Measurement system for engineering geological drilling while drilling

A measurement-while-drilling and engineering geology technology, applied in the field of exploration and measurement, can solve the problems of twisting and inability to measure the torque of rotating parts, and achieve the effect of continuous data, conducive to real-time monitoring and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

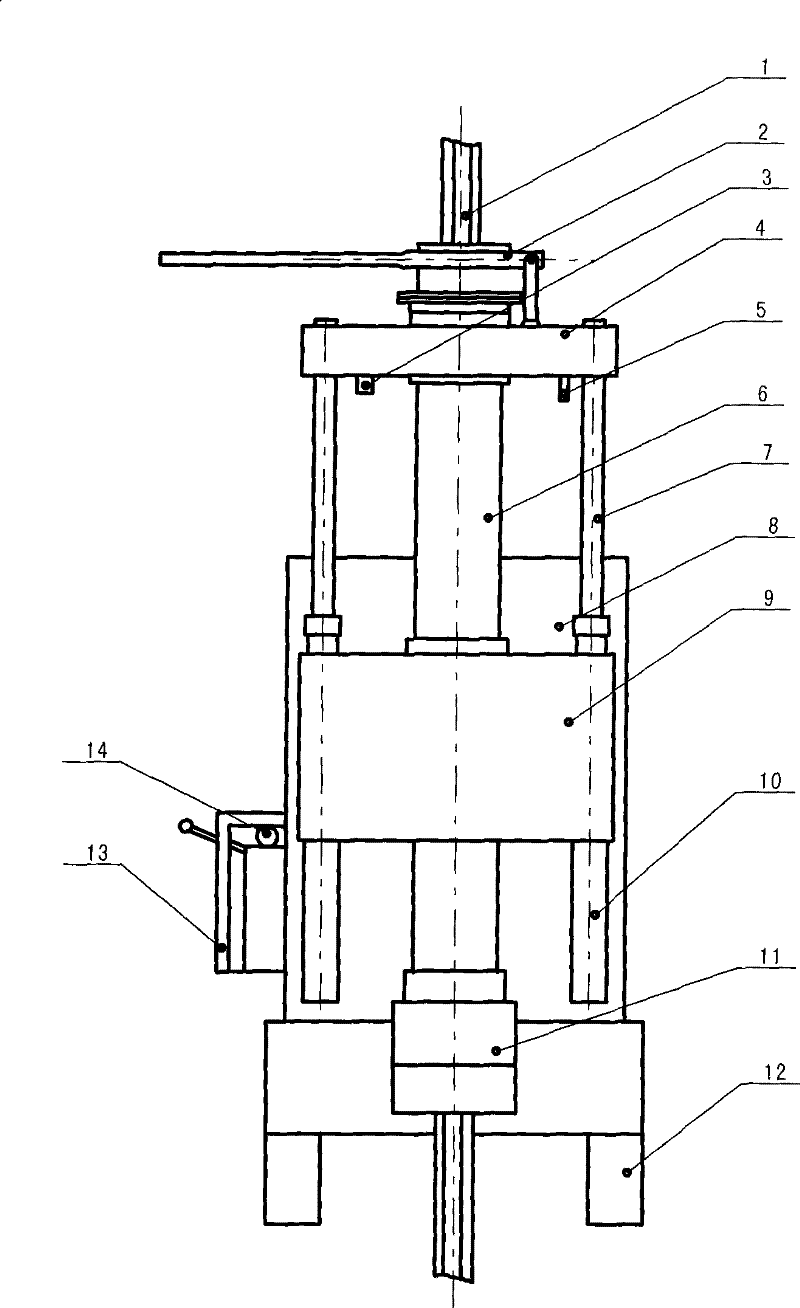

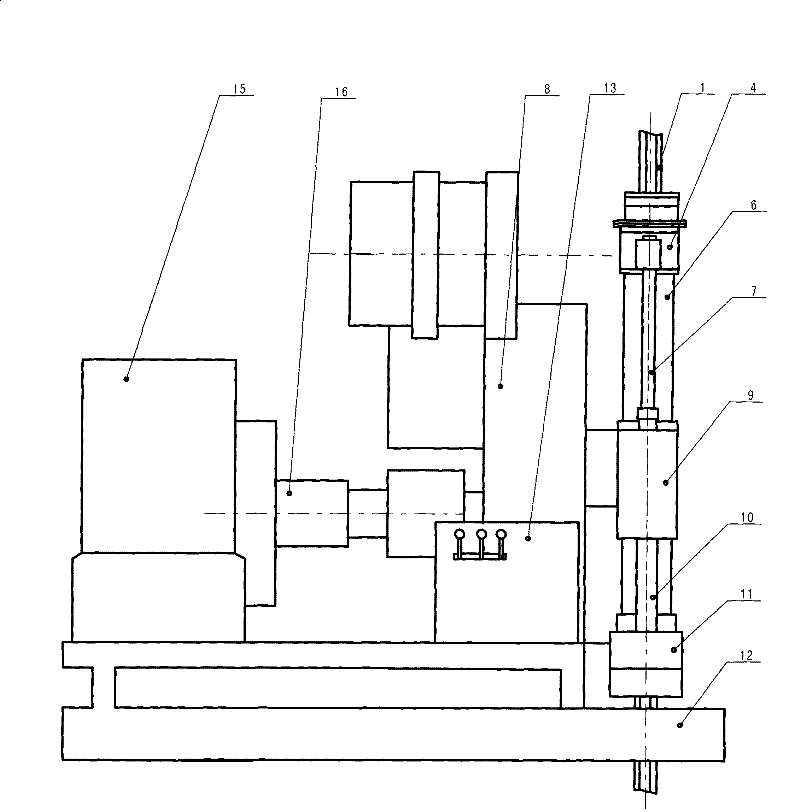

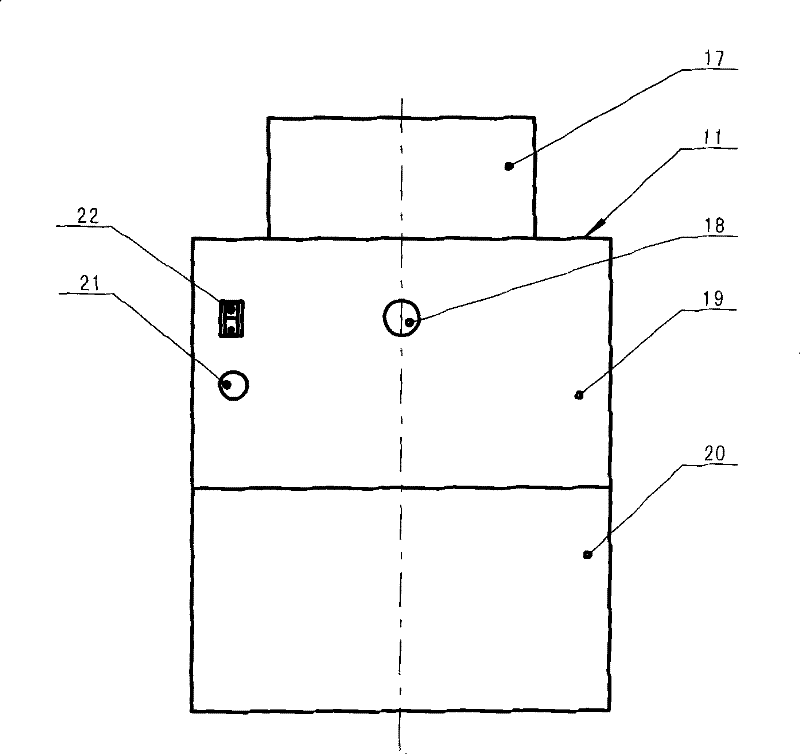

[0020] A measurement-while-drilling system for engineering geological drilling, which consists of a power machine 15, a transmission shaft 16, a reduction box 8, a chassis 12, a hydraulic control box 13, a hexagonal kelly 1, a machine head housing 9, a beam 4, a vertical shaft 6, Piston rod 7, hydraulic cylinder 10, torque measuring device 11, oil pressure measuring device 14, rotational speed measuring device 3, displacement measuring device 5 constitute. The power machine, reduction box and hydraulic control box are fixed on the chassis. The output horizontal shaft of the reduction box drives the vertical shaft to rotate through the bevel gear. The hydraulic control box controls the hydraulic cylinder and makes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com