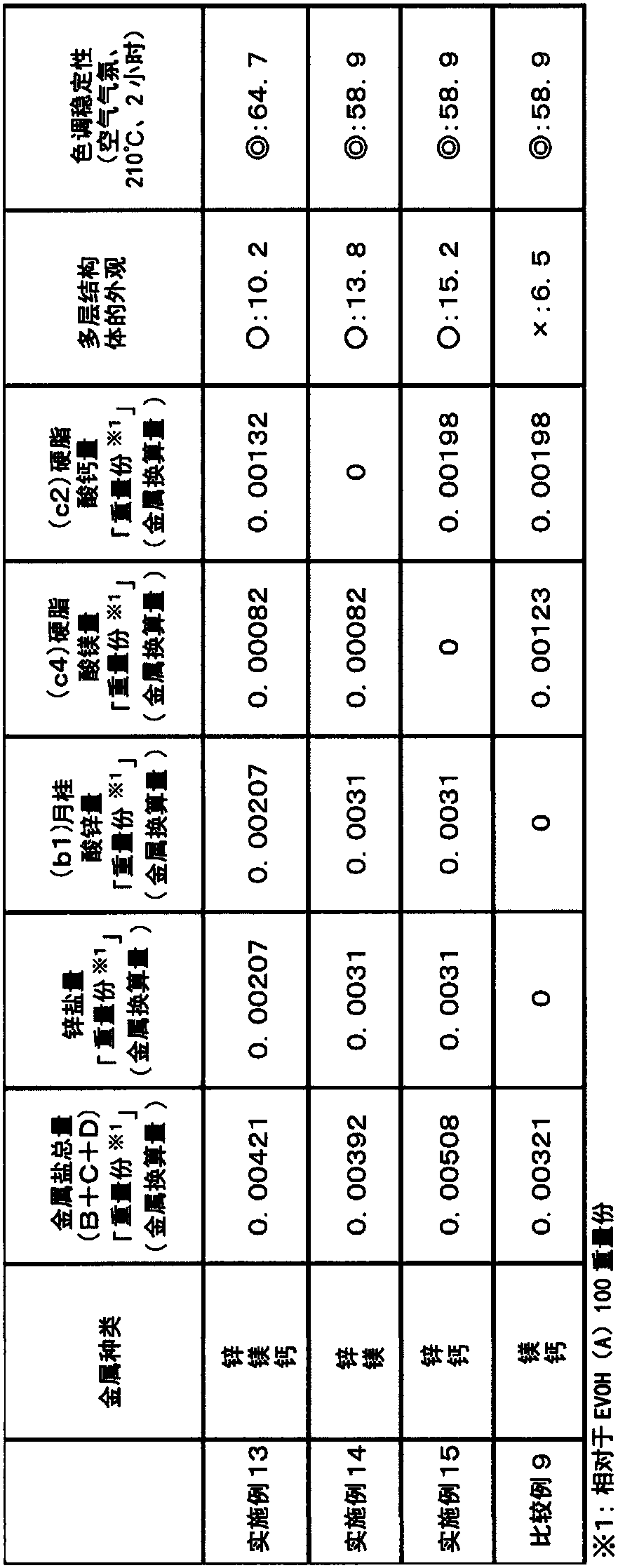

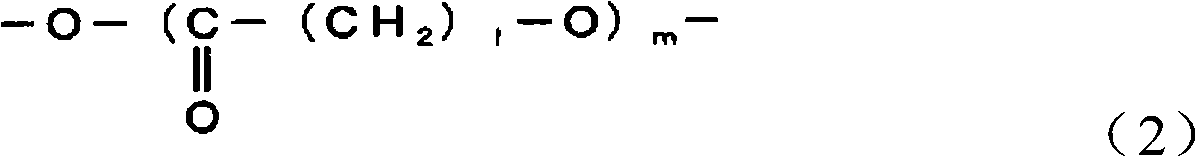

Resin composition and multilayer structure using same

PendingCN108473743ABad apperanceImprove tone deteriorationSynthetic resin layered productsPolymer scienceVinyl ester

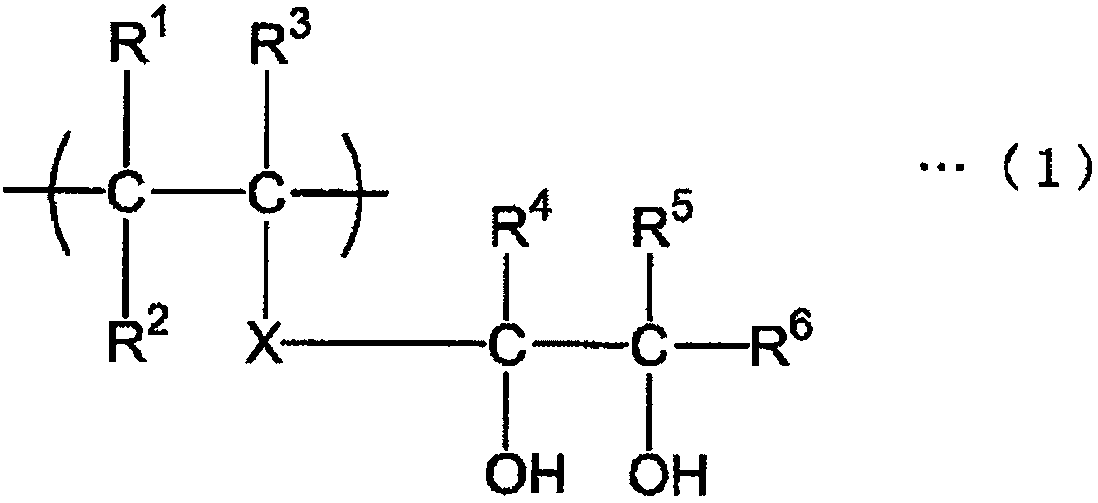

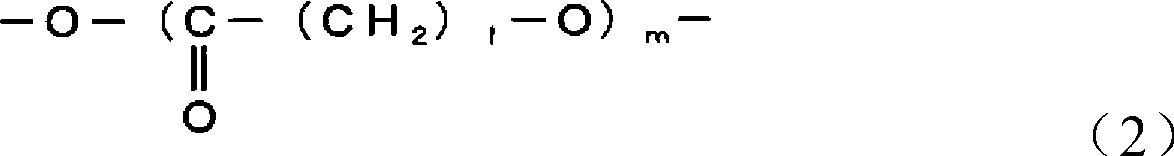

Provided is a resin composition containing a saponified ethylene-vinyl ester copolymer (A) and fatty acid metal salts, the resin composition being intended to make it possible to form a multilayer structure having suppressed occurrence of defects of appearance and improved deterioration of color tone during melt molding, wherein the resin composition is characterized in that the fatty acid metal salts are at least two fatty acid metal salts selected from C3-12 fatty acid metal salts (B), C13-20 fatty acid metal salts (C), and C21-29 fatty acid metal salts, and at least one among the fatty acidmetal salts selected from (B), (C), and (D) is a zinc salt.

Owner:MITSUBISHI CHEM CORP

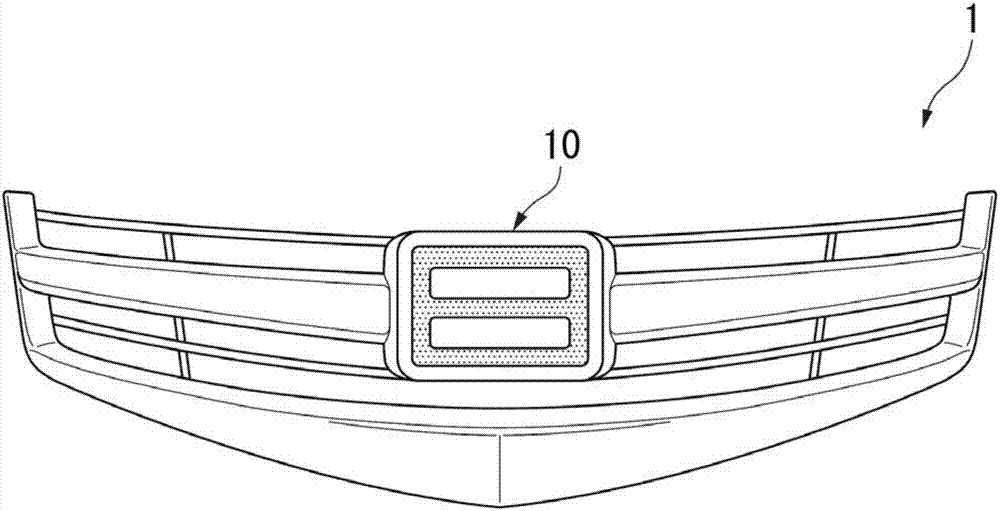

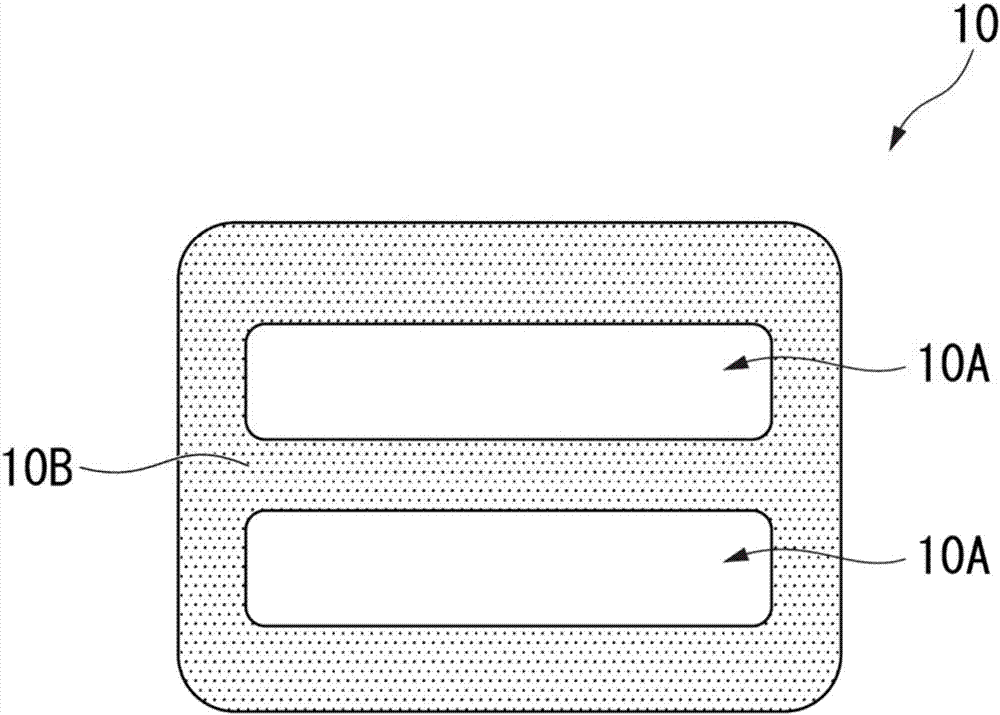

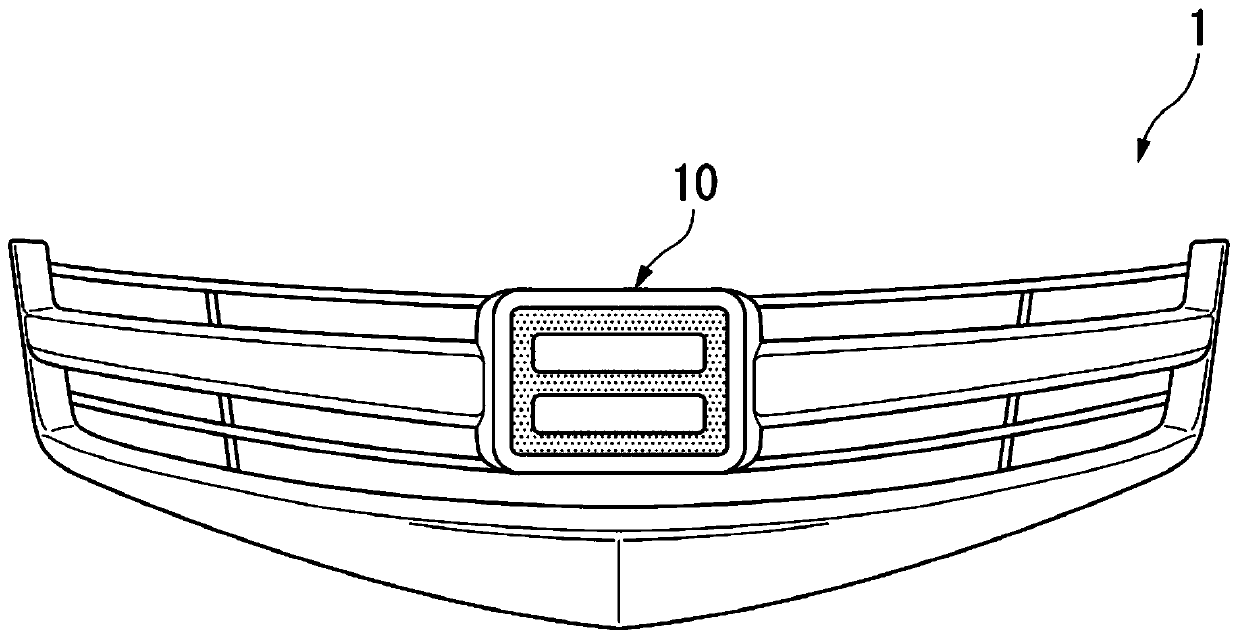

Method for manufacturing radar cover and radar cover

ActiveCN107073774AReduce heat loadSuppression of poor appearanceRadiating element housingsDe-icing/drying-out arrangementsRadarEngineering

A method for manufacturing a radar cover for covering a radar unit for sensing the ambient conditions of a vehicle includes the steps of: preparing a base provided with a concave part formed of a transparent layer with a colored layer laminated on a part other than the concave part, and a shining member provided with a basal part having a shining layer on a surface thereof and with an edge part; arranging the base and the shining member such that the edge part of the shining member and the colored layer of the base come in contact with each other and the shining layer of the basal part and the concave part face each other; and fixing the edge part and the colored layer to each other.

Owner:FALTEC CO LTD

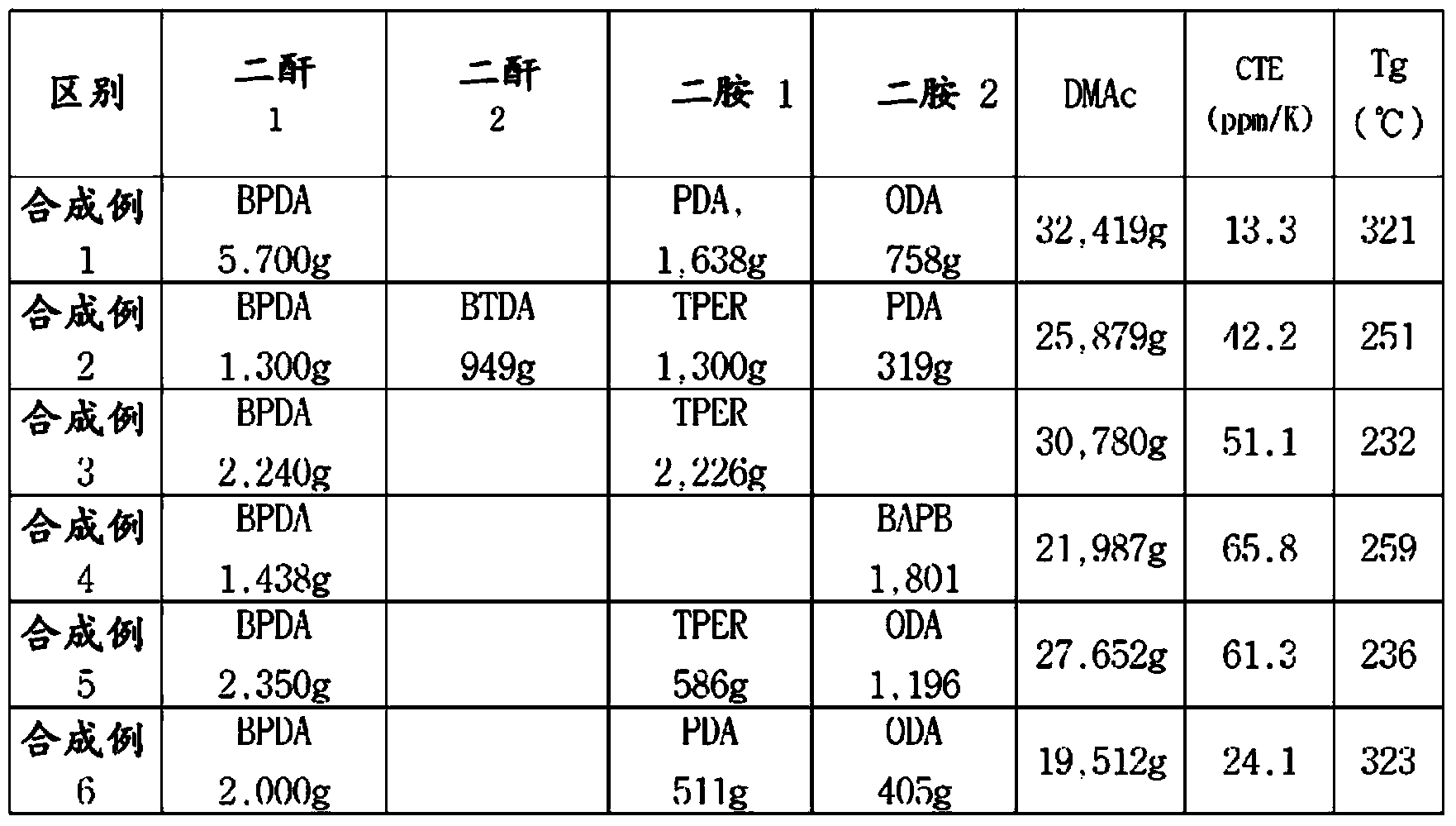

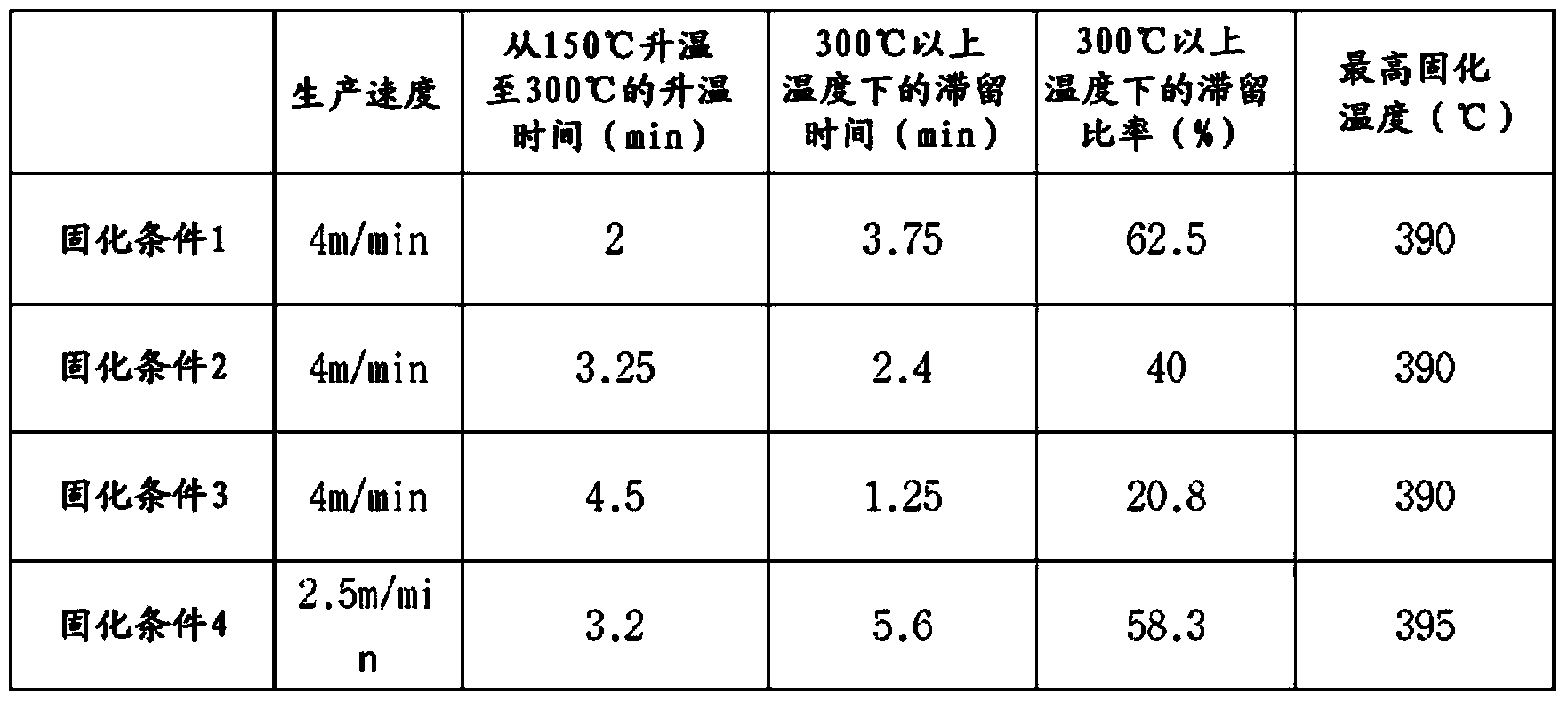

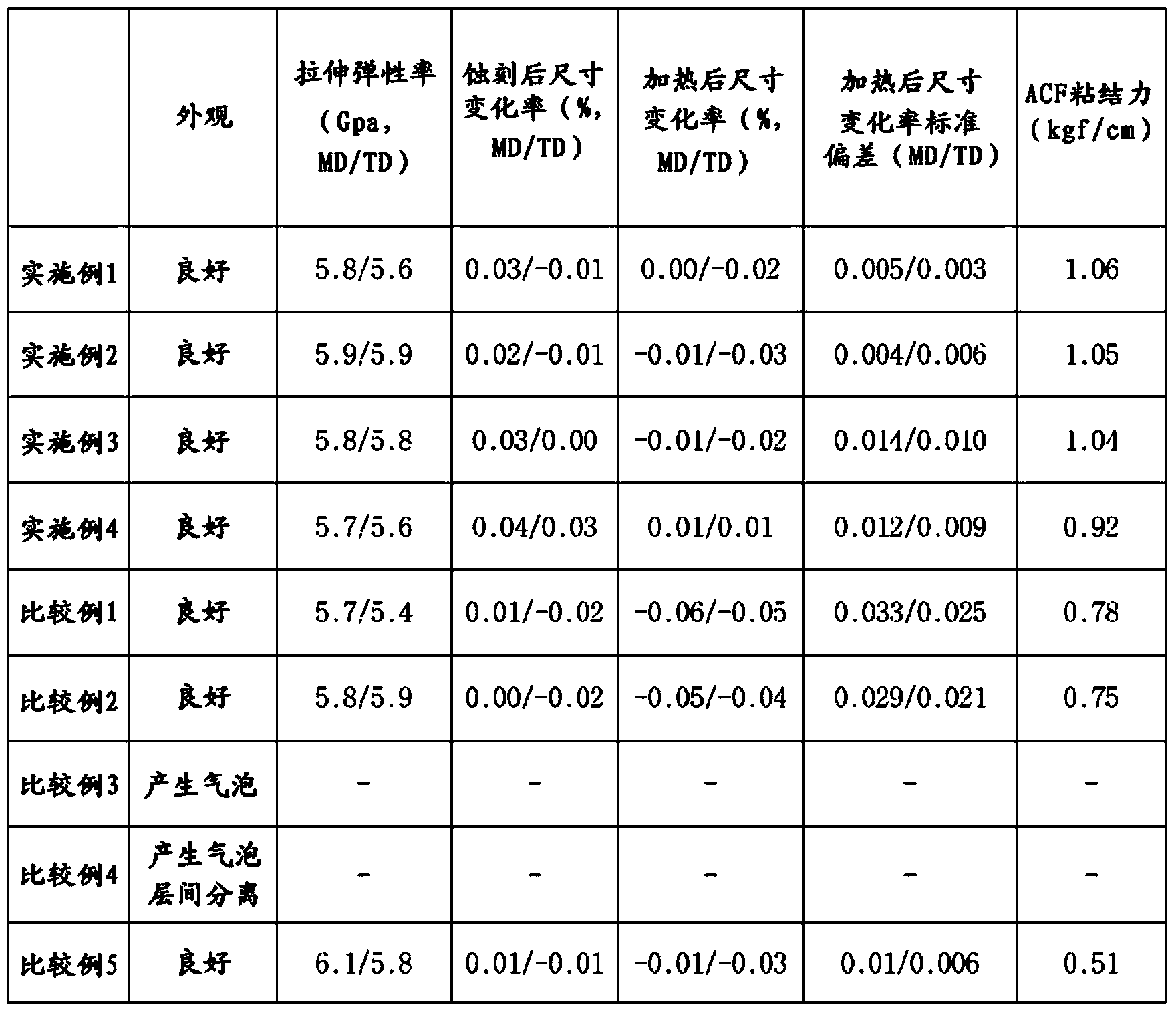

Flexible metal clad laminate and preparation method thereof

ActiveCN104066574ASuppression of poor appearanceExcellent adhesion and dimensional stabilityFlexible printed circuitsLaminationMetal foilPrinted circuit board

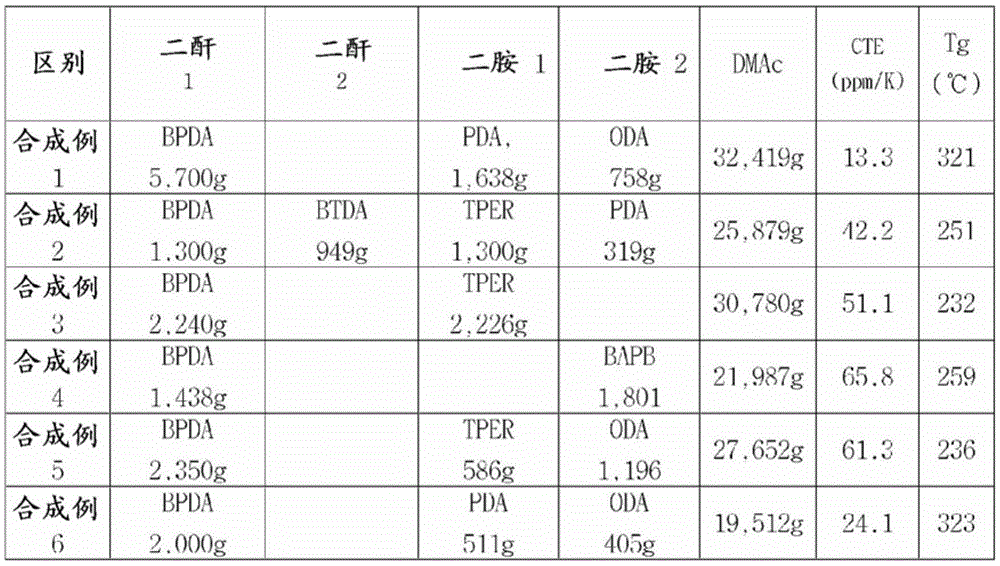

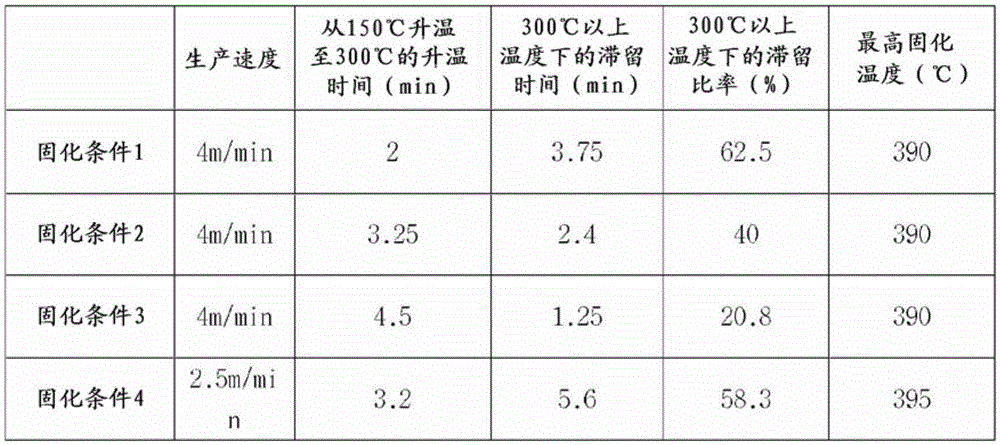

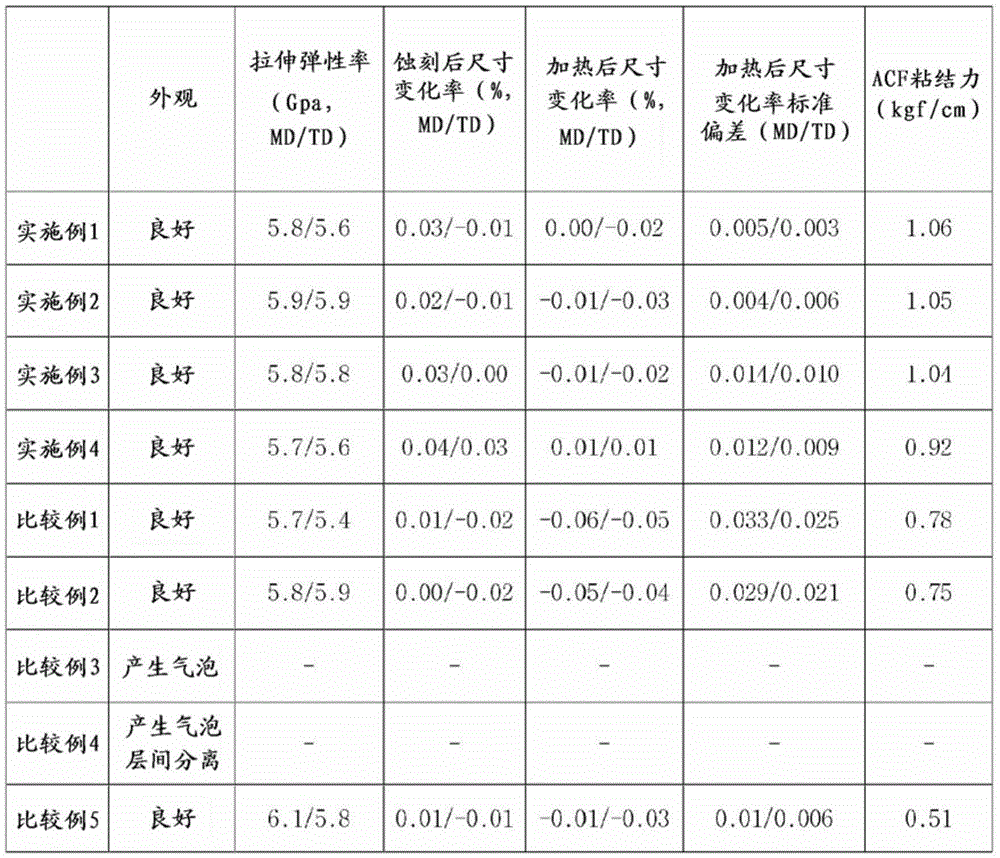

The present invention provides a flexible metal clad laminate comprising a multilayered polyimide film comprising: a metal foil; a first polyimide layer having a glass transition temperature of 300 DEG C or lower, located on the metal foil; a second polyimide layer located on the first polyimide layer; and a third polyimide layer located on the second polyimide layer. According to the present invention, the flexible metal clad laminate solves the problem of appearance defects due to foaming and the like during a curing process in a continuous curing device using infrared rays as a heat source, shows no delamination due to excellent adhesive strength, and has remarkable ACF adhesive strength and dimensional stability, and is thus expected to be useful for preparation of a flexible printed circuit board.

