Power module base unit and power module

A technology of power modules and substrates, which is applied in the direction of electrical components, circuits, and electric solid-state devices, can solve the problems that it is difficult to accurately locate multiple insulating substrates, it is difficult to obtain the position accuracy of insulating substrates, and it is difficult to achieve integration. Achieve high integration, improve connection reliability, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0088] Next, examples performed to confirm the effects of the present invention will be described.

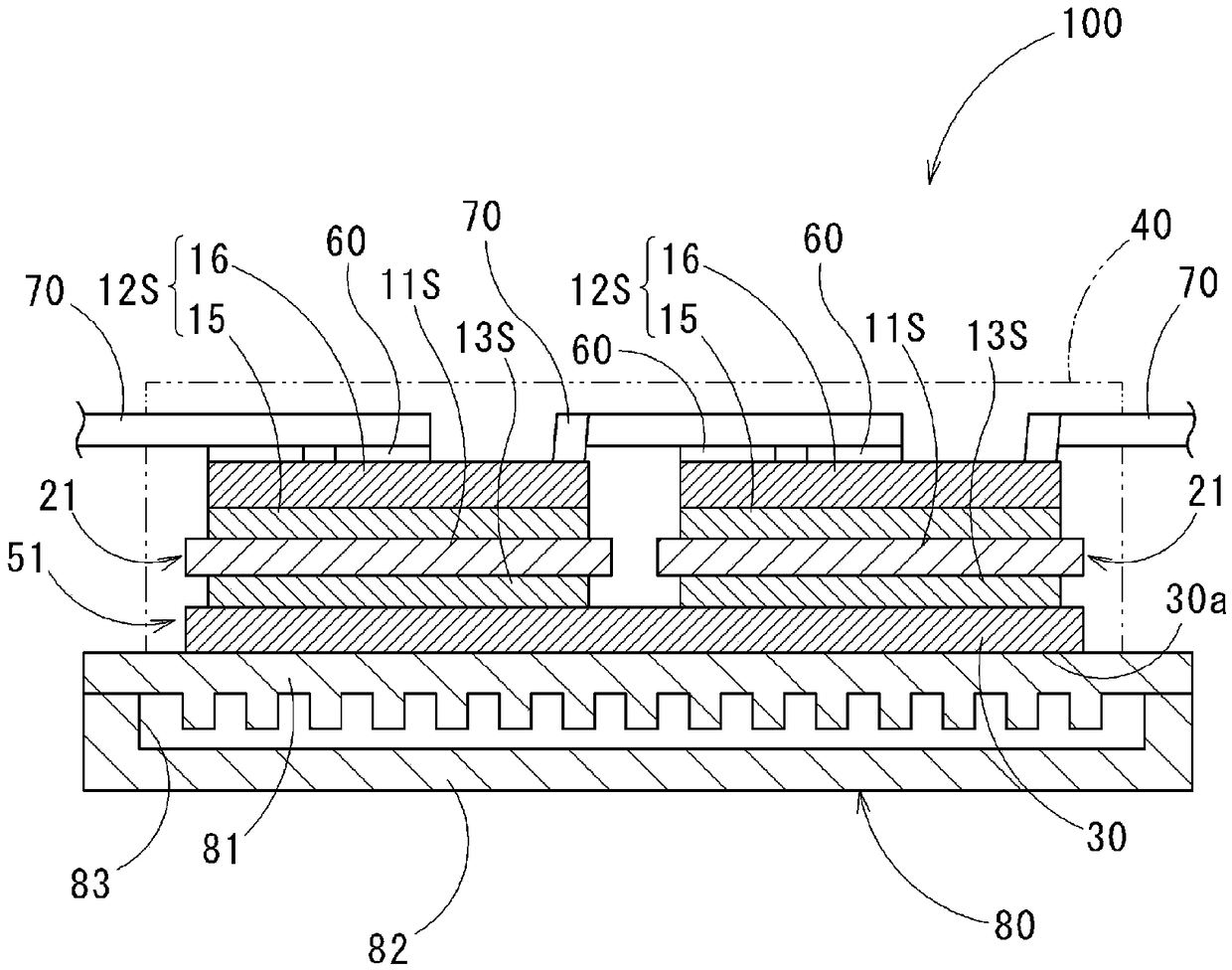

