Dynamic-static pressure lubricating type flow distribution plate

A flow plate, dynamic and static pressure technology, applied in the field of hydraulic components, can solve the problems affecting the reliability and service life of the plunger pump, increase leakage and other problems, achieve the effect of long arm, reduce leakage and enhance the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

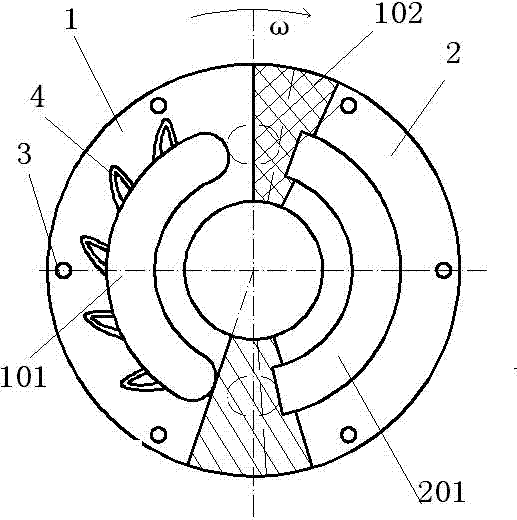

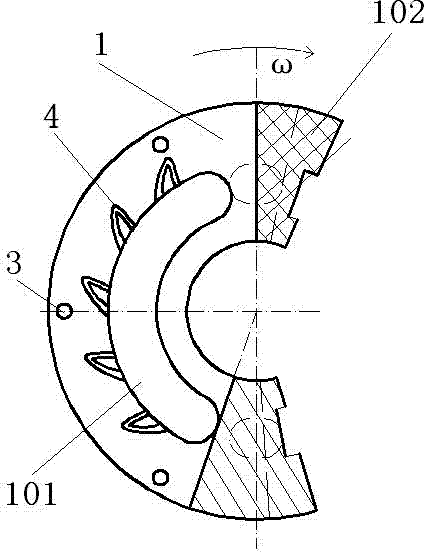

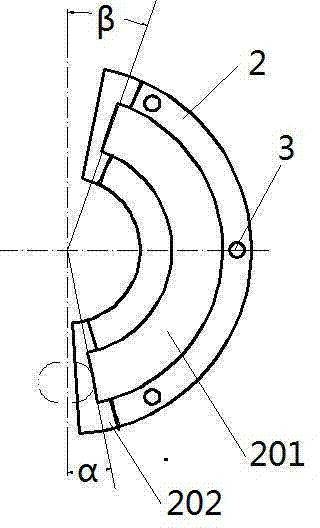

[0016] Embodiment 1: A dynamic and static pressure lubricated distribution plate, which is disc-shaped as a whole, see figure 1 , including a waist-shaped high-pressure oil discharge port 101 on one side, a waist-shaped low-pressure oil suction port 201 isolated from the former on the other side, and an installation positioning hole 3 near the outer peripheral side. The plunger pump flow plate is divided into blocks by oil discharge 1 and the oil-absorbing block 2 are spliced together, and the oil-discharging block 1, see figure 2 , greater than oil-absorbing block 2, see image 3 and Figure 4 , the splicing positions are respectively located at the beginning and end edges of the waist-shaped low-pressure oil suction port 201, and the upper joint 102 of the oil discharge block 1 is overlapped above the lower joint 202 of the oil suction block, and the outer diameter of the plunger pump distribution plate The outer diameter of the end face of the corresponding rotor cylin...

Embodiment 2

[0017] Embodiment 2: The structural principle is the same as that of Embodiment 1, and the difference is that the upper joint 102 of the oil discharge block 1 is overlapped above the lower joint 202 of the oil suction block, and the unloading area of the upper joint 102 of the oil discharge block is a downward slope , the slope is 0.5°, the highest point of the slope starts from the center line of the upper dead zone, and descends to the minimum thickness of the upper joint 103 of the oil discharge block, that is, the lowest point of the lower slope, as shown in the grid area; the oil discharge block The preloading area of the upper joint 103 is an upward slope with a slope of 1°. The lowest point of the slope begins at the minimum thickness of the upper joint of the oil discharge block, and ends at the tangent line of the edge line at the beginning of the high-pressure oil discharge port, that is, the highest point of the upper slope. See The hatched area in the figure. T...

Embodiment 3

[0019] Embodiment 3: The structural principle is the same as that of Embodiment 2, the upper joint 102 of the oil discharge block 1 is overlapped above the lower joint 202 of the oil absorption block, and the unloading area of the upper joint 102 of the oil discharge block is a downward slope with a slope of - 0.5°, the highest point of the slope starts from the center line of the upper dead zone, and descends to the minimum thickness of the upper joint 103 of the oil discharge block, that is, the lowest point of the lower slope, as shown in the grid area in the figure; the upper joint 103 of the oil discharge block The preloading area of the pump is an upward slope with a slope of 0.5°. The lowest point of the slope starts from the minimum thickness of the upper joint of the oil discharge block, and ends at the tangent line of the edge line at the beginning of the high-pressure oil discharge port, that is, the highest point of the upward slope, as shown in the figure. Slas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com