Owner:NEXFLEX CO LTD

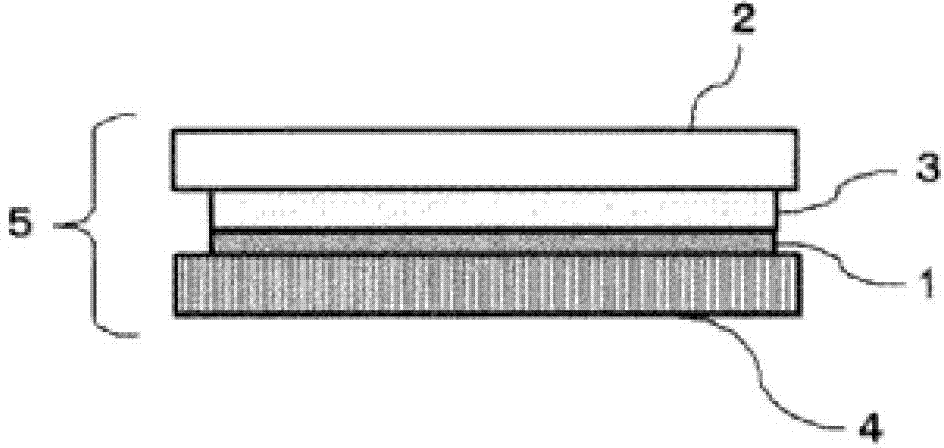

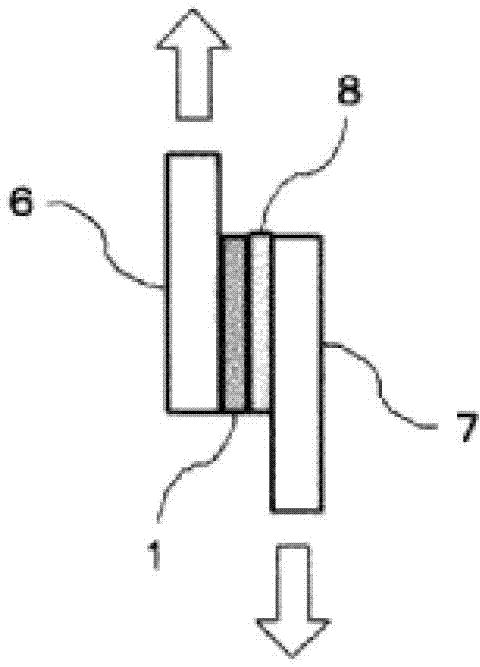

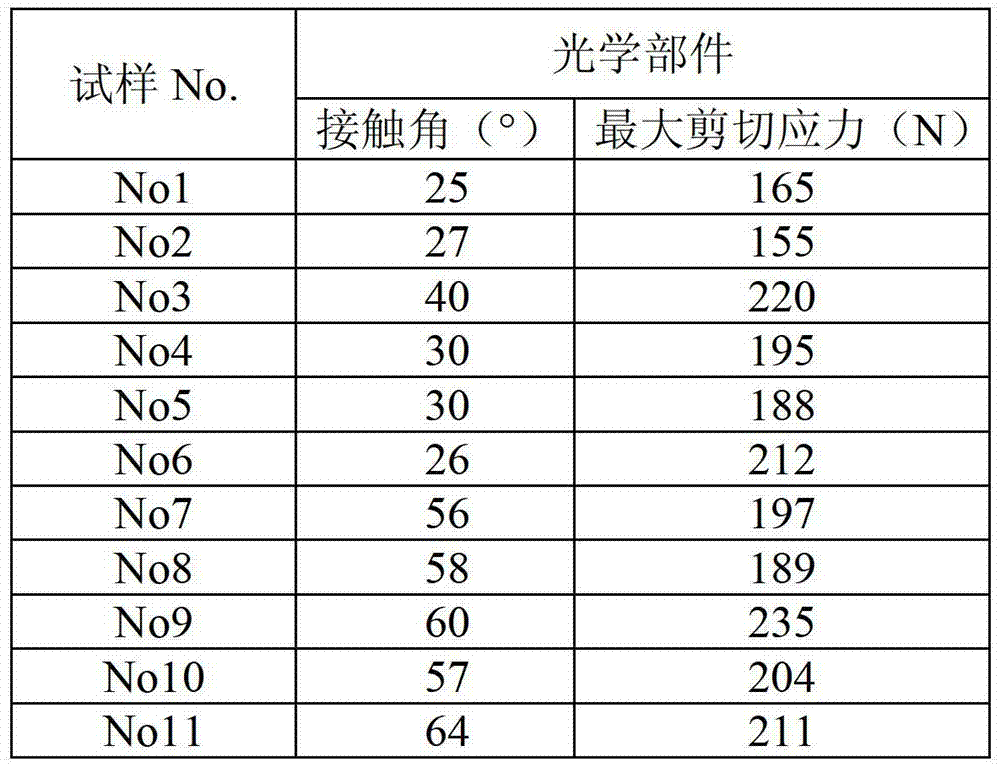

Optical member and application of same

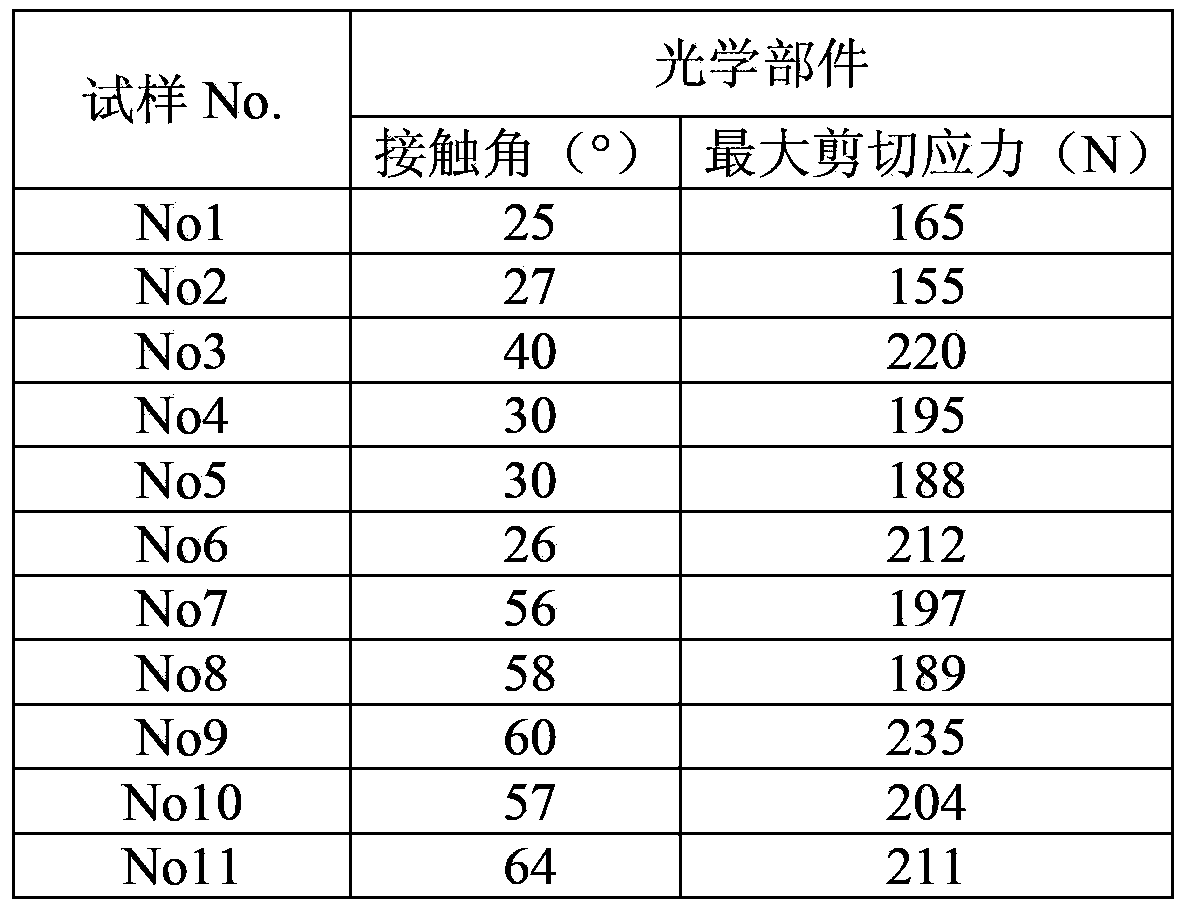

ActiveCN103097923ASuppression of poor appearanceDiffusing elementsPolarising elementsChemistryAdhesive

An optical member for use in an image display device provided with the optical member, a transparent protective member, and an adhesive layer interposed therebetween, and further provided with an image display disposed on the side opposite from the adhesive layer on the optical member. The optical member satisfies condition (1); that is, an evaluative adhesive having an isoprene polymer as the principal component thereof and containing 14 wt% of dicyclopentenyloxyethyl methacrylate, 8 wt% of benzyl methacrylate, 2 wt% of methyl methacrylate, and 0.2 wt% of a photopolymerization initiator is dripped in an amount of 10 [mu]L onto the surface of the optical member and then allowed to stand for 5 minutes, whereupon the contact angle between the optical member and the evaluative adhesive is 55 DEG or less. The invention provides an optical member in which appearance defects due to bubbles forming between the optical member and the transparent protective member can be reduced, and further provides an image display device in which such appearance defects are reduced through the use of the optical member.

Owner:SUMITOMO CHEM CO LTD

Transparent electrically conductive film and touch panel including the same

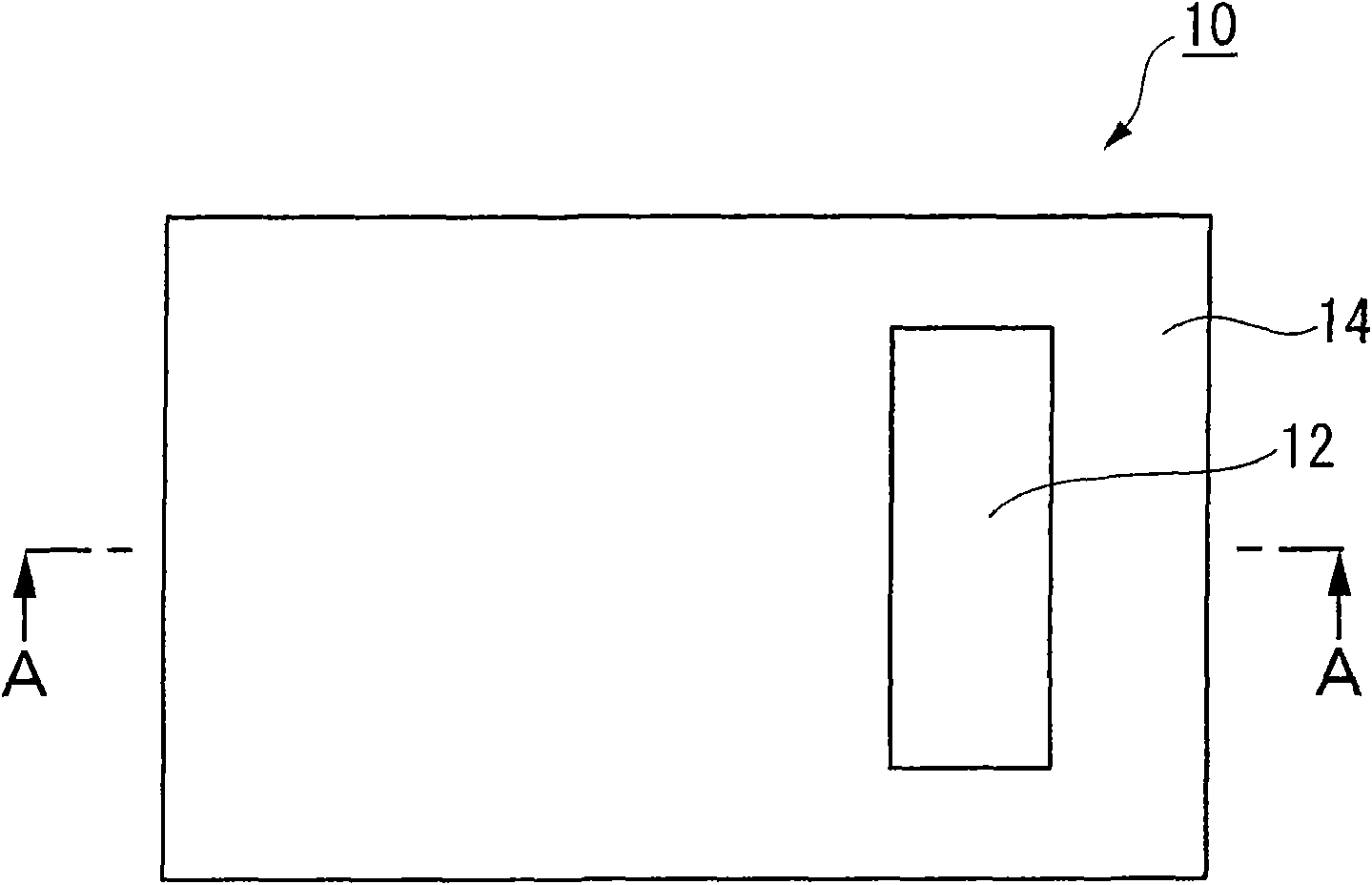

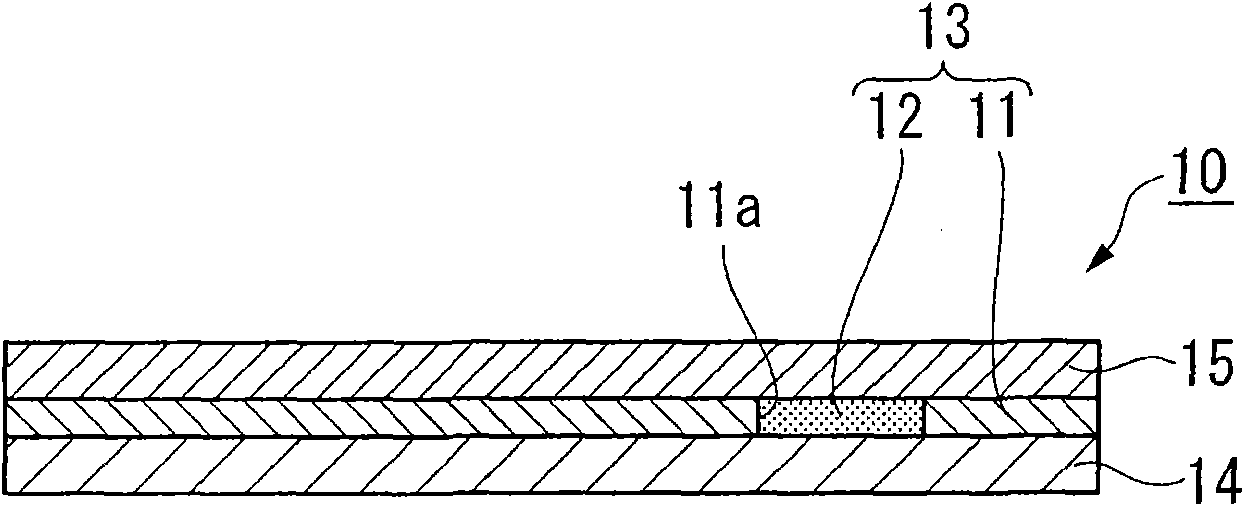

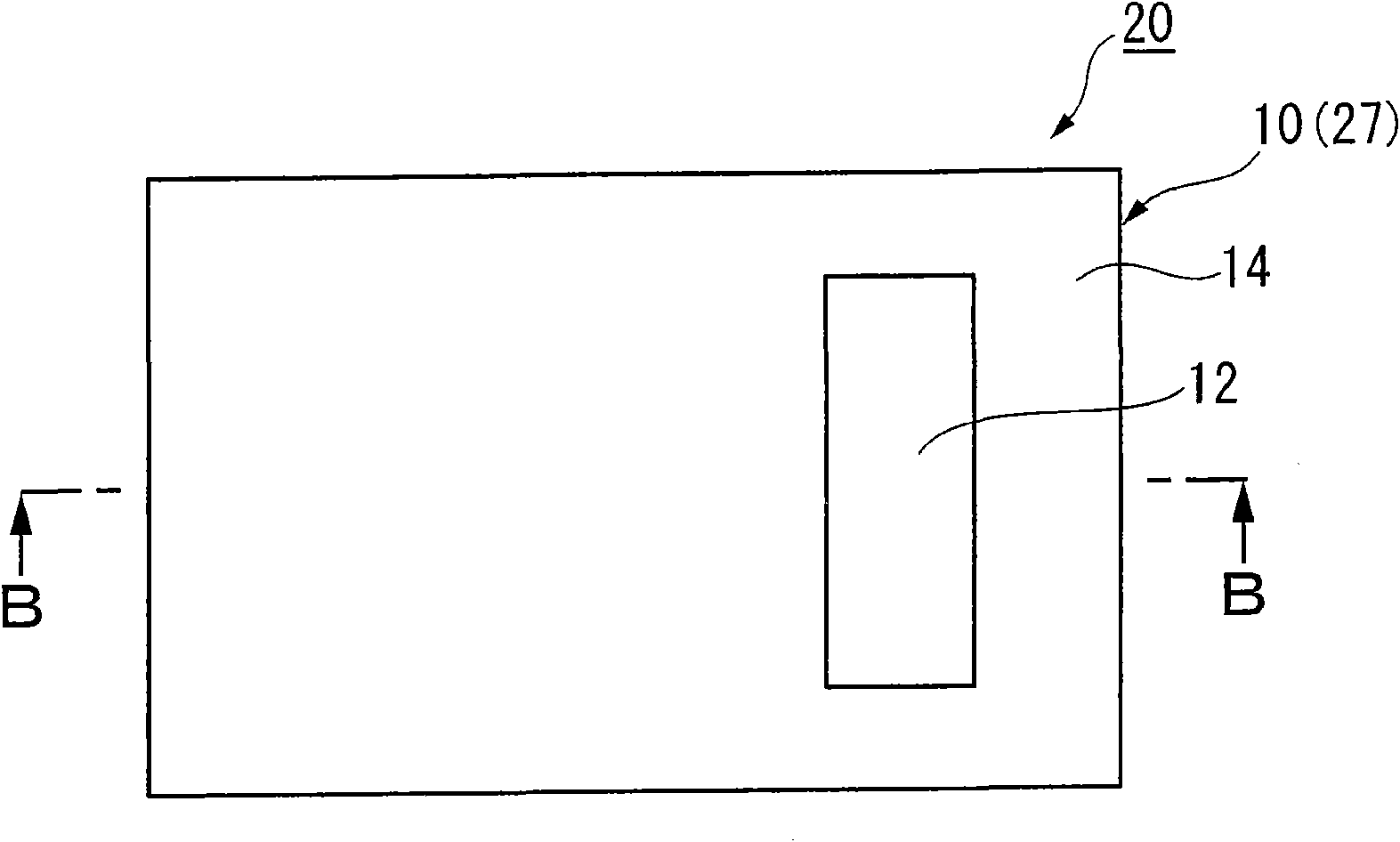

InactiveCN101630541AAvoid damageInhibitionConductive layers on insulating-supportsSynthetic resin layered productsPolypyrroleHardness

The invention aims to provide a transparent electrically conductive film capable of suppressing the occurrence of damage or crack of organic conductive layer and capable of improving the writing durability for the pen input of touch panel, for example, and a touch panel including the same. A transparent electrically conductive film (11) is formed by providing a soft resin layer (13) on a transparent substrate (12) and laminating an organic conductive layer (14) thereon; under the condition that temperature is 20 degrees centigrade and relative humidity is 50%, the Martens hardness of the softresin layer (13), tested by a ultramicroscopic hardness testing device, is 0.1-70N / sq.mm and the soft resin layer has self-repairing property. The soft resin layer (13) is formed by coating a hard composition to the transparent substrate (1) and hardening it. The hard composition contains a specific repeated unit of 10-90% by weight. The organdic conductive high molecule forming the organic conductive layer (14) can be selected from polythiophene, polypyrrole, polyaniline or polyquinoxaline.

Owner:NOF CORP

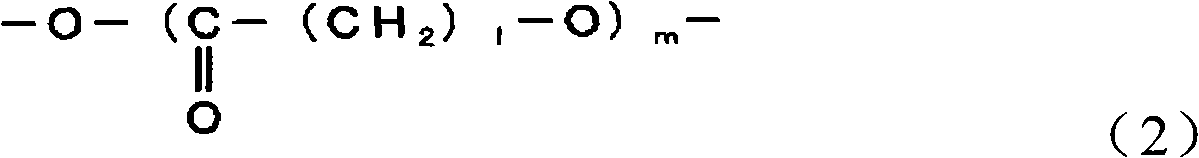

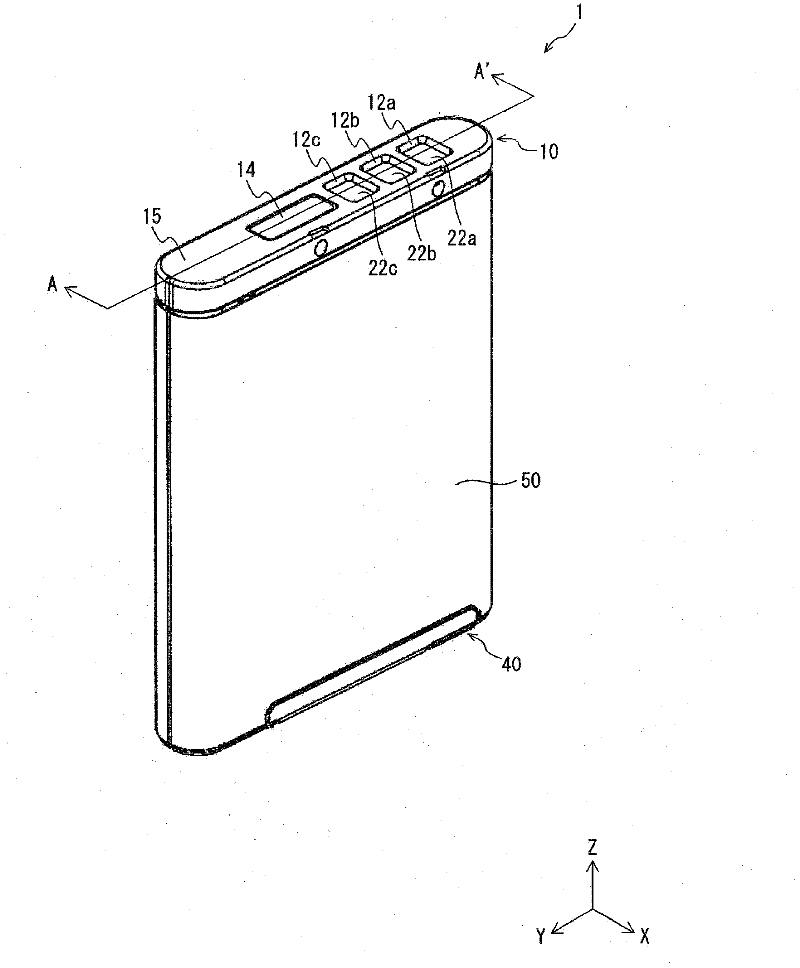

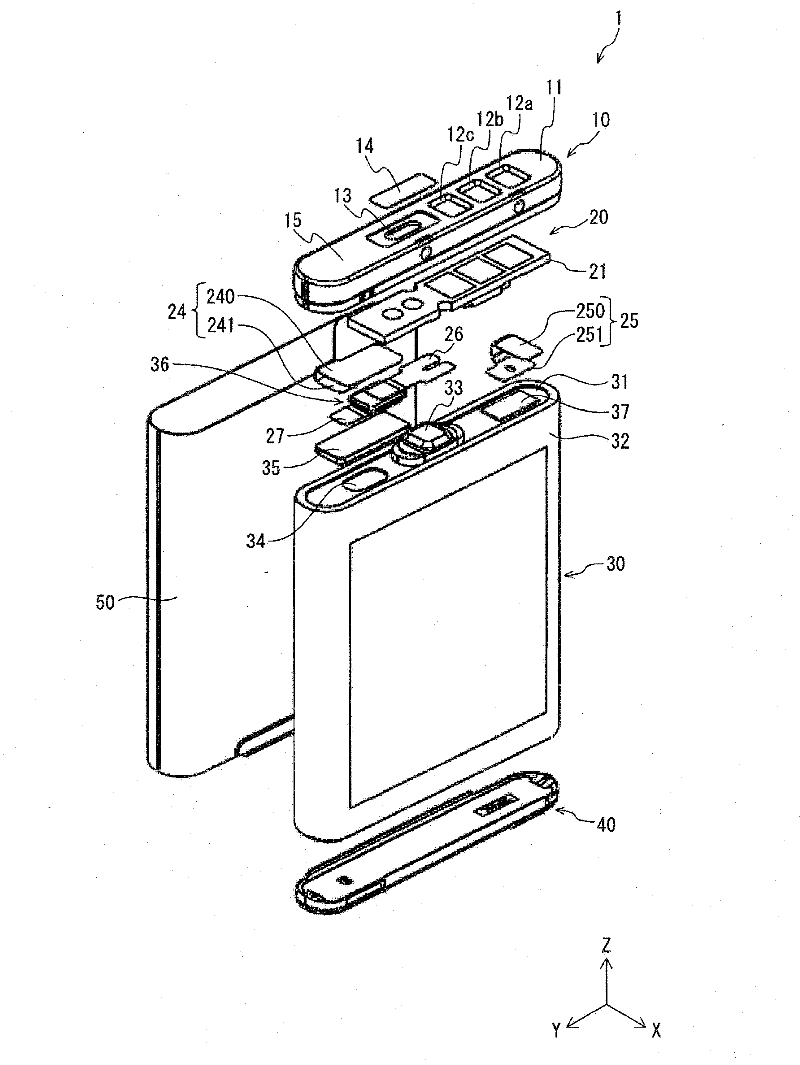

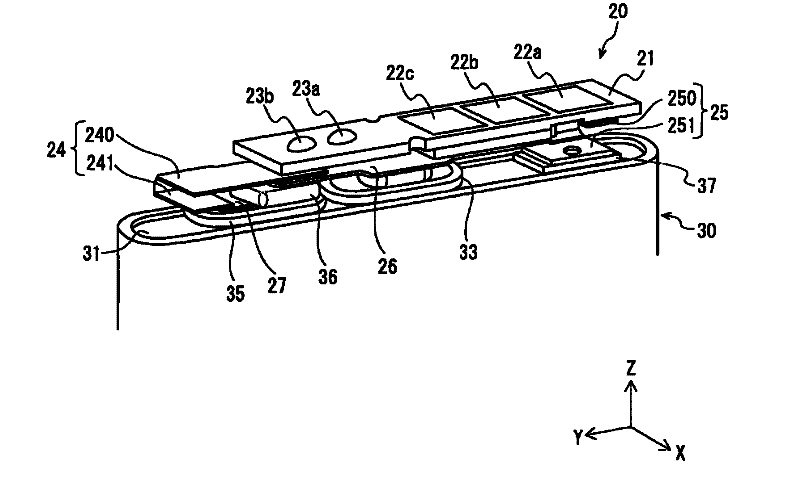

Packaged cell

InactiveCN102447127AProtection miniaturizationShorten the lengthFinal product manufactureSecondary cells manufactureSize reductionElectrical and Electronics engineering

The present invention provides a packaged cell which can realize appropriate production cost reduction by size reduction and shortening of a circuit substrate and properly prevent appearance deterioration caused by an air pore of a resin injected member and therefore has excellent characteristic. An upper surface of a packing plate (31) of the packaged cell (1) is provided with a protective circuit substrate (20) which is short in a Y direction. Furthermore a wiring plate (24) is equipped through a mode that a panel part (240) extends from a Y-direction end of the substrate (20). When the panel part (240) is separated from the packing plate (31), a resin injected member (10) is used for coating the protective circuit substrate (20) and a wiring plate (24) therein. Therefore, a resin block area (15) is divided through the panel part (240), thereby preventing appearance deterioration caused by the air pore.

Owner:SANYO ELECTRIC CO LTD

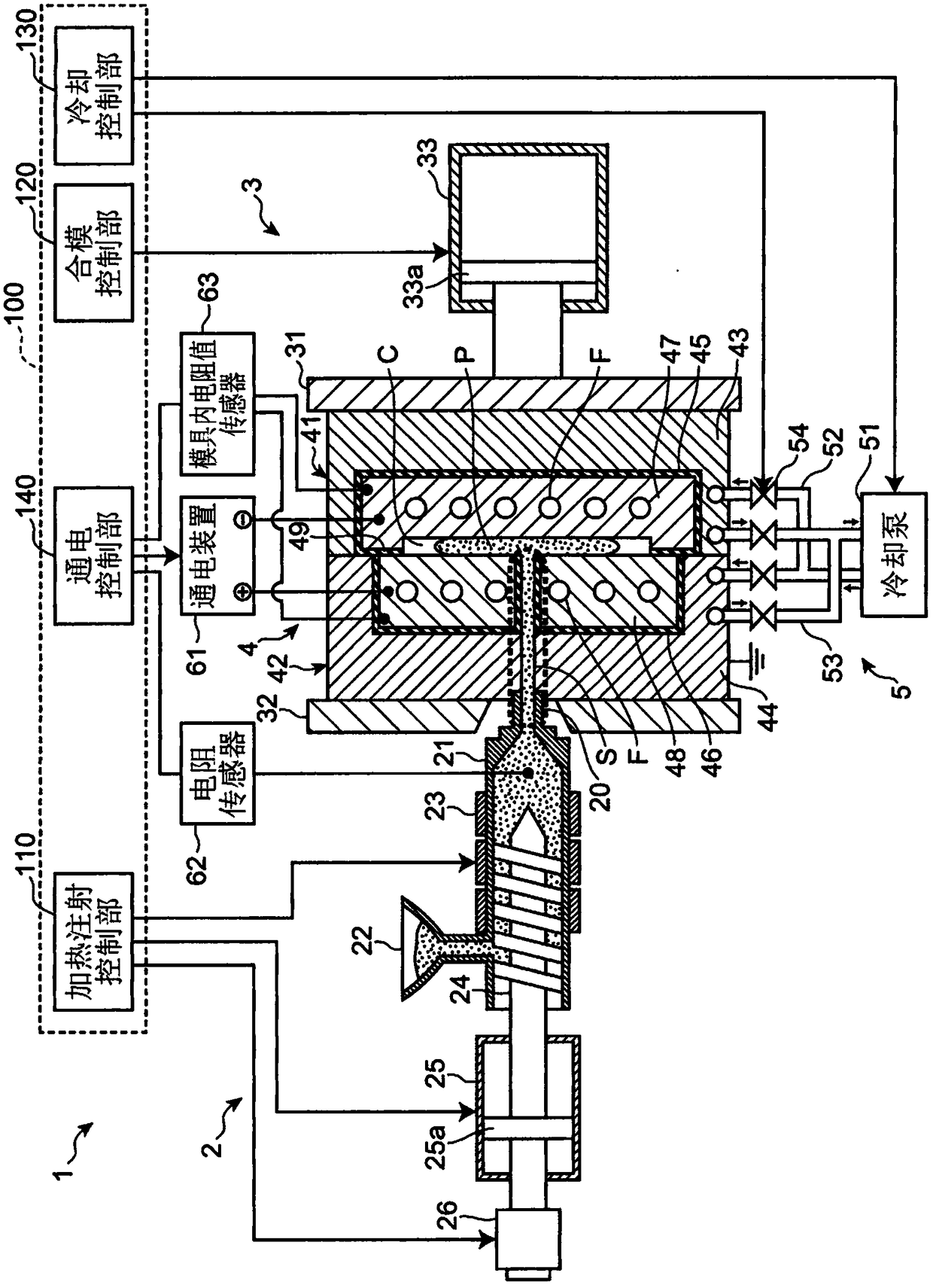

Injection molding apparatus and injection molding method

InactiveCN109070420ASuppression of poor appearanceUniform conductivityDomestic articlesPolymer scienceStatic mixer

When injection molding using an electrically conductive material, the present invention limits the lengthening of injection molding cycles and the occurrence of molded product appearance defects and imparts uniform electric conductivity to the molded product. An injection molding apparatus is provided with a heating and injection means for heating and melting an electrically conductive material toa flowable temperature and injecting same into a molding mold. In said molding mold, at least a portion of forming surface of the cavity has multiple electrically conductive sections that are insulated from each other and a prescribed voltage is applied between the electrically conductive sections. A static mixer is provided in the region from the tip of the heating and injection means to the flow channel for the electrically conductive material.

