Method for producing heat-shielding ply structure, heat-shielding ply structure, and transparent laminate film for ply structure

A technology of transparent layer and laminated layer, which is applied in the direction of chemical instruments and methods, coatings, layered products, etc., to achieve the effects of cost reduction, diffusion inhibition, and excellent mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0168] A description of the present invention will now be specifically provided with reference to Examples.

[0169] 1. Production of transparent laminated film (with grooves)

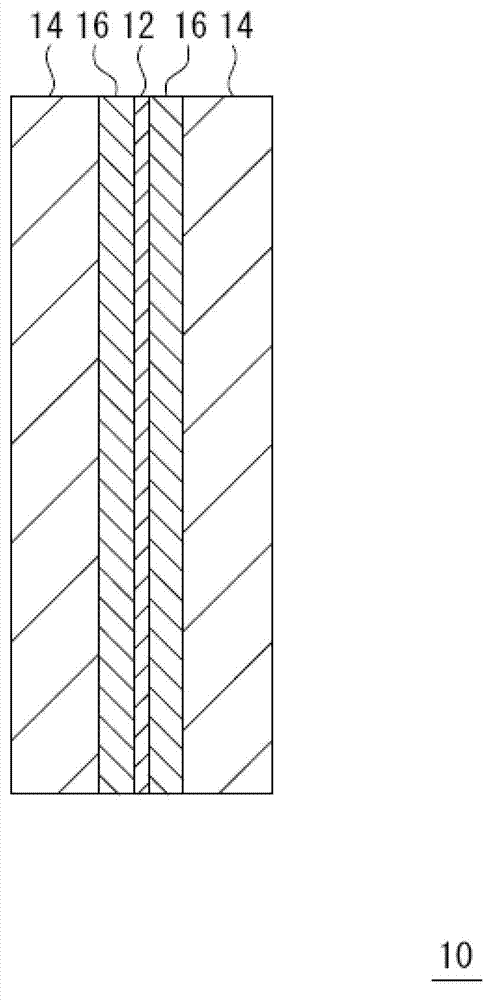

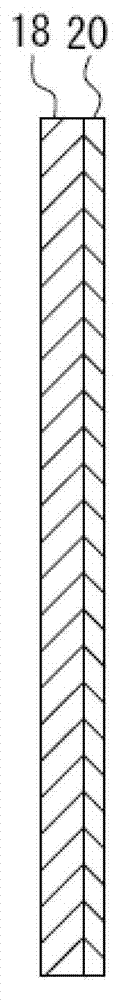

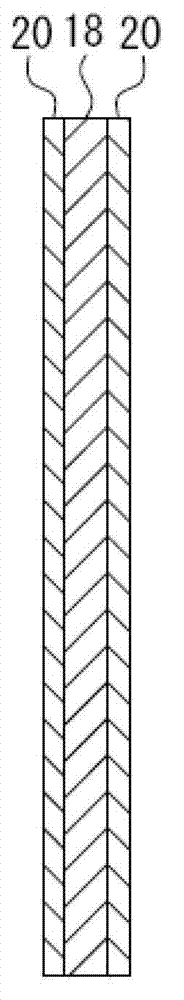

[0170] Each transparent laminated film according to the embodiment includes a 7-layer laminated layer structure part. In each of the 7-layer laminated layer structures, the following layers are laminated layer by layer on one easy-adhesive layer of a PET film having easy-adhesive layers on both sides: Formed by a sol-gel method and UV irradiation TiO 2 Layer (1st layer) | Layer (2nd layer) formed by post-oxidizing the unit of metal Ti layer / Ag-Cu alloy layer / metal Ti layer | TiO formed by sol-gel method and ultraviolet irradiation 2 Layer (3rd layer) | Layer (4th layer) formed by post-oxidizing the unit of metal Ti layer / Ag-Cu alloy layer / metal Ti layer | TiO formed by sol-gel method and ultraviolet irradiation 2 Layer (layer 5) | Layer formed by post-oxidizing the unit of metal Ti layer / Ag-Cu alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com