Injection molding method, injection-molded product, and injection mold

A technology of injection molding and molded products, which is applied in household appliances, other household appliances, thin material processing, etc., and can solve problems such as difficulty in suppressing dents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0038] (structure)

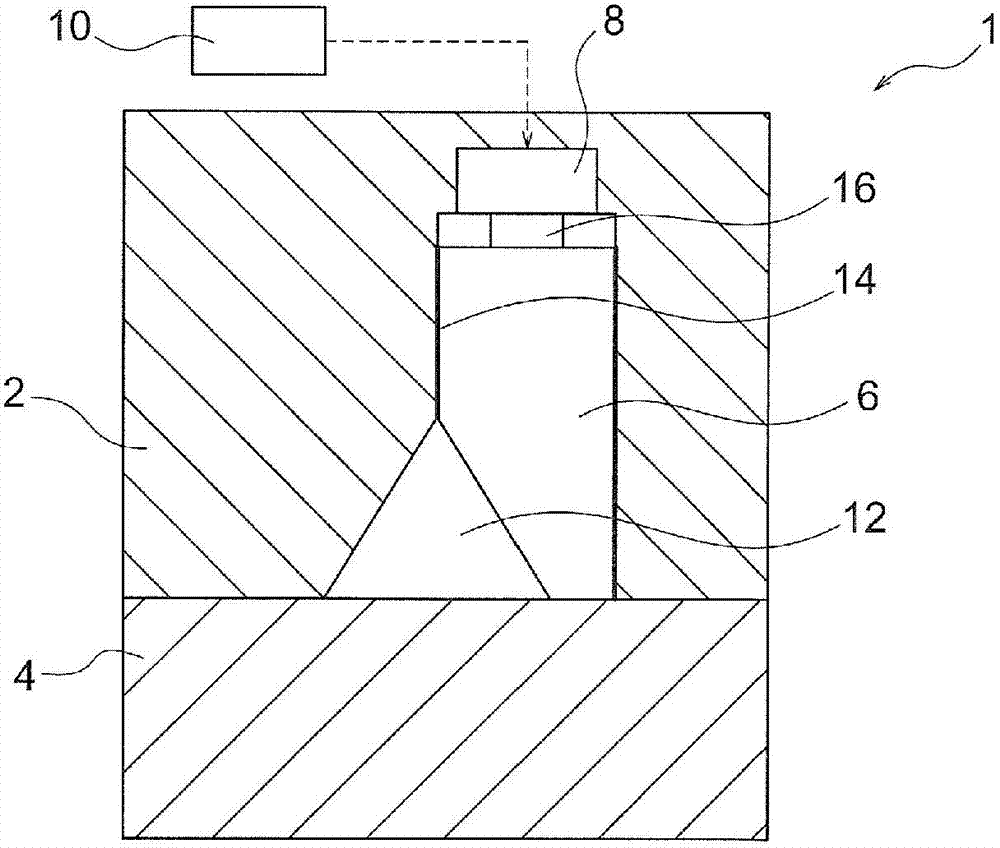

[0039] First, combine figure 1 The structure of the injection molding die in the first embodiment will be described.

[0040] figure 1 It is a figure which shows the schematic structure of the injection molding die 1, and is a cross-sectional view of the injection molding die 1. FIG.

[0041] figure 1 The injection molding mold 1 shown in the figure is to inject molten resin into the molding space (cavity) formed between a set of molds when a set of molds capable of closing and opening the molds is in a closed state, and make the mold A device for manufacturing injection molded products by solidifying injected molten resin. In addition, the description related to the molding space will be described later.

