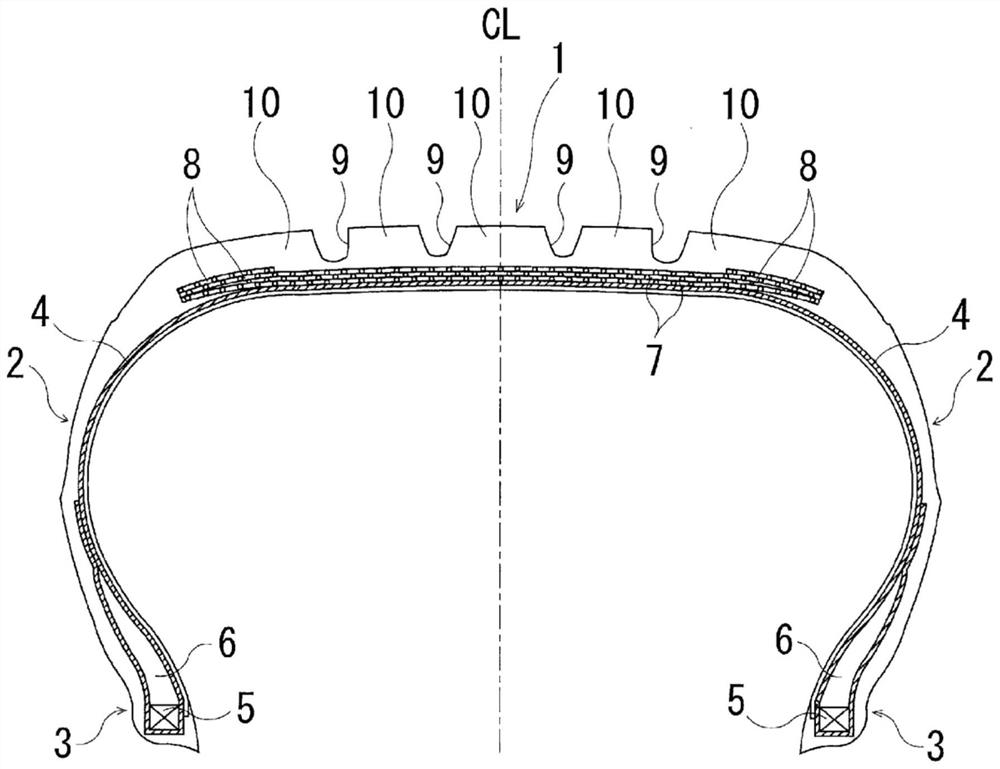

Pneumatic tire

A pneumatic tire, tire circumferential technology, applied in road vehicle tires, tire parts, tire tread/tread pattern, etc., can solve the problem of insufficient braking performance, and achieve the goal of suppressing poor appearance and improving braking performance, the effect of reducing appearance defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