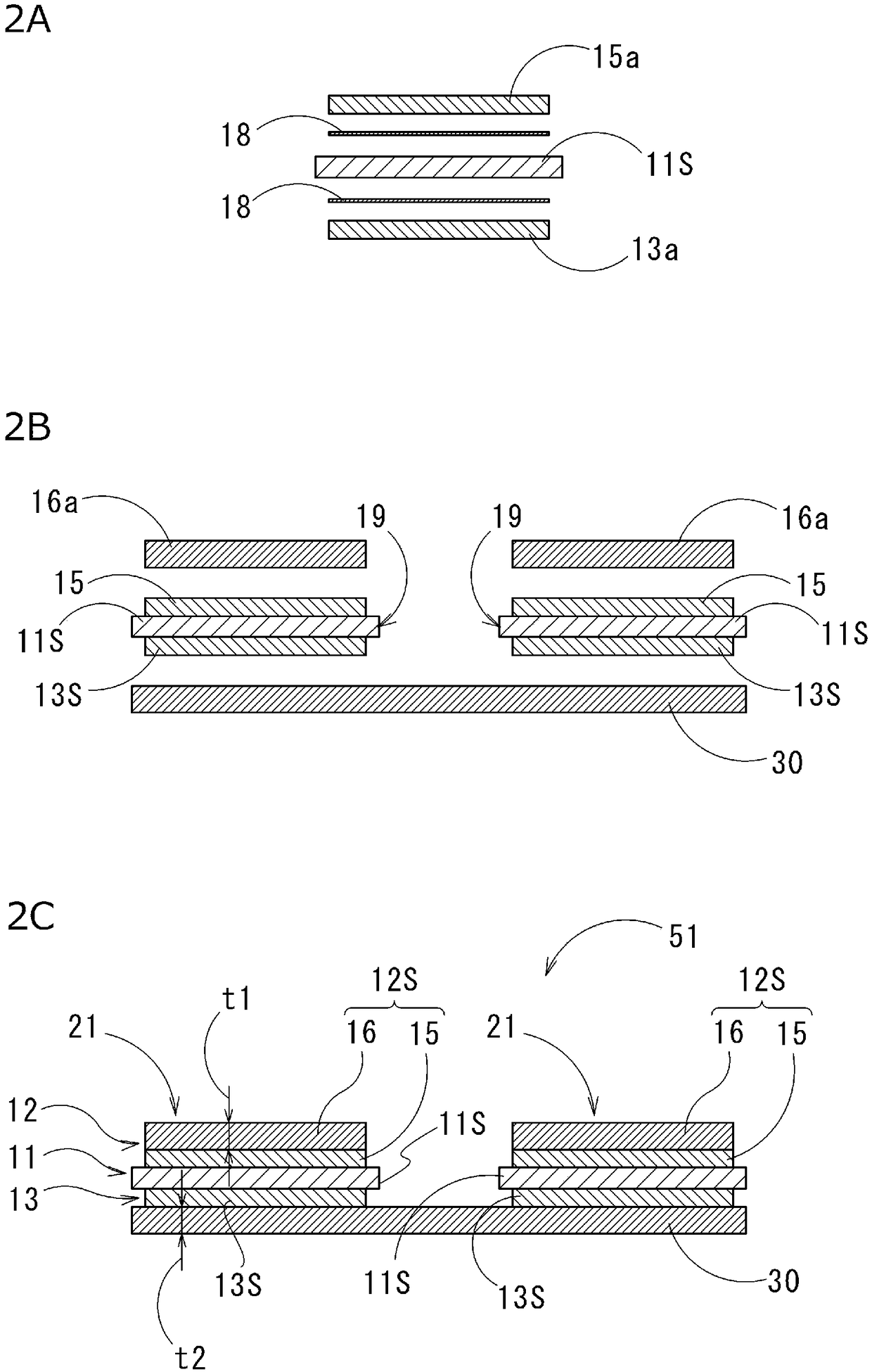

[0089] As a sample of the substrate unit for a power module, a ceramic substrate composed of AlN with a thickness of 0.635 mm was prepared as a ceramic substrate layer, and a 0.6 mm-thick aluminum plate with a purity of 99.99 Aluminum plate with mass % or more (4N). Pass C1020 (yield strength = 195N / mm 2 ) or heat-resistant alloy ZC manufactured by Mitsubishi Shindoh Co., Ltd. (yield strength = 280N / mm 2 ), prepare plates with the thicknesses shown in Table 1. In addition, the value of yield strength is the value at room temperature (25 degreeC). The planar dimensions of each component were formed as shown in Table 1.