Owner:MAZDA MOTOR CORP

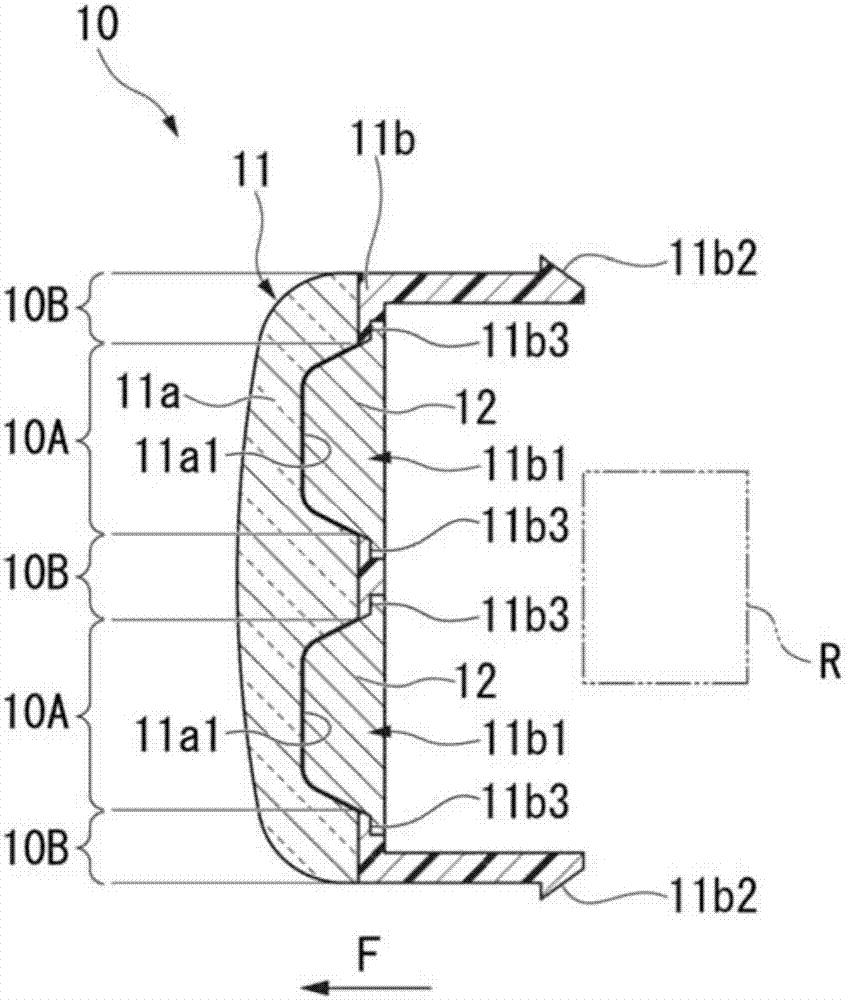

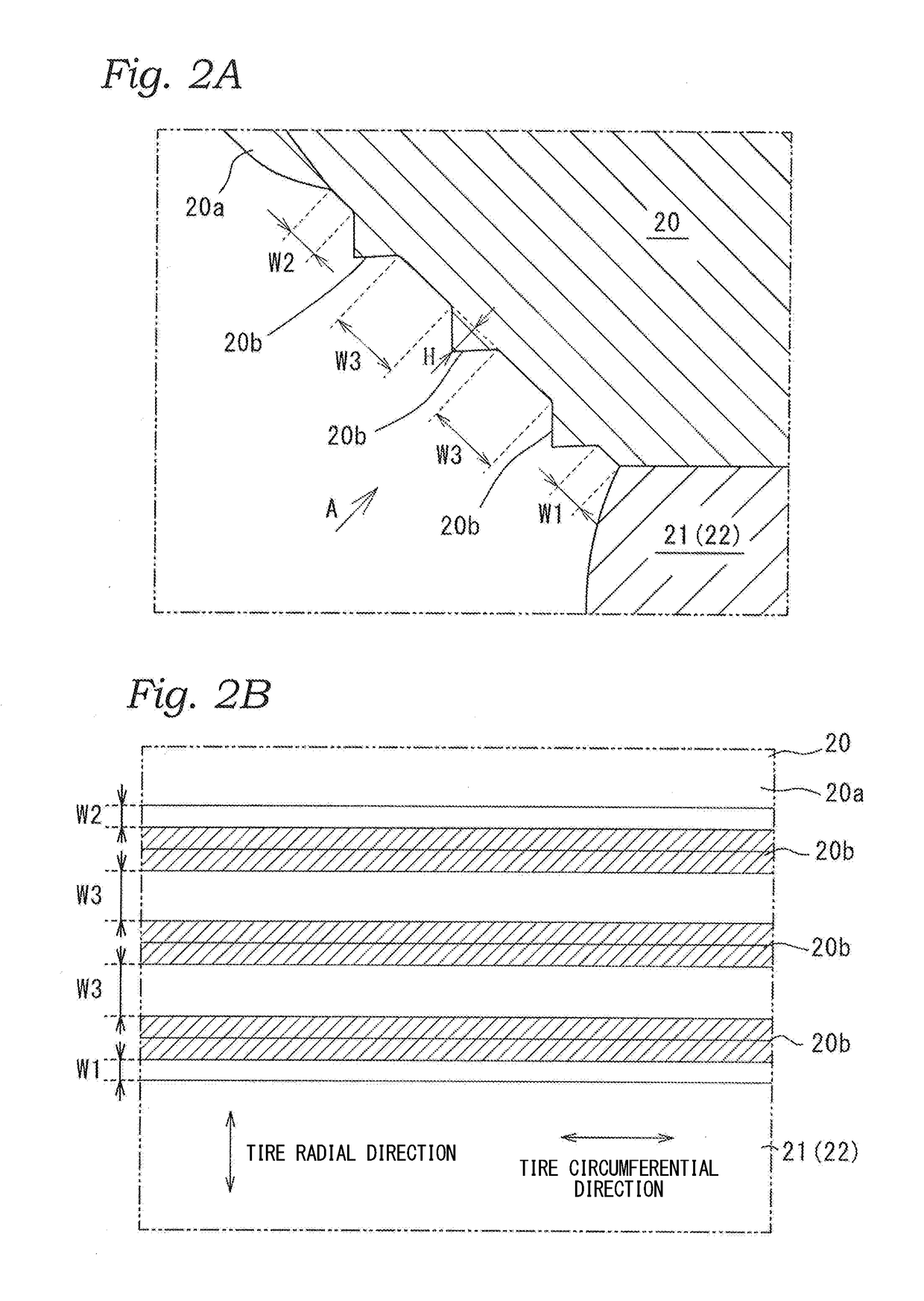

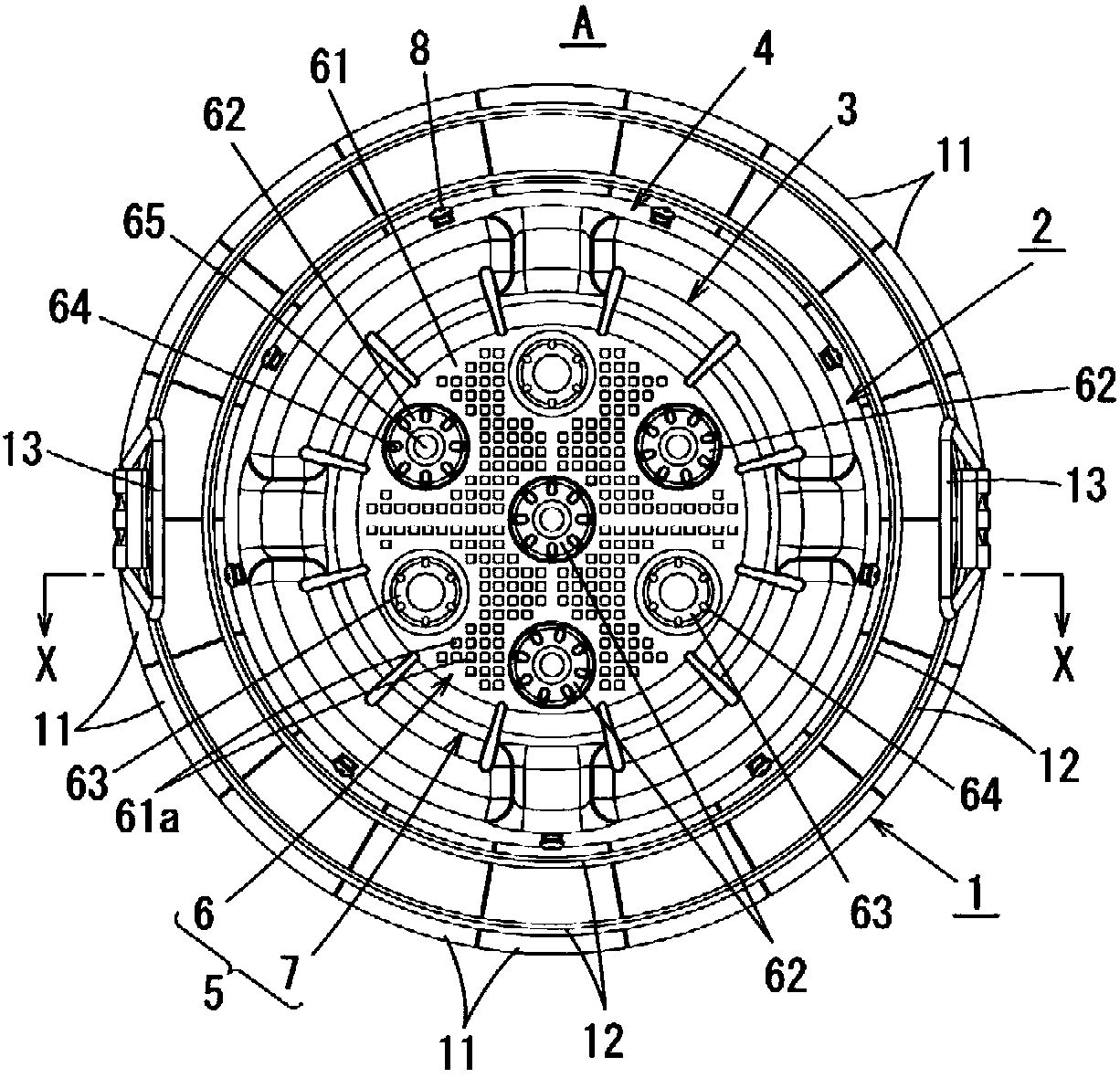

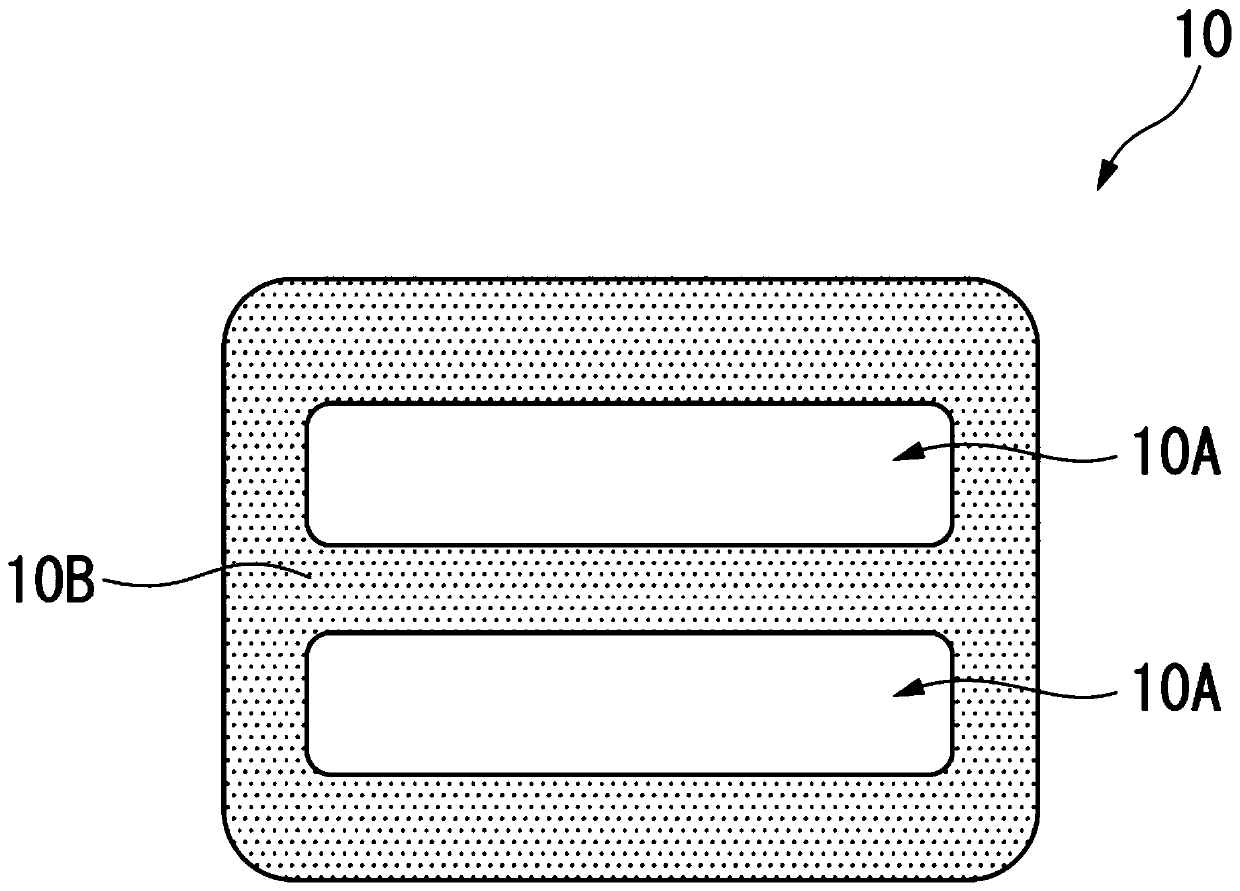

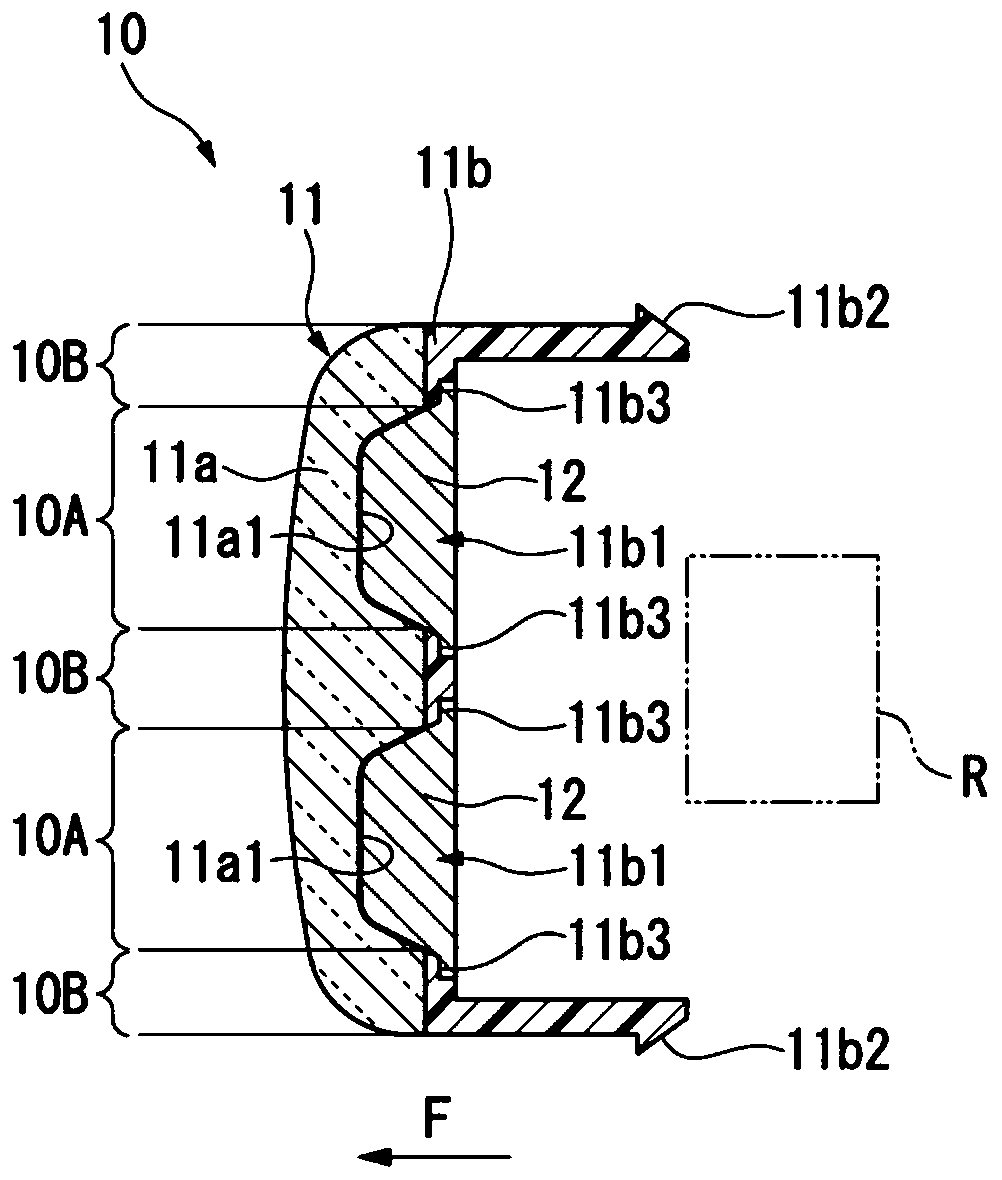

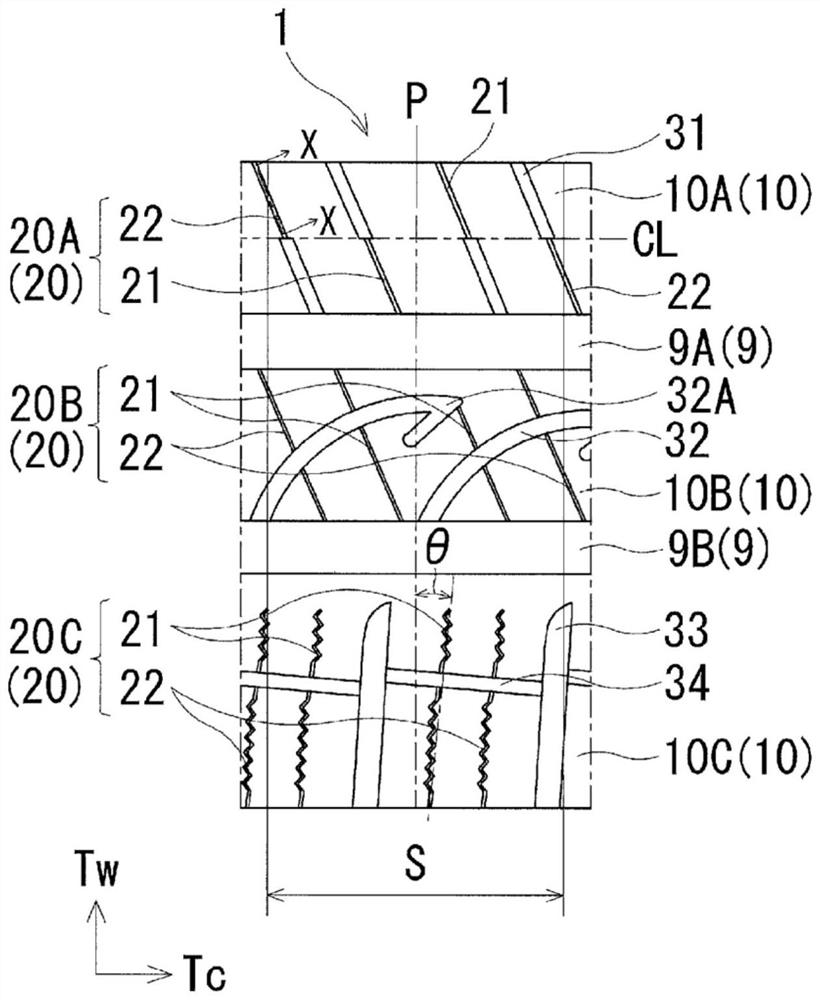

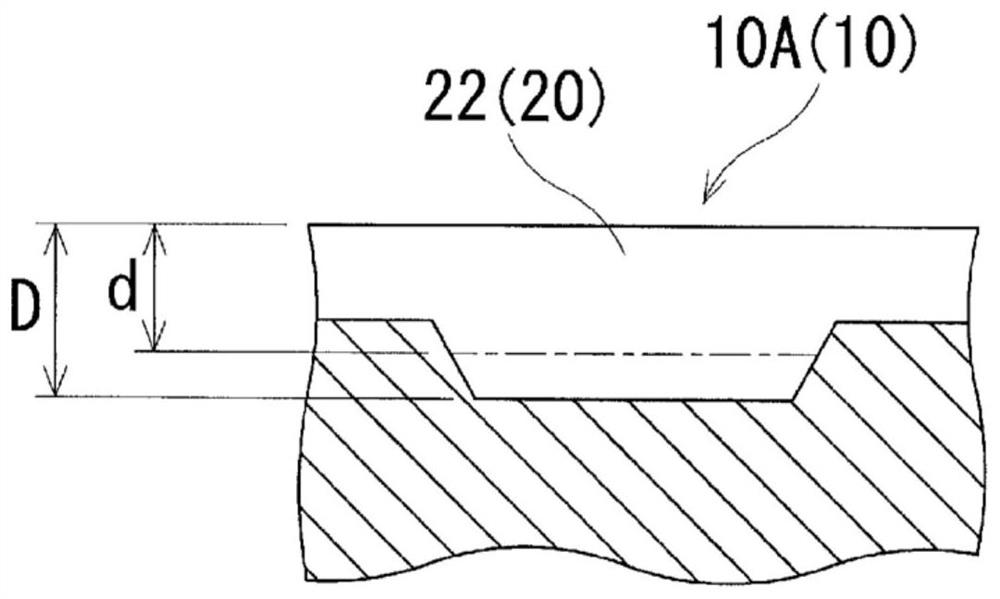

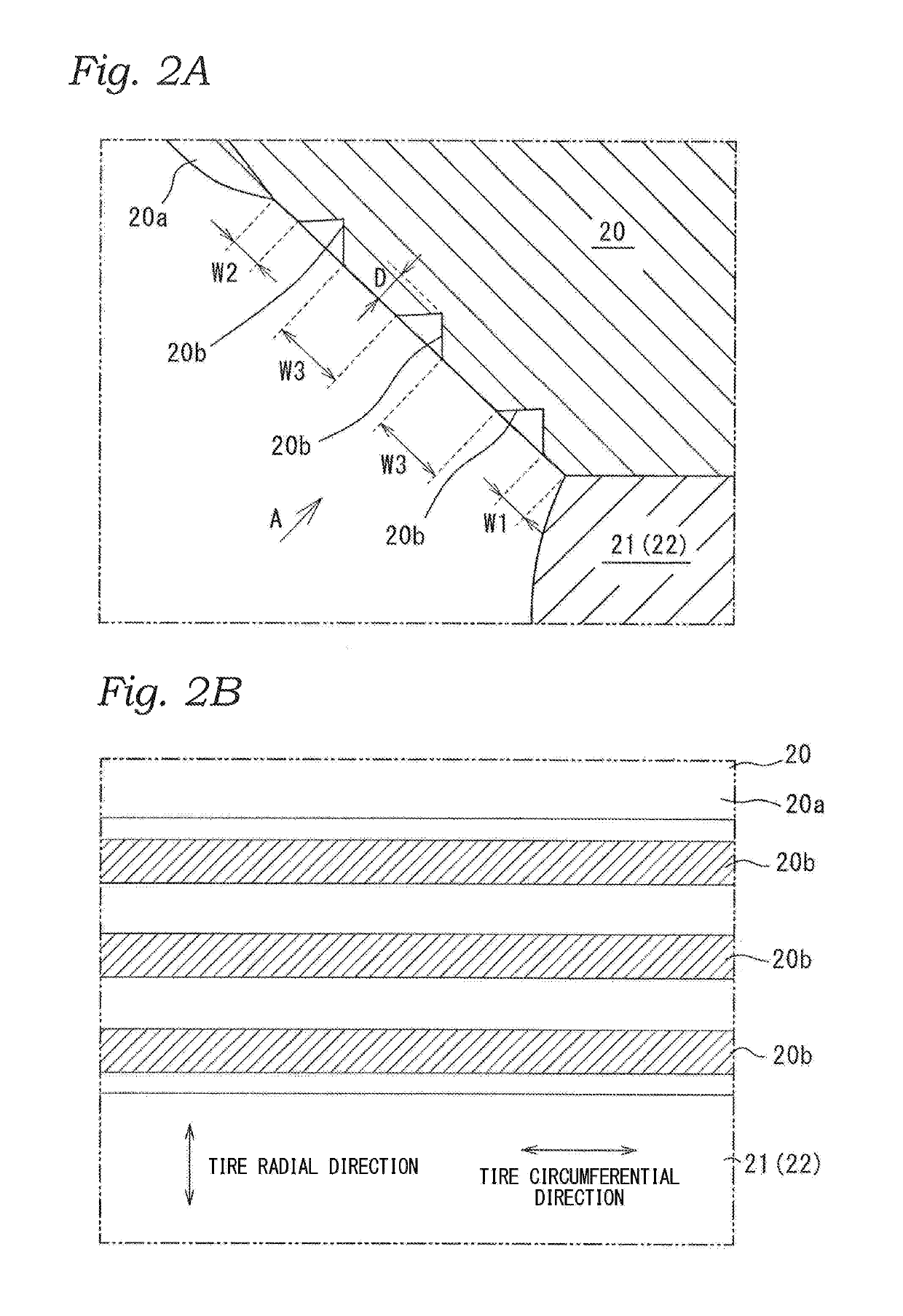

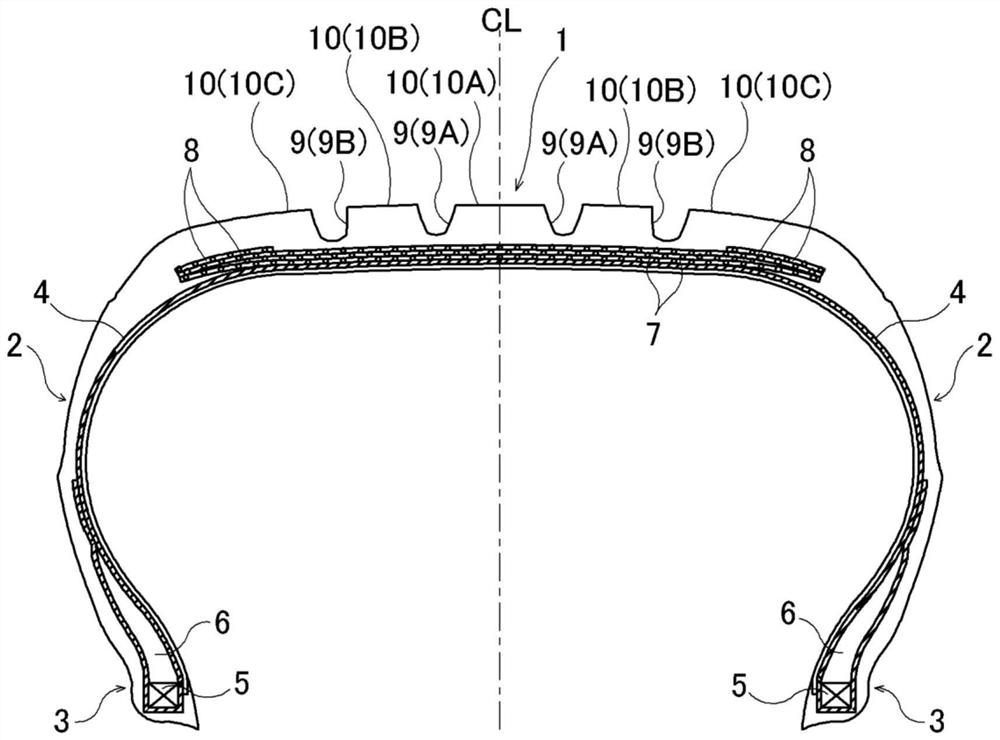

Pneumatic tire