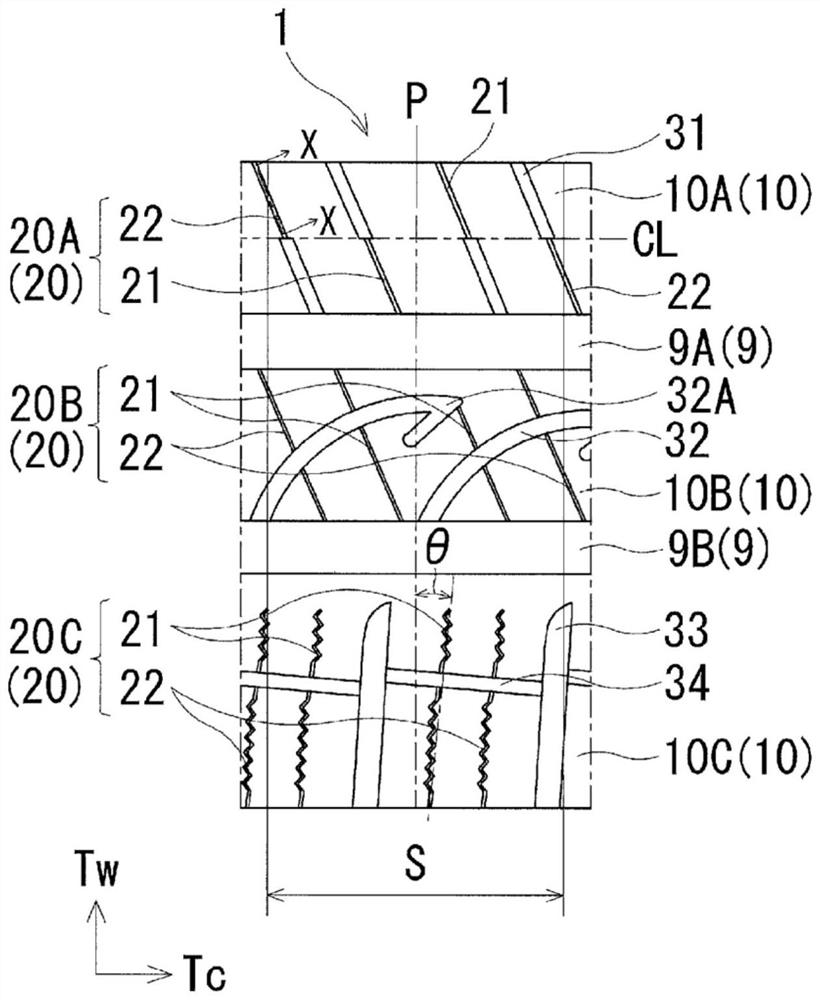

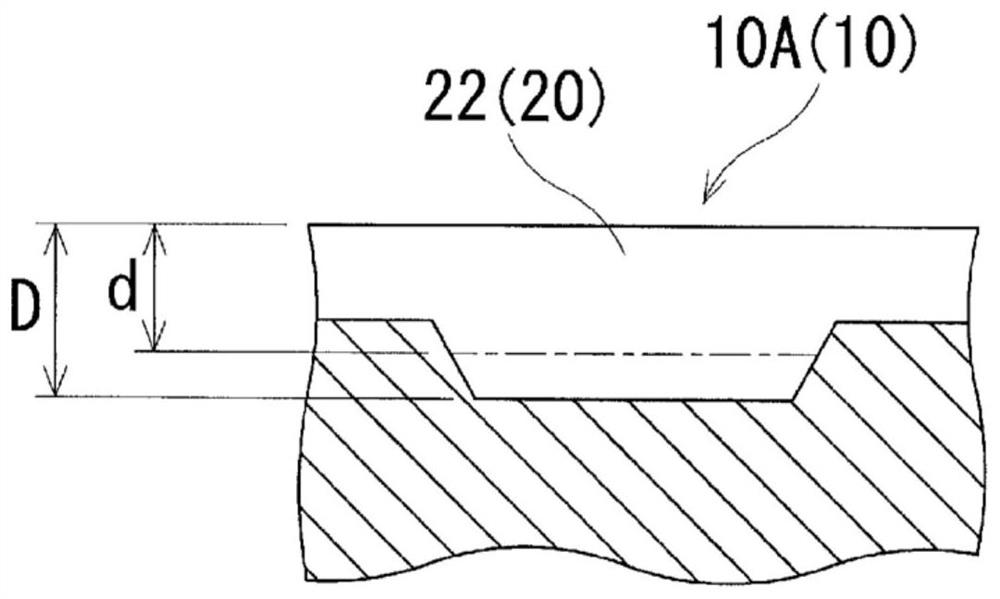

[0042] Tires of Conventional Example, Comparative Example, and Examples 1 to 7 were produced. These tires had a tire size of 205 / 55R16 and were provided with: a plurality of circumferential grooves extending in the tire circumferential direction in the tread portion; These circumferential grooves define; and a plurality of sipes extending in the tire width direction in at least one row of land portions, the tread portion being formed of a plurality of sectors divided in the tire circumferential direction, in the pneumatic tire, as shown in Table 1 Set the following: the presence or absence of sipe in the boundary area, the presence or absence of shallow bottom sipe, the range of the boundary area, the bottom elevation ratio of shallow bottom sipe, and the shallow bottom in each land portion. Comparison of the number of sipe lines, the inclination angle θ of the sipe in the center land portion, the inclination angle θ of the sipe in the middle land portion, and the inclination a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com