Optical member and application of same

A technology for optical components and components, applied in optical components, optics, nonlinear optics, etc., can solve problems such as adhesive rejection, bubble generation in optical components and transparent protective components, and achieve the effect of suppressing poor appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

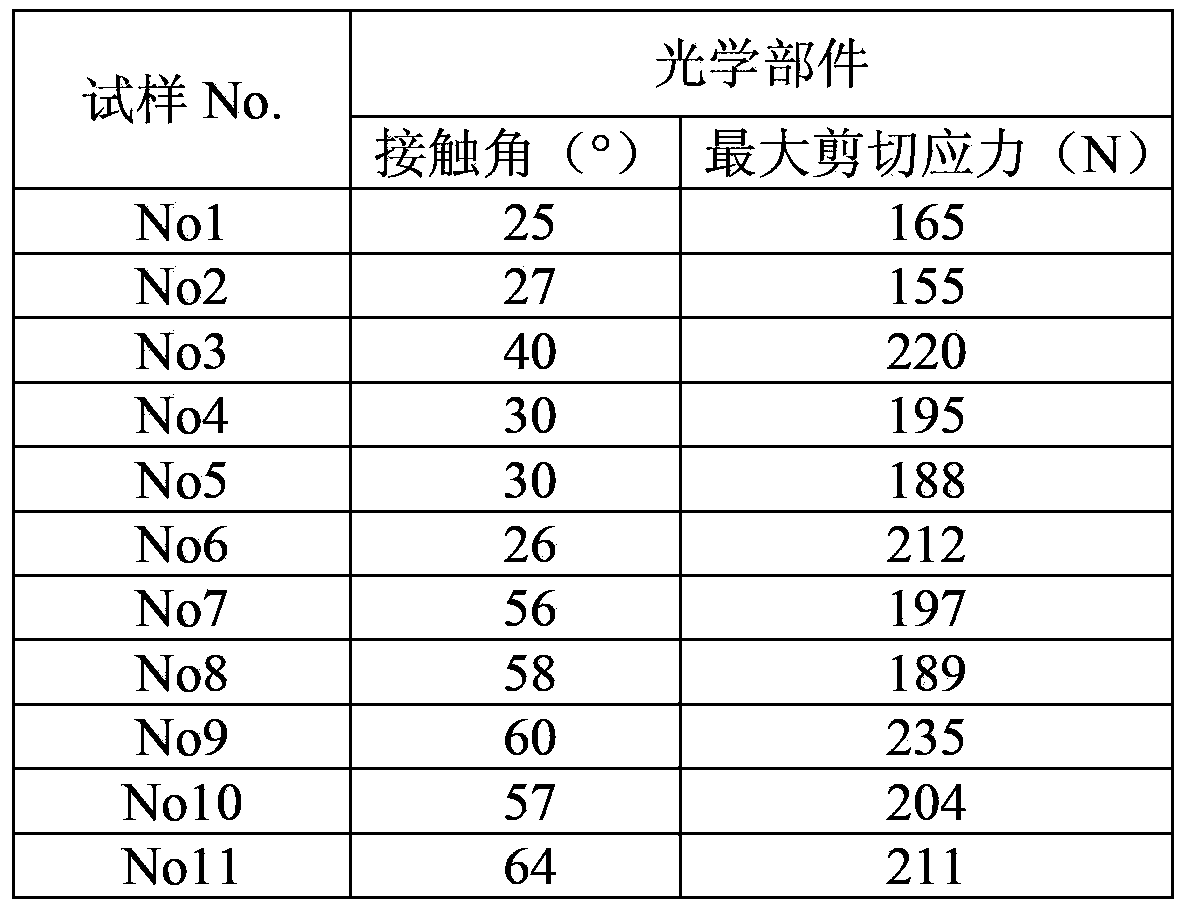

[0075] The present invention is further described in detail with examples below, but the present invention is not limited to these examples.

[0076]

[0077] A binder for evaluation that was analyzed as follows by gas chromatography was used.

[0078] Main ingredient: Isoprene polymer

[0079] Dicyclopentenyloxyethyl methacrylate: 14% by weight

[0080] Benzyl methacrylate: 8% by weight

[0081] Methyl methacrylate: 2% by weight

[0082] Photopolymerization initiator (Yanjiagu 184): 0.2% by weight

[0083] Other additives: (meth)acrylate monomer 0.8% by weight, acetone, 2,4,6-trimethylbenzoic acid, 1-octyl mercaptan, diphenylphosphine Peak observed, but below limit of quantitation.)

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com