Manufacturing method of aero-engine composite material fan blade metal stiffened edge

An aero-engine and metal strengthening technology, which is applied to aircraft parts, transportation and packaging, etc., can solve problems such as easy instability of tools, small fillet precision of superplastic forming cannot meet design requirements, uneven thickness distribution, etc., and achieve simple Cutting and argon arc welding, the processing process is simple and efficient, and the cutting process is simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

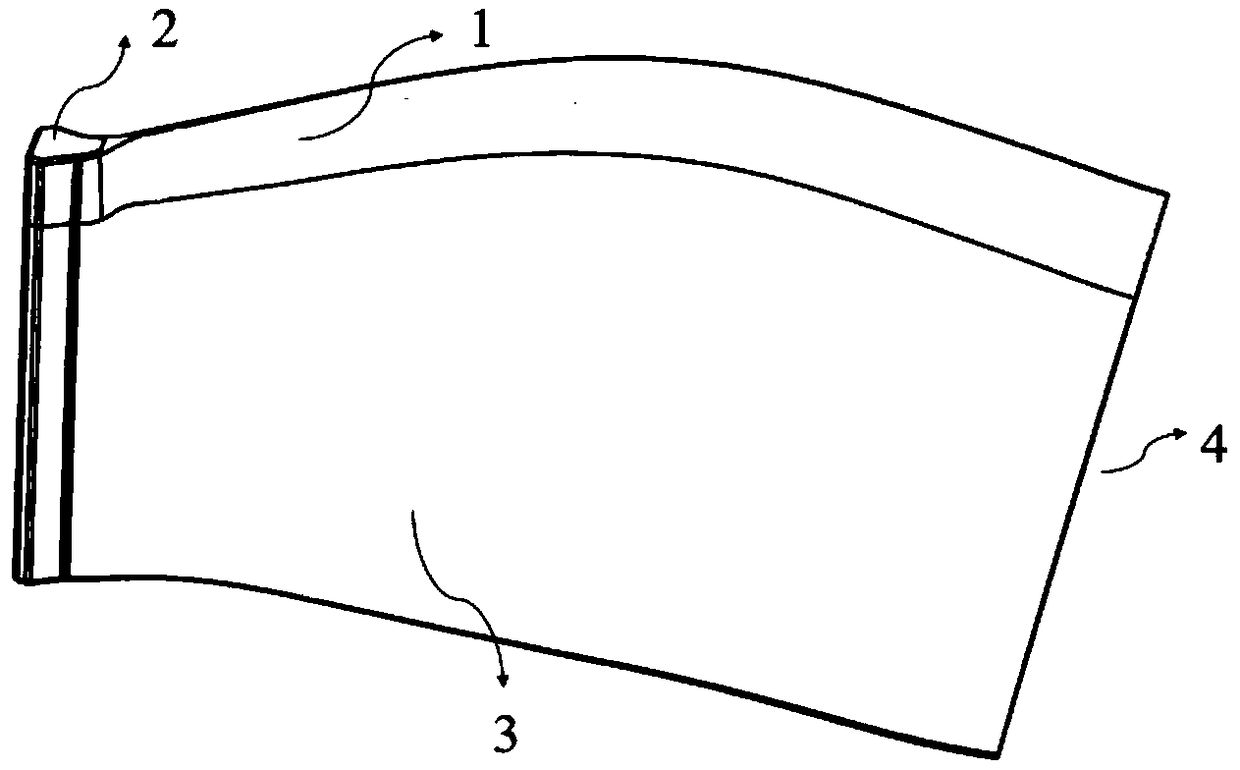

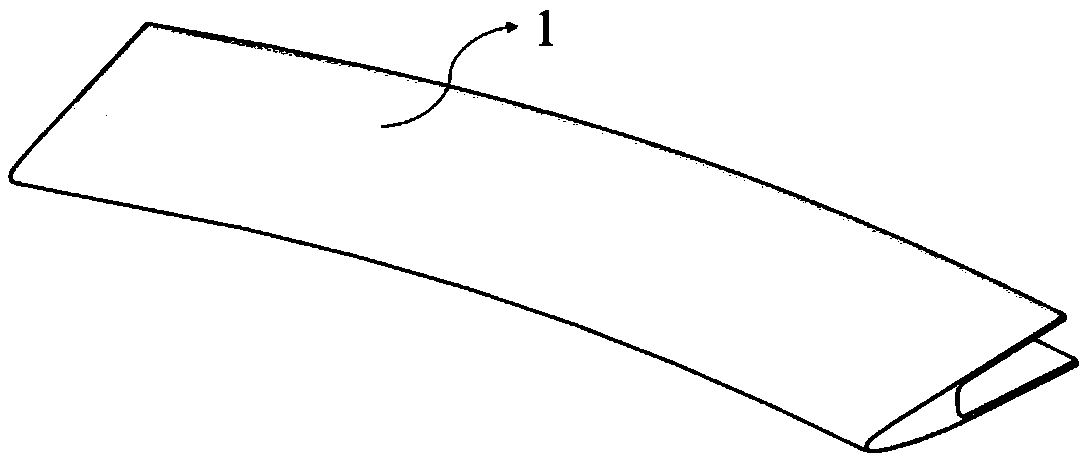

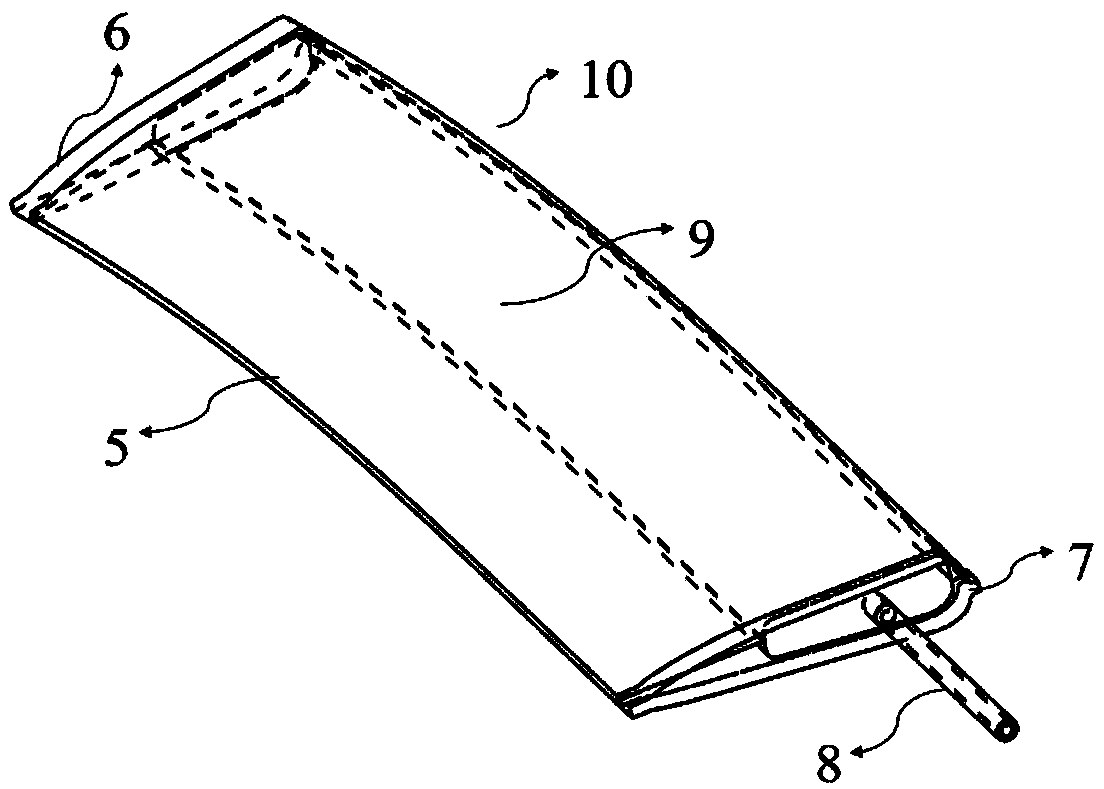

[0043] In order to ensure its aerodynamic performance, the aero-engine composite fan blade 4 generally has a complex streamlined shape. The metal reinforcing edge 1 must also have complex spatial geometry, and most of them are special-shaped thin-walled structures with narrow and deep cavities. The inner cavity of the reinforcement side is closely connected with the composite material airfoil 3 by means of gluing or the like. In the present invention, the metal reinforcing edge 1 will be processed and manufactured efficiently by adopting multi-processes of piece cutting, thermoplastic forming, diffusion connection and edge trimming. Firstly process the corresponding first blank 13 and the second blank 14, then carry out thermoplastic forming to the first blank 13 and the second blank 14, cut out the inner cavity of the cavity, and obtain the first preform 15, the second preform 16; then the first prefabricated part 15 and the second prefabricated part 16 are diffused and conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com