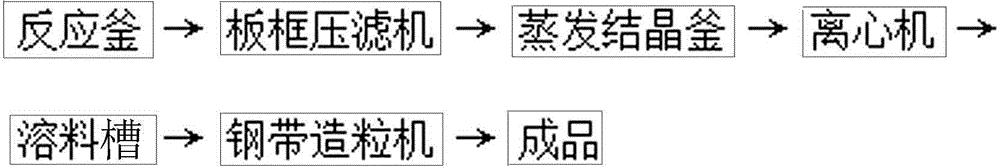

Method for producing full-water-soluble flaky magnesium nitrate through steel belt granulator

A technology of magnesium nitrate and granulator, applied in directions such as magnesium nitrate, can solve problems such as poor water solubility, easy agglomeration and purity of magnesium nitrate, achieve the effects of improving water solubility and content, facilitating storage and transportation, and solving poor water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

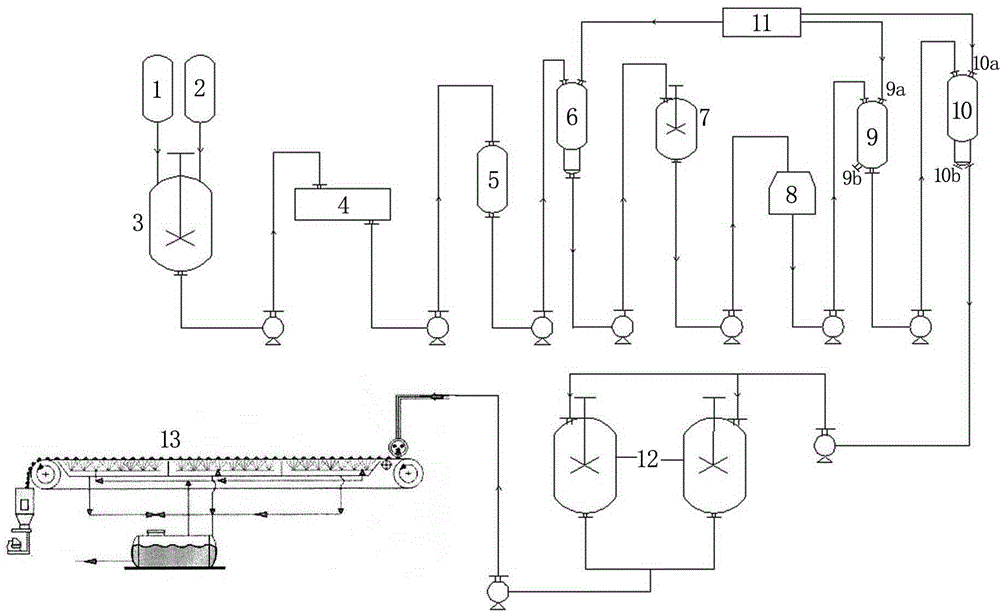

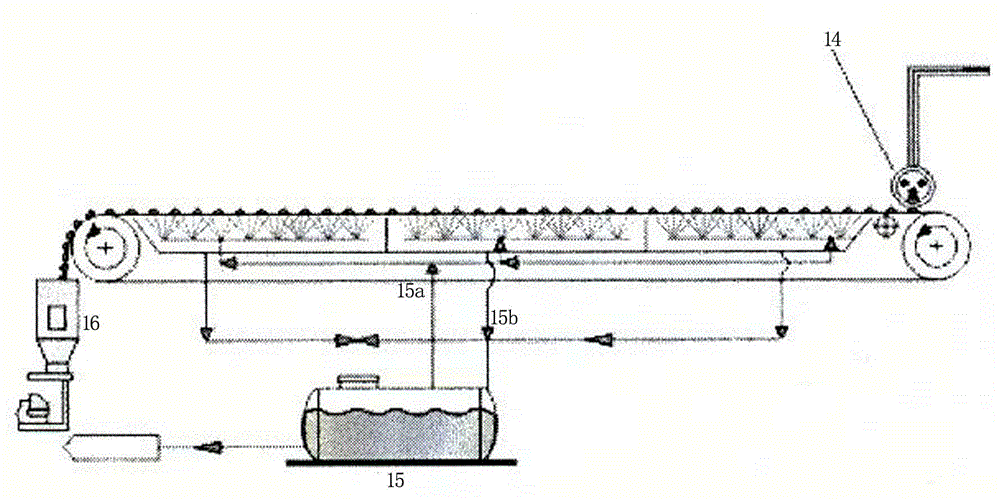

[0012] Example 1 A method for producing fully water-soluble flaky magnesium nitrate using a steel belt granulator, comprising the following steps: (a) adding magnesium oxide and nitric acid to the reaction kettle at a molar ratio of 1:2 for neutralization reaction, and nitric acid solution The concentration is 40%, the temperature is controlled at 80°C and the reaction is stirred for 1.5 hours, and then the pH of the reaction solution is adjusted to 6.5 with magnesium oxide; (b) The obtained magnesium nitrate neutralization solution is filtered into a plate and frame filter press to obtain a transparent filtrate; ( c) Pump the filtrate into the primary evaporator for evaporation and concentration, and evaporate to a specific gravity of 1.200g / cm 3 (d) Pump the concentrated magnesium nitrate solution into the cooling crystallization tank, add dilute nitric acid with a concentration of 42% to adjust the pH of the solution to 3, stir and cool, and white magnesium nitrate crystals ...

Embodiment 2

[0015] Example 2 A method for producing fully water-soluble flaky magnesium nitrate using a steel belt granulator, comprising the following steps: (a) adding magnesium oxide and nitric acid to the reaction kettle at a molar ratio of 1:2 for neutralization reaction, and nitric acid solution The concentration is 42%, the temperature is controlled at 78°C and the reaction is stirred for 2.0 hours, and then the pH of the reaction solution is adjusted to 7.0 with magnesium oxide; (b) The magnesium nitrate neutralization solution obtained is filtered by a plate and frame filter press to obtain a transparent filtrate; ( c) Pump the filtrate into the primary evaporator for evaporation and concentration, and evaporate to a specific gravity of 1.300g / cm 3 (d) Pump the concentrated magnesium nitrate solution into the cooling crystallization tank, add dilute nitric acid with a concentration of 40% to adjust the pH of the solution to 3.5, stir and cool, when the circulating water cools down...

Embodiment 3

[0018] Example 3 A method for producing fully water-soluble flake-shaped magnesium nitrate using a steel belt granulator, comprising the following steps: (a) adding magnesium oxide and nitric acid to the reaction kettle at a molar ratio of 1:2 for neutralization reaction, and nitric acid solution The concentration is 41%, the temperature is controlled at 70°C and the reaction is stirred for 2.5 hours, and then the pH of the reaction solution is adjusted to 7.5 with magnesium oxide; (b) The magnesium nitrate neutralization solution obtained is filtered into a plate and frame filter press to obtain a transparent filtrate; ( c) Pump the filtrate into the primary evaporator for evaporation and concentration, and evaporate to a specific gravity of 1.320g / cm 3 (d) Pump the concentrated magnesium nitrate solution into the cooling crystallization tank, add dilute nitric acid with a concentration of 38% to adjust the pH of the solution to 5, stir and cool, and white magnesium nitrate cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com