Negative electrode for power storage device, power storage device, and electrical device

a technology of power storage device and negative electrode, which is applied in the direction of non-aqueous electrolyte accumulator electrode, cell components, electrical apparatus, etc., can solve the problems of promoting the deterioration of the power storage device, and achieve excellent cycle characteristics, high charge and discharge efficiency, and high capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0046]In this embodiment, a negative electrode and an electrolyte and solvent of an electrolytic solution that are used in a power storage device of one embodiment of the present invention will be described. In addition, a method for fabricating a negative electrode will be described.

[Negative Electrode Structure 1]

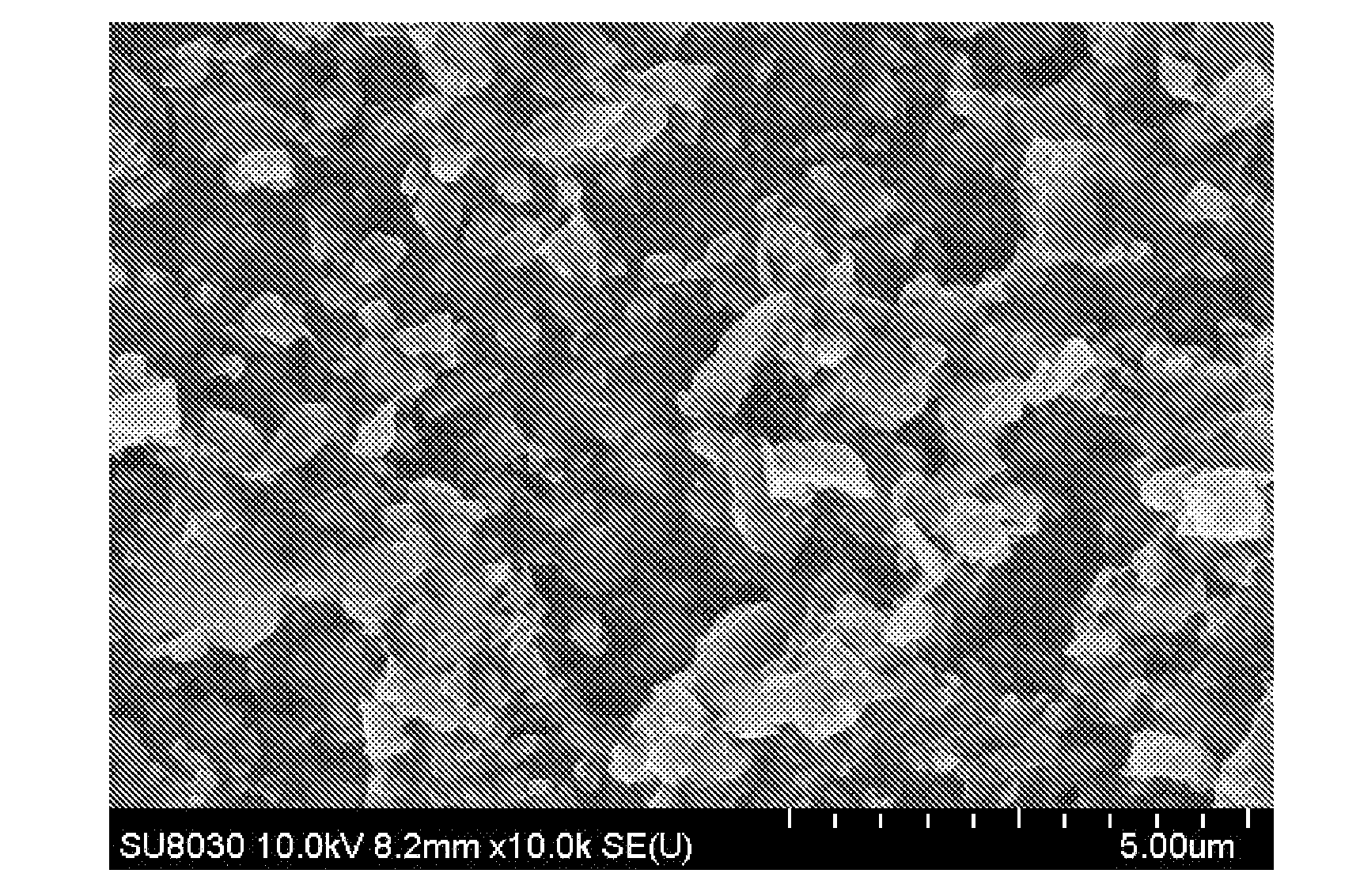

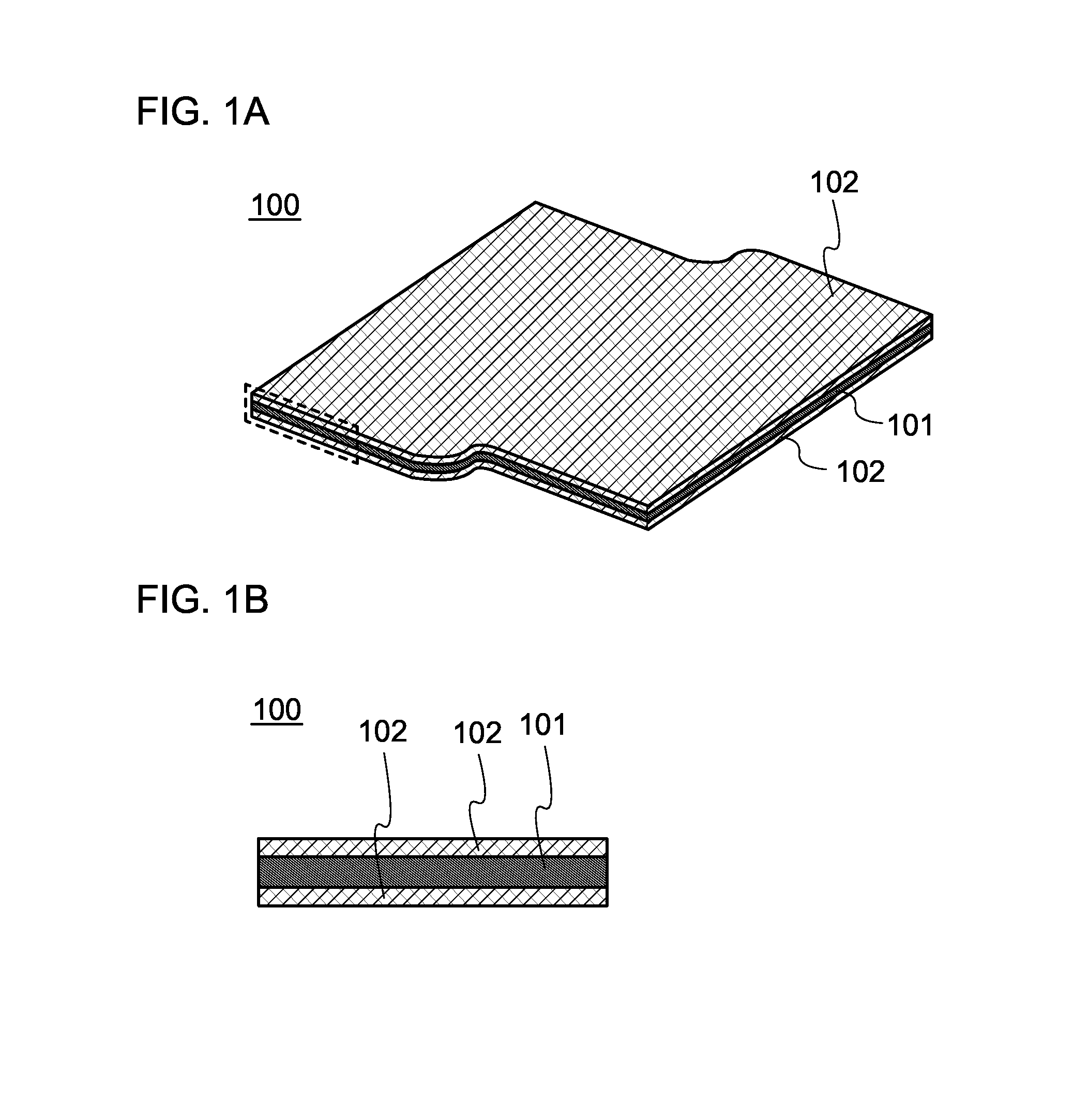

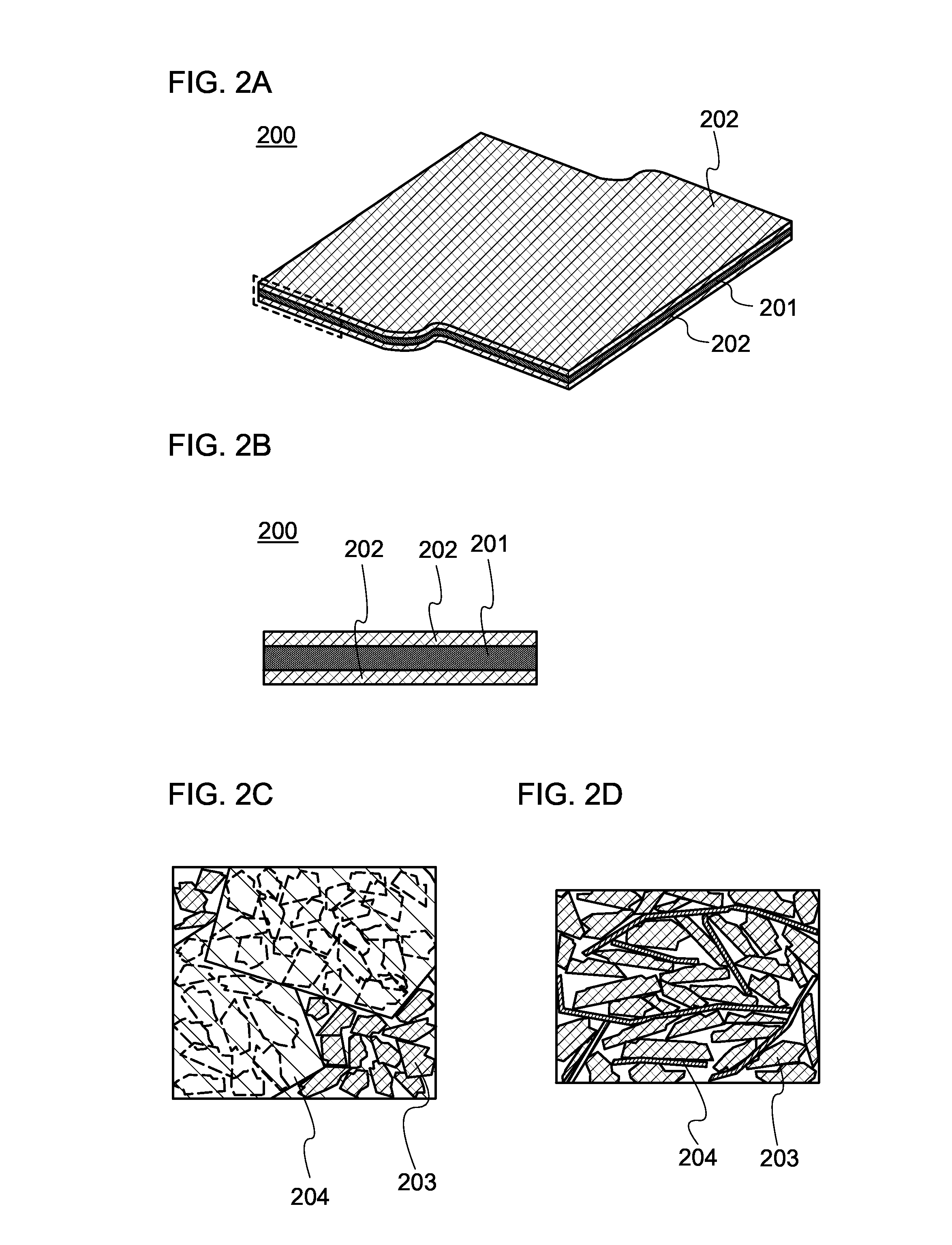

[0047]FIG. 1A is an overhead view of a negative electrode, and FIG. 1B is a cross-sectional view of a portion surrounded by a broken line in FIG. 1A. A negative electrode 100 has a structure in which a negative electrode active material layer 102 is provided over a negative electrode current collector 