Manufacturing method of pneumatic tire

A technology for a pneumatic tire and a manufacturing method, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of increased winding time, longer forming time, cracks in rubber belts, etc., so as to improve production efficiency and improve adhesion. , to ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

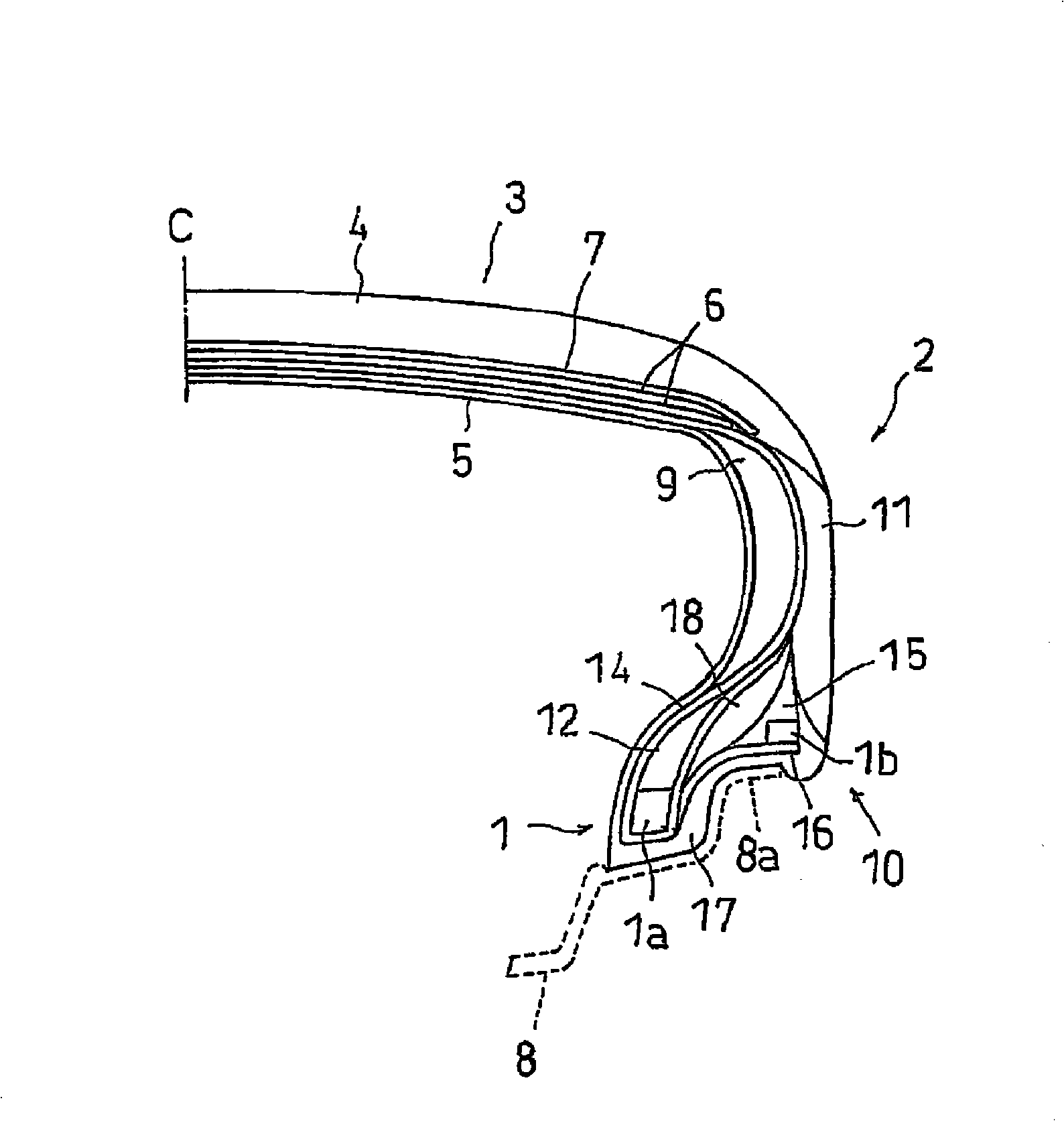

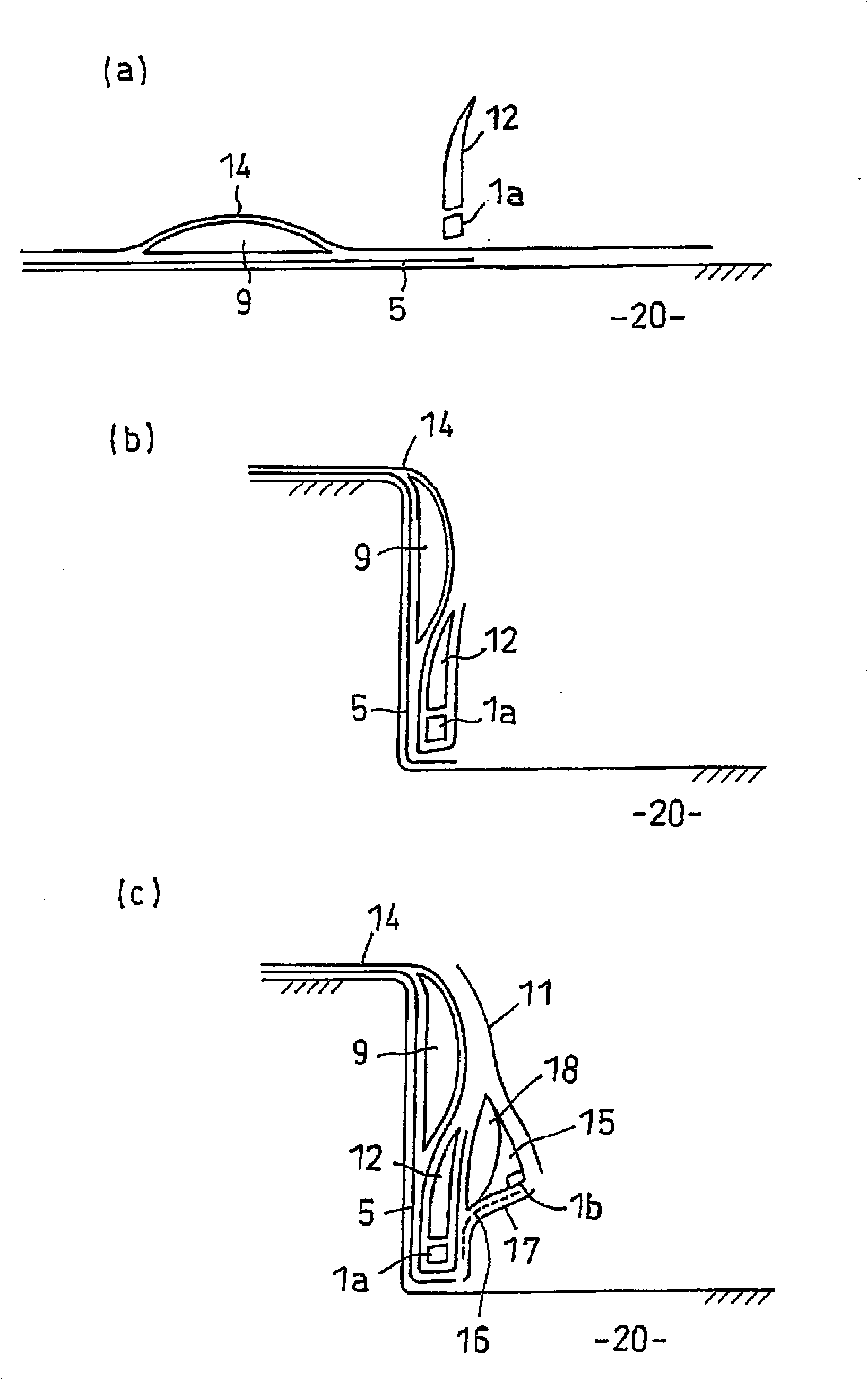

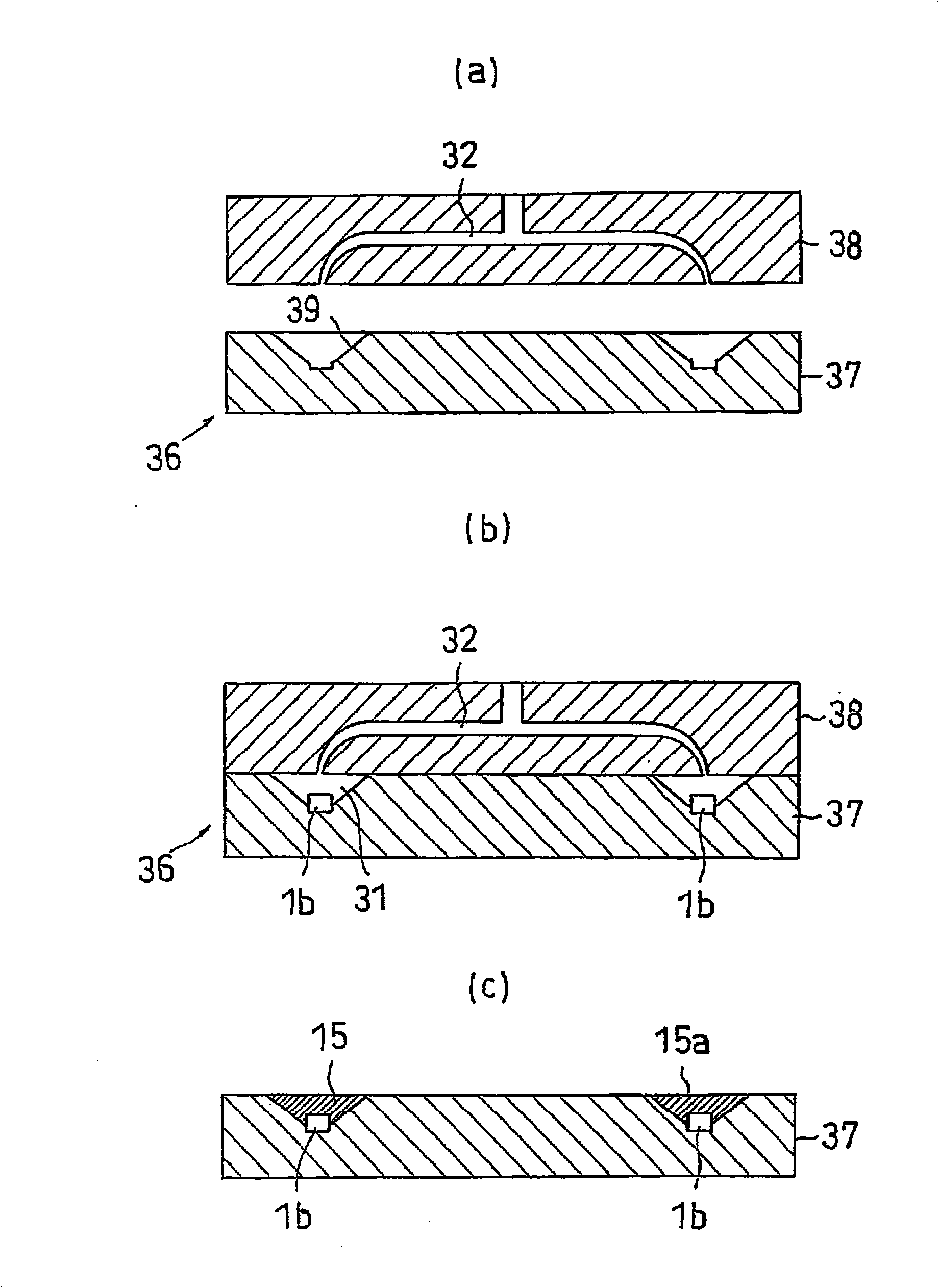

[0023] Embodiments of the present invention will be described with reference to the drawings.

[0024] figure 1 is a half cross-sectional view showing a tire meridian of an example of a pneumatic tire manufactured according to the present invention. The pneumatic tire includes a pair of bead portions 1 , sidewall portions 2 extending radially outward from the respective bead portions 1 of the tire, and a tread portion 3 provided between these sidewall portions 2 . In the bead portion 1 are arranged an annular bead 1a constituted by an aggregate of bead wires, and a bead filler 12 formed into a triangular cross-sectional shape on the outer side of the bead 1a in the tire diameter direction, and The ends of the carcass ply 14 are rolled up outside in such a manner that they are clamped, wherein the bead wires are made of steel wire or the like.

[0025] An inner liner rubber 5 for maintaining air pressure is arranged on the inner peripheral side of the carcass ply 14 . Furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com