Recombined bamboo board stuck energy-dissipating wood structural node

A technology for recombining bamboo boards and wood structures, which is applied in building structure and construction, etc., can solve the problems of easy splitting and damage of wood in the node area, weak strength and deformation ability, etc., and achieve excellent deformation ability and energy consumption ability. Anti-seismic performance, convenient construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

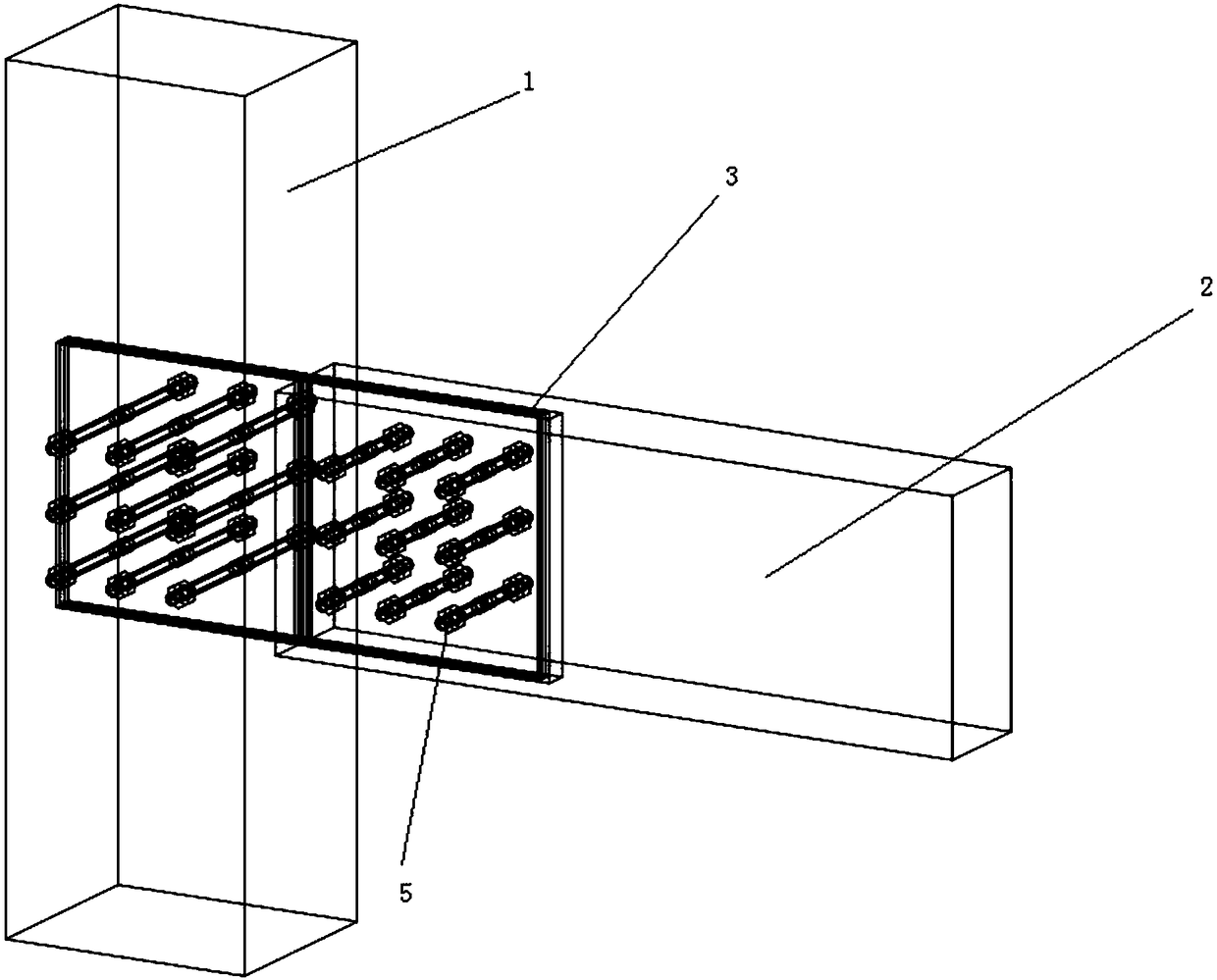

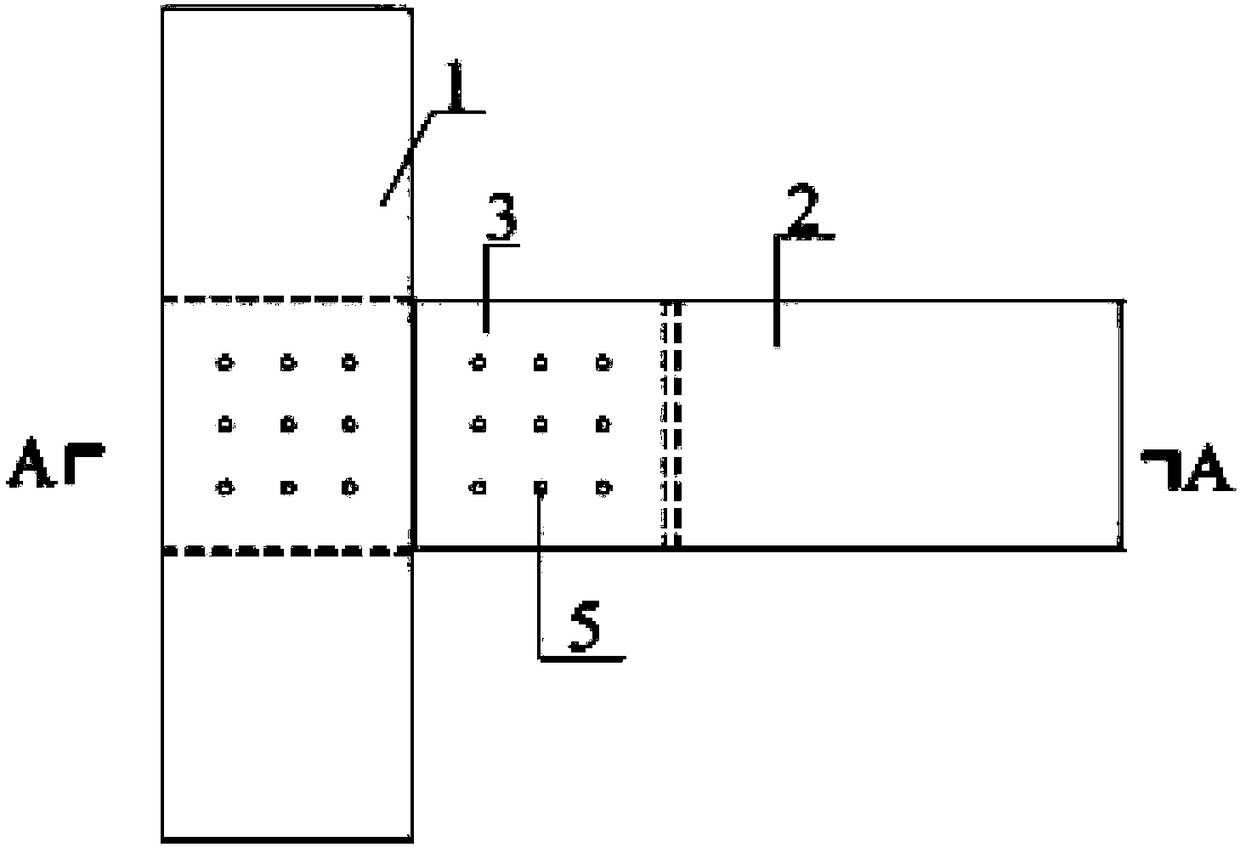

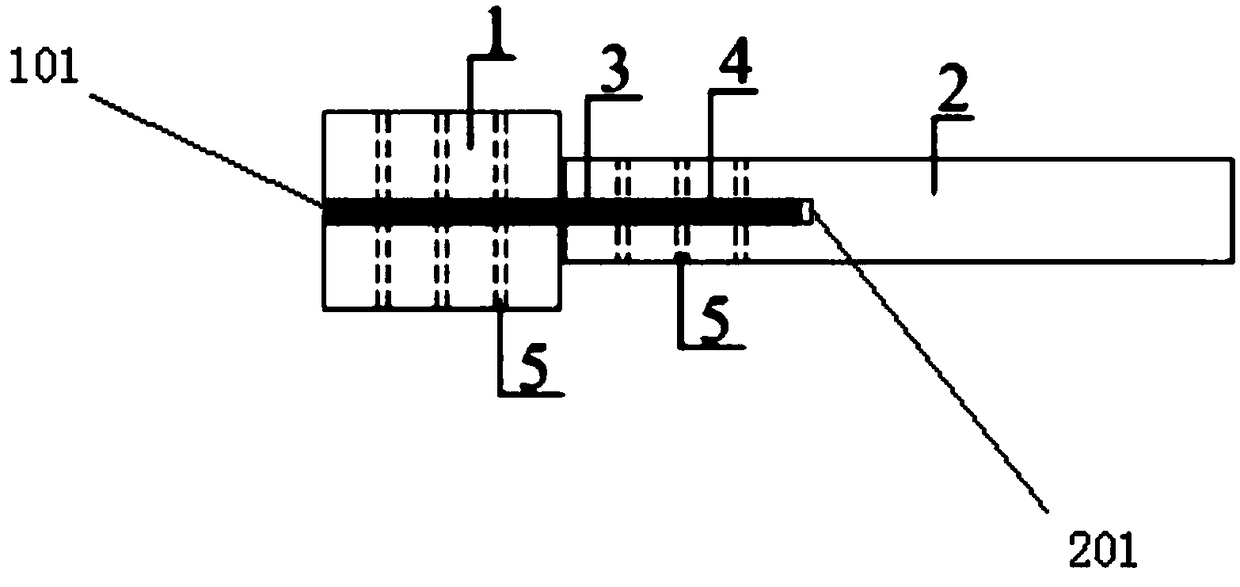

[0019] as attached Figure 1~3 As shown, an energy-dissipating wooden structure node pasted with recombined bamboo boards is characterized in that it includes a wooden component 1, a wooden component 2 2, an inner filling steel plate 3 and a metal connector 5;

[0020] The first wooden component 1 and the second wooden component 2 are arranged vertically close to each other, the side surface of the wooden component 1 has a groove 101, and the end surface of the wooden component 2 2 has a One 101 corresponds to the groove two 201, and the recombined bamboo board 4 is pasted on the inner surface of the groove one 101 and the groove two 201, and one end of the inner filling steel plate 3 is fixedly installed in the groove one 101, and the other end is fixedly installed in the groove one 101. In the second tank 201, the inner filling steel plate 3 is located between the first tank 101 and the recombined bamboo board 4 on the inner side of the second tank 201.

[0021] One end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com