Automatic conveying system of large equipment coating line

A conveying system and large-scale equipment technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of spraying quality, workpiece shaking, low work efficiency, etc., to achieve high transfer efficiency, accurate arrival position, and land occupation small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

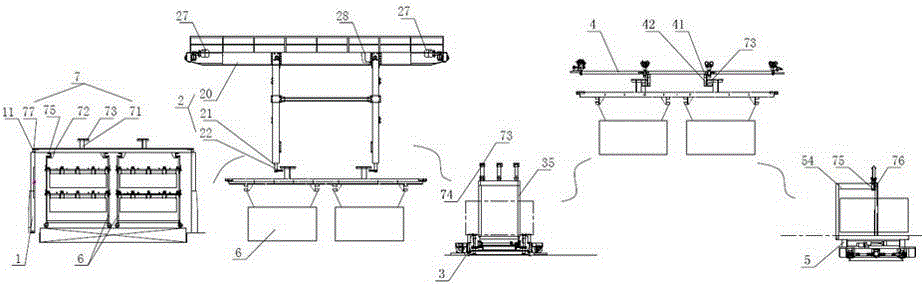

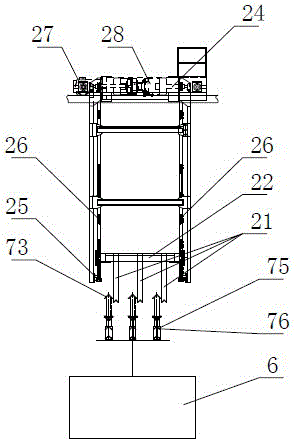

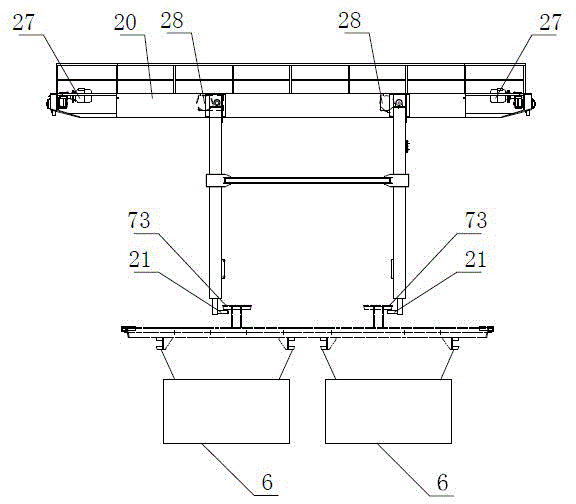

[0021] Such as figure 1 As shown, the present invention provides an automatic conveying system for a large-scale equipment coating line, which includes a workpiece storage rack 1, a program-controlled conveyor 2, a rolling bed conveyor 3, and a friction accumulation chain conveyor line 4 arranged in sequence from front to back And the spreader workpiece separation device 5 that is positioned at the rear of the friction accumulation chain conveyor line 4, the workpiece storage rack 1 is connected with a spreader transfer frame 7, and the workpiece storage rack 1 is used to hold the workpiece bracket, and its specific structure is a prior art , not to go into details here, the spreader transfer frame 7 is connected with the workpiece bracket 6, the top of the spreader transfer frame 7 is equipped with an upwardly extending lifting arm 71, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com