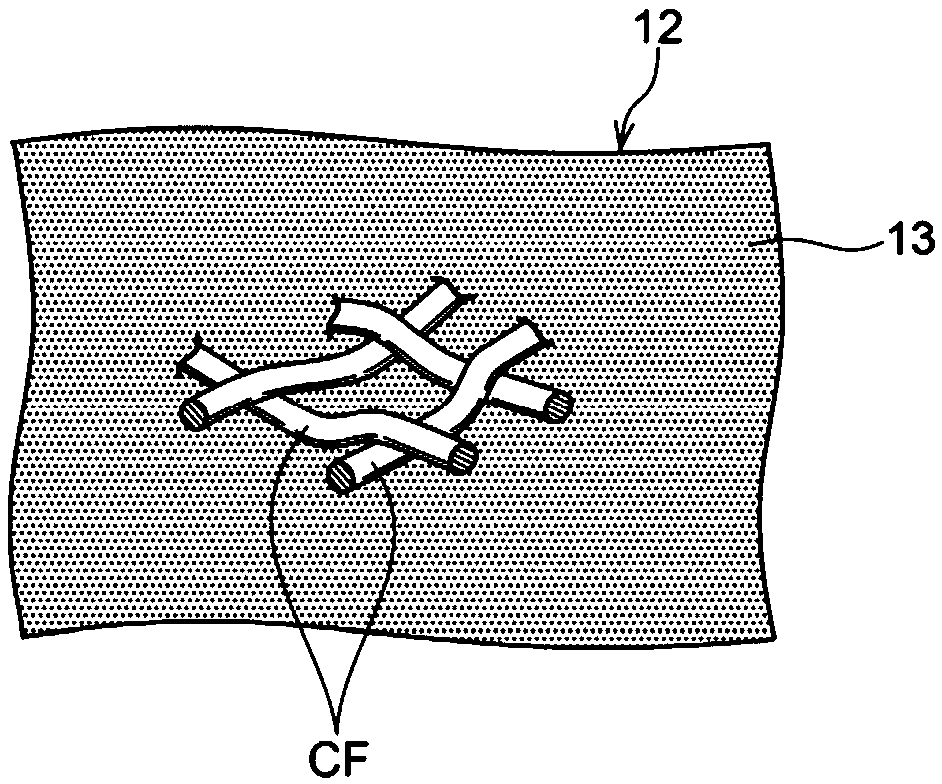

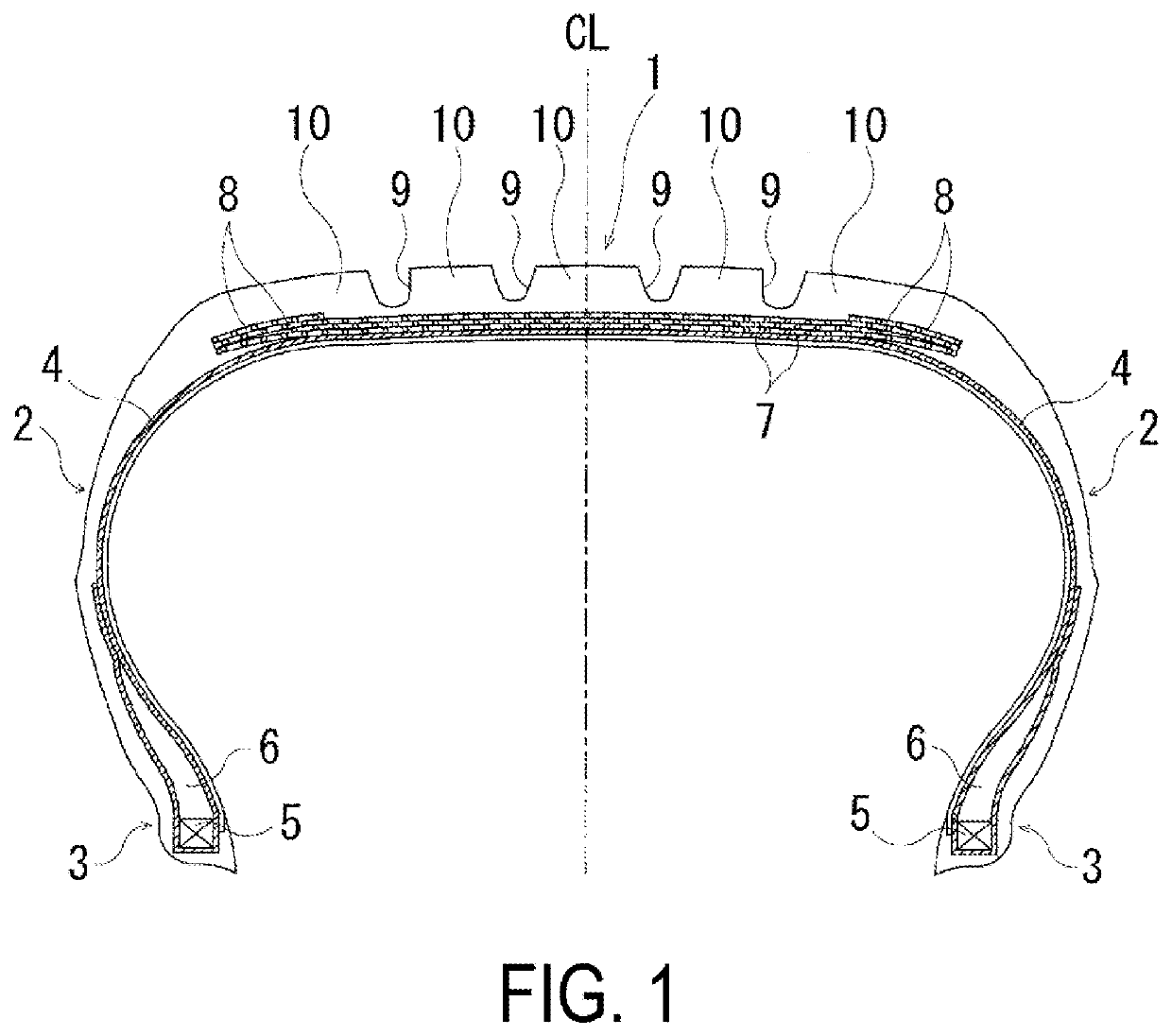

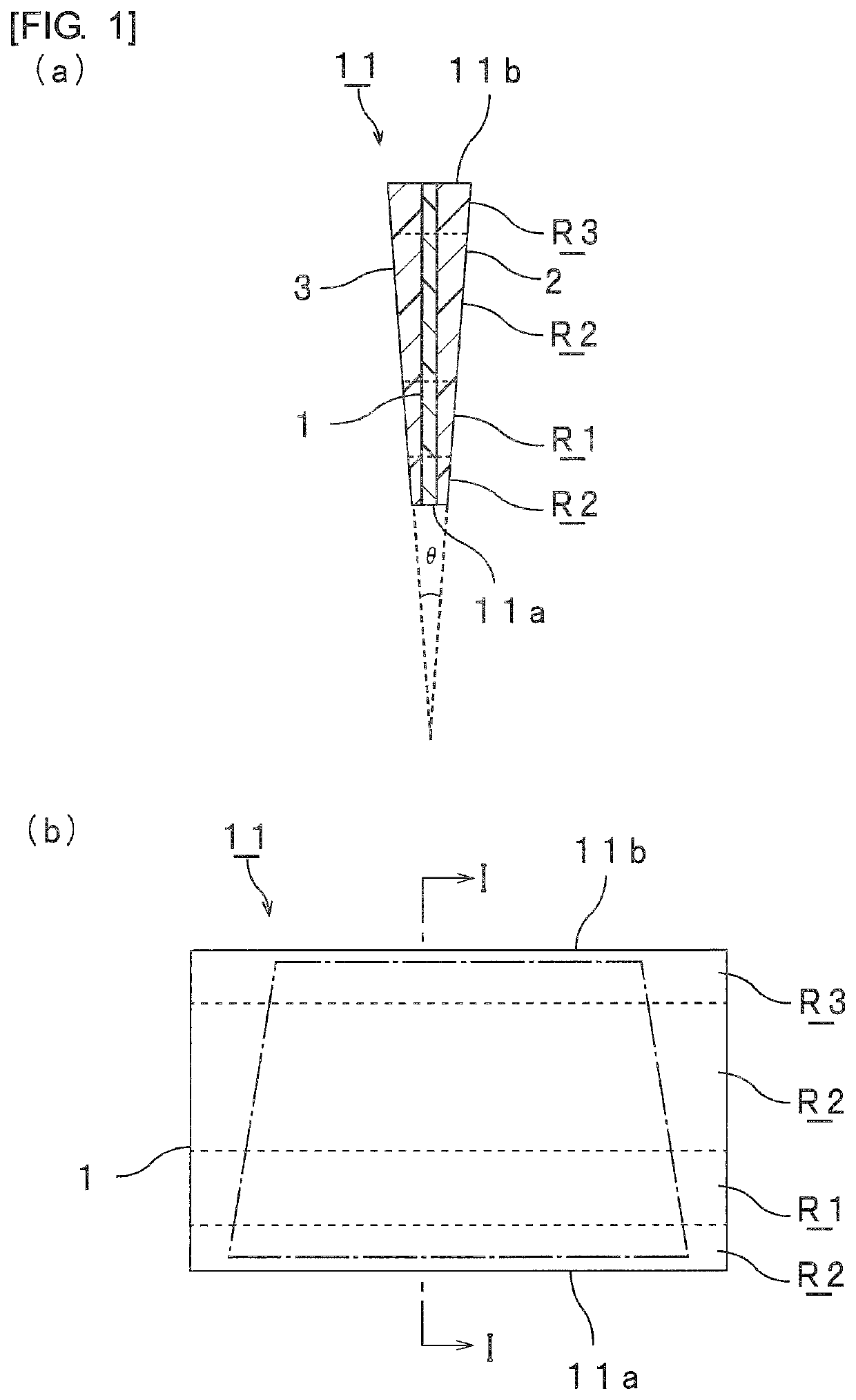

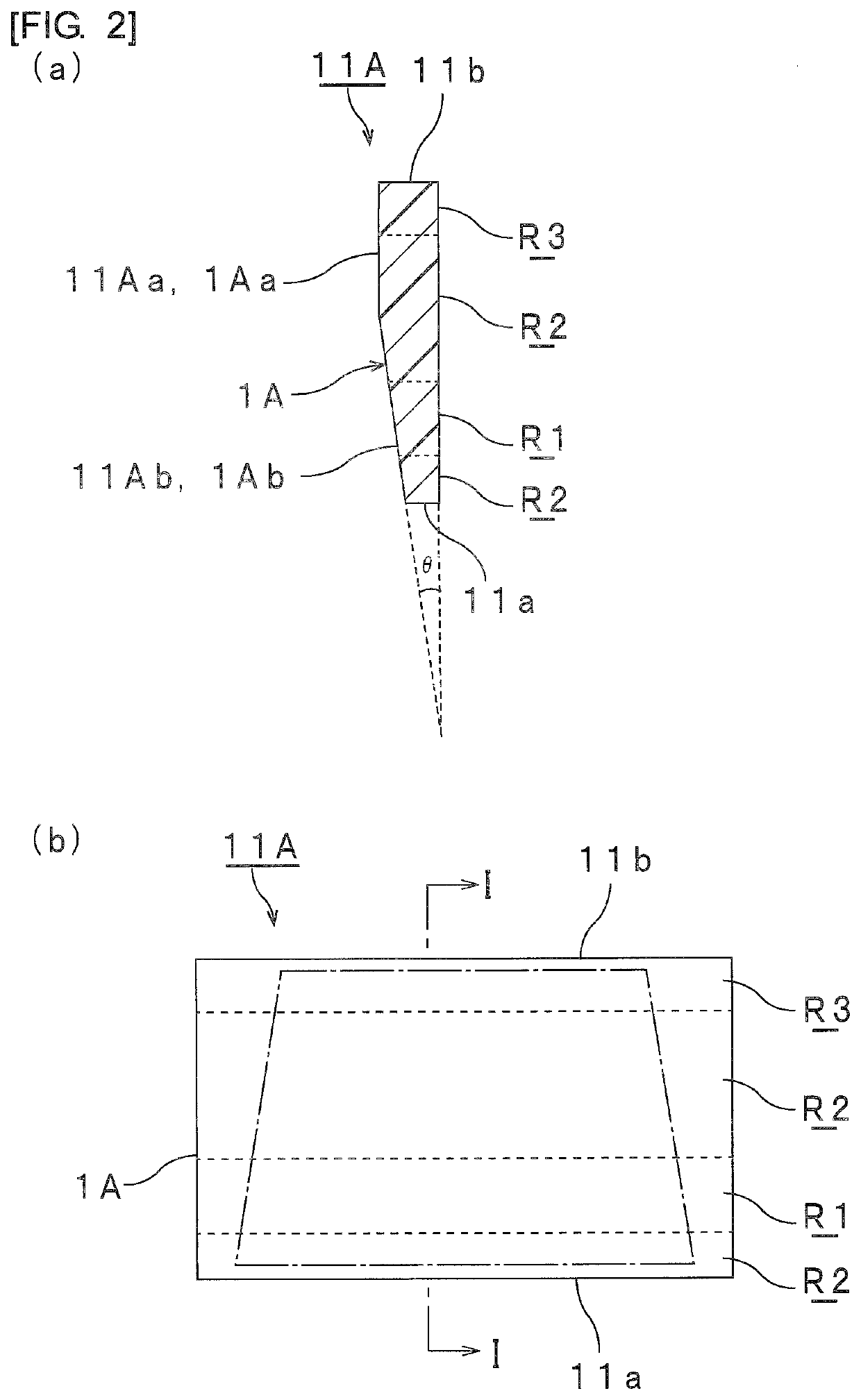

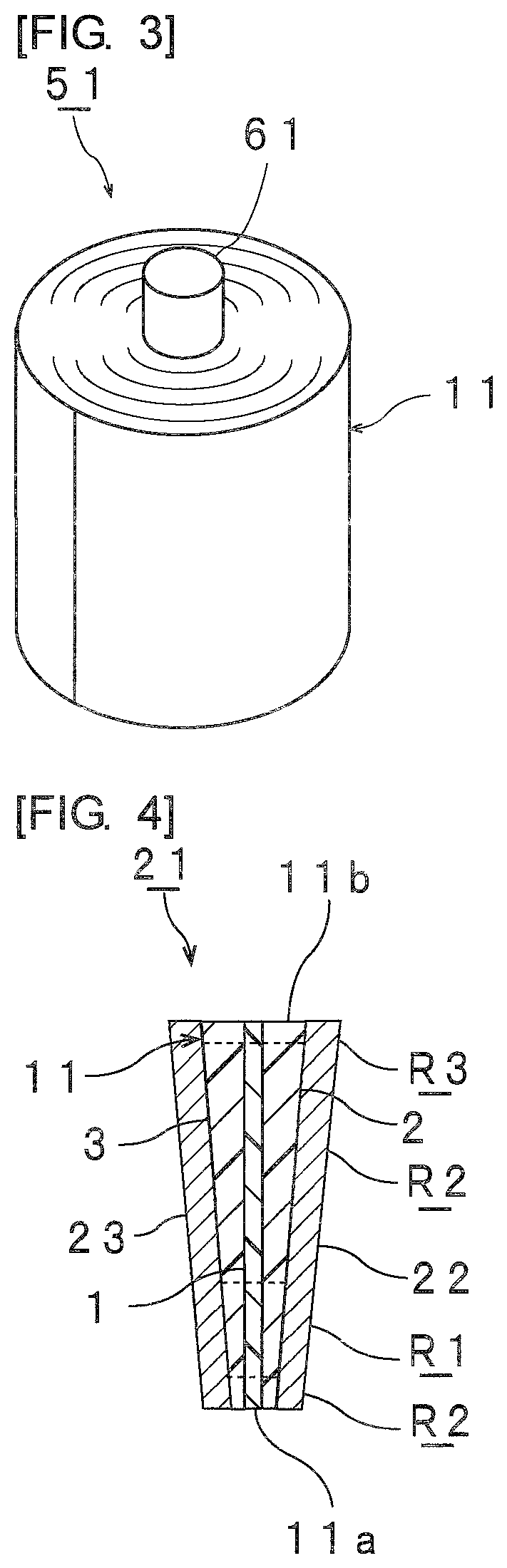

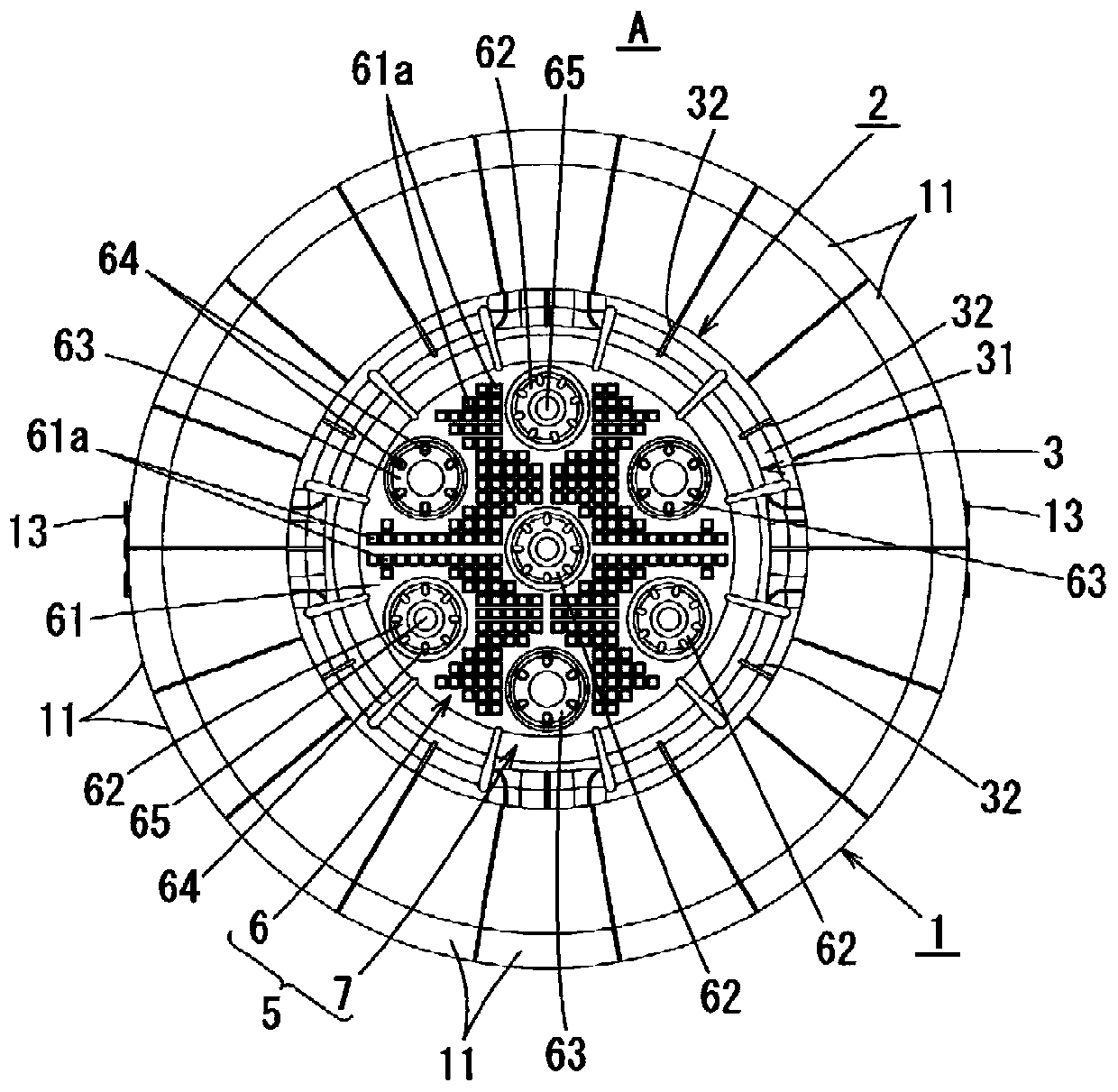

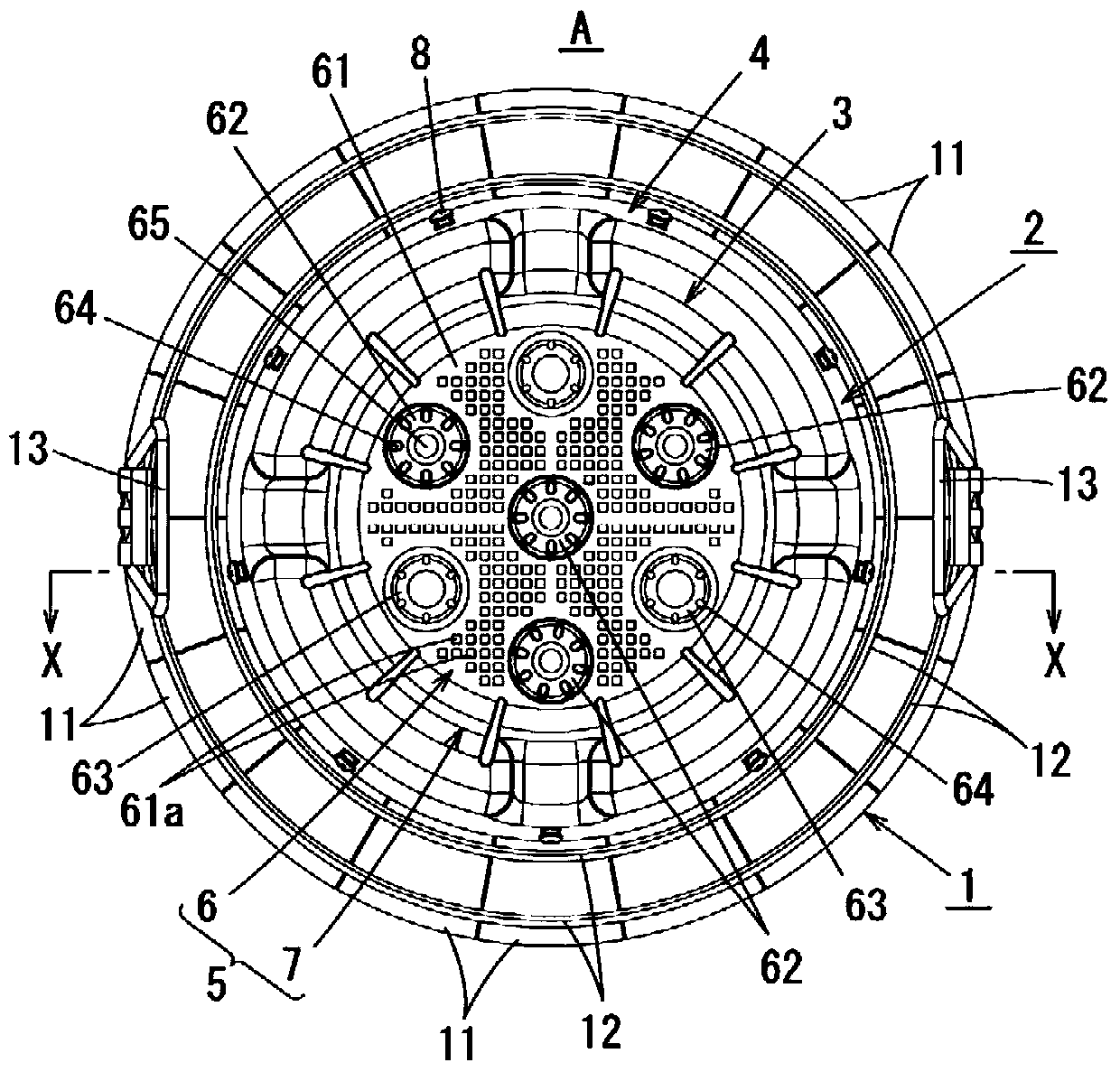

ActiveUS20180037062A1Suppression of poor appearanceTyresPneumatic tyre reinforcementsEngineeringMechanical engineering

