Matching type forming method and device of fuel battery metal flow field plate

A fuel cell and metal flow technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the difficulty and cost increase in the processing of micro-punch and concave molds, and is not suitable for low-cost mass manufacturing of micro-flow field plates and flow channel processing. Inefficiency and other issues, to ensure sustainability and repeatability, improve forming accuracy and quality, and have strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

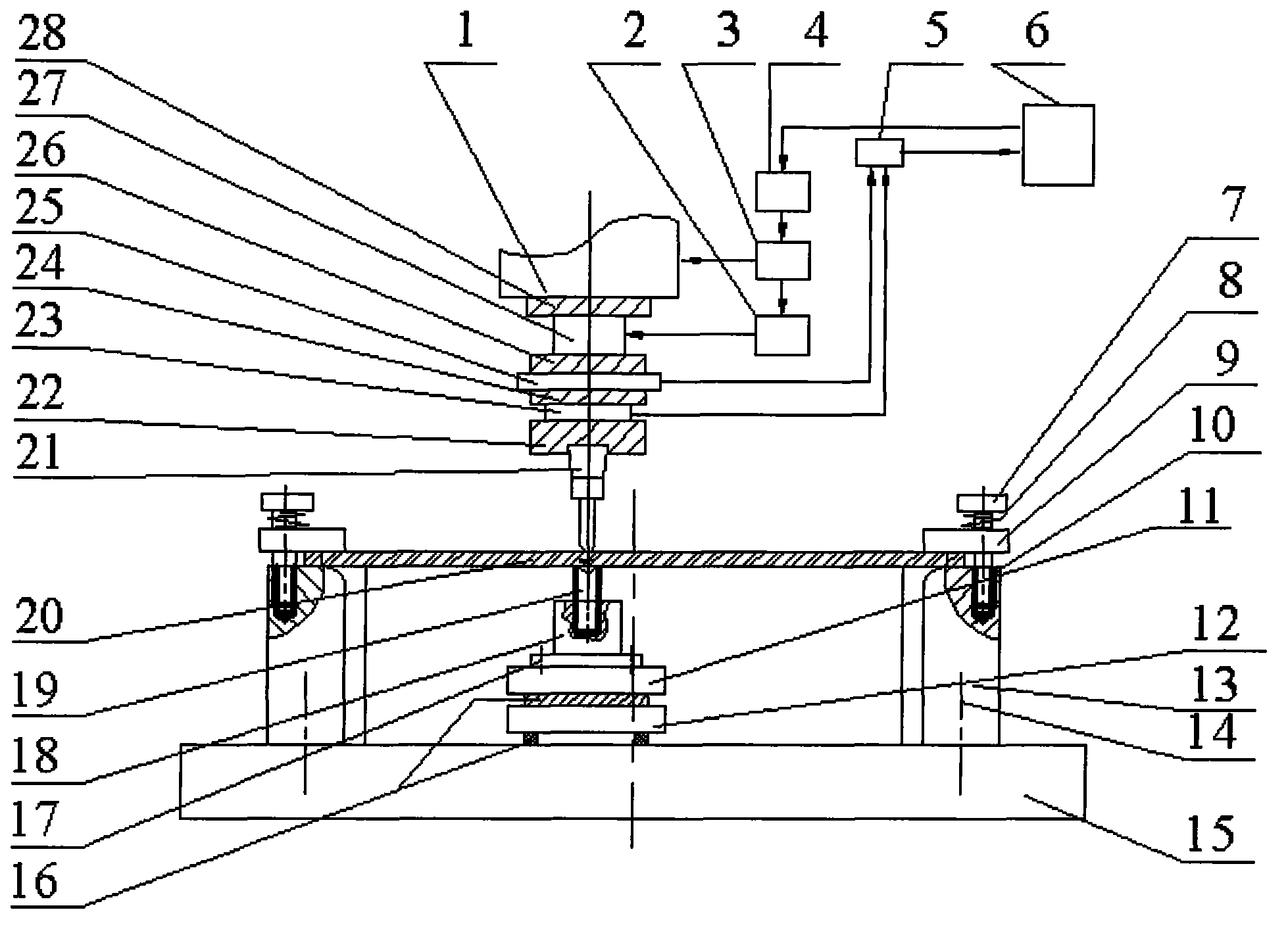

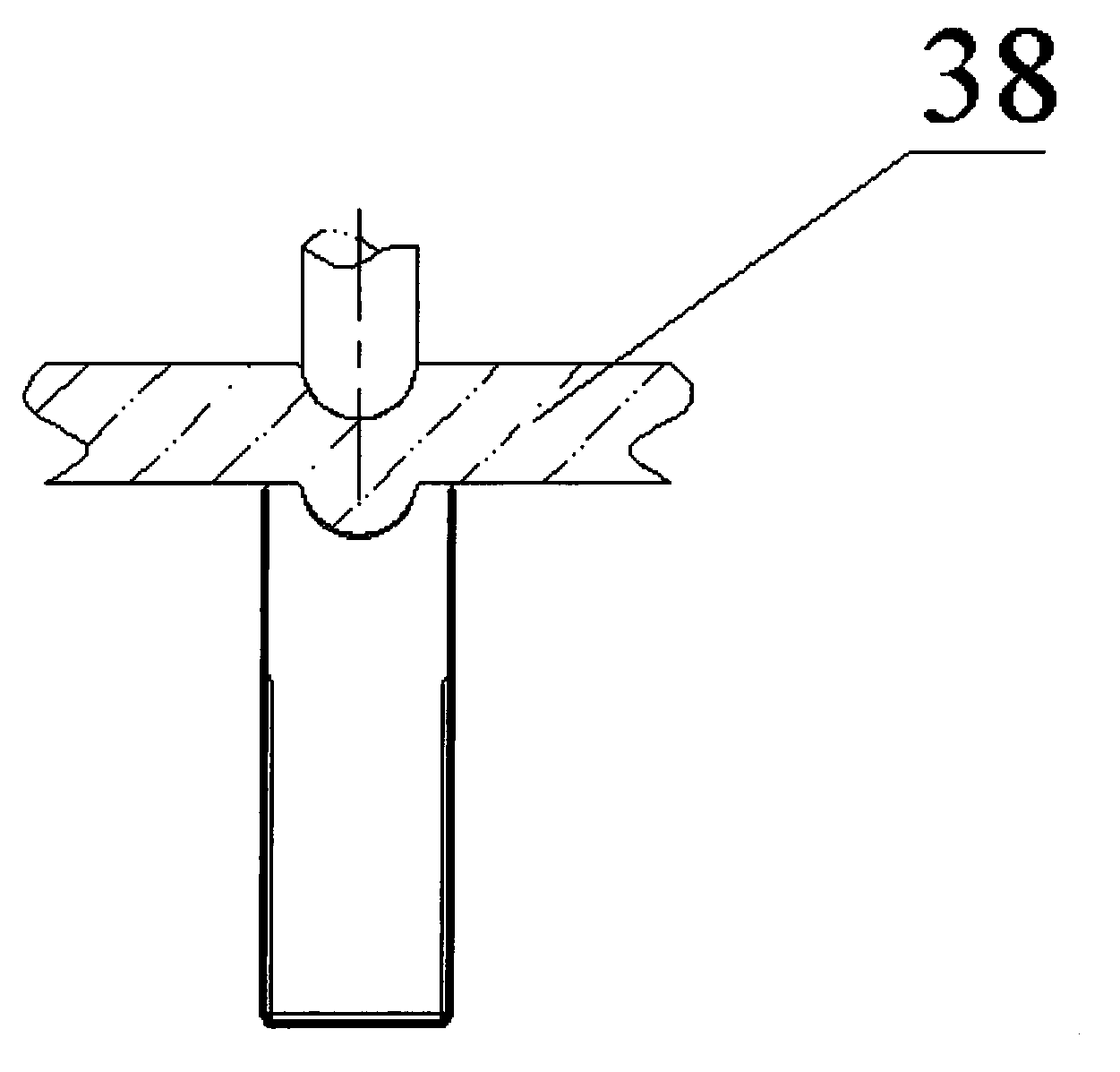

[0042] combine figure 1 , figure 2 , Figure 5 , Figure 8 , the forming method of the fuel cell serpentine metal flow field plate is as follows:

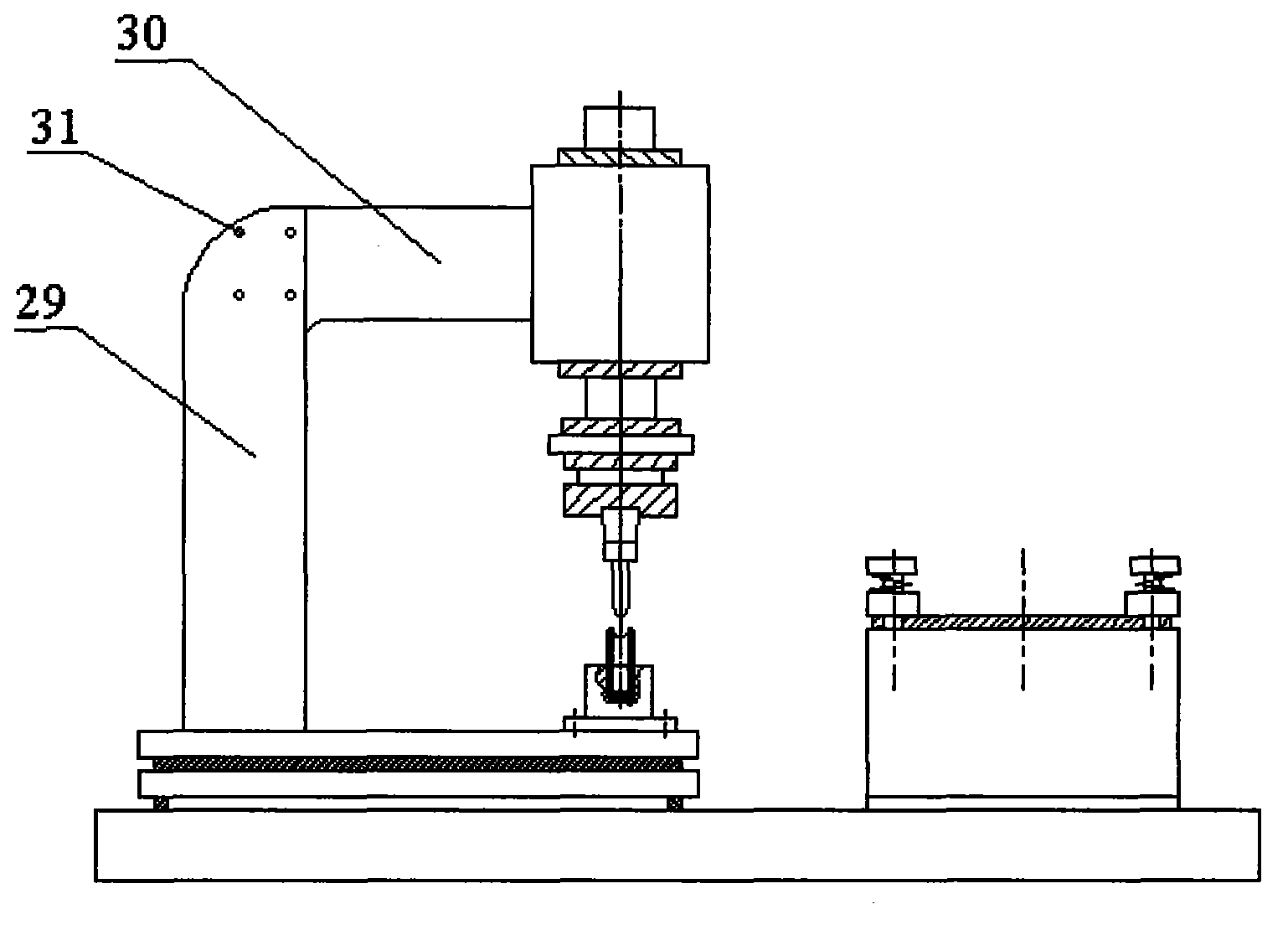

[0043] Its forming method is to design and process the upper forming die (punch) 21 and the lower forming die (concave) 19 with a semicircular shape according to the semicircular cross-sectional shape, size and precision of the serpentine runner that needs to be formed, The base material 20 is stainless steel with a thickness of 100 μm, and a rectangular plate with an external dimension of 1.2 cm×1.2 cm. First install the X-axis guide rail on the base 15, the X-axis guide rail is provided with an X-axis platform 12 that can move thereon, the Y-axis guide rail is provided on the X-axis platform, and the Y-axis guide rail is provided with The Y-axis platform 11 that can move on it, the left side of the Y-axis platform 11 is equipped with a column 29, the top of the column 29 is equipped with a beam 30, the beam 30 is embedded in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com