Tubular ventilation device, control method thereof and air conditioner which uses tubular ventilation device

A technology for ventilation devices and cross-flow fans, which is applied in heating and ventilation control systems, airflow control components, ventilation systems, etc., and can solve problems such as irreversible air inlet and outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

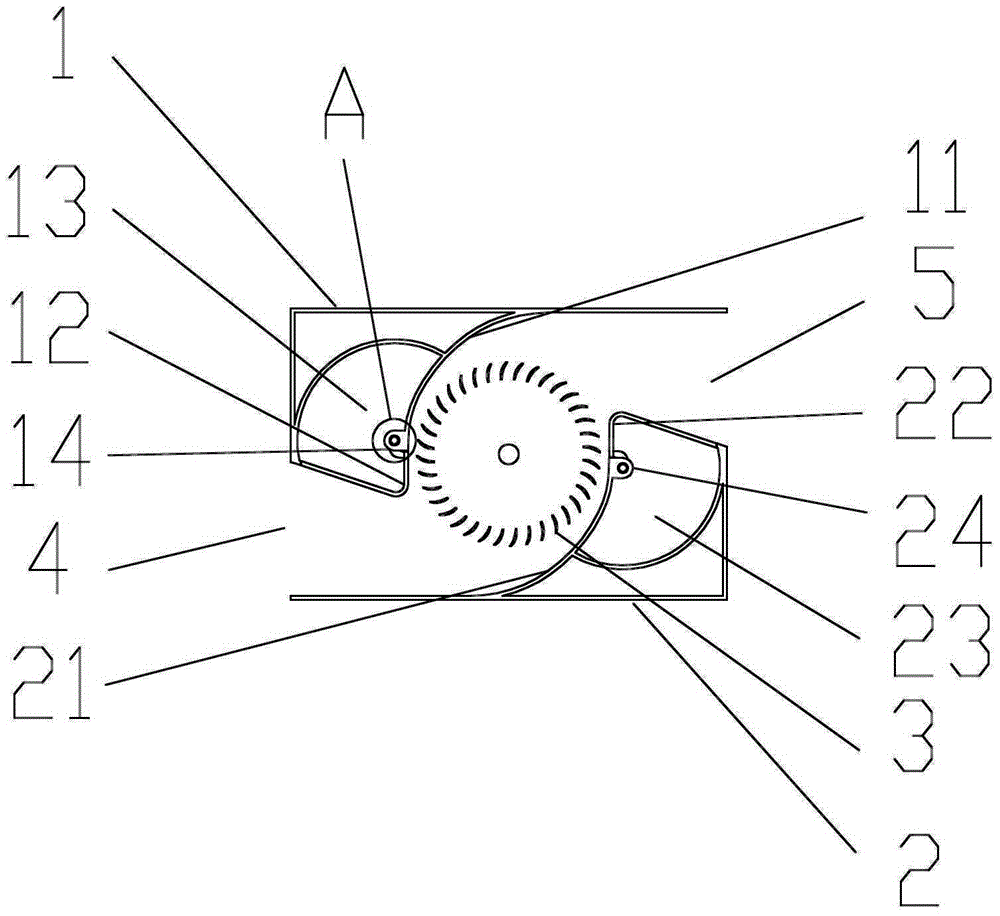

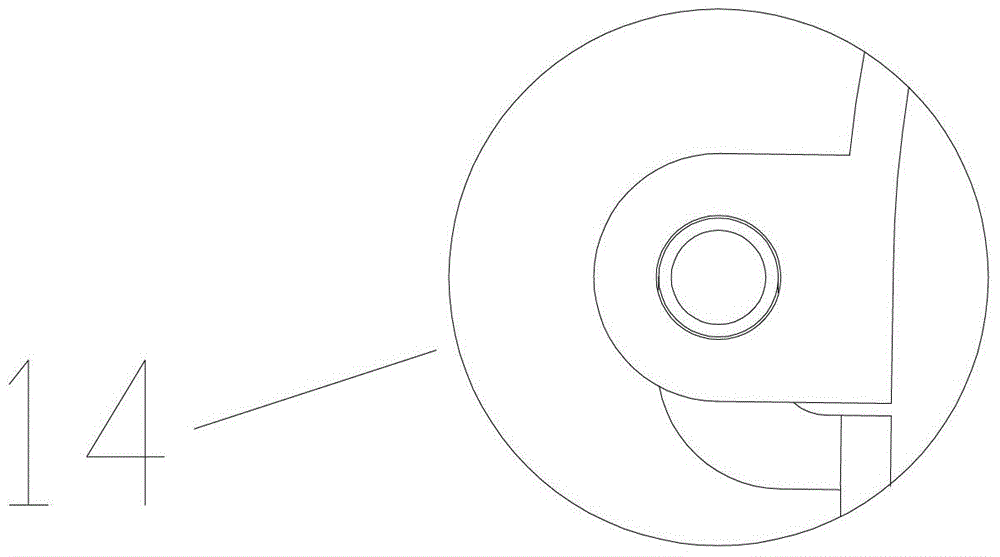

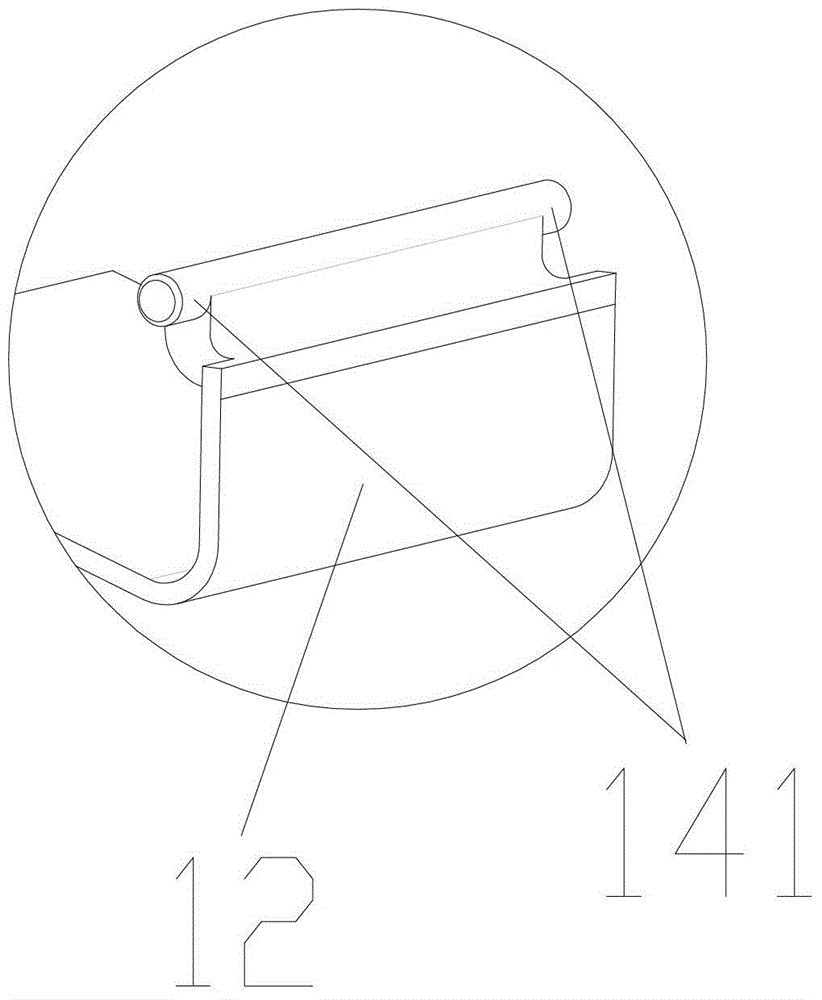

[0024] See figure 1 , the cross-flow ventilation device of the present embodiment includes an outer casing and a cross-flow fan 3 disposed in the outer casing, the outer casing includes a first casing 1 and a second casing 2, and the first casing 1 and the second casing The body 2 encloses a first vent 4 and a second vent 5 respectively. The first housing 1 includes a first volute 11, a first volute tongue 12, and a first volute tongue adjustment groove 13; the second housing 2 includes a second volute 21, a second volute tongue 22, a second Worm tongue adjustment groove 23. The first volute 11 is movably connected with the first volute tongue 12, so that the first volute tongue 12 has a working position and a hidden reversing position by moving along the first volute tongue adjustment groove 13; the second volute 21 and the second volute tongue 22 are movably connected, so that the second volute tongue 22 has a working position, and the hidden waiting for moving along the s...

Embodiment 2

[0034] Compared with the first embodiment, this embodiment is mainly different in the movable connection mode of the volute case and the volute tongue, and other components or structures are common, so no more details are given here.

[0035] In this embodiment, the first volute 11 and the first volute tongue 12 are movably connected through a first sliding assembly; the second volute 21 and the second volute tongue 22 are movably connected through a second sliding assembly. The first sliding assembly includes a first sliding groove provided on the first volute 11 and a first sliding block arranged on the first volute tongue 12, and the sliding block is matched with the sliding groove. By driving the first slider to move on the first chute, the first volute tongue 12 moves to the working position or the waiting position; and drives the second sliding assembly in the same way, so that the second volute tongue 22 moves to the waiting position correspondingly Or the working posit...

Embodiment 3

[0038] In order to further increase the scope of application of the cross-flow ventilation device, this technical solution can also be applied to a cross-flow ventilation device with more than two ventilation openings.

[0039] In this embodiment, each ventilation port needs to be provided with a volute tongue and a volute that are flexibly connected. By controlling part of the volute tongue to be in the waiting position and the other part of the volute tongue to be in the working position in a targeted manner, to meet the requirements for entering and exiting. Air volume requirements and / or different requirements for inlet and outlet locations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com