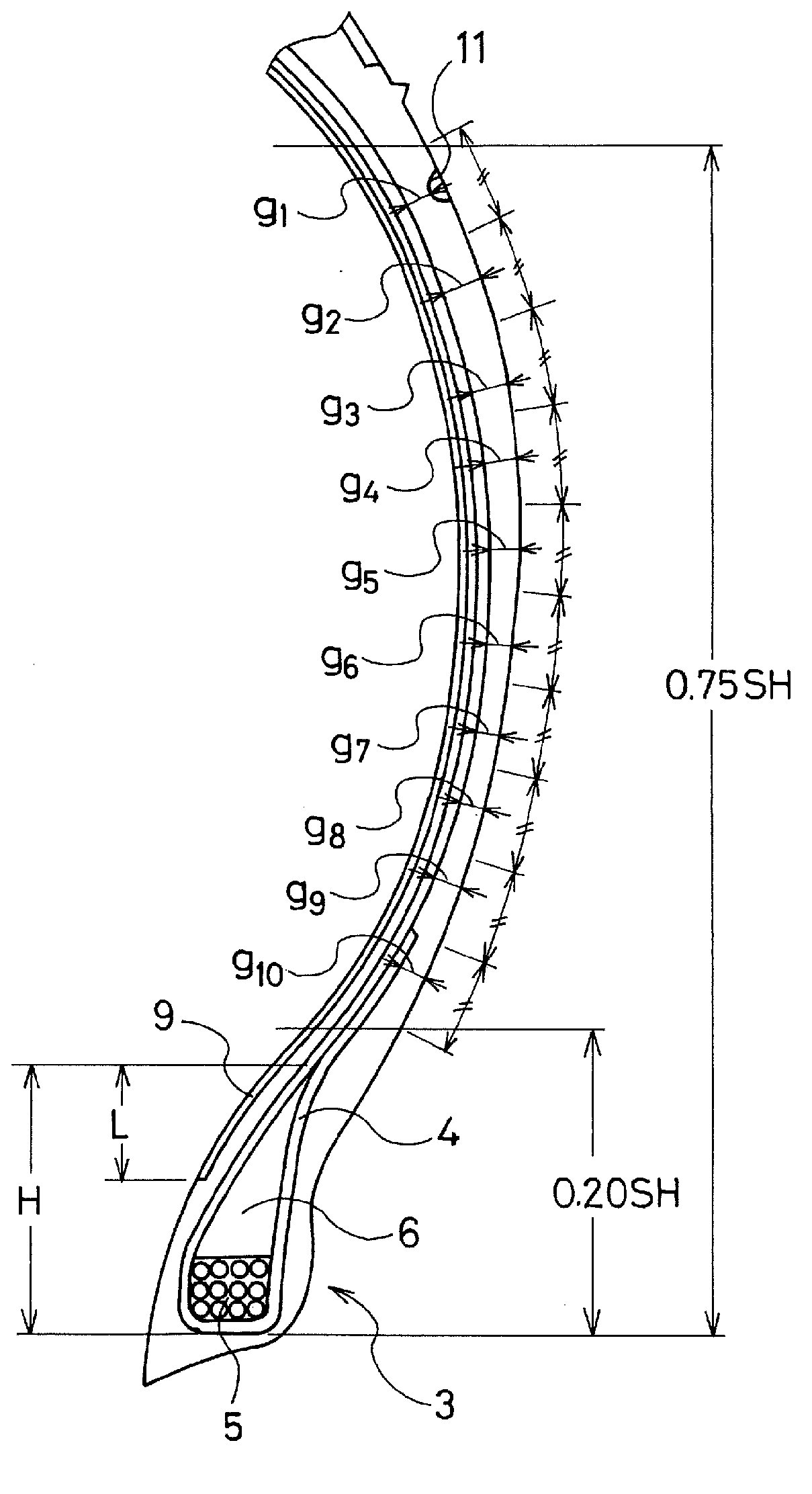

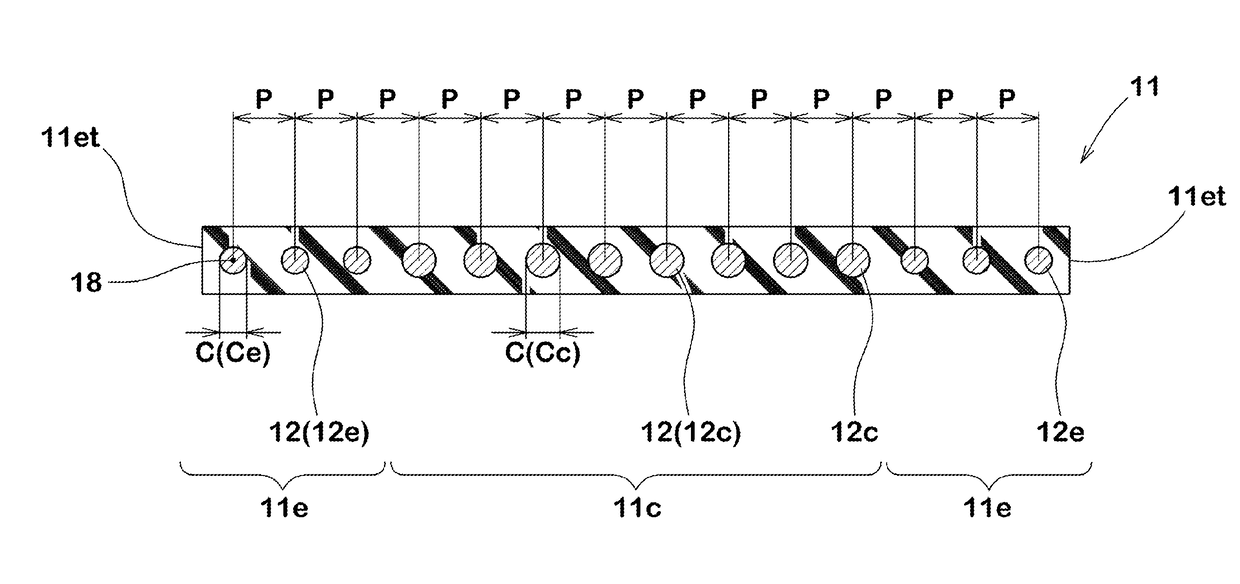

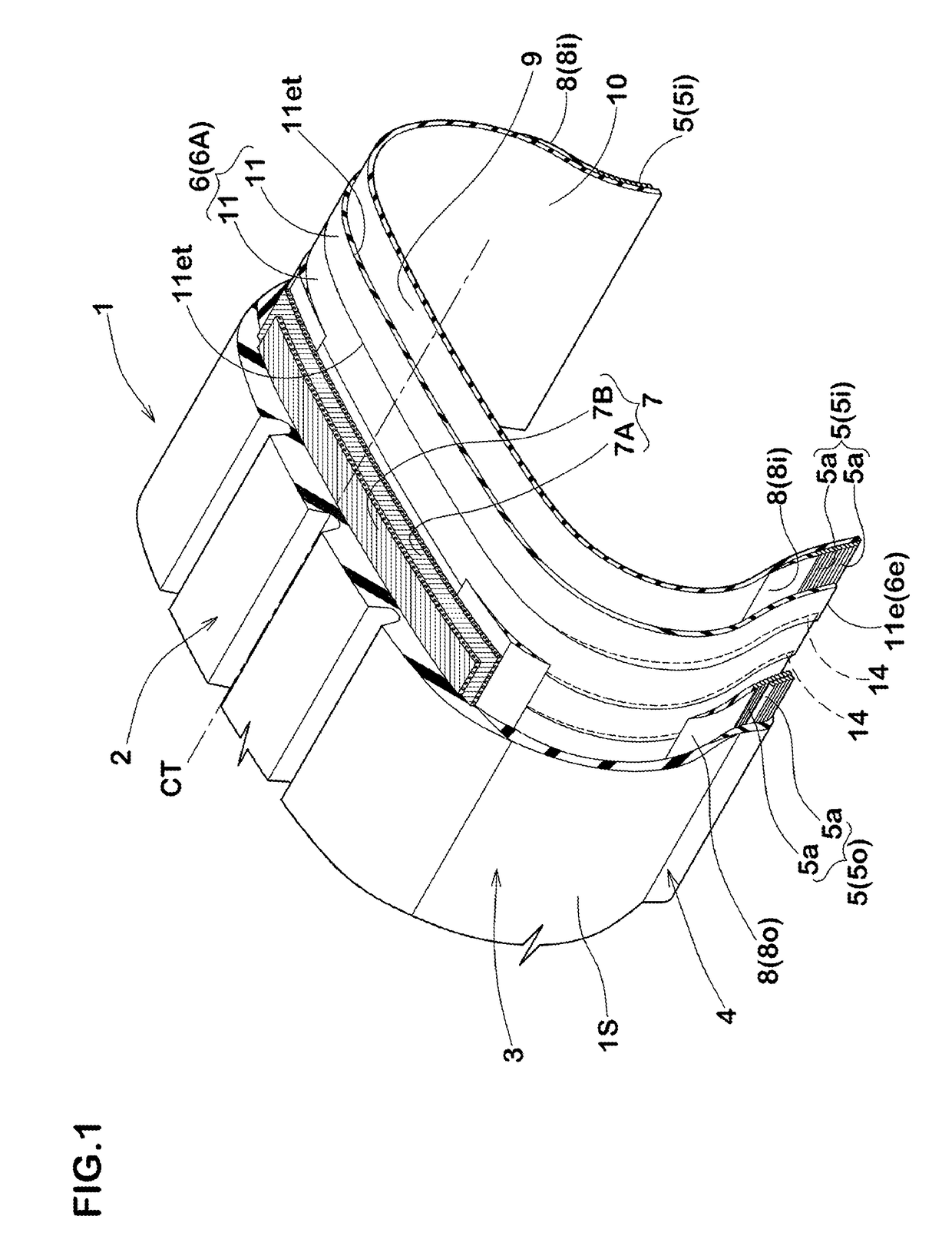

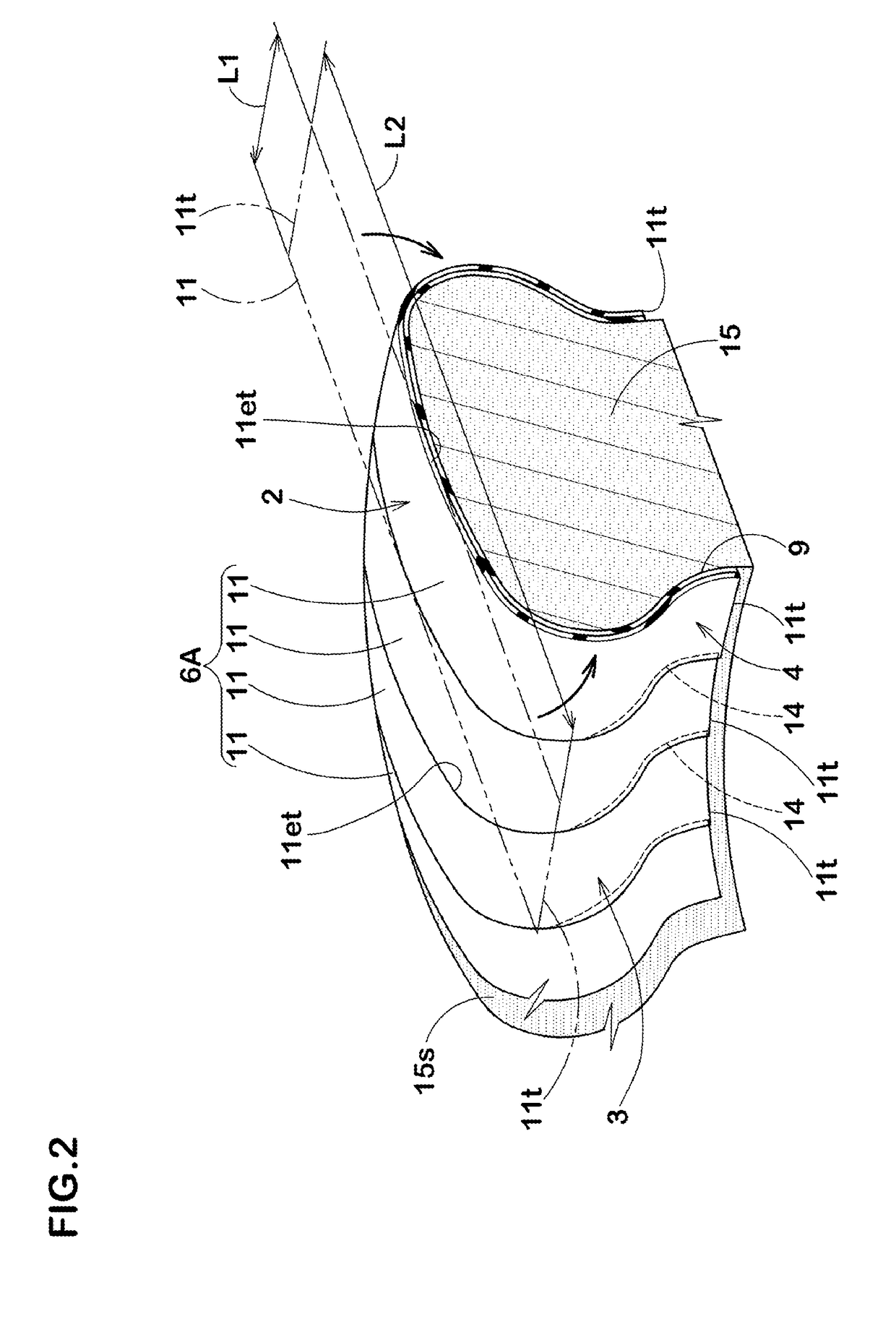

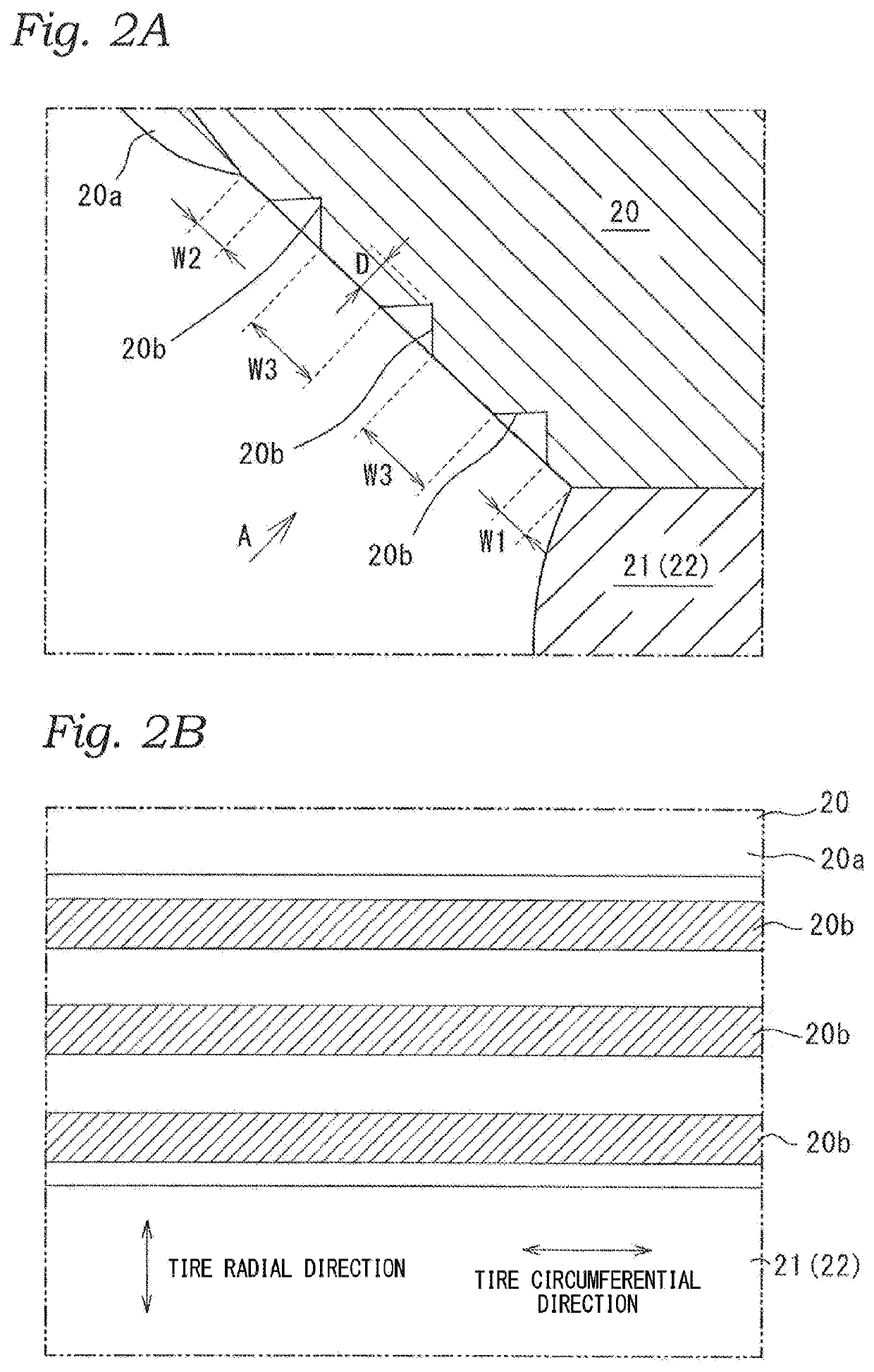

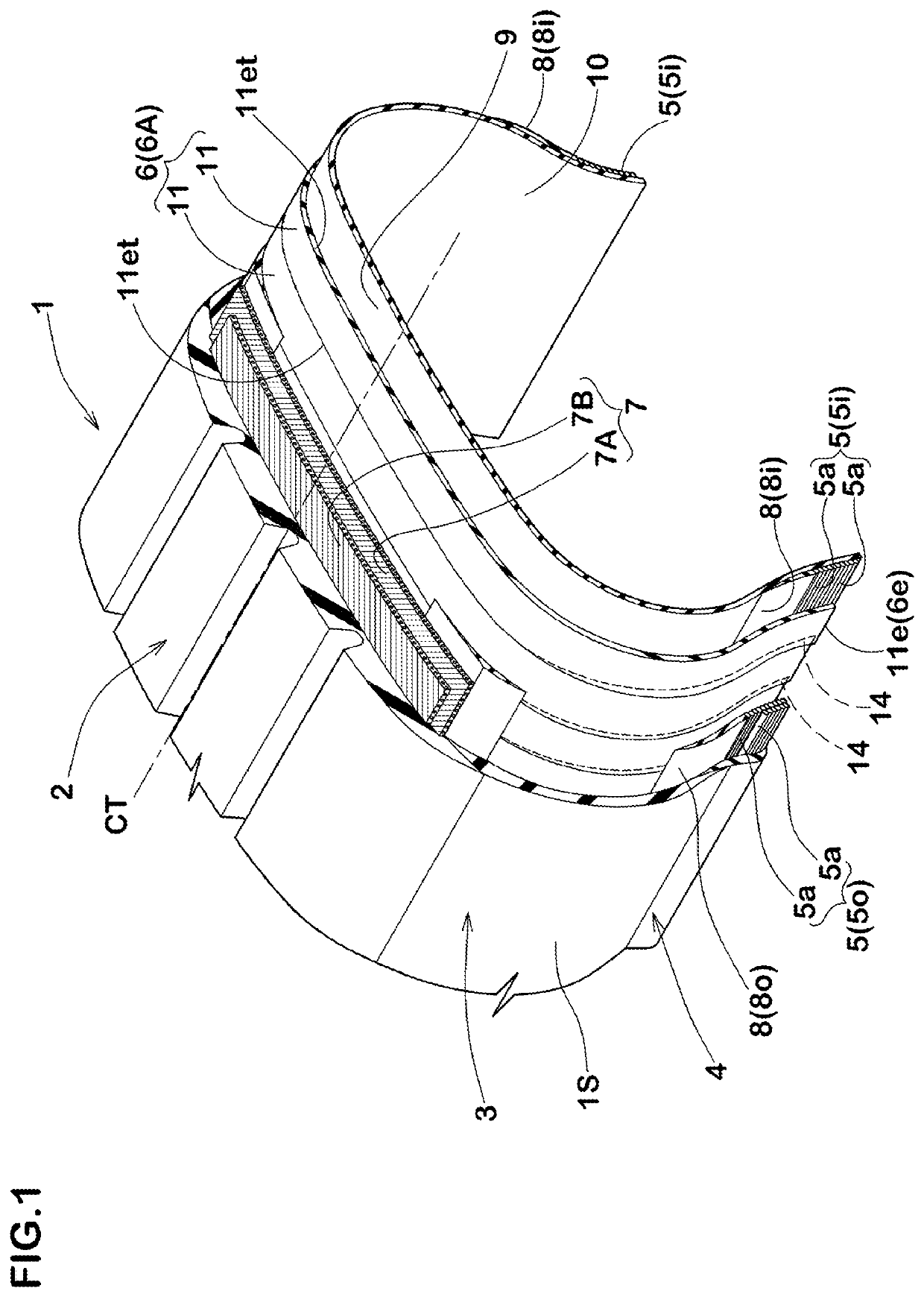

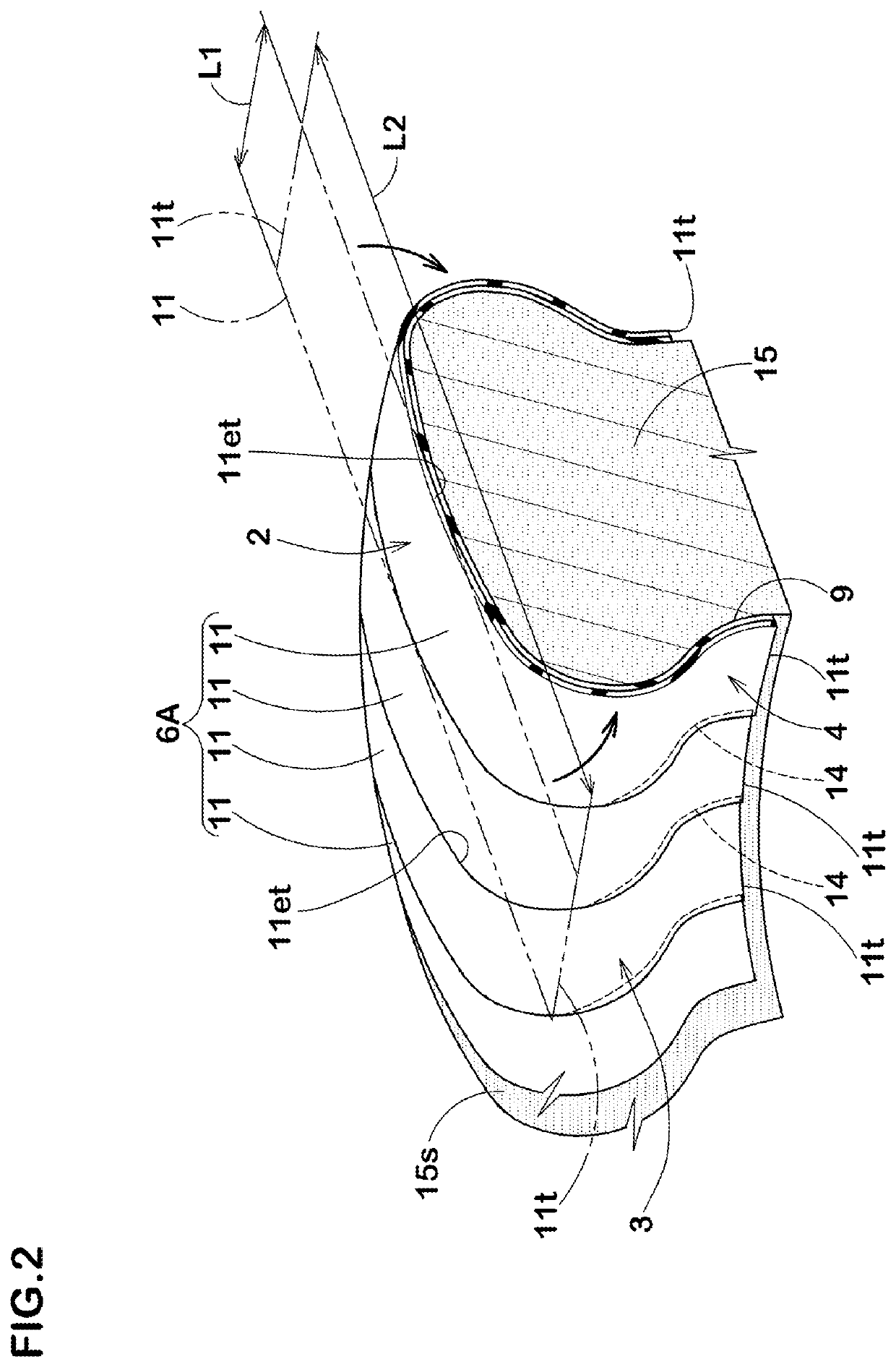

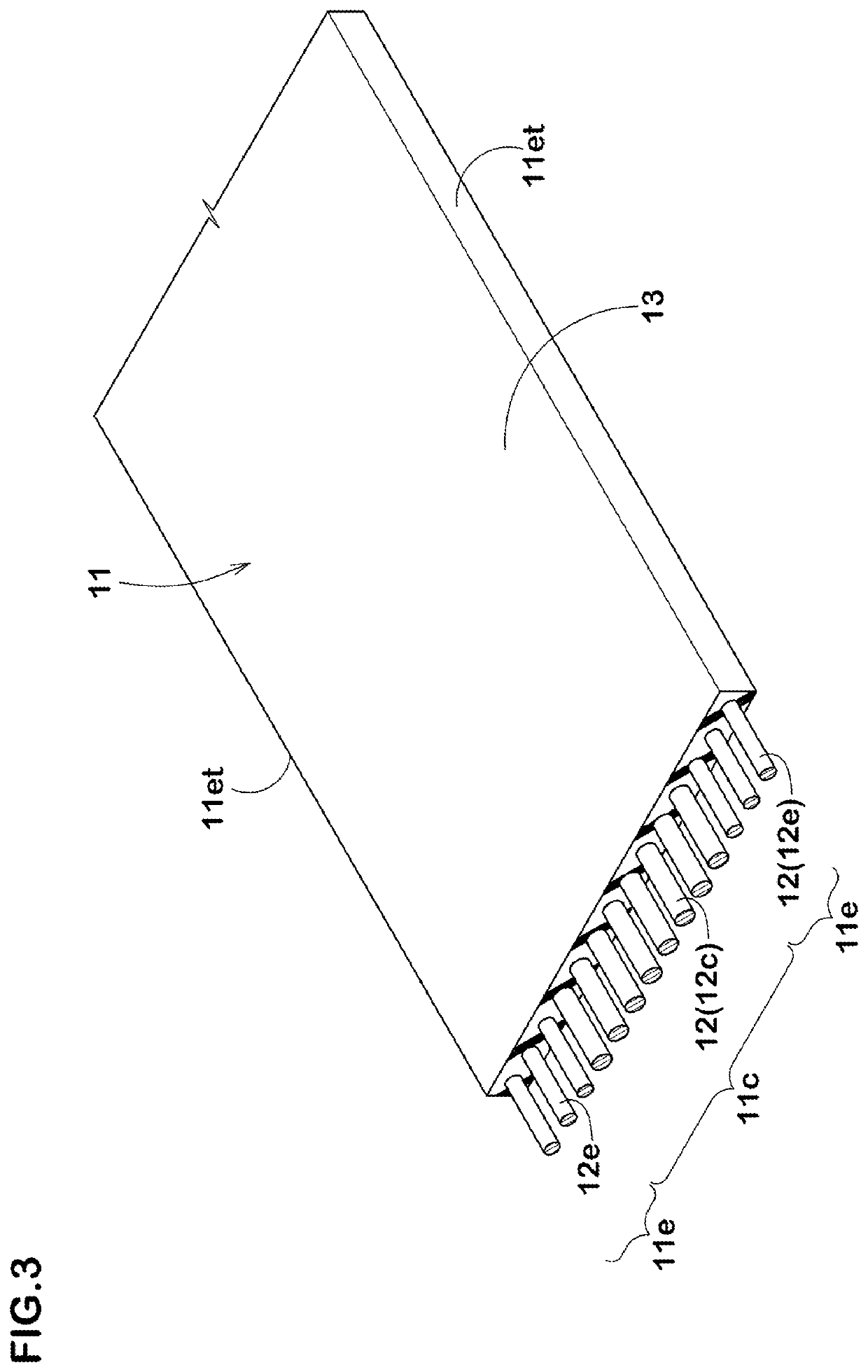

A pneumatic tire 1 comprises a carcass 6 comprising at least one carcass ply 6A extending between bead portions 4 via sidewall portions 3 and a tread portion 2. The carcass ply 6A comprises strip-shaped ply pieces 11 longer in a tire radial direction than in a tire circumferential direction arranged circumferentially. Each of the ply pieces 11 comprises a plurality of carcass cords 12 arranged in parallel in the tire radial direction and at least partly overlapping each other with the ply pieces 11 circumferentially adjacent. At least one of the carcass cords 12 arranged in at least one of side edge portions 11e in the tire circumferential direction of each of the ply pieces 11 having a diameter (Ce) smaller than a diameter (Cc) of at least one of the carcass cords 12 arranged in a center portion 11c of each of the ply pieces 11.

