Infrared-shielding sheet, interlayer film for infrared-shielding laminated glass, and infrared-shielding laminated glass and method for manufacturing same

A technology of infrared and shielding sheets, which is applied in the field of new infrared shielding sheets, can solve problems such as inability to use, and achieve the effects of improved temperature reduction effect, low haze, and excellent manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0154] (Production of high refractive index resin layer)

[0155] Titanium oxide particles with an average primary particle size of 35 nm (trade name "TTO-51A", manufactured by Ishihara Sangyo Co., Ltd.) 1.4 parts, KAYARAD DPHA 0.4 parts, 2-methyl-1-[4-(methylthio)phenyl ]-2-morpholinopropan-1-one (BASF Japan Co., Ltd. "IRGACURE 907") 0.05 parts, and dispersant (trade name "DISPERBYK-2001", BYK Chemicals Japan Co., Ltd.) 0.3 parts were added to 7 parts of toluene were dispersed at a peripheral speed of 10 m / s using a bead mill to prepare a high-refractive-index resin coating liquid for forming a high-refractive-index resin layer. The average dispersed particle diameter of the titanium oxide fine particles was 45 nm.

[0156] Next, the high-refractive-index resin coating liquid was applied to the PET base material with a wire bar coater, and the toluene was evaporated by drying at 100° C. for 2 minutes, followed by UV irradiation to produce a high-refractive-index resin layer....

Embodiment 2

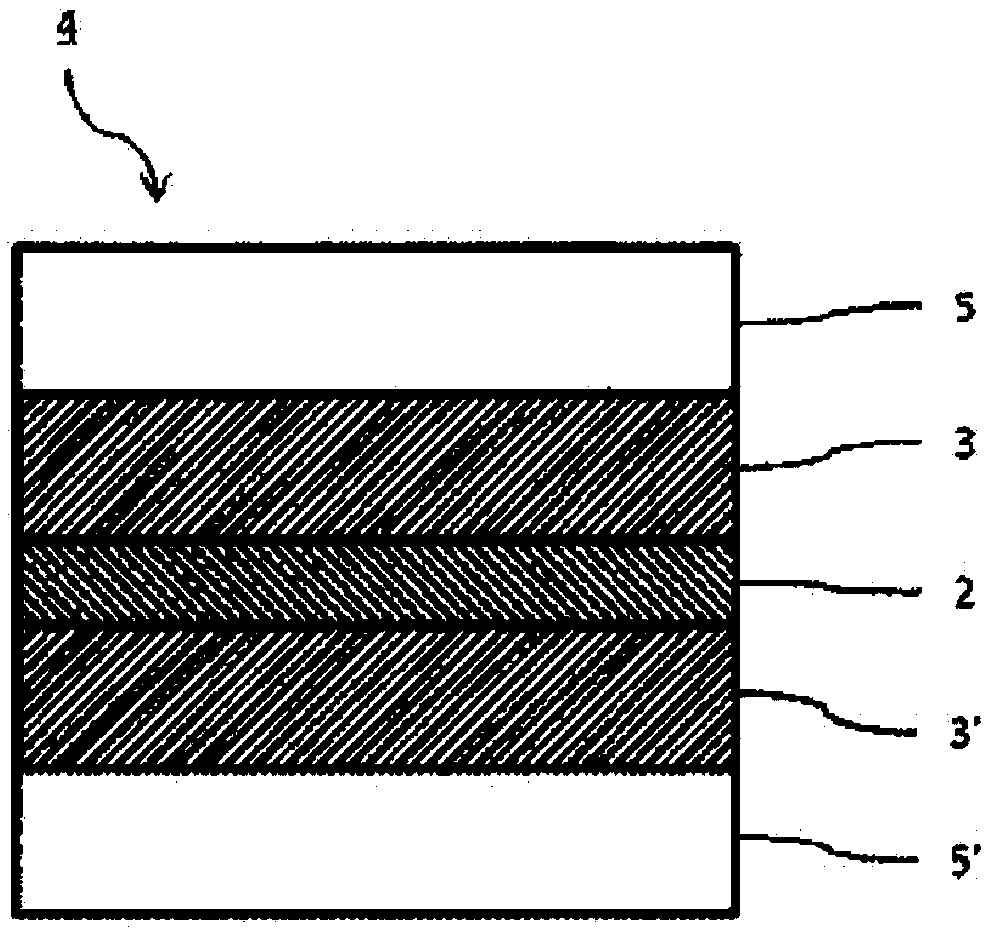

[0171] (Production of interlayer film for laminated glass)

[0172] The PVB film which is a 1st intermediate film was laminated|stacked on the laminated film side of the infrared shielding sheet produced in Example 1, and the laminated body was obtained. The laminated body at a position of 1 mm or less from the end of the infrared shielding sheet on the entire circumference (four sides) is pinched by two laminating heating rolls arranged on the front side and the back side of the obtained laminated body, and the The infrared shielding sheet is bonded to the first intermediate film by thermocompression. At this time, as for the heating roll for lamination, the temperature of the lamination roll on the side of the intermediate film was set at 25° C. so as not to damage the embossing on the back side of the first interlayer film, and on the contrary, the layer on the side of the infrared absorbing dye layer The temperature of the heating roll for pressing was set at 120° C. so a...

Embodiment 3

[0176] Using the interlayer film for laminated glass used in Example 2, glass plate (float flat glass FL3, manufactured by CENTRALGLASS Co., Ltd.) / first interlayer film / infrared shielding sheet / second interlayer film / green glass plate (Green ral MFL3, (manufactured by Central Glass Co., Ltd.) was laminated in the same manner as in Example 2 to produce a laminated glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com