Special grinding machine for sucker rod

A special grinding machine and sucker rod technology, applied in the direction of grinding machine, abrasive belt grinder, grinding bed, etc., can solve the economic loss, can not solve the problems of water leakage, oil leakage, gas leakage, affecting the civilized production of oil fields, etc. Thick and thin effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and embodiment the present invention is further described

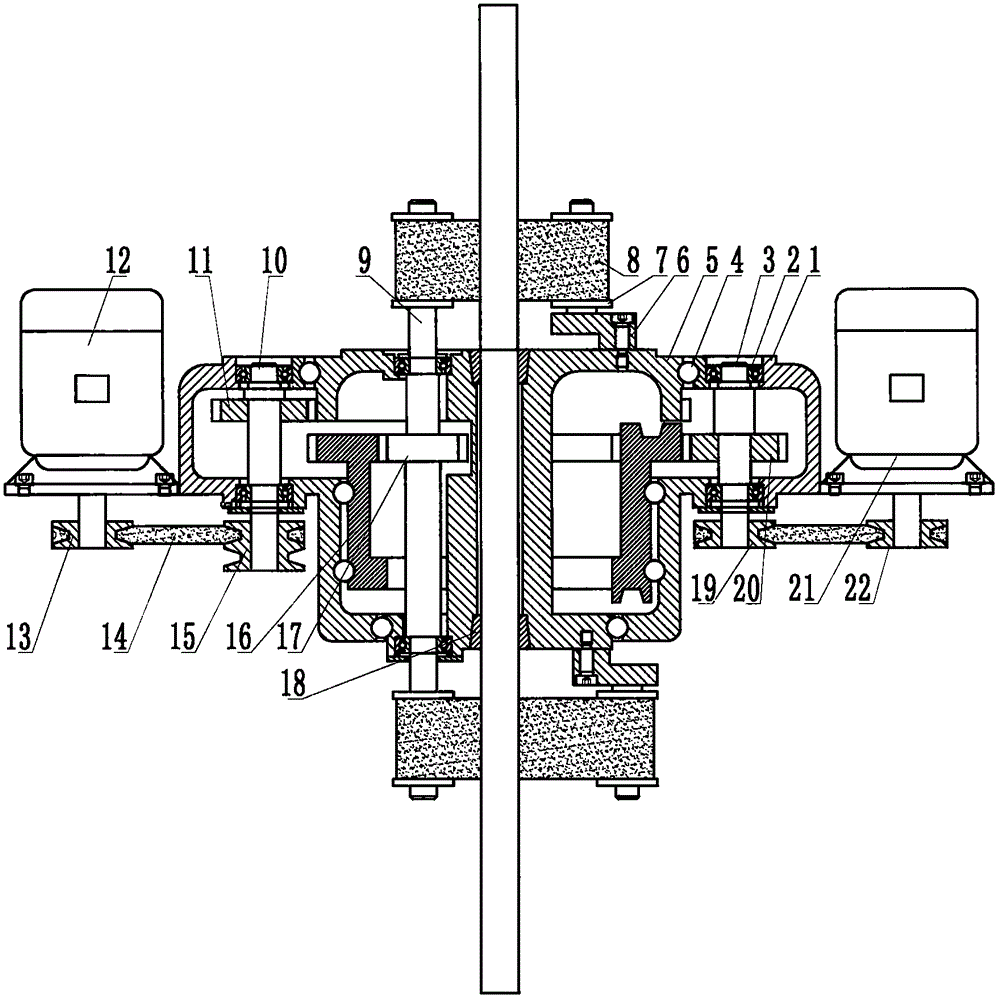

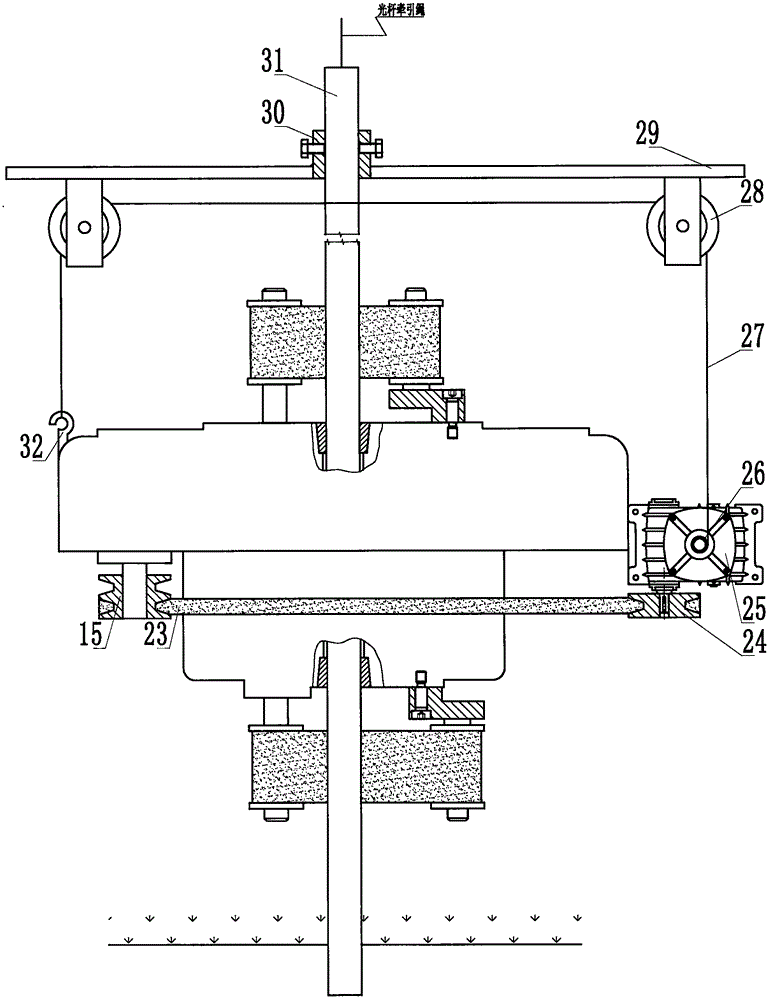

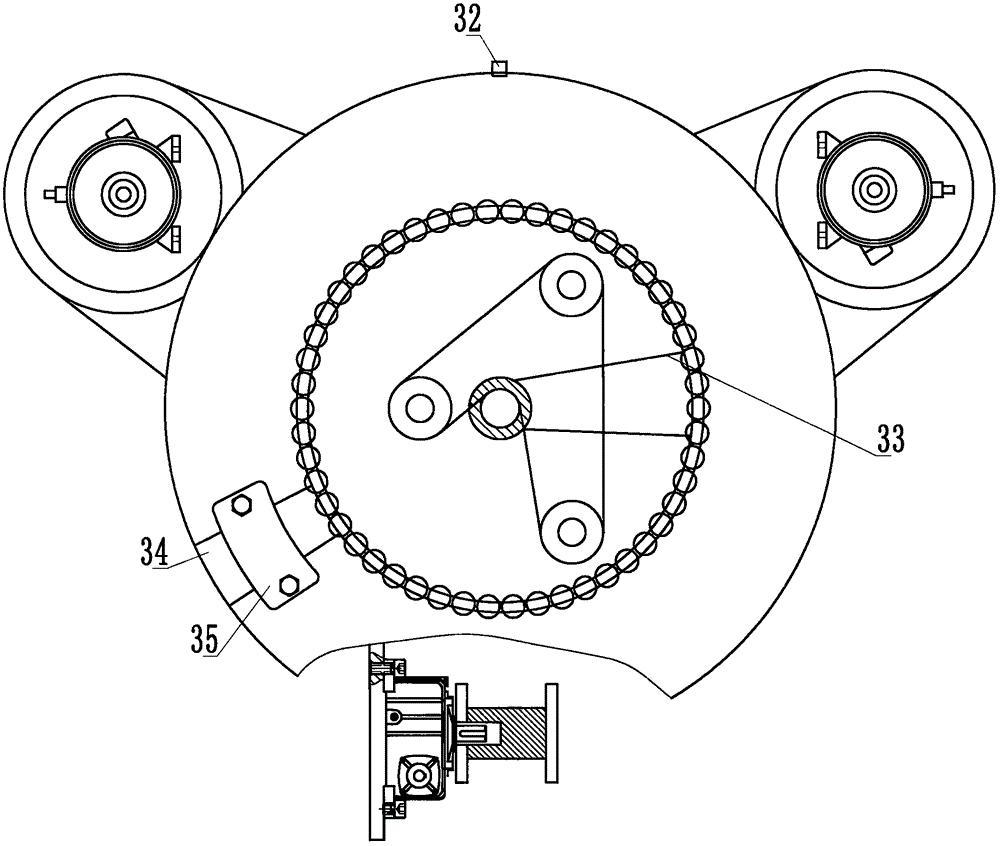

[0011] Such as Figure 1-Figure 3 As shown, the special grinding machine for sucker rods has the following structure: the shell 1 is a hollow circular table shell made of metal, and the inner circle of the shell 1 is provided with arc-shaped chutes for installing balls on the top, middle and bottom respectively. The outer upper end of the casing 1 is provided with a wire rope hook 32, and the upper end of the outer casing 1 is provided with an opening 2 34; the outer casing 1 is respectively equipped with a vertical motor 1 12, a vertical motor 2 21 and a worm gear reducer 25, and the vertical motor One 12 lower end is equipped with belt pulley one 13, vertical motor two 21 lower ends are equipped with belt pulley three 22; The position corresponding to the vertical motor 2 21 is provided with a shaft 3, the upper and lower ends of the shaft 3 are slidingly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com