Owner:SUMITOMO RUBBER IND LTD

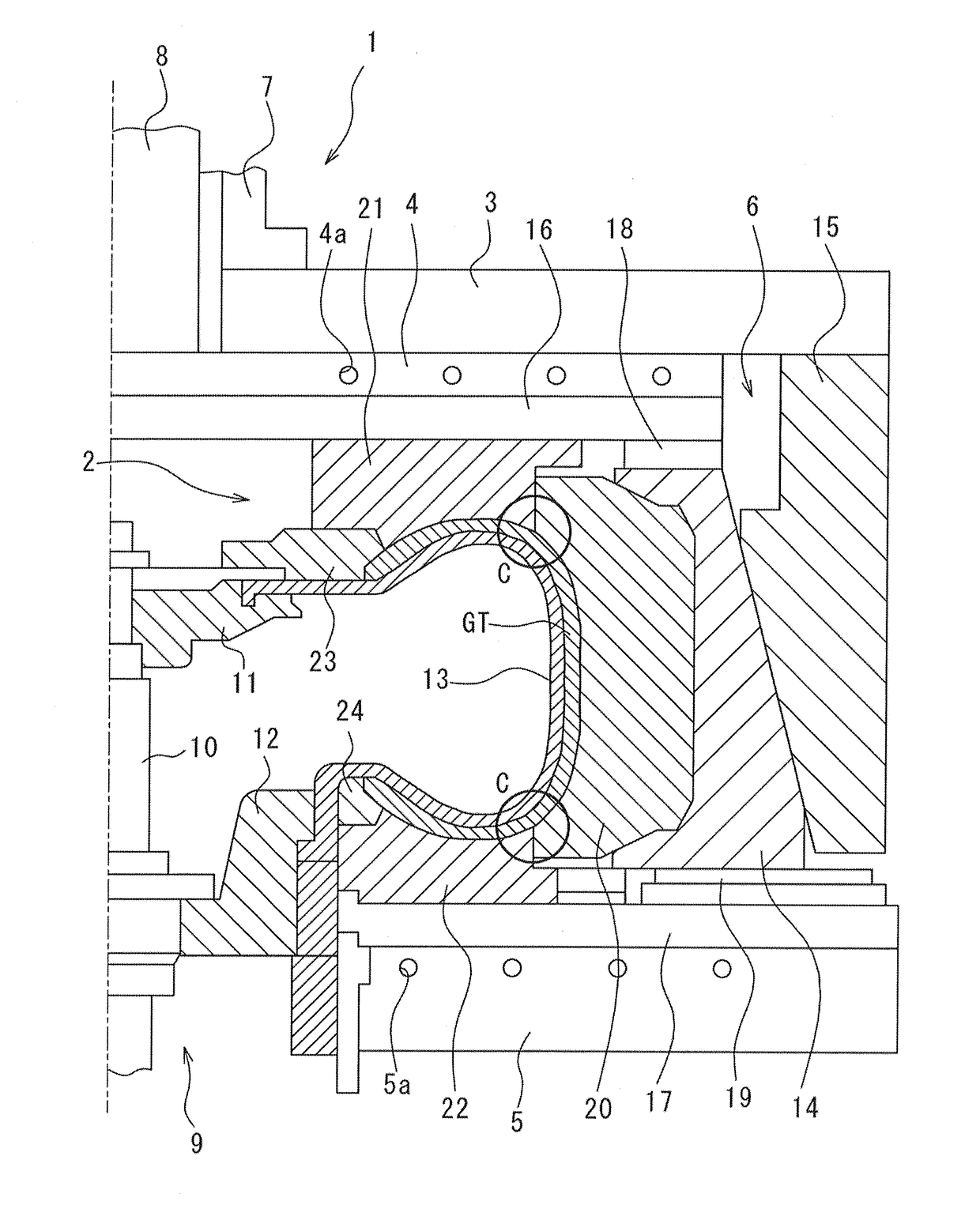

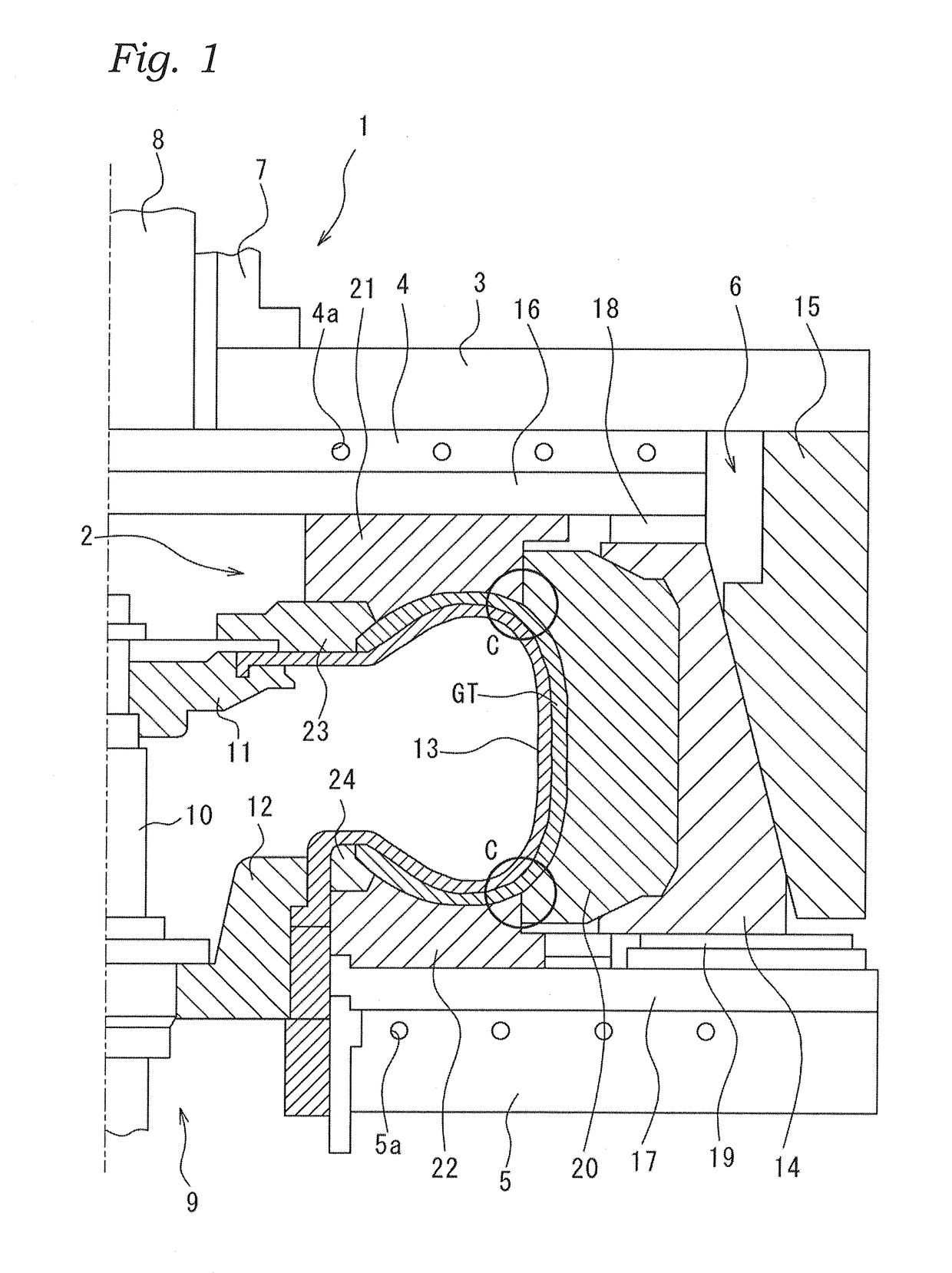

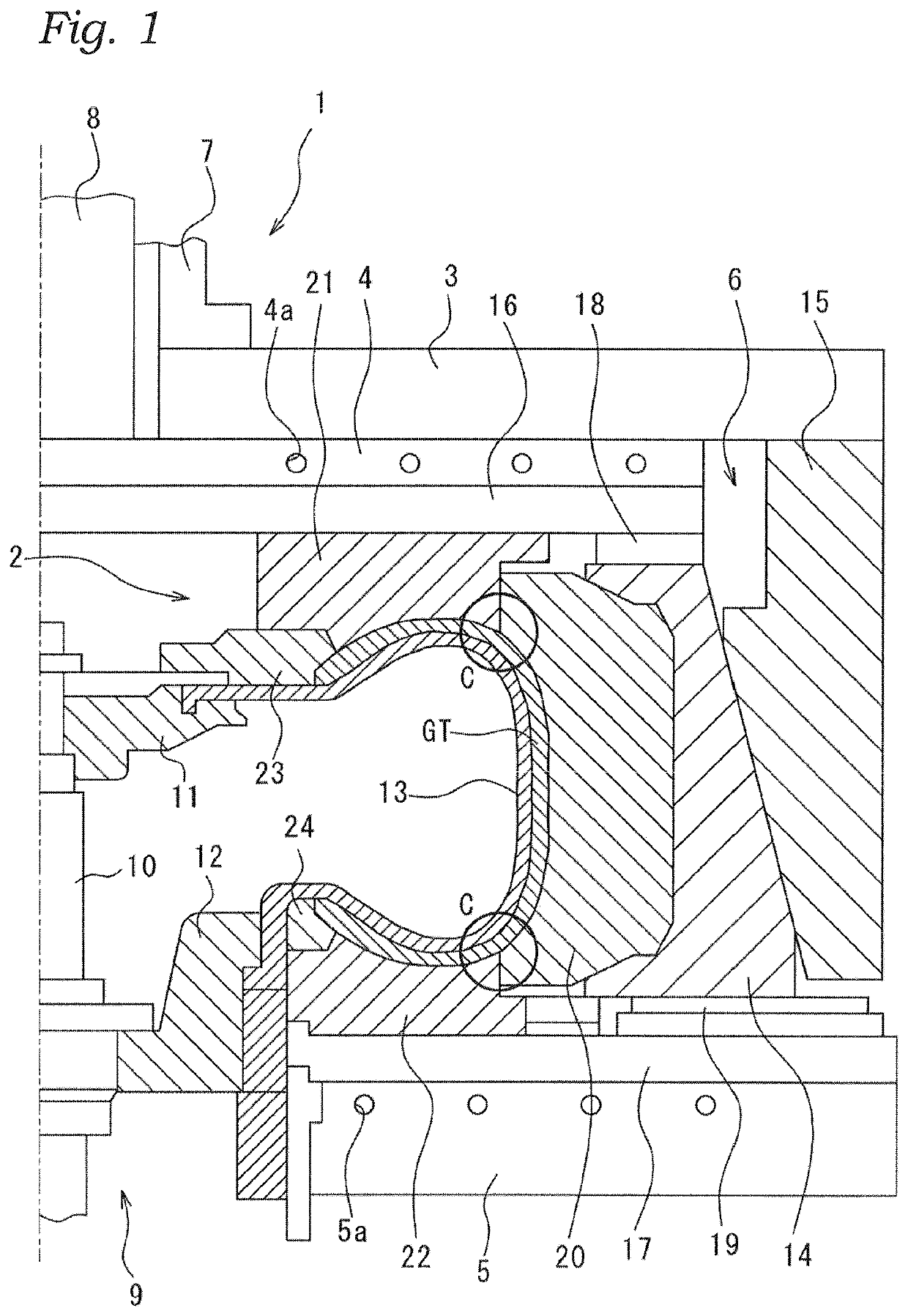

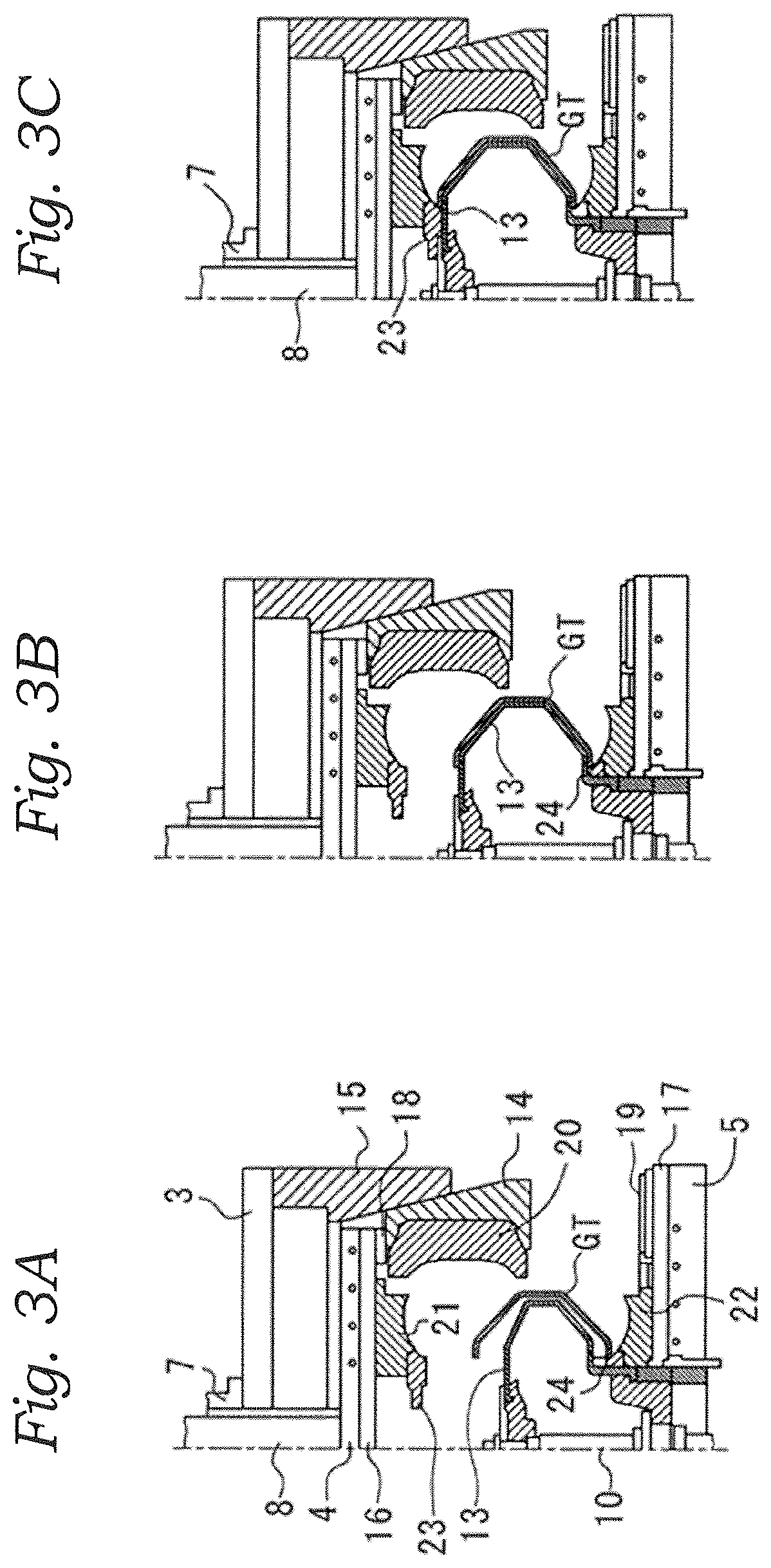

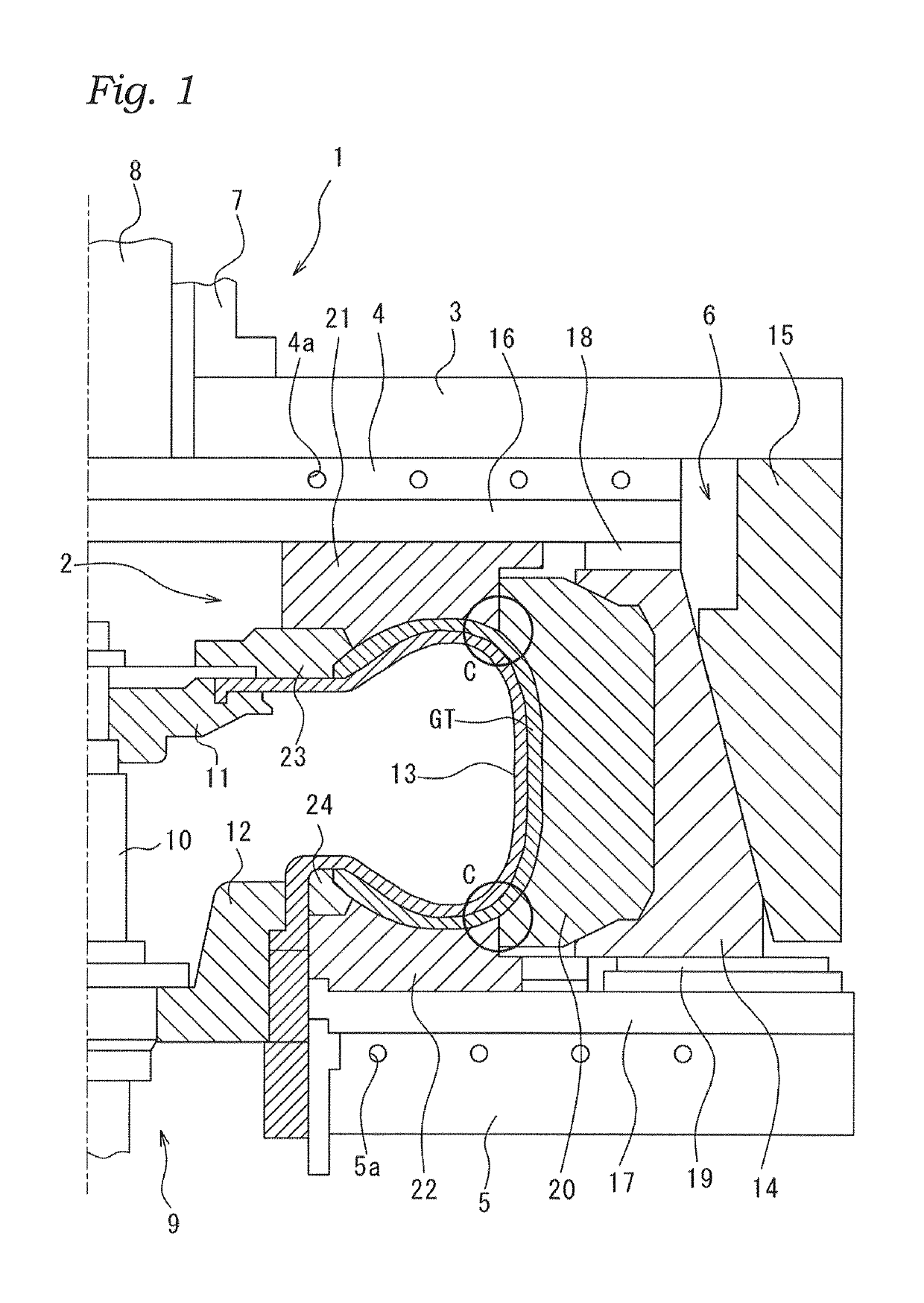

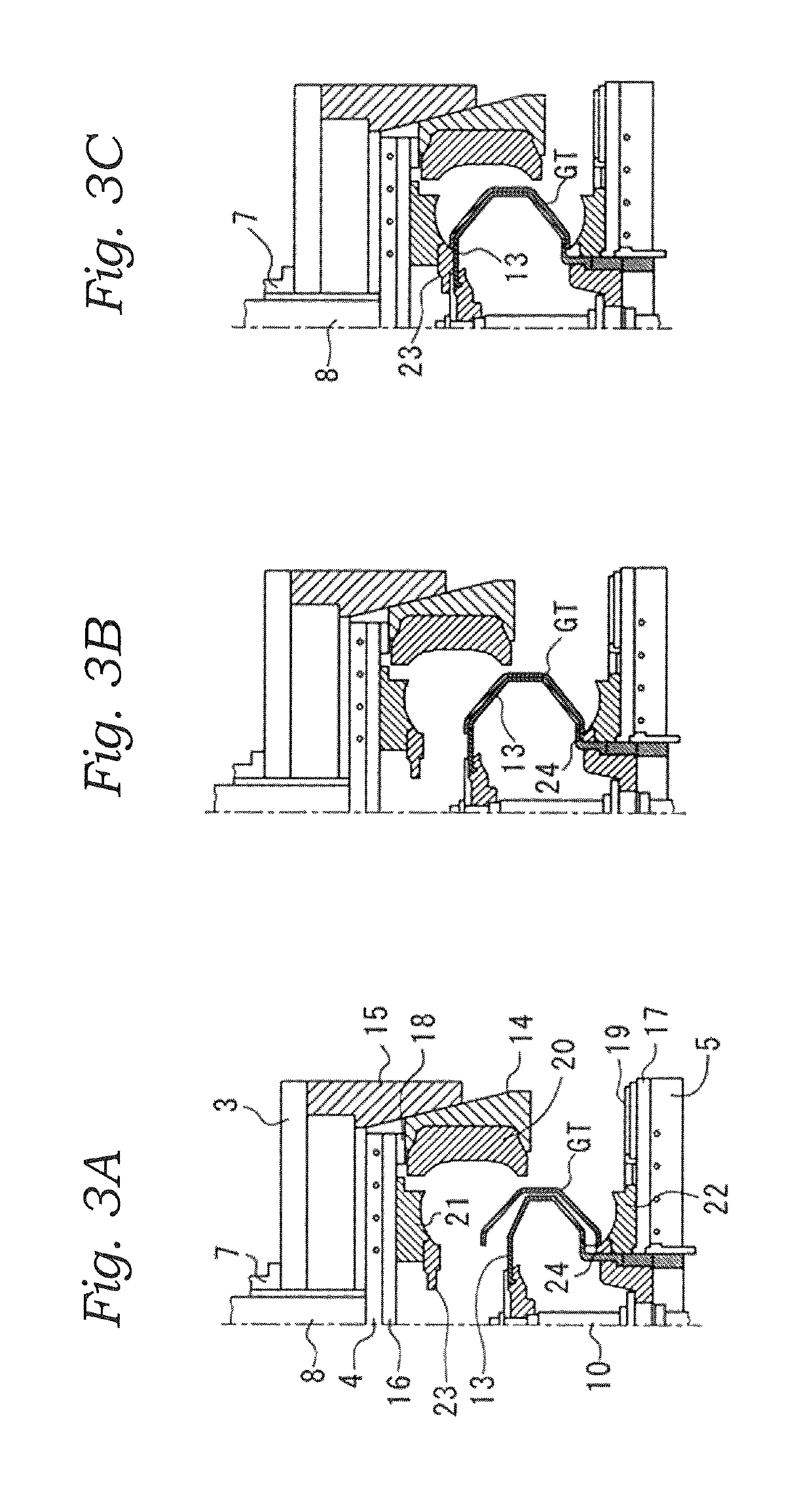

Tire vulcanization mold and pneumatic tire

ActiveUS20180169983A1Maintaining aesthetic appearanceSuppression problemTyresInflatable tyresVulcanizationEngineering

A tire vulcanization mold including a sector mold divided into a plurality of pieces along a circumferential direction of a green tire, the sector mold configured to vulcanization mold a tread portion of the green tire into a predetermined shape, and an upper mold and a lower mold disposed on both sides of the green tire so as to sandwich the green tire therebetween in an axial direction of the green tire, the upper mold and lower mold configured to vulcanization mold a side portion of the green tire into a predetermined shape. The sector mold has a weir portion in a vicinity of a fitting portion between the sector mold, and the upper mold and the lower mold.

Owner:TOYO TIRE & RUBBER CO LTD

Optical member and application of same

InactiveCN103097923BSuppression of poor appearanceDiffusing elementsPolarising elementsDicyclopentenyloxyethyl methacrylateAdhesive

An optical member for use in an image display device provided with the optical member, a transparent protective member, and an adhesive layer interposed therebetween, and further provided with an image display disposed on the side opposite from the adhesive layer on the optical member. The optical member satisfies condition (1); that is, an evaluative adhesive having an isoprene polymer as the principal component thereof and containing 14 wt% of dicyclopentenyloxyethyl methacrylate, 8 wt% of benzyl methacrylate, 2 wt% of methyl methacrylate, and 0.2 wt% of a photopolymerization initiator is dripped in an amount of 10 µL onto the surface of the optical member and then allowed to stand for 5 minutes, whereupon the contact angle between the optical member and the evaluative adhesive is 55° or less. The invention provides an optical member in which appearance defects due to bubbles forming between the optical member and the transparent protective member can be reduced, and further provides an image display device in which such appearance defects are reduced through the use of the optical member.

Owner:SUMITOMO CHEM CO LTD

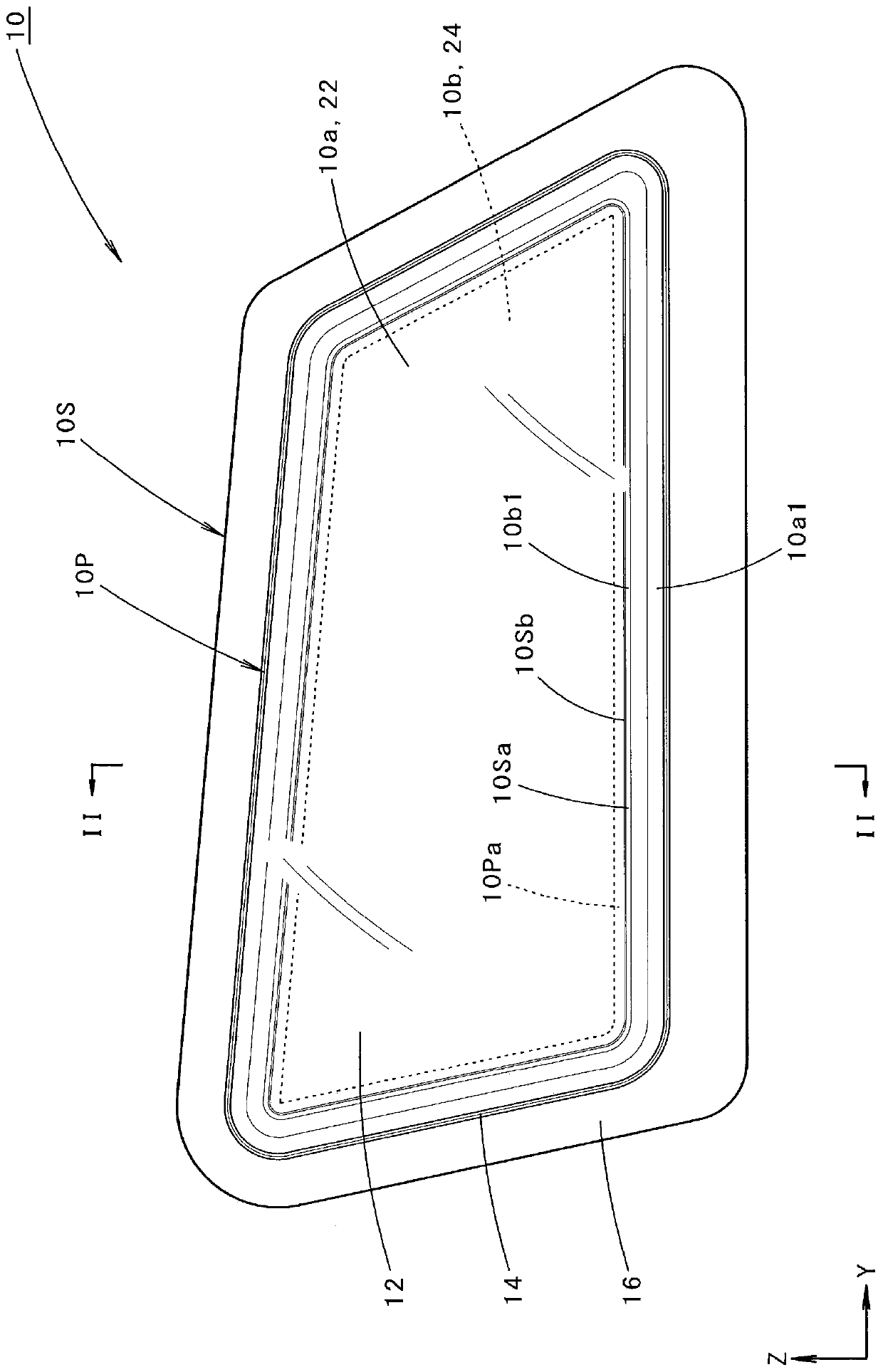

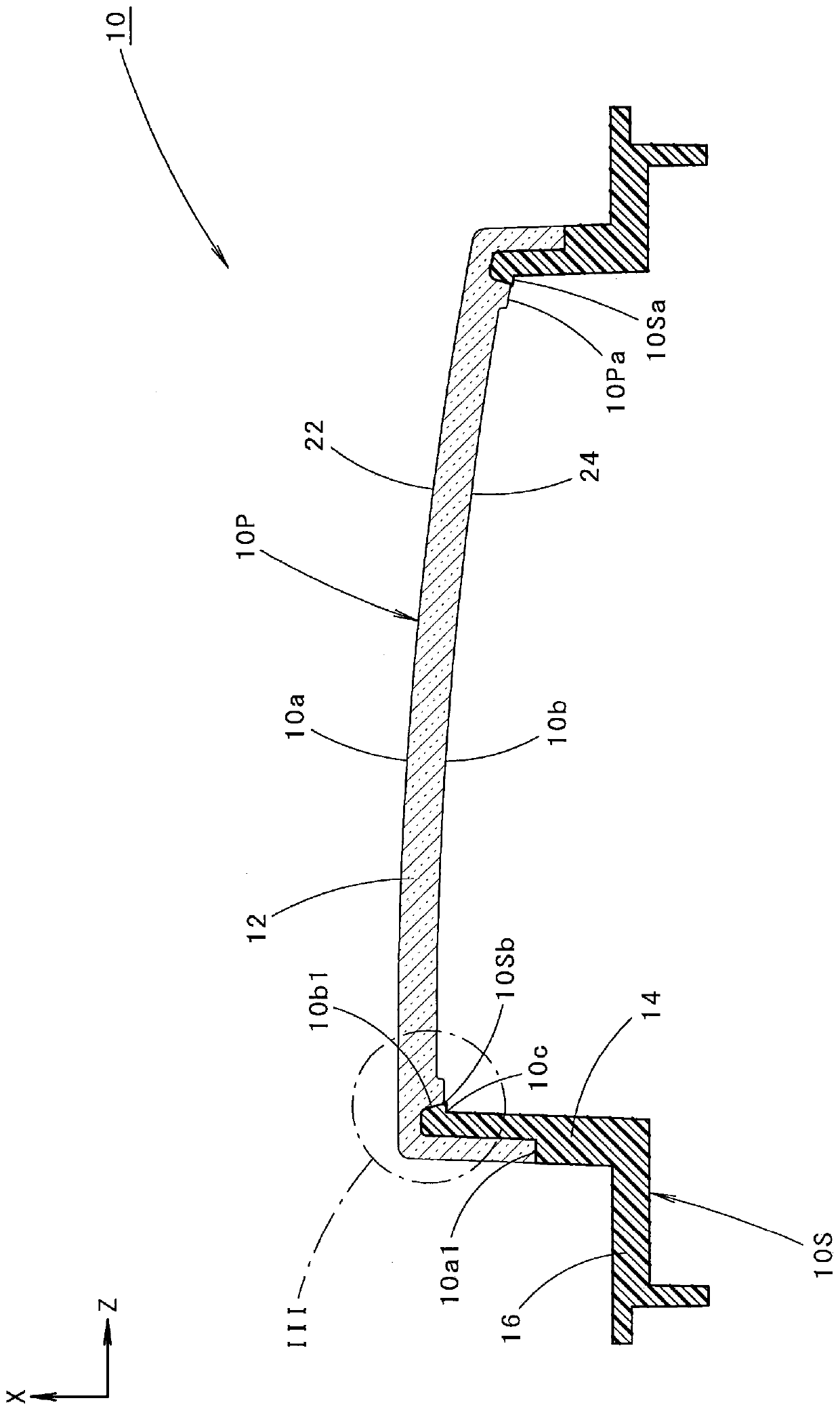

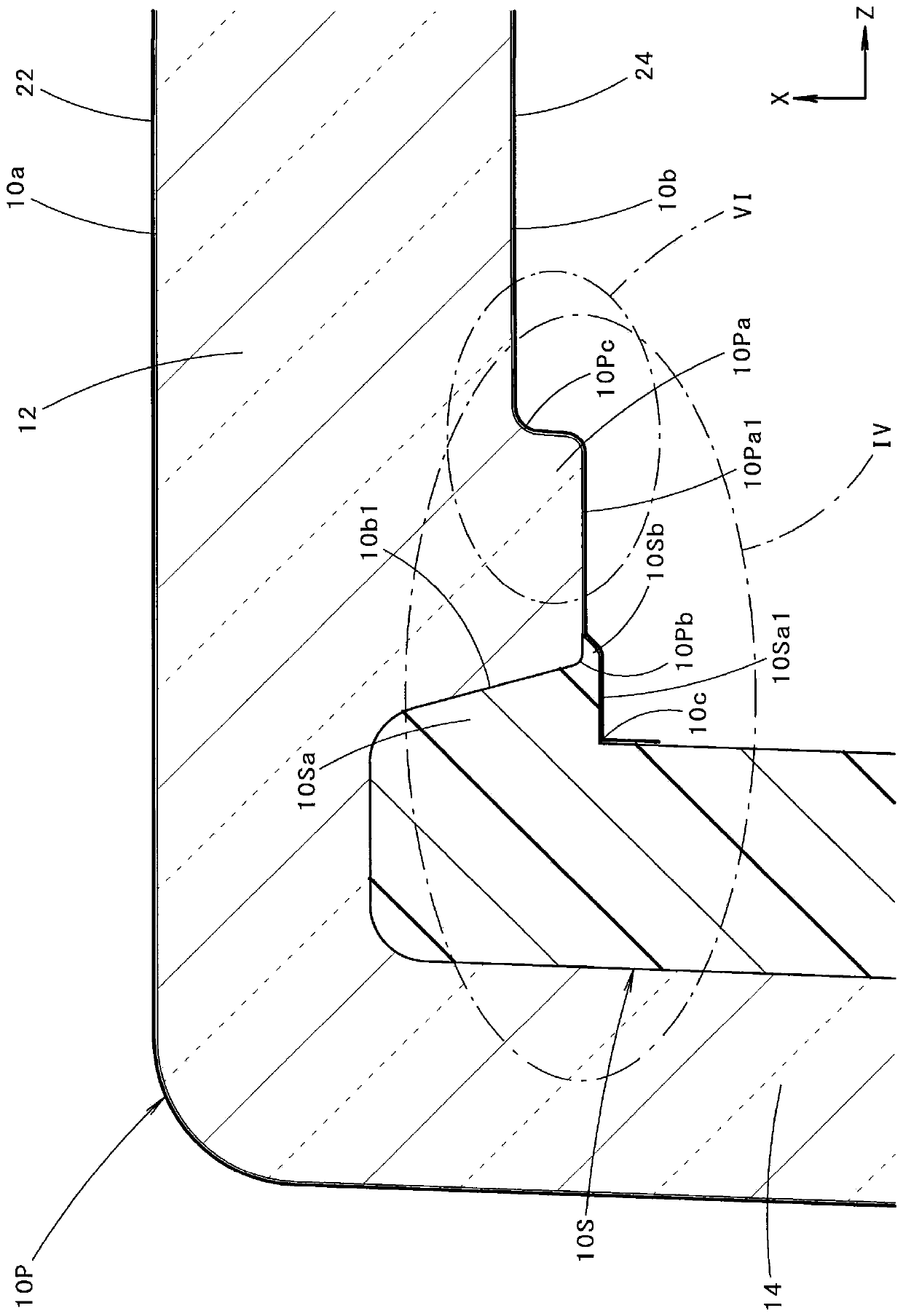

2-color formed lens

ActiveCN111175859AReduce gapCrack suppressionVehicle headlampsLighting and heating apparatusOphthalmologyJoint surface

The invention relates to a 2-color formed lens. The problem is to effectively inhibit appearance defects in a 2-color molded lens with an anti-fog coating film formed on the inner surface. A coveringpart (10Sb) is formed by extending from a joint surface (10b1) with a primary molded product (10P) along an inner surface (10Pa1) of a thick part (10Pa) of the primary molded product to cover the primary molded product at a body side run-in part (10Sa) of a secondary molded product (10S) formed along an inner surface (10b) of a 2-color formed lens (10) from a lens peripheral wall part (14) to a lens body part (12), thereby preventing a groove-shaped gap from being formed at a corner part (10Pb) of the primary molded product. Even if it takes a certain time or more before the completion of curing after the anti-fogging coating film (24) is formed on the inner surface (10b) of the lens, the occurrence of cracks around the corner of the primary molded article can be effectively suppressed.

Owner:KOITO MFG CO LTD

Flexible metal foil laminate and method for producing the same

ActiveCN104066574BImprove adhesionGood dimensional stabilityPrinted circuit aspectsLaminationVitrificationMetal foil

The present invention relates to a flexible metal foil laminate comprising a multilayer polyimide film, said multilayer polyimide film comprising: a metal foil; a first polyimide layer on said metal foil, and having a glass transition temperature below 300°C; the second polyimide layer is located on the first polyimide layer; and the third polyimide layer is located on the second polyimide layer. The flexible metal foil laminate of the present invention solves the problem of poor appearance caused by blistering during the curing process in a continuous curing machine using infrared rays as a heat source, and does not cause delamination due to its excellent adhesion. The directional conductive adhesive film has excellent adhesion and dimensional stability, so it is useful in the manufacture of flexible printed circuit boards.

Owner:NEXFLEX CO LTD

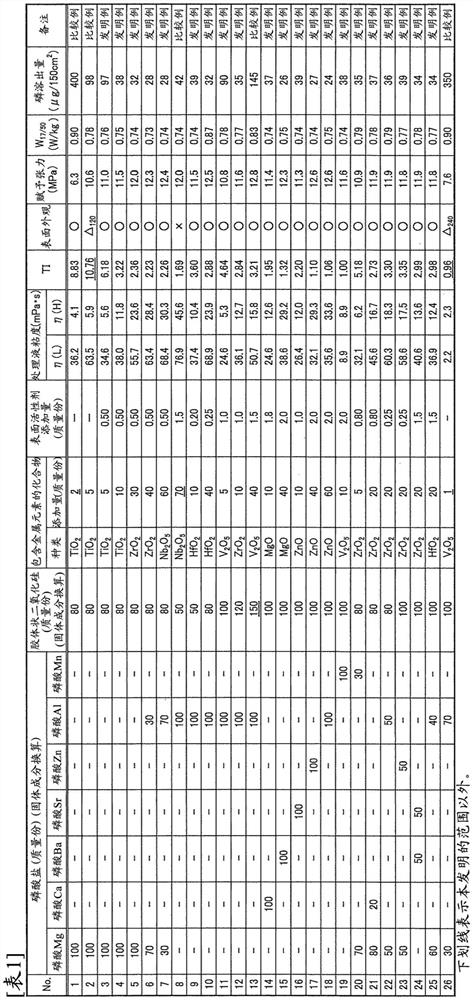

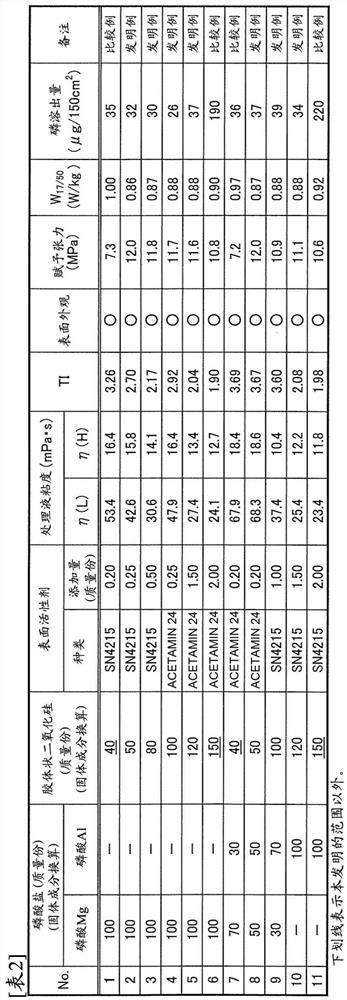

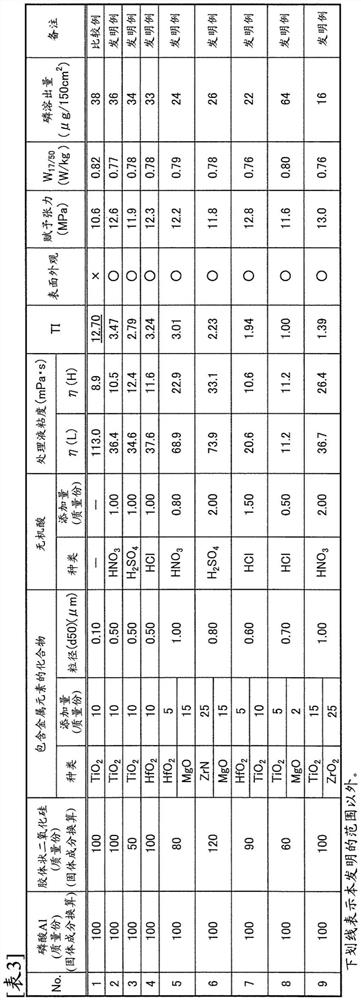

Treatment solution for insulating coating, grain-oriented electrical steel sheet with insulating coating, and manufacturing method thereof

ActiveCN112534083BExcellent iron loss reduction effectReduce tensionPretreated surfacesInorganic material magnetismColloidal silicaChromium free

The present invention provides an insulating coating treatment solution capable of forming a chromium-free insulating coating excellent in moisture absorption resistance, capable of imparting high tension, and excellent in reducing iron loss, and capable of suppressing the occurrence of coating unevenness when coating a steel plate. resulting in poor appearance. The insulating coating treatment solution is used to form a chromium-free insulating coating on the surface of the grain-oriented electrical steel sheet, and the insulating coating treatment solution contains: one of the phosphates selected from Mg, Ca, Ba, Sr, Zn, Al, and Mn or two or more phosphates; colloidal silica; and particles of compounds containing metal elements, with respect to 100 parts by mass of the phosphate, the content of the colloidal silica is expressed as SiO 2 The solid content is 50 to 120 parts by mass in terms of solid content, and the content of the particles of the compound containing metal elements is 5 to 60 parts by mass in terms of metal elements, and the thixotropic index (TI) of the insulating coating treatment solution is 1.00 Above and below 10.00.

