Thermoplastic resin composition and molded article

A technology of thermoplastic resin and composition, which is applied in the direction of antenna, antenna parts, electrical components, etc., can solve the problems of inability to obtain surface hardness, alkali resistance and impact resistance polycarbonate resin composition, etc., and achieve excellent mechanical strength, Excellent impact resistance and excellent alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

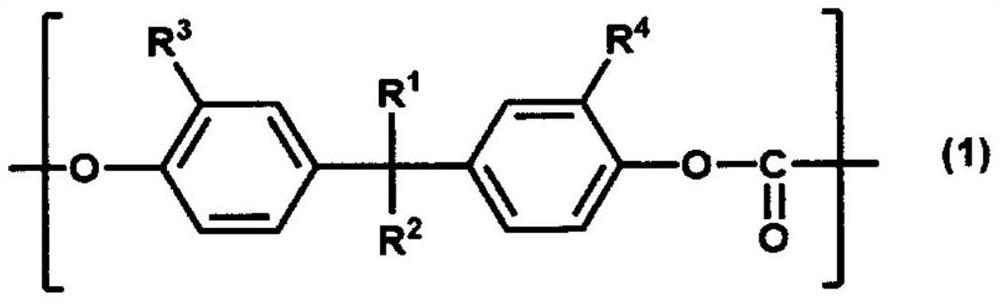

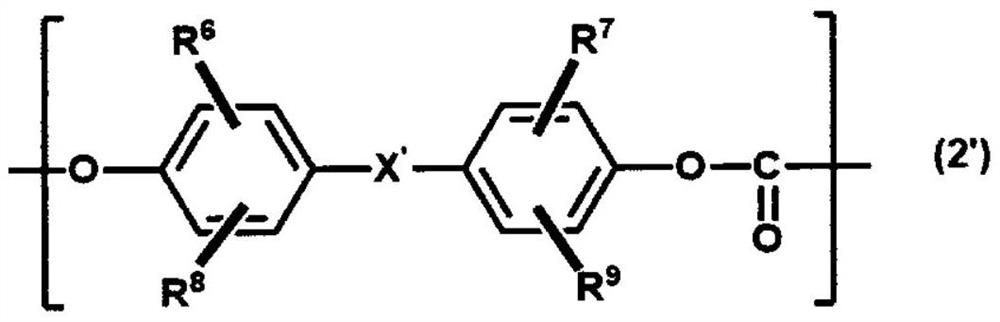

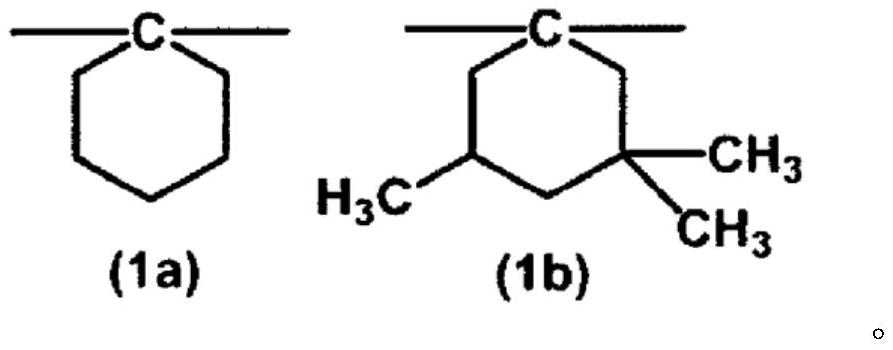

Method used

Image

Examples

Embodiment 1

[0530] Add 4,4-methylenebis(2,6-dimethylphenol) (TmBPF) ( Tokyo Chemical Industry Co., Ltd.) 23.34 g (about 0.091 mol), 2,2-bis(4-hydroxy-3-methylphenyl) propane (BPC) (Honshu Chemical Co., Ltd.) 93.37 g (about 0.364 mol), carbonic acid 99.97 g (about 0.467 mol) of diphenyl ester (DPC) and a 0.4% by mass aqueous solution of cesium carbonate as a catalyst were prepared so that the cesium carbonate contained in 1 mol of all dihydroxy compounds was 3 μmol, and a raw material mixture was prepared.

[0531] Next, the inside of the glass reactor was decompressed to about 50 Pa (0.38 Torr), followed by repressurization to atmospheric pressure with nitrogen, and this operation was repeated three times, and the inside of the reactor was replaced with nitrogen. After nitrogen substitution, the external temperature of the reactor was set at 220° C., and the internal temperature of the reactor was gradually raised to dissolve the mixture. Thereafter the stirrer was rotated at 100 rpm. The...

Embodiment 2

[0536] 46.69 g (about 0.182 mol) of TmBPF (manufactured by Tokyo Chemical Industry Co., Ltd.), 70.02 g (about 0.273 mol) of BPC (manufactured by Honshu Chemical Co., Ltd.), 99.97 g (about 0.467 mol) of DPC, and 0.4% by mass of cesium carbonate as a catalyst The aqueous solution was added so that cesium carbonate was 5 μmol per 1 mol of all the dihydroxy compounds to prepare a raw material mixture, and it was carried out by the method described in Example 1 except that.

[0537] For the polycarbonate resin obtained in this way, each evaluation was implemented by the above-mentioned procedure. The results are shown in Table 1 and Table 3.

Embodiment 3

[0539] 93.37 g (about 0.364 mol) of TmBPF (manufactured by Tokyo Chemical Industry Co., Ltd.), 23.34 g (about 0.091 mol) of BPC (manufactured by Honshu Chemical Co., Ltd.), 99.97 g (about 0.467 mol) of DPC, and 0.4% by mass of cesium carbonate as a catalyst The aqueous solution was added so that cesium carbonate was 8 μmol per 1 mol of all the dihydroxy compounds to prepare a raw material mixture, and it was carried out by the method described in Example 1 except that.

[0540] For the polycarbonate resin obtained in this way, each evaluation was implemented by the above-mentioned procedure. The results are shown in Table 1 and Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com