Substrate for power module with heat sink, and power module

A technology for power modules and heat sinks, applied in the field of power module substrates and power modules, can solve problems such as damage to bonding reliability, increase in thermal resistance, damage to the adhesion of heat sinks and coolers, etc., and achieve the effect of not easy to warp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

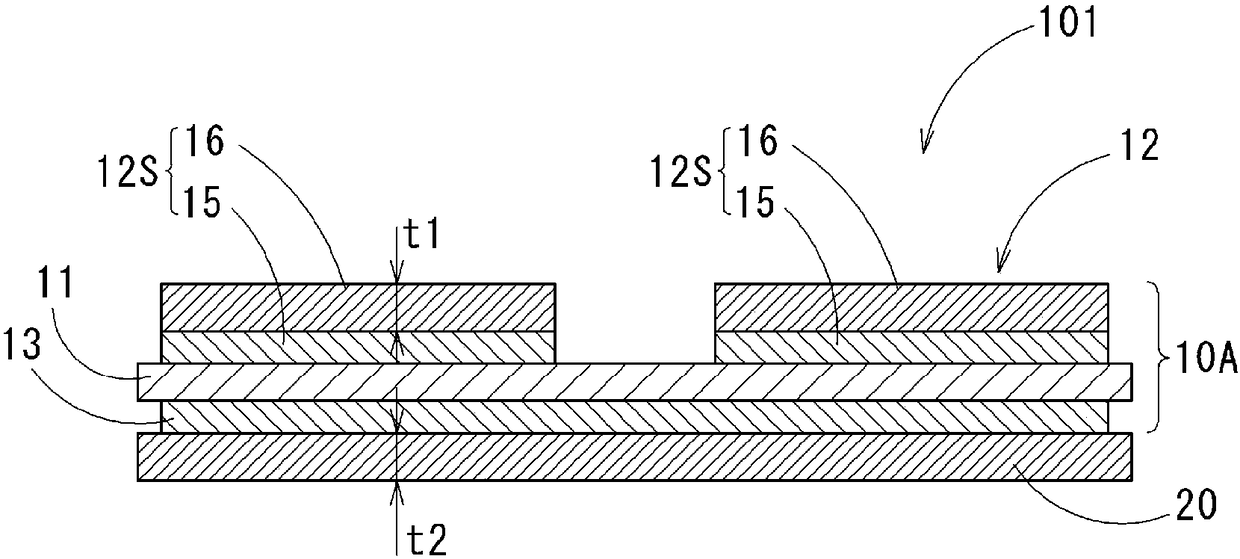

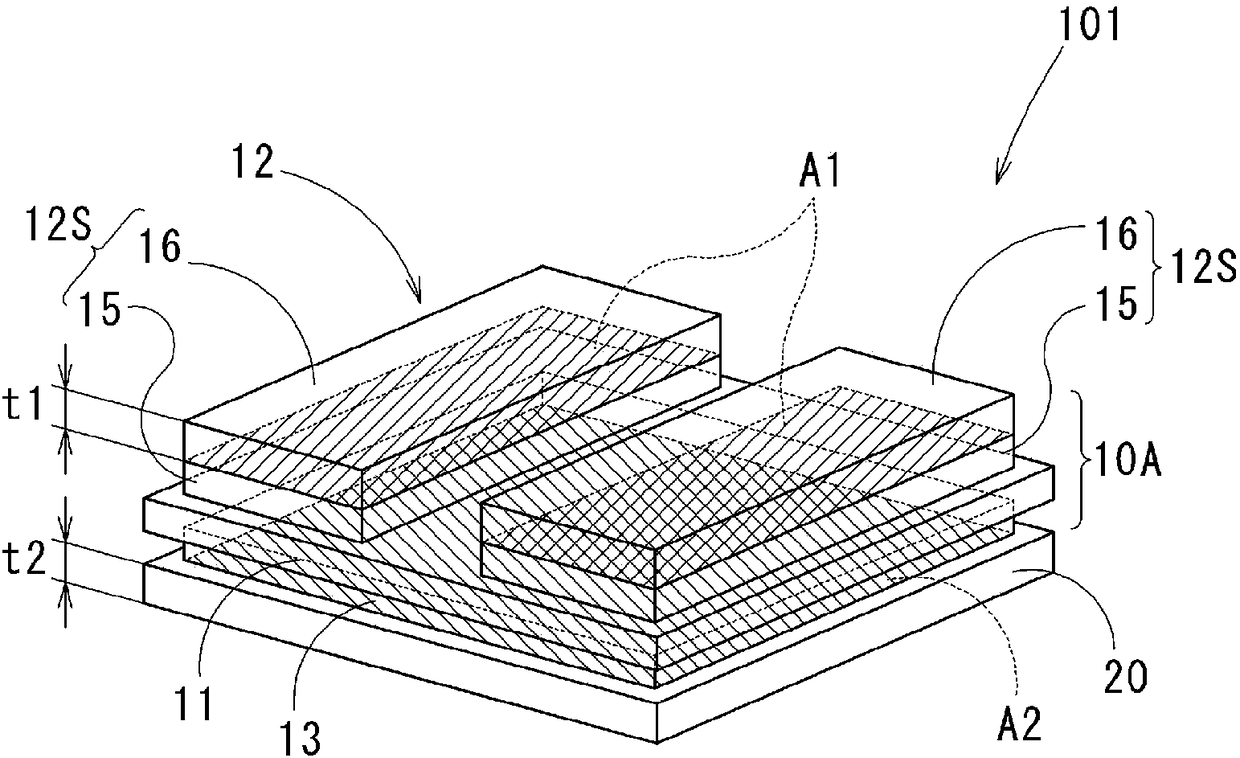

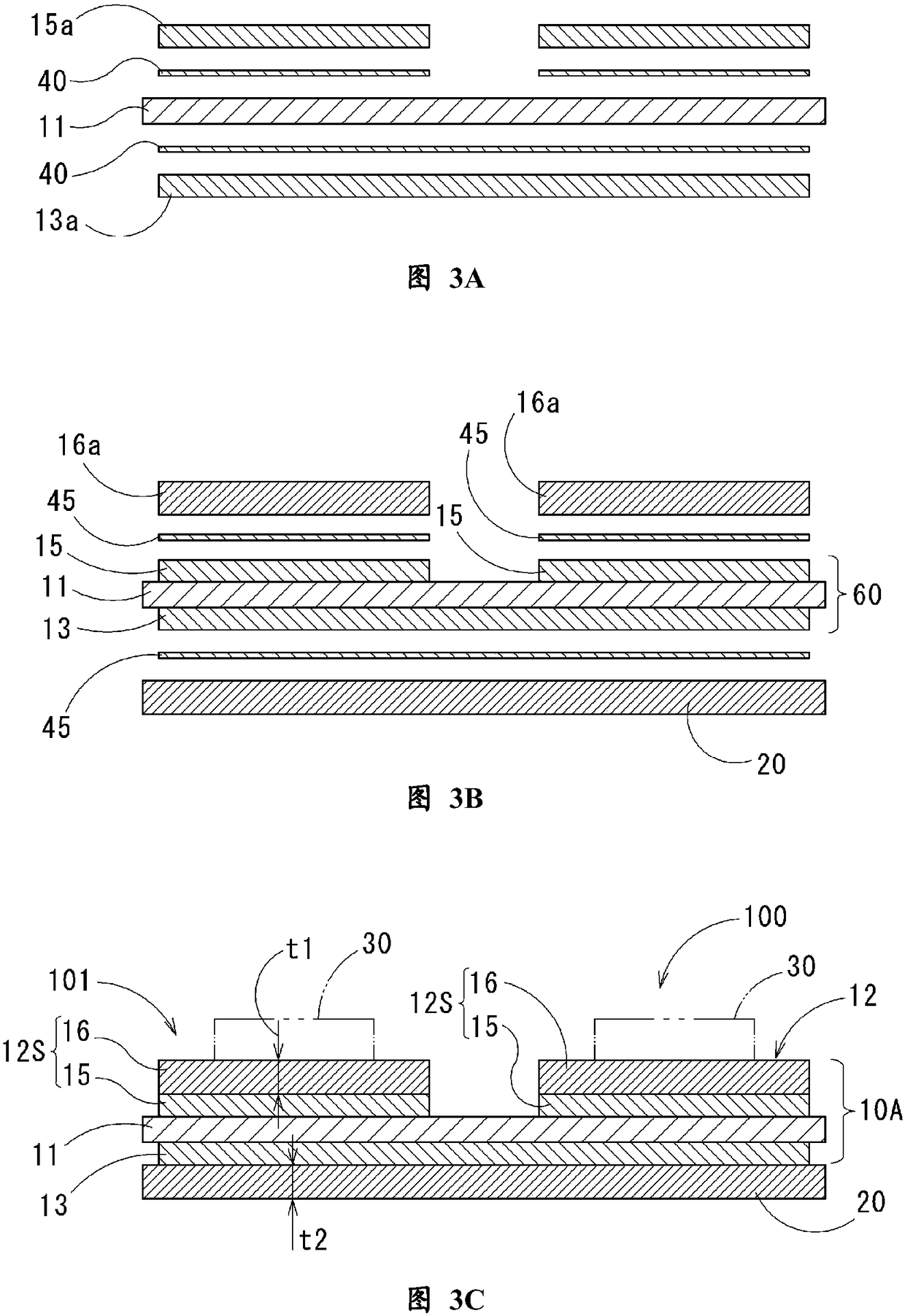

[0060] figure 1 as well as figure 2 The power module substrate 101 with a heat sink according to the first embodiment shown in FIG. image 3 As shown in C, the power module 100 is manufactured by mounting a semiconductor element 30 such as a semiconductor wafer on the surface of the heat sink-attached power module substrate 101 .

[0061] The power module substrate 10A includes a ceramic substrate 11, a circuit layer 12 composed of a plurality of small circuit layers 12S bonded to one surface of the ceramic substrate 11 by soldering, and a plurality of small circuit layers 12S bonded to the other surface of the ceramic substrate 11 by soldering. A sheet of metal layer 13 . And, if figure 1 as well as figure 2 As shown, the small circuit layers 12S of the power module substrate 10A are bonded to one surface of the ceramic substrate 11 at intervals. Furthermore, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com