Owner:JFE STEEL CORP

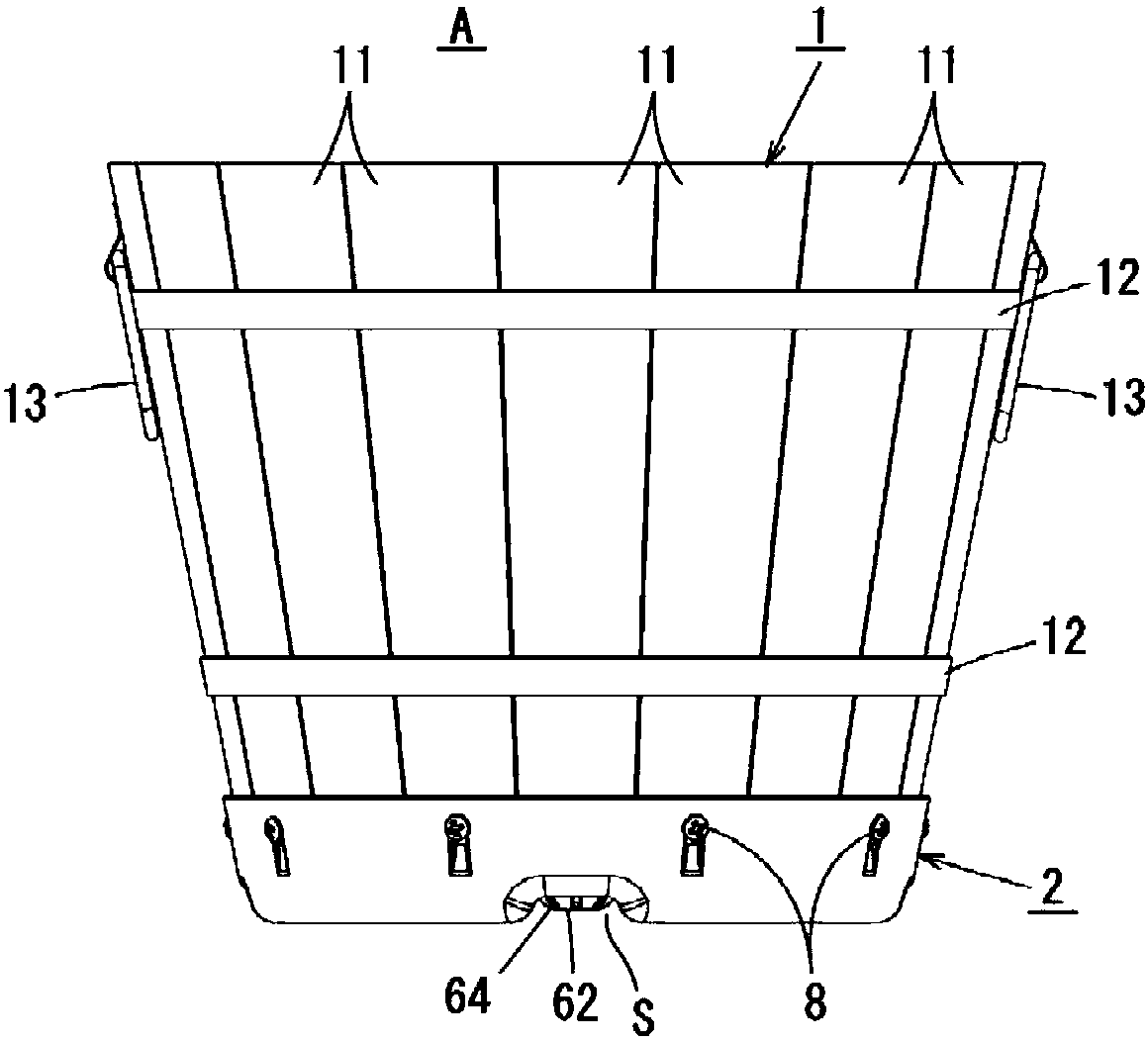

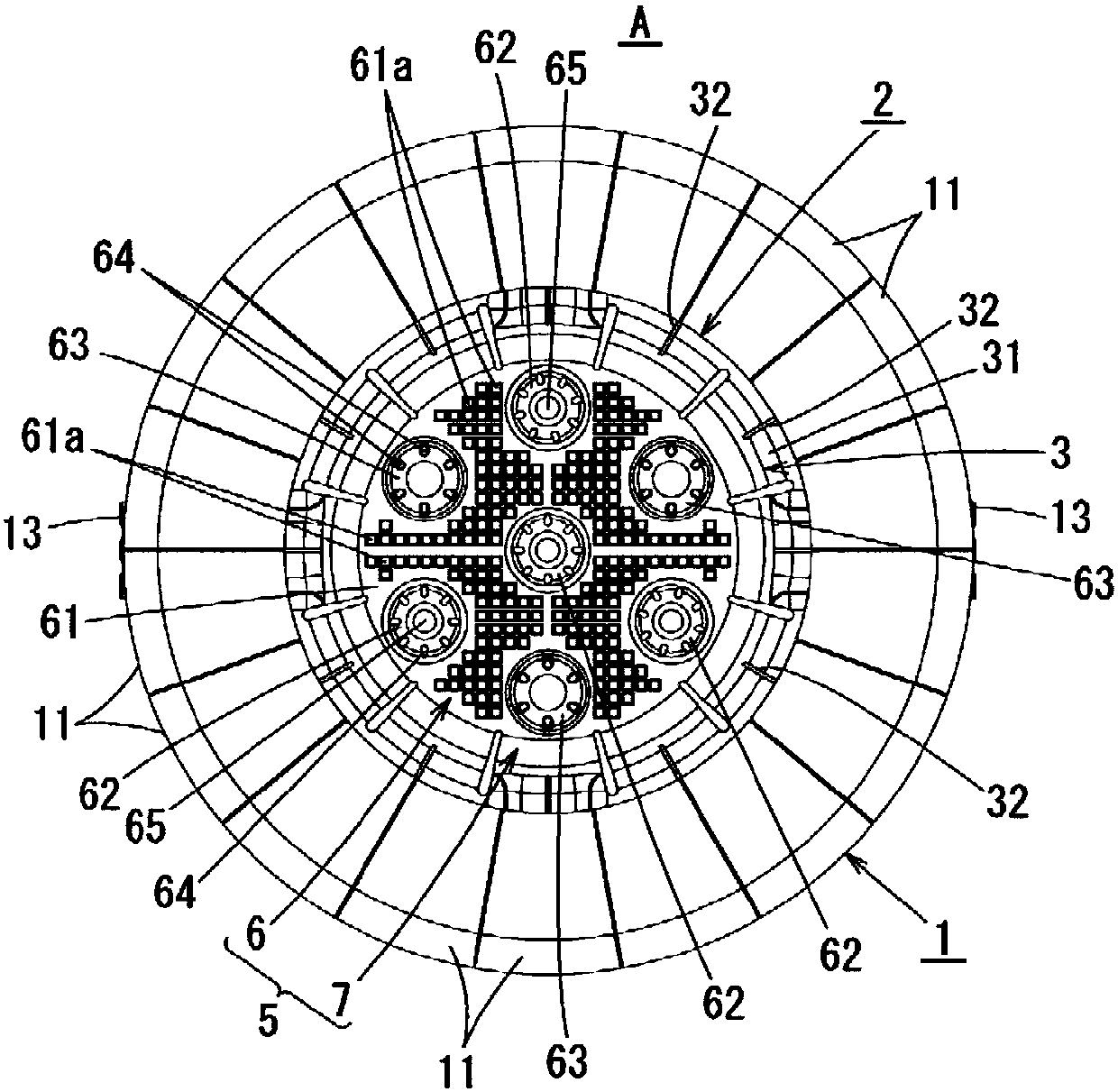

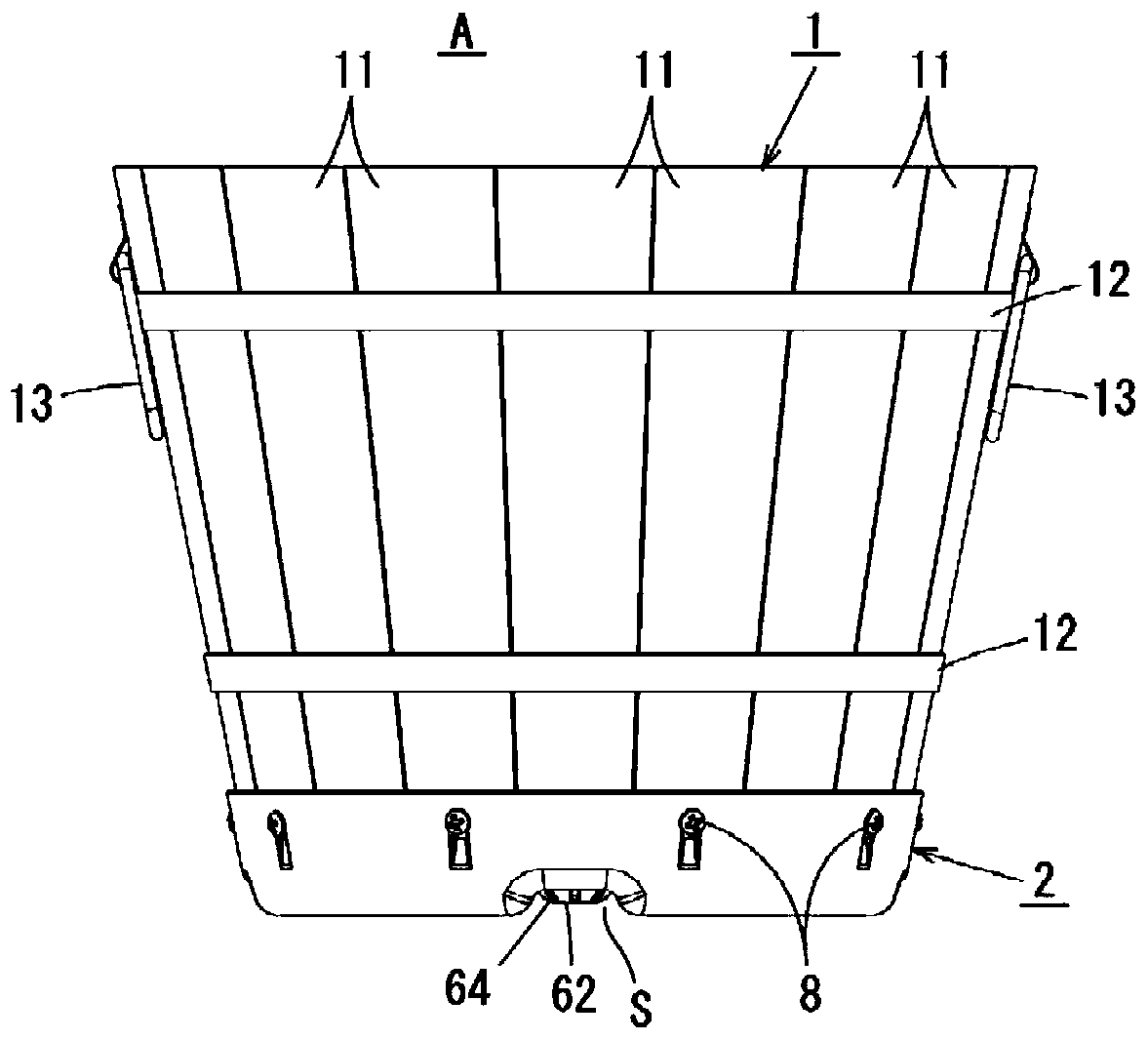

Bottom member of planter and planter using said bottom member

ActiveCN107920474ASuppression of poor appearanceIncreased durabilityCultivating equipmentsReceptacle cultivationEngineeringSynthetic resin

The purpose of the present invention is to provide a bottom member of a planter in which the occurrence of rot, mold, and the like in a side wall lower-end side of a planter having a wooden side wallcan be suppressed to improve durability, and a highly durable planter that uses this bottom member. Mounted on a side wall member 1, which is made of a wooden material and shaped as a cylinder open inthe top and bottom, is a bottom member 2 made of a synthetic resin and provided with an undersurface cover portion 3 that has a lower end receiving part 32 for receiving the lower end surface of theside wall member 1 and that has a ring shape as seen in plan view, an outer wall cover part 4 interconnected with the undersurface cover portion 3 and arranged so as to cover the outer peripheral surface of the lower end part of the side wall member 1, and a bottom portion 5 interconnected with the interior of the undersurface cover portion 3 and having a water-draining hole. The bottom member 2 is mounted so that the lower end opening of the side wall member 1 is closed by the bottom portion 5, the undersurface of the side wall member 1 is covered by the undersurface cover portion 3, and theouter periphery of the lower end part of the side wall member 1 is covered by the outer wall cover part.

Owner:GAO XIUMING

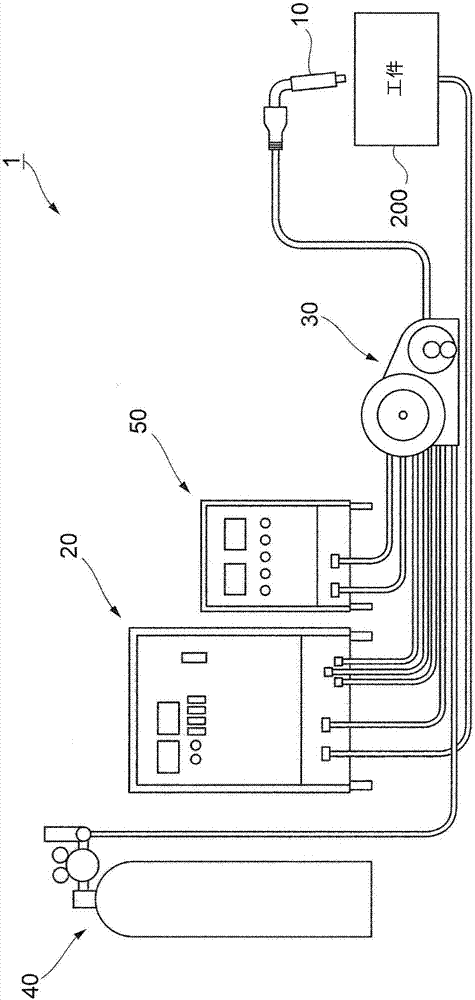

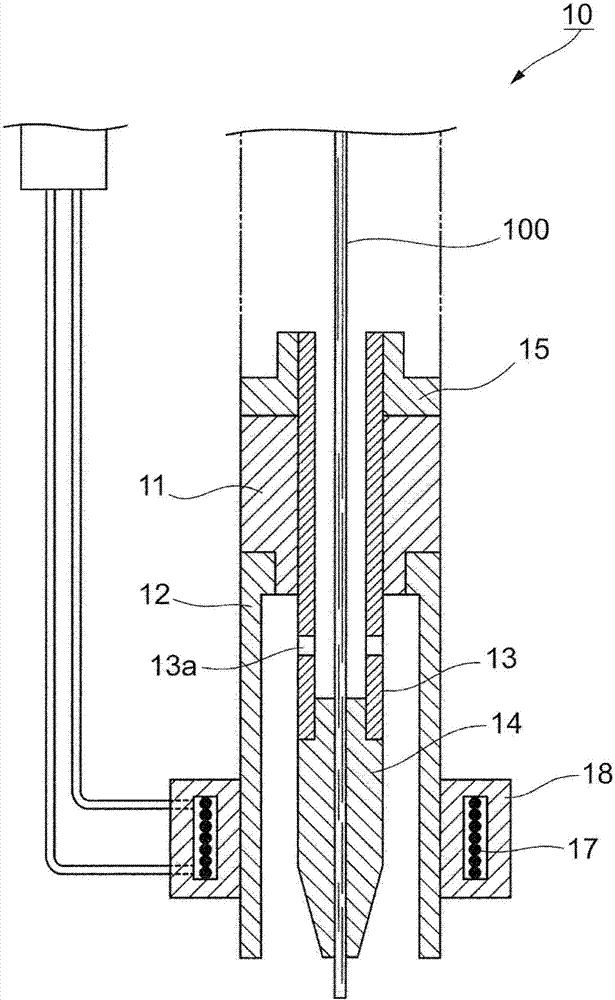

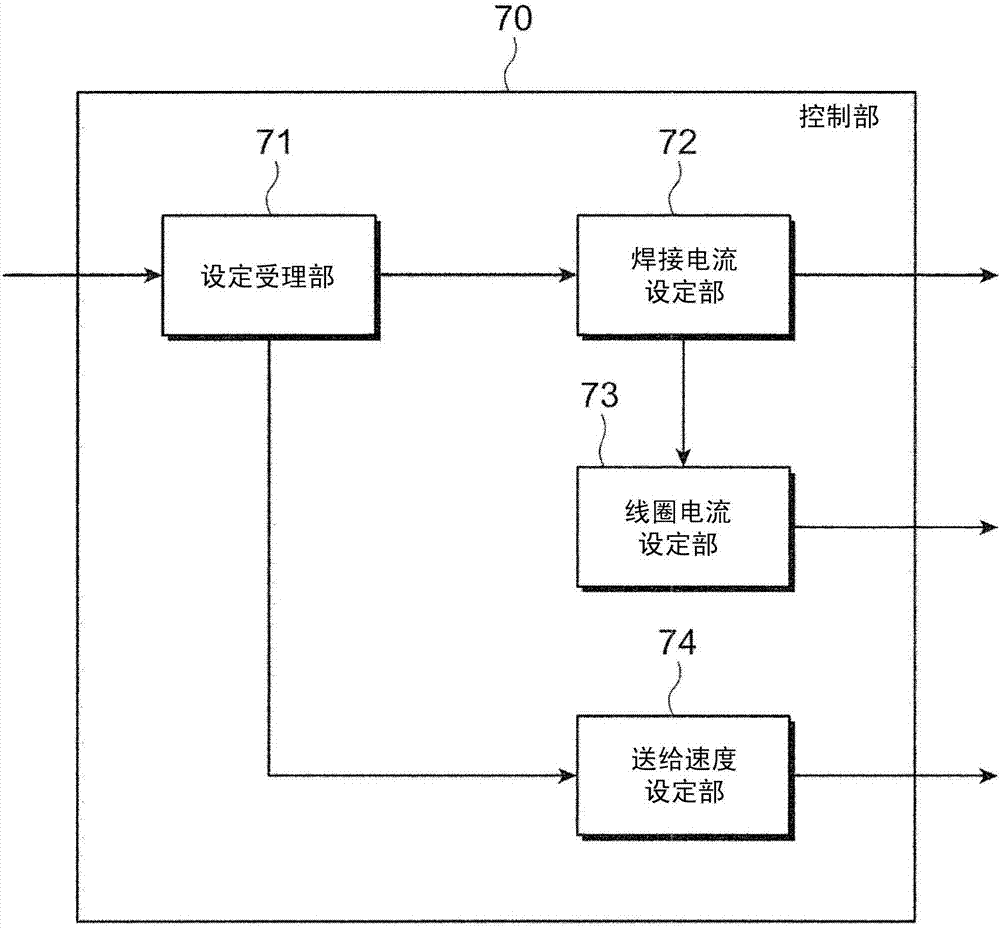

Manufacturing method of welded product, welding method, welding device

ActiveCN105163892BSuppression of poor appearanceWelding/cutting auxillary devicesArc welding apparatusPorosityMelting tank

In gas-shielded arc welding using a primer-coated steel sheet as a base material and using an active gas and a flux-cored wire, occurrence of poor appearance of the welded part due to porosity defects originating from the primer is suppressed. In a method for producing a welded product in which a first steel plate and a second steel plate made of a primer-coated steel plate are arranged in a T-shape and welded at the corners formed at the two places, the inner side of the outer skin made of steel is filled with flux. The flux-cored wire (100) and the shielding gas (carbon dioxide) are formed, and the welding current is supplied to the corner by the flux-cored wire (100) through the arc under the shielding gas, and a molten pool (400) is formed at the corner, and for the welding An alternating magnetic field is applied to the pool, so that the welding current (A) and the magnetic flux density (mT) of the alternating magnetic field have the relationship of 20000≤welding current×magnetic flux density≤30000, and the welding current and alternating magnetic field are set in this way.

Owner:KOBE STEEL LTD

Tire vulcanization mold and pneumatic tire

InactiveUS20210379851A1Poor appearanceSuppression of poor appearanceTyresInflatable tyresPolymer scienceVulcanization

A tire vulcanization mold including a sector mold divided into a plurality of pieces along a circumferential direction of a green tire, the sector mold configured to vulcanization mold a tread portion of the green tire into a predetermined shape, and an upper mold and a lower mold disposed on both sides of the green tire so as to sandwich the green tire therebetween in an axial direction of the green tire, the upper mold and the lower mold configured to vulcanization mold a side portion of the green tire into a predetermined shape. The sector mold has a relief groove in a vicinity of a fitting portion between the sector mold, and the upper mold and the lower mold.

Owner:TOYO TIRE & RUBBER CO LTD

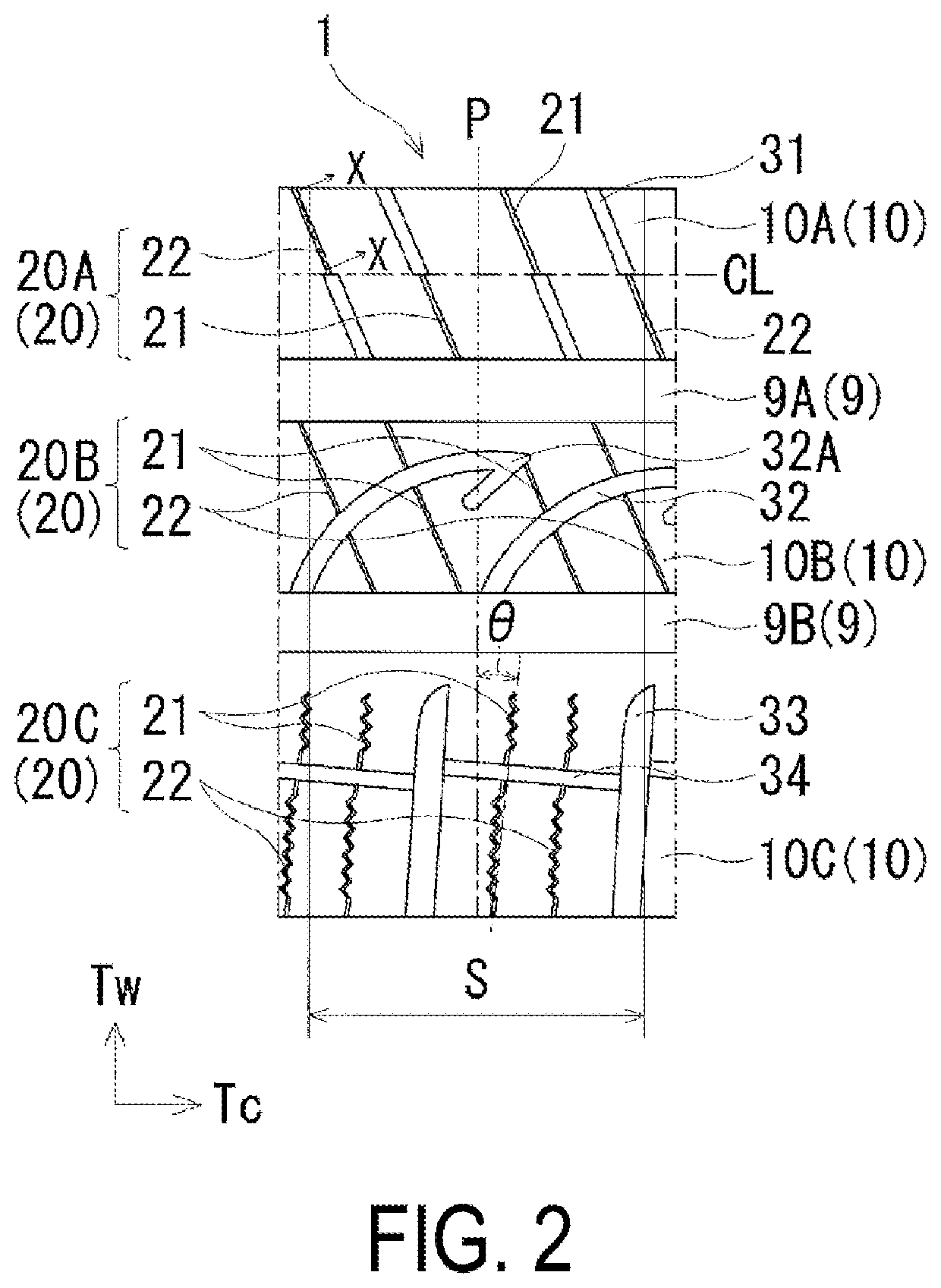

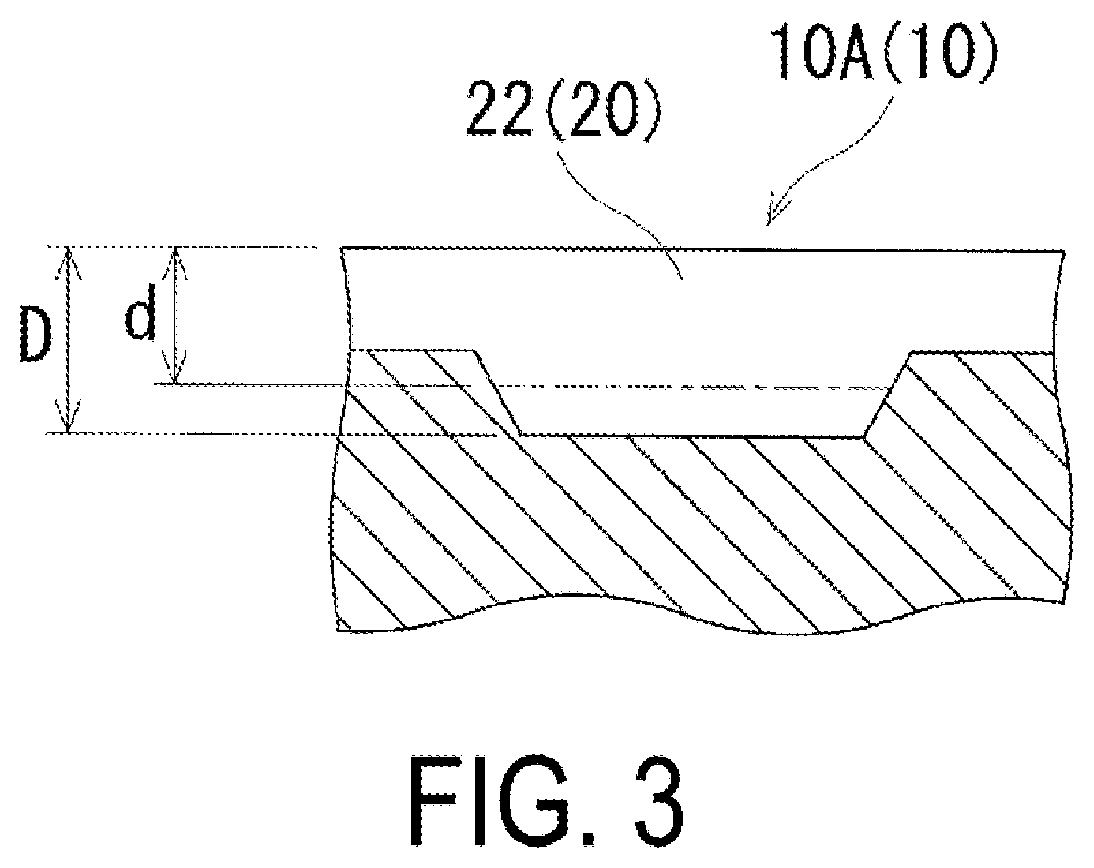

Pneumatic tire with carcass ply comprising plurality of partly overlapping strip-shaped ply pieces

ActiveUS10981417B2Suppression of poor appearanceTyresPneumatic tyre reinforcementsMechanical engineeringTread

A pneumatic tire 1 comprises a carcass 6 comprising at least one carcass ply 6A extending between bead portions 4 via sidewall portions 3 and a tread portion 2. The carcass ply 6A comprises strip-shaped ply pieces 11 longer in a tire radial direction than in a tire circumferential direction arranged circumferentially. Each of the ply pieces 11 comprises a plurality of carcass cords 12 arranged in parallel in the tire radial direction and at least partly overlapping each other with the ply pieces 11 circumferentially adjacent. At least one of the carcass cords 12 arranged in at least one of side edge portions 11e in the tire circumferential direction of each of the ply pieces 11 having a diameter (Ce) smaller than a diameter (Cc) of at least one of the carcass cords 12 arranged in a center portion 11c of each of the ply pieces 11.