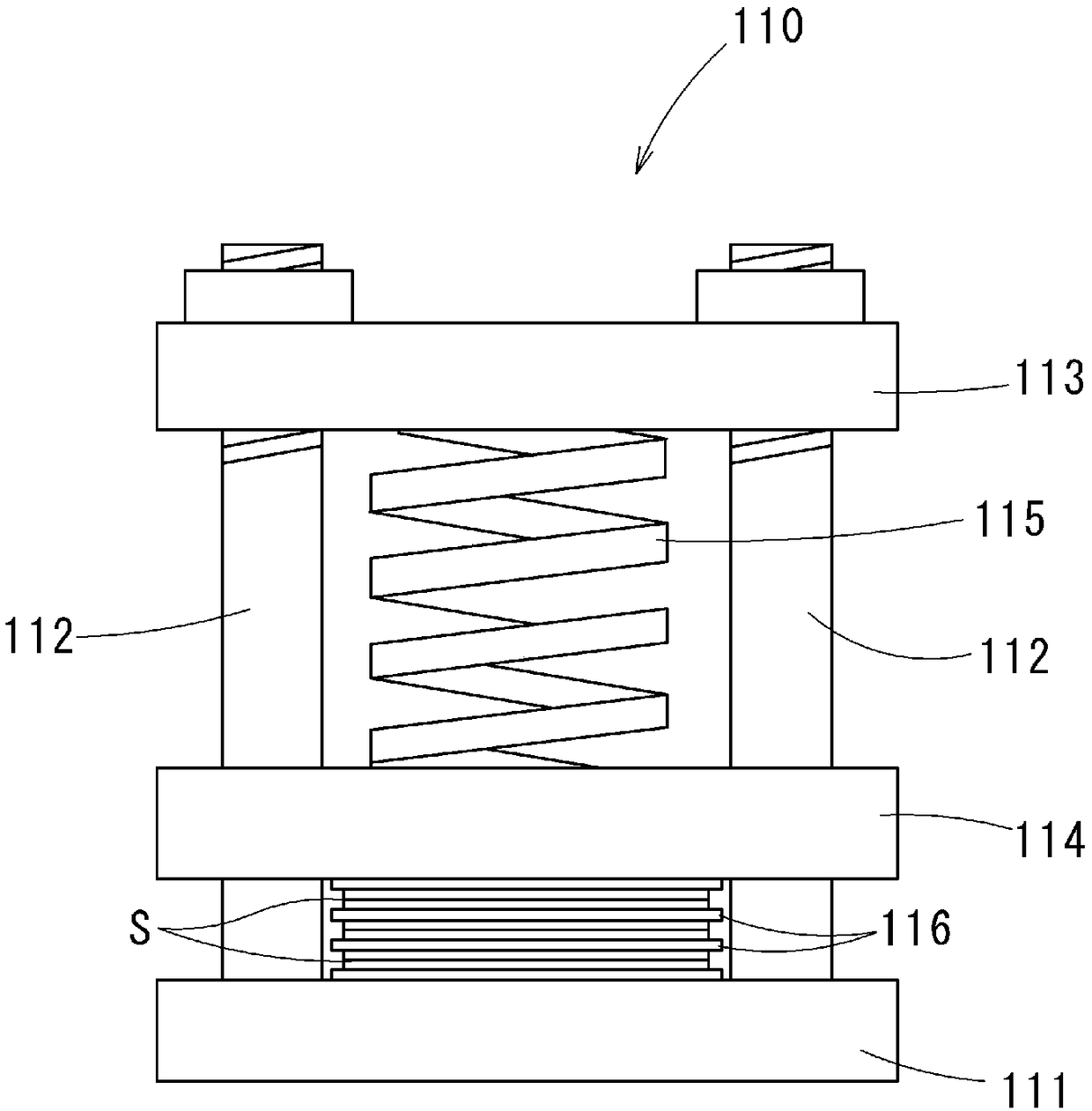

[0090] These were joined by the joining method described in the said embodiment, and the sample of the board|substrate unit for power modules was produced. "Embodiment" in Table 1 indicates which embodiment of the production method each sample was produced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com