101. Although the negative electrode active material layers 102 are provided so that the negative electrode current collector 101 is sandwiched therebetween in FIGS. 1A and 1B, the negative electrode active material layer 102 may be formed over only one surface of the negative electrode current collector 101. The negative electrode active material layer 102 includes a negati...

embodiment 2

[0112]In this embodiment, the structure of a power storage device including the negative electrode fabricated by the fabricating method described in Embodiment 1 will be described with reference to FIGS. 11A to 11C, FIGS. 12A and 12B, FIG. 13, and FIGS. 14A and 14B. Structural examples of power storage devices (storage batteries) will be described with reference to FIGS. 15A and 15B, FIGS. 16A and 16B, FIGS. 17A to 17C, FIGS. 18A to 18C, and FIGS. 19A and 19B. Examples of electrical devices will be described with reference to FIGS. 20A1 to 20B2.

[Coin-type Storage Battery]

[0113]FIG. 11A is an external view of a coin-type (single-layer flat type) storage battery, and FIG. 11B is a cross-sectional view thereof.

[0114]In a coin-type storage battery 300, a positive electrode can 301 doubling as a positive electrode terminal and a negative electrode can 302 doubling as a negative electrode terminal are insulated from each other and sealed by a gasket 303 made of polypropylene or the like. ...

example 1

[0185]In this example, half cells were fabricated using the negative electrode described in Embodiment 1 and measurement of the half cells was performed.

[0186]Silicon wafers were ground. Table 1 shows samples of the ground silicon as Samples A to H and Comparative Sample I. The silicon wafers used had n-type conductivity / p-type conductivity and resistivities shown in Table 1. The plane directions of the silicon wafers in Table 1 are all the (100) plane. First, each of the silicon wafers was cut into 6-cm squares and ground in a mortar. After that, grinding was further performed in a ball mill with a ball diameter of 3 mm under the conditions of RPM and treatment time that are shown in Table 1. Balls and the silicon ground in a mortar were put in a 54-ml ball mill. The weight of the balls is 22 g, and the weights of silicon are as follows: Samples A, E, H: 2 g; Samples B, C, D, F, G: 4 g; and Comparative Sample I: 8 g. Acetone was used as a solvent. The size of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| resistivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com