Owner:SUMITOMO RUBBER IND LTD

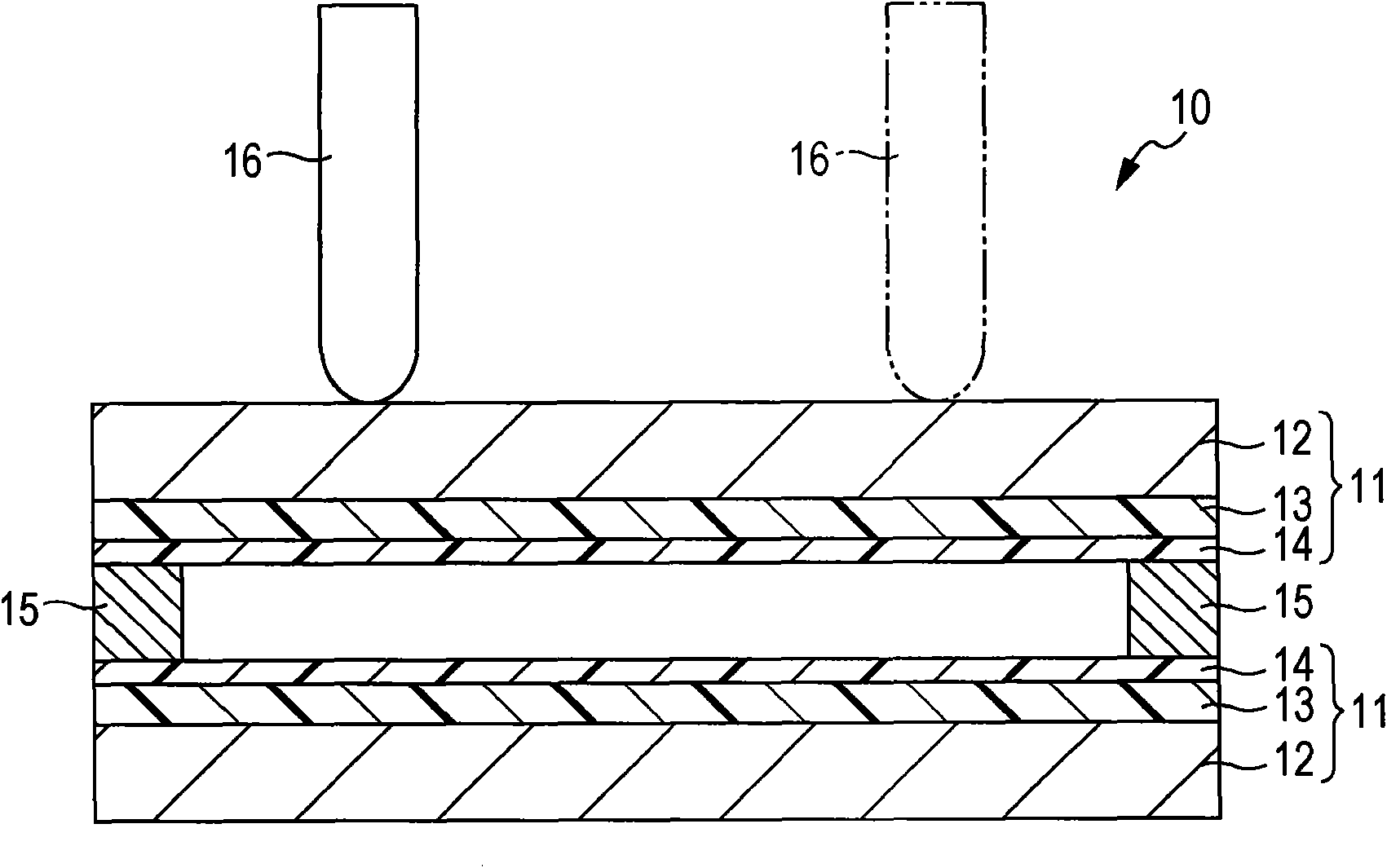

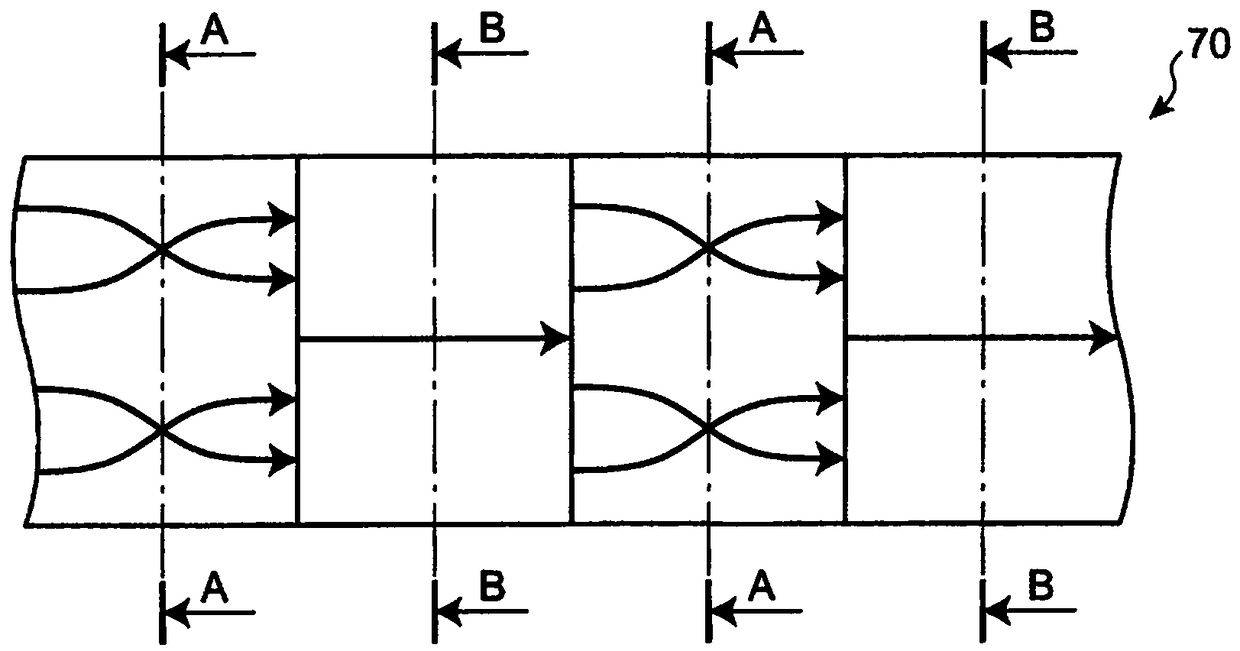

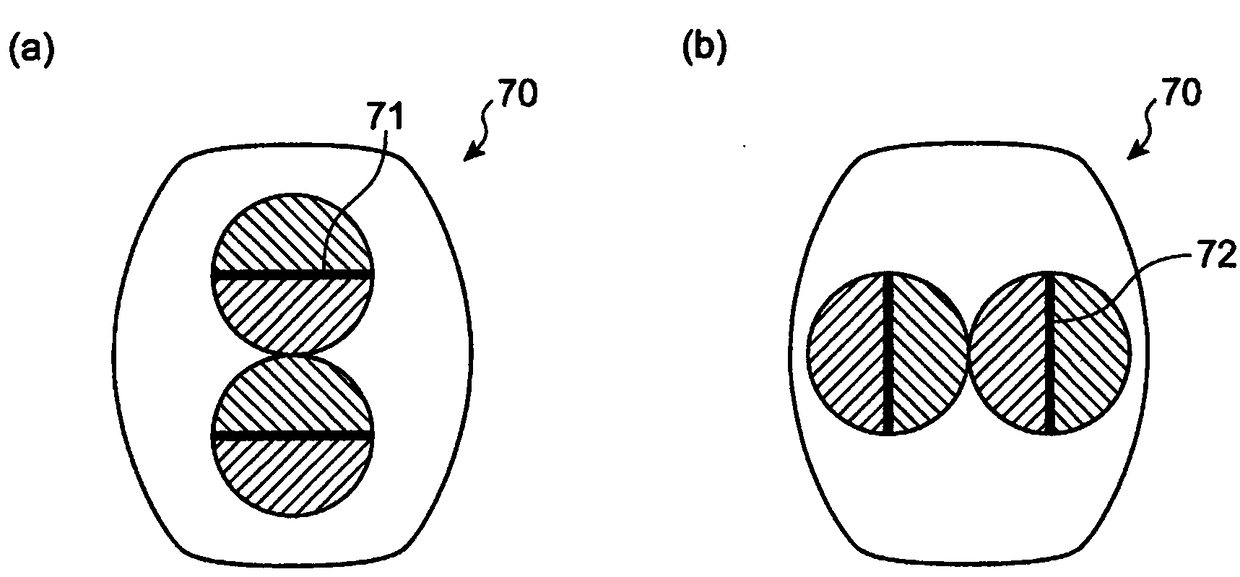

Fiber-reinforced thermoplastic resin member welding method and welding device

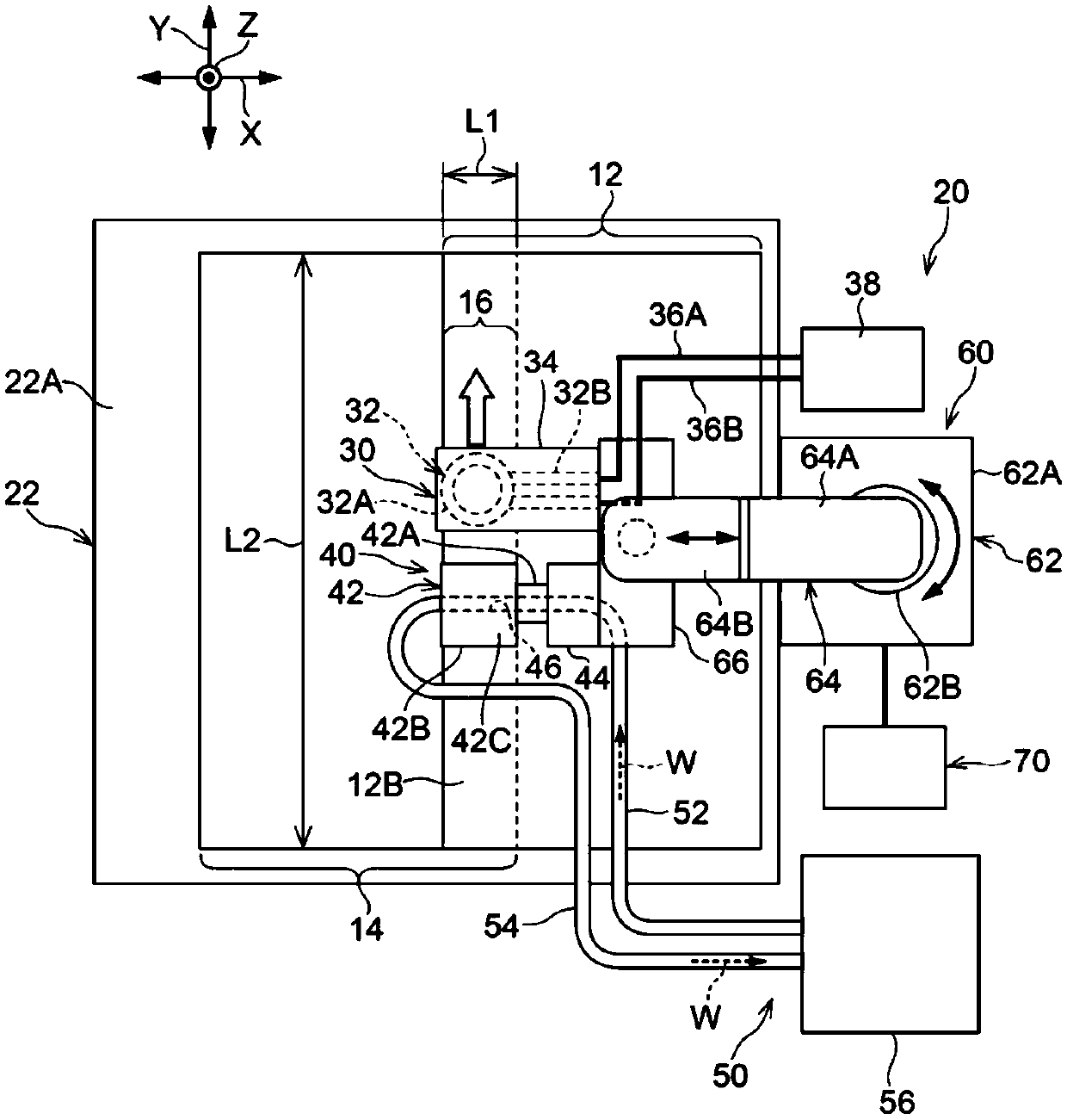

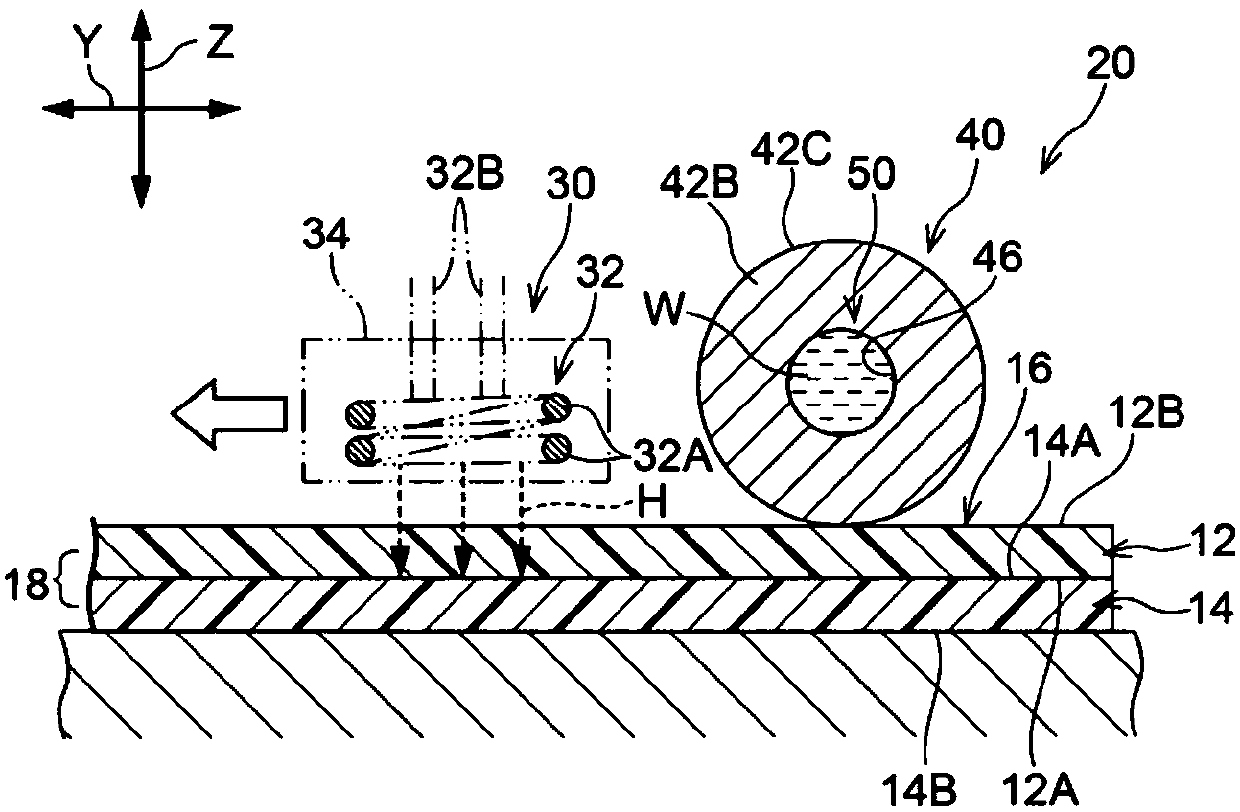

A fiber-reinforced thermoplastic resin member welding method includes: heating, by a heating unit, a welding target portion in which plural fiber-reinforced thermoplastic resin members layered on topof each other, each of the plural fiber-reinforced thermoplastic resin members including thermoplastic resin as a main composition, and the thermoplastic resin including reinforcing fibers; applying pressure, by a pressure applying unit, to the welding target portion; and cooling, by a cooling unit, at least a surface of the welding target portion at the same time as when the welding target portion is being heated by the heating unit or after the welding target portion has been heated by the heating unit.

Owner:TOYOTA JIDOSHA KK

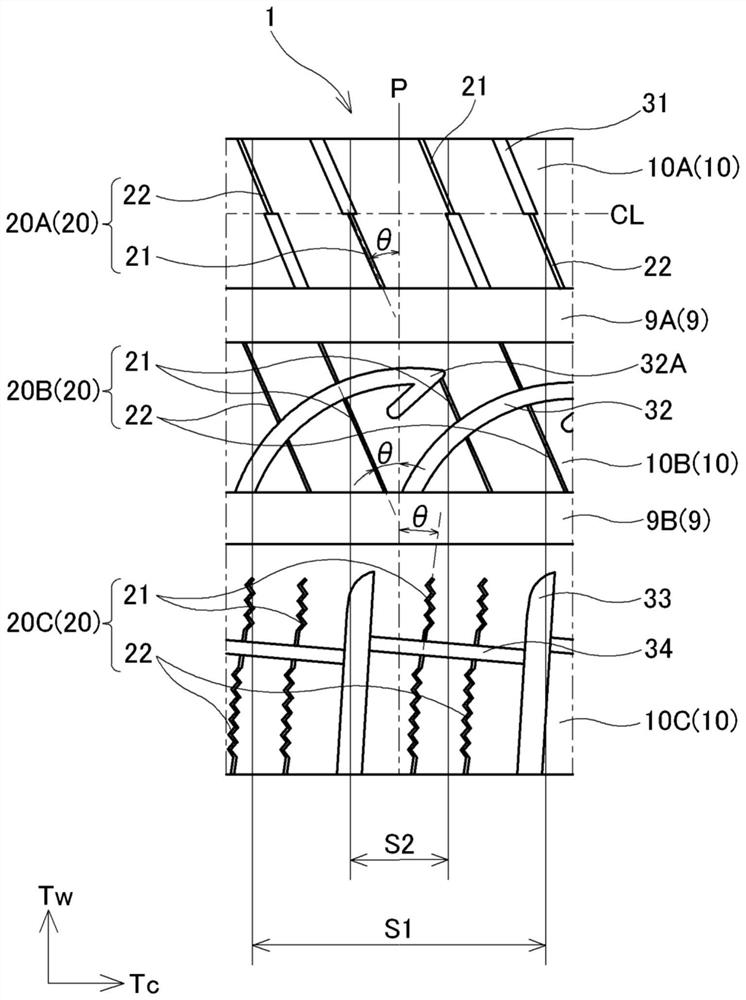

Pneumatic tire

PendingUS20210323356A1Improve braking effectReduce appearanceRoad vehicle tyresRoad vehiclesStructural engineeringMechanical engineering

A pneumatic tire includes a tread portion molded by sectors divided in a tire circumferential direction. The pneumatic tire includes circumferential grooves, rows of land portions, and sipes. The circumferential grooves extend in the tire circumferential direction in the tread portion. The rows of land portions are defined by the circumferential grooves. The sipes extend in a tire width direction in at least one row of the rows of land portions. The sipes include at least one shallow bottom sipe and regular sipes. The at least one shallow bottom sipe is disposed in a boundary region including a dividing position of each of the sectors. The regular sipes are disposed at positions more separated from the dividing position of each of the sectors than the at least one shallow bottom sipe. The at least one shallow bottom sipe is shallower than the regular sipes.

Owner:THE YOKOHAMA RUBBER CO LTD

Transparent electrically conductive film and touch panel including the same

InactiveCN101630541BAvoid damageInhibitionConductive layers on insulating-supportsSynthetic resin layered productsPolypyrroleHardness

Owner:NOF CORP

Method for manufacturing radome and radome

ActiveCN107073774BReduce heat loadSuppression of poor appearanceRadiating element housingsDomestic articlesRadarEngineering

A method for manufacturing a radome, the radome covering a radar unit for detecting a situation around a vehicle, comprising the steps of preparing: a base part having a recess formed by a transparent layer, and a colored layer is stacked on a portion other than the recess; a glossy member including a base portion and an edge portion having a glossy layer on a surface thereof, the base portion and the glossy member are arranged such that the edge portion of the glossy member abuts the colored layer of the base portion, In addition, the glossy layer of the base portion faces the concave portion, and the edge portion and the colored layer are fixed.

Owner:FALTEC CO LTD

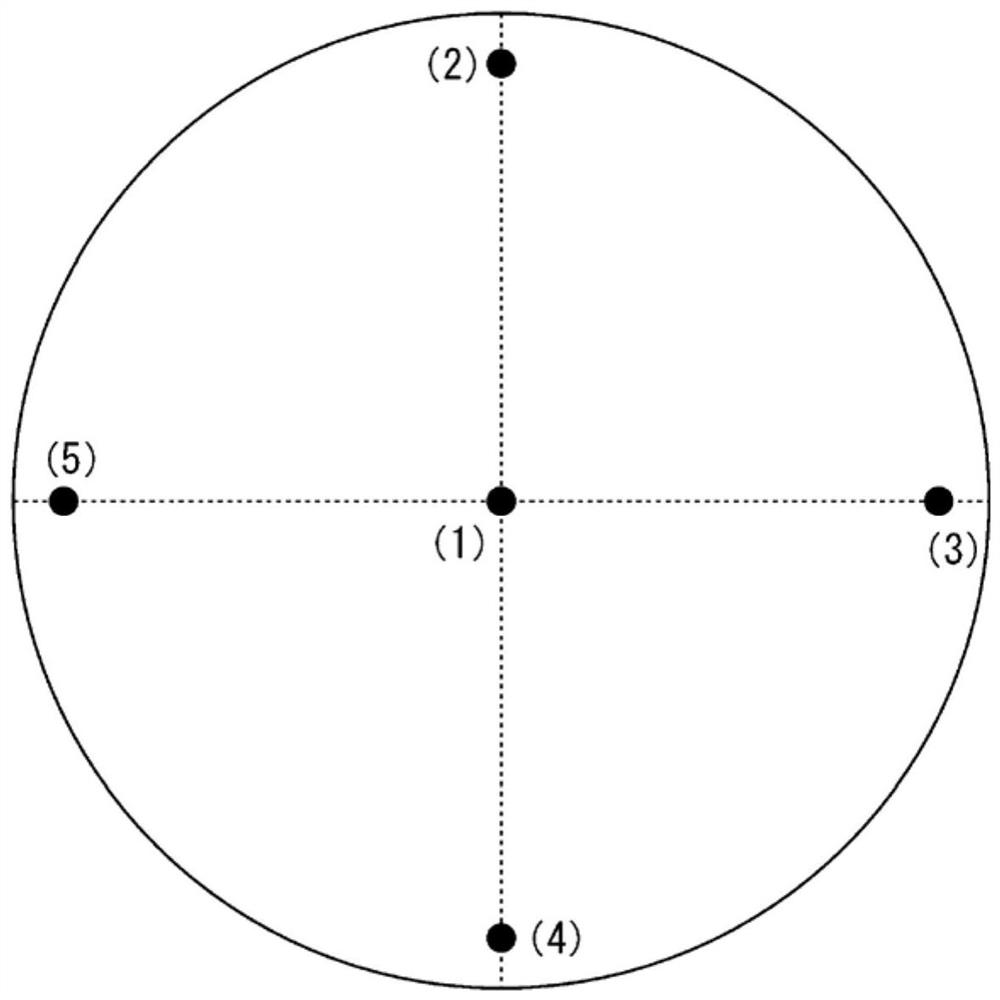

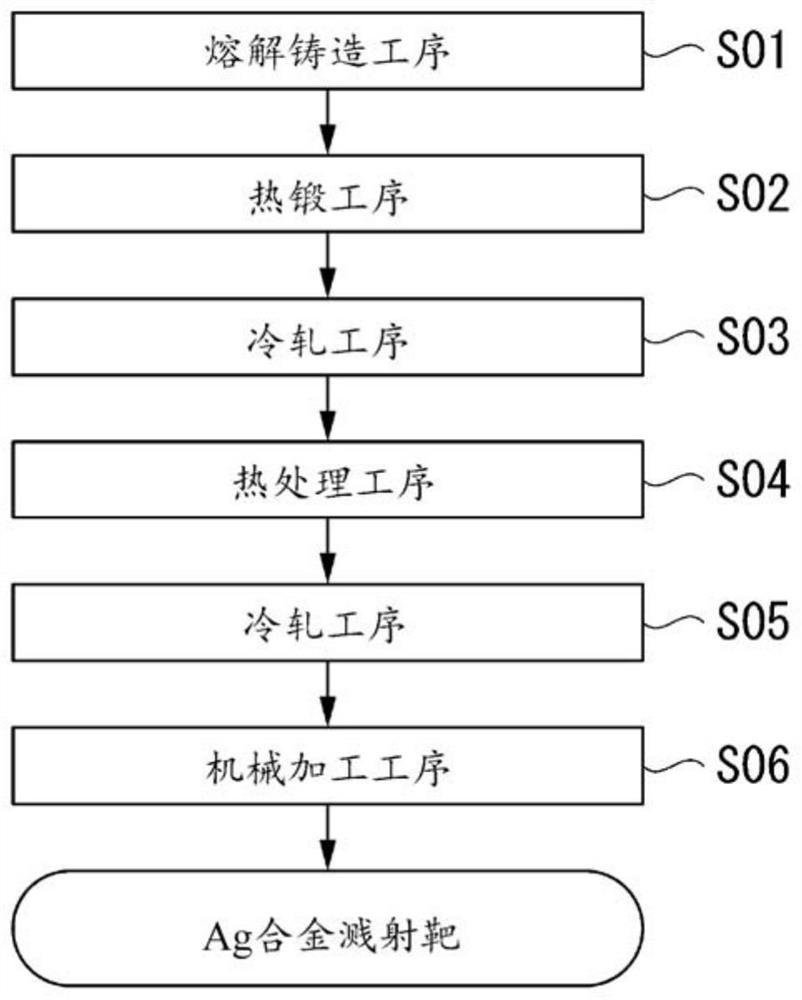

Ag alloy sputtering target

PendingCN114096326AImprove reflectivityExcellent resistance to sulfurationEntertainmentVacuum evaporation coatingSputteringAg alloy

This Ag alloy sputtering target comprises an Ag alloy that includes Ge and In, and the crystallite diameter thereof as derived by the Scherrer equation is 220 angstrom or less. The Ag alloy preferably has a composition containing In in a range of 0.1-1.5 mass% (inclusive) and Ge in a range of 0.1-7.5 mass% (inclusive), the balance being Ag and unavoidable impurities.

Owner:MITSUBISHI MATERIALS CORP

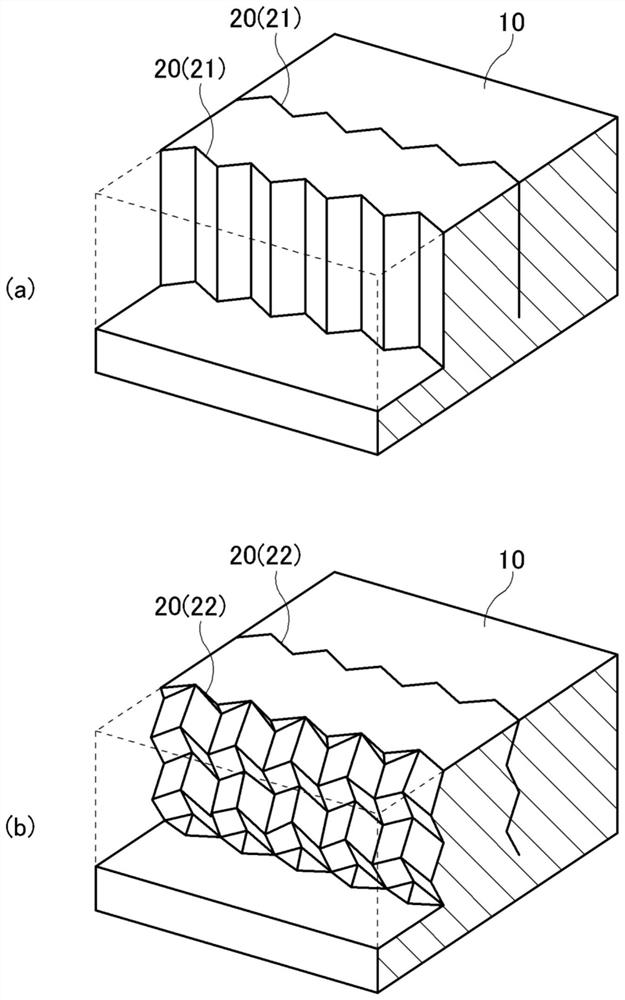

Pneumatic tire

ActiveCN112533769ANo change in appearanceImprove braking effectRoad vehicle tyresTyre tread bands/patternsRoad surfaceControl theory

Provided is a pneumatic tire for which it is possible to improve braking performance on a wet road surface and a snowy road surface without changing the appearance of the tire and reduce the possibility of the appearance being degraded. The tread portion 1 of this pneumatic tire has: a plurality of circumferential grooves 9 that extend in the tire circumferential direction; a plurality of rows ofland portions 10 that are partitioned by the circumferential grooves 9; and a plurality of sipes 20 that extend in the tire width direction in at least one row of the land portions 10. The tread portion 1 is molded by a plurality of sectors which are divided in the tire circumferential direction. The sipes 20 include: at least one shallow sipe 21 that is disposed in a boundary region S including the sector division position P; and a plurality of normal sipes 22 that are arranged at positions further away from the sector division position P than the shallow sipe 21. The shallow sipe 21 is madeshallower than the normal sipes 22.

Owner:THE YOKOHAMA RUBBER CO LTD

Window base material, card having module housed therein, and method for manufacturing card having module housed therein

InactiveCN101529451ASuppression of poor appearanceKeep confidentialOther printing matterRecord carriers used with machinesEngineeringComputer module

The present invention discloses a window base material is provided with an intermediate layer having a window section made of a transparent resin and a colored section made of a colored resin surrounding the window section; and transparent first base material and second base material sandwiching the intermediate layer. A card having a module housed therein is provided with a module having a display element; an adhesive layer covering the module; and a pair of third base material and fourth base material sandwiching the module by having the adhesive layer in between. The third base material is composed of the window base material, and the display section of the display element is arranged to face the window section of the window base material. Thus, the easily manufactured card which houses the display element as an electronic component and permits the display section of the display element to be visually inspected from the external is provided.

Owner:TOPPAN MOORE CO LTD

pneumatic tire

InactiveCN103221233BModerate Rigidity VariationsMake up for driving stabilityWithout separate inflatable insertsSpecial tyresElastomerThermoplastic elastomer

Owner:THE YOKOHAMA RUBBER CO LTD

Tire vulcanization mold and pneumatic tire

InactiveUS10272626B2Poor appearanceSuppression of poor appearanceTyresInflatable tyresVulcanizationEngineering

A tire vulcanization mold including a sector mold divided into a plurality of pieces along a circumferential direction of a green tire, the sector mold configured to vulcanization mold a tread portion of the green tire into a predetermined shape, and an upper mold and a lower mold disposed on both sides of the green tire so as to sandwich the green tire therebetween in an axial direction of the green tire, the upper mold and the lower mold configured to vulcanization mold a side portion of the green tire into a predetermined shape. The sector mold has a relief groove in a vicinity of a fitting portion between the sector mold, and the upper mold and the lower mold.

Owner:TOYO TIRE & RUBBER CO LTD

Pneumatic tire

ActiveCN112996671AAvoid fitSuppression of poor appearanceTyre tread bands/patternsRoad surfaceMechanical engineering

Provided is a pneumatic tire that makes it possible to improve braking performance on a wet road surface and a snow road surface while the outer appearance of the tire remains unchanged and reduce occurrence of deterioration of outer appearance. In a pneumatic tire which is provided with a plurality of rows of land sections partitioned by a plurality of circumferential grooves extending in the tire circumferential direction, and in which a tread section is formed from a plurality of sectors divided in the tire circumferential direction, a plurality of sipes extending in the tire width direction are formed in the land sections. Three-dimensional sipes in which the sipe shape appearing on the tread surface varies in the depth direction of the sipes, and two-dimensional sipes in which the sipe shape appearing on the tread surface is constant in the depth direction of the sipes are provided. The ratio R1 of the number of three-dimensional sipes to the total number of sipes in a first boundary region within 15 mm on one side in the circumferential direction of the tire, centered on the division position of the sector block, and the ratio Rt of the number of three-dimensional sipes to the total number of sipes on the entire tread portion satisfy the relation of R1< Rt.

Owner:THE YOKOHAMA RUBBER CO LTD

Laminated glass intermediate film, rolled body, and laminated glass

InactiveUS20200039189A1Easy to operateSuppression of poor appearanceWindowsWindscreensPolymer scienceSurface resistivity

Provided is an interlayer film for laminated glass capable of enhancing the handling property of the interlayer film, and suppressing poor appearance of the laminated glass. An interlayer film for laminated glass according to the present invention contains a thermoplastic resin, the interlayer film for laminated glass has one end and other end being on an opposite side of the one end, the other end has a thickness larger than a thickness of the one end, a surface resistivity at the one end of the interlayer film after standing is 9.5×1013Ω or less when the interlayer film has been left to stand for 7 days at 10° C. and relative humidity of 50%, and a surface resistivity at the other end of the interlayer film after standing is smaller than the surface resistivity at the one end of the interlayer film after standing.

Owner:SEKISUI CHEM CO LTD

Flowerpot bottom member and flowerpot using the same

ActiveCN107920474BSuppression of poor appearanceIncreased durabilityCultivating equipmentsReceptacle cultivationStructural engineeringSynthetic resin

[Problem] An object of the present invention is to provide: a planter bottom member that enables improvement in durability by suppressing decay or occurrence of mold or the like on the side wall lower end side of a planter having a wooden side wall; and a planter using the bottom member and having excellent durability. [Solution] A bottom member 2 is attached to a side wall member 1 formed of a wood material and having a cylindrical shape opened at upper and lower sides. The bottom member 2 includes: a lower surface cover portion 3 formed of a synthetic resin, having a ring shape in plan view, and having lower end receiving portions 32 for receiving a lower end surface of the side wall member 1; an outer wall cover portion 4 formed continuously to the lower surface cover portion 3 and provided so as to cover an outer circumferential surface of a lower end portion of the side wall member 1; and a bottom portion 5 formed continuously inward from the lower surface cover portion 3 and having a draining hole. The lower end opening of the side wall member 1 is closed by the bottom portion 5, the lower surface of the side wall member 1 is covered by the lower surface cover portion 3, and the lower end outer circumference of the side wall member 1 is covered by the outer wall cover portion.

Owner:GAO XIUMING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com