Electric turning device for piston compressor

A technology for electric cranking and compressors, which is applied to electromechanical devices, electric components, machines/engines, etc., can solve the problems of burning motors, small space, and small footprint of the cranking device, so as to avoid damage and structure. Compact, overall safety-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

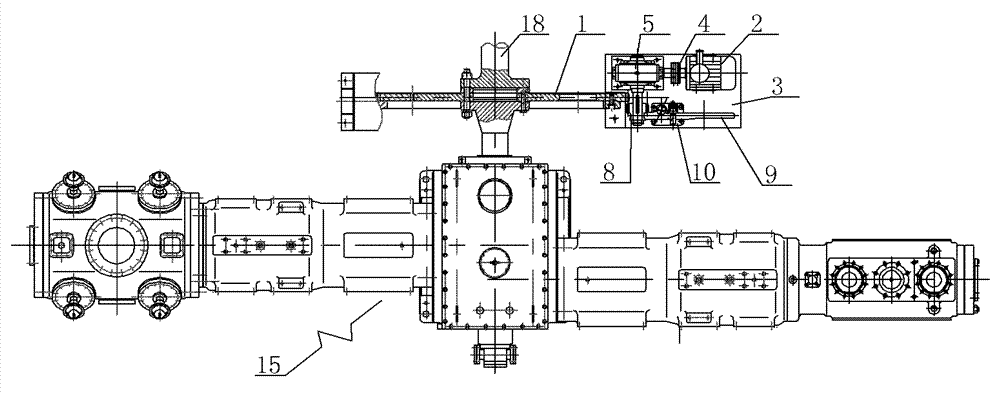

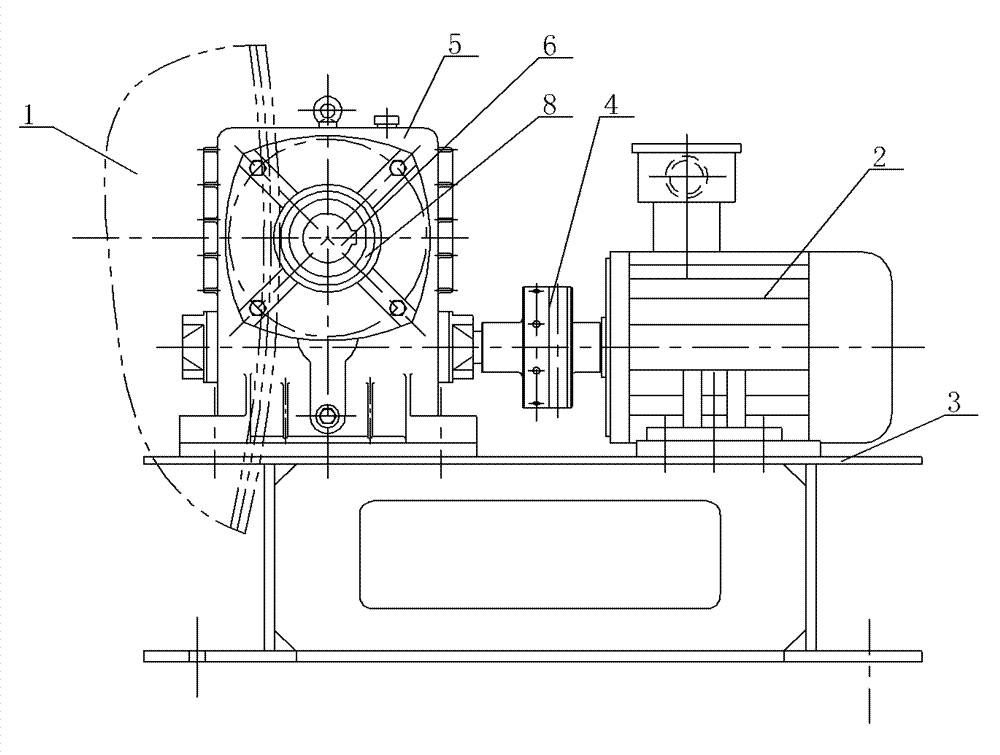

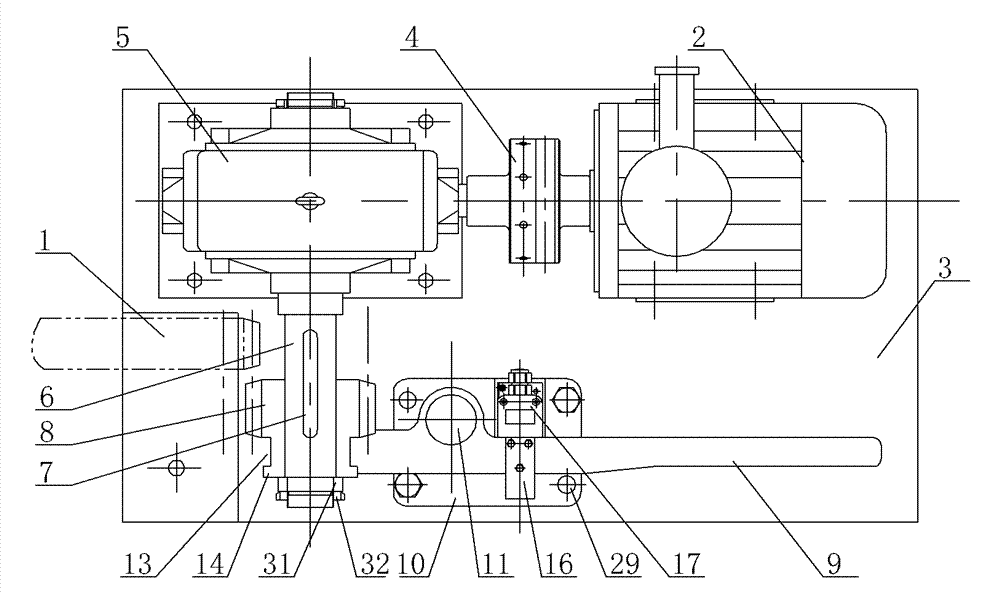

[0022] An electric cranking device for a piston compressor, see Figure 1 to Figure 8 : It includes a crank gear 1, a crank motor 2, and a base 3, the crank motor 2 is supported on the base 3, the crank motor 2 is specifically an explosion-proof motor, and the output end of the crank motor 2 is connected to one end of the overrunning clutch 4, The other end of the overrunning clutch 4 is connected to the input end of the worm gear reducer 5, and the worm gear reducer 5 is supported on the base 3. The exposed output part of the worm gear reducer 5 is specifically the sliding shaft 6, and the front end of the exposed part of the sliding shaft 6 passes through The set of flat key 7 is connected with pinion 8, and pinion 8 can slide axially along the flat key 7. One side of pinion 8 is arranged with lever 9,

[0023] A lever seat 10 is arranged on the base 3, and the lever 9 is positioned on the lever seat 10 through the rotating shaft 11. The upper end surface of the inner side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com