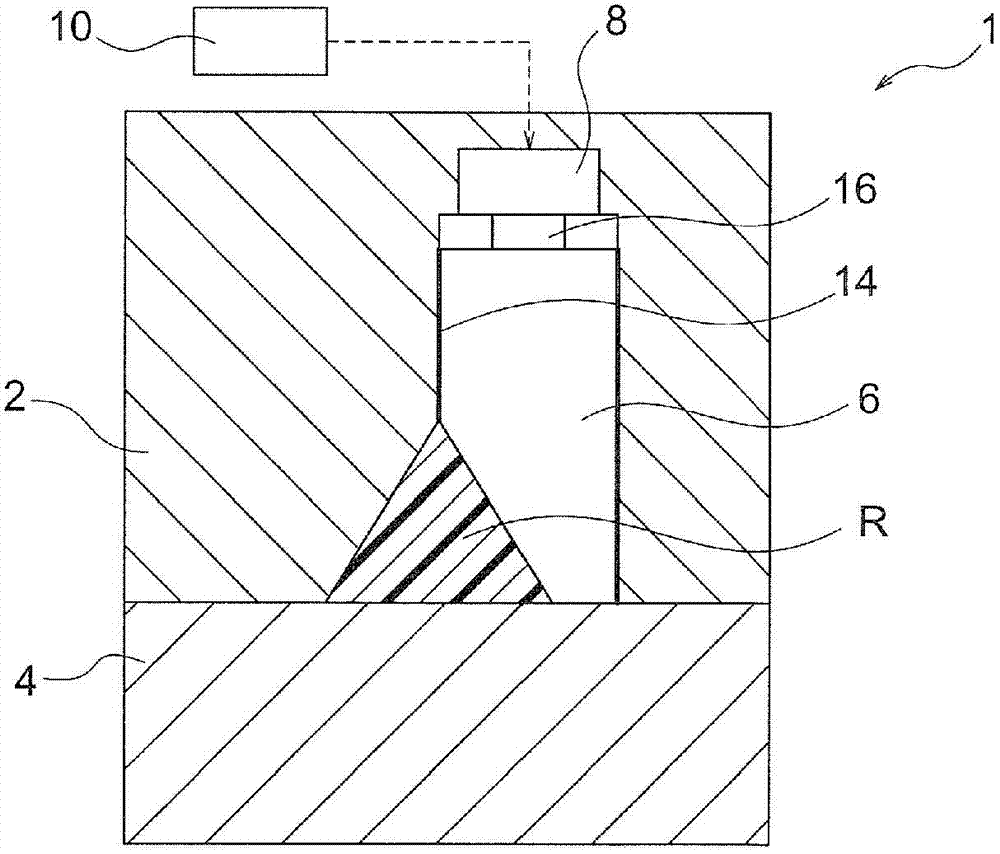

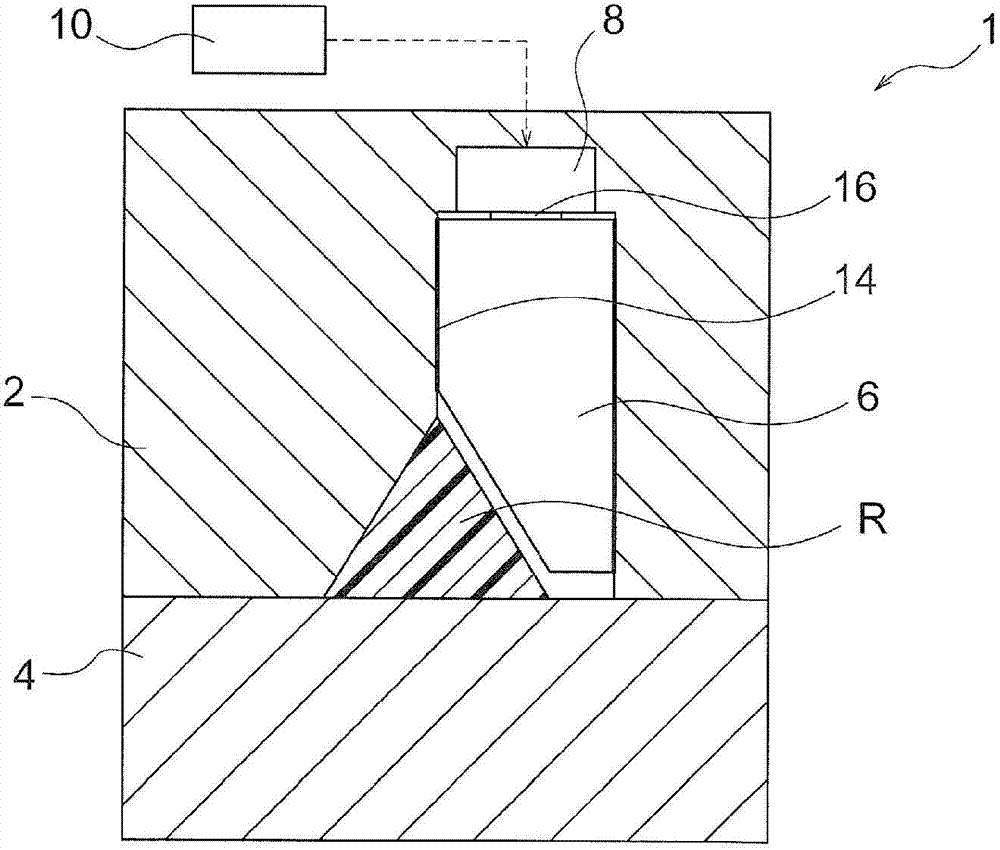

[0042] Here, in the first embodiment, the case where the injection molded product has light transparency and has a cross-sectional shape of an equilateral triangle or a prism approximately equilateral triangle will be described as an example. This...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com