Automobile hub spraying device

A technology of automobile wheel hub and spraying device, applied in the direction of spraying device, etc., can solve problems such as affecting the health of workers, easily absorbing paint mist exhaust gas, spraying dead corners, etc., achieving the effect of good spraying effect, high degree of automation, and guaranteeing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

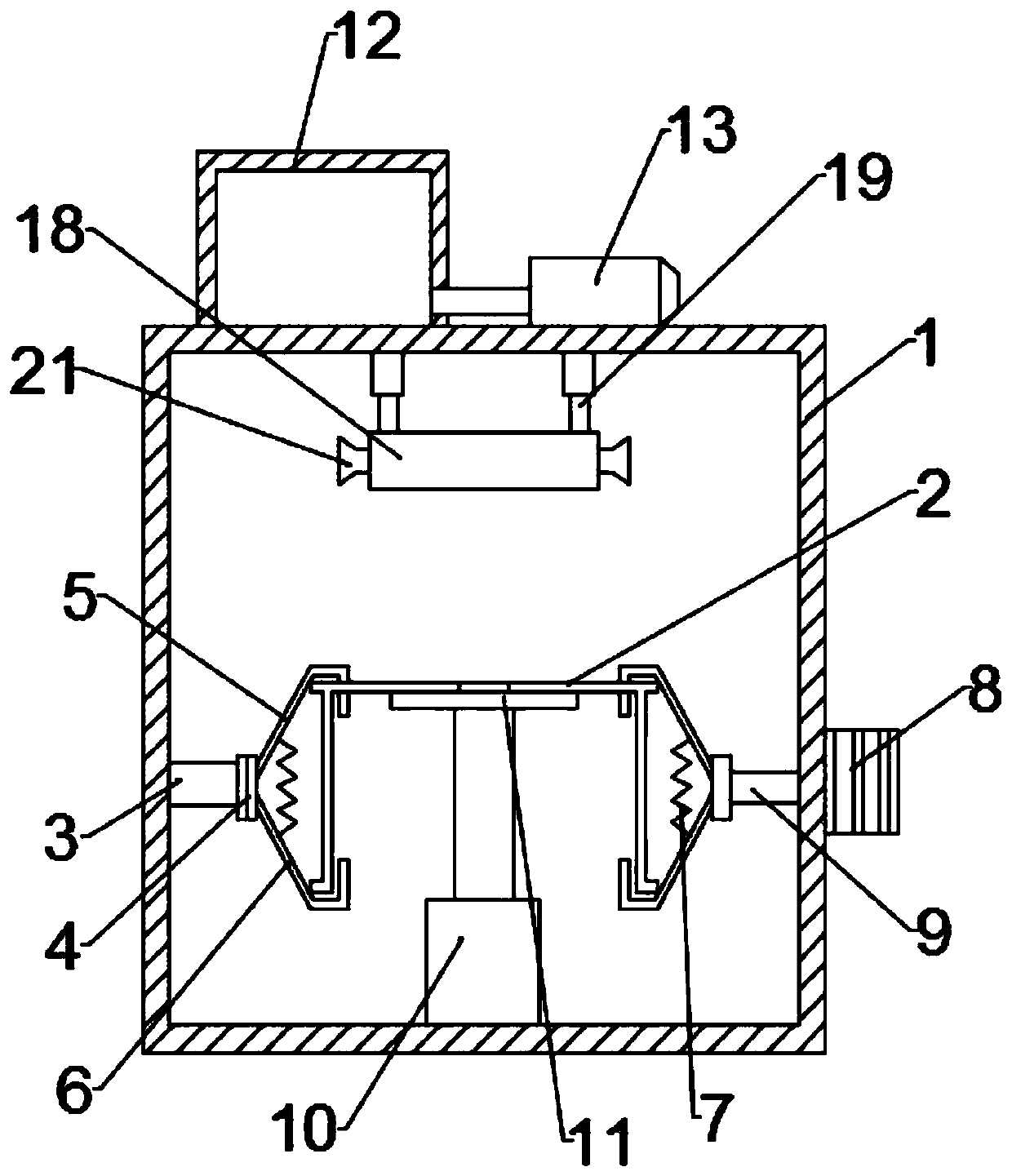

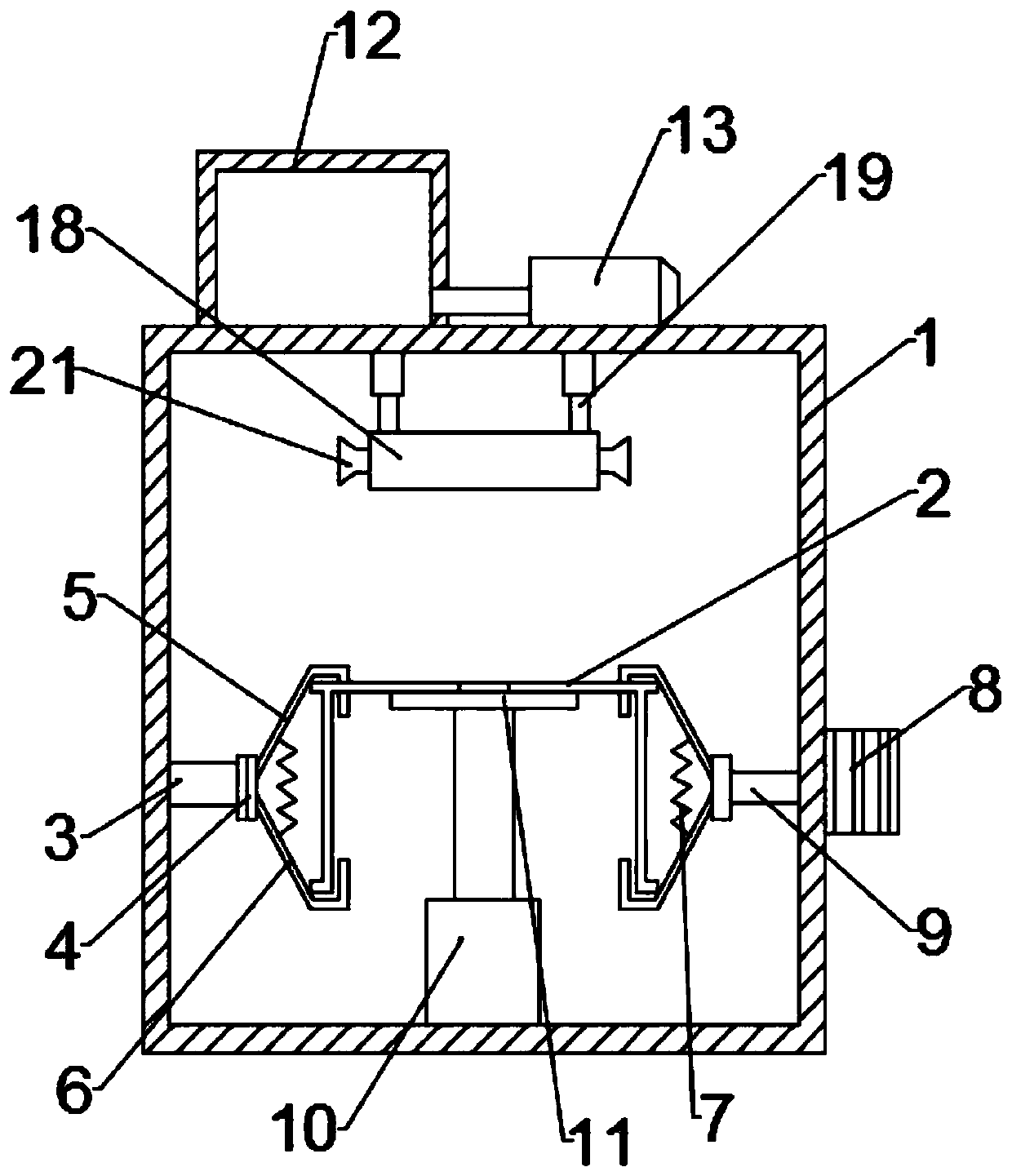

[0029] see figure 1 , in one embodiment provided by the present invention, a kind of automobile hub spraying device, comprises box body 1, and the inside of described box body 1 has: the reversible fixing mechanism that is used for installing automobile wheel hub 2, is used for described automobile wheel hub 2 multi-angle spraying mechanism for spraying; the multi-angle spraying mechanism includes a straight paint collection pipe 15 and an annular paint collection pipe 18, and the straight paint collection pipe 15 is located inside the annular paint collection pipe 18; The multi-angle spraying mechanism is located above the reversible fixing mechanism.

[0030] The automobile wheel hub spraying device has a high degree of automation and good spraying effect. First, the automobile wheel hub 2 is fixed by a reversible fixing mechanism, and then the surface of the automobile wheel hub 2 is sprayed by using a multi-angle spraying mechanism. Since the multi-angle spraying mechanism...

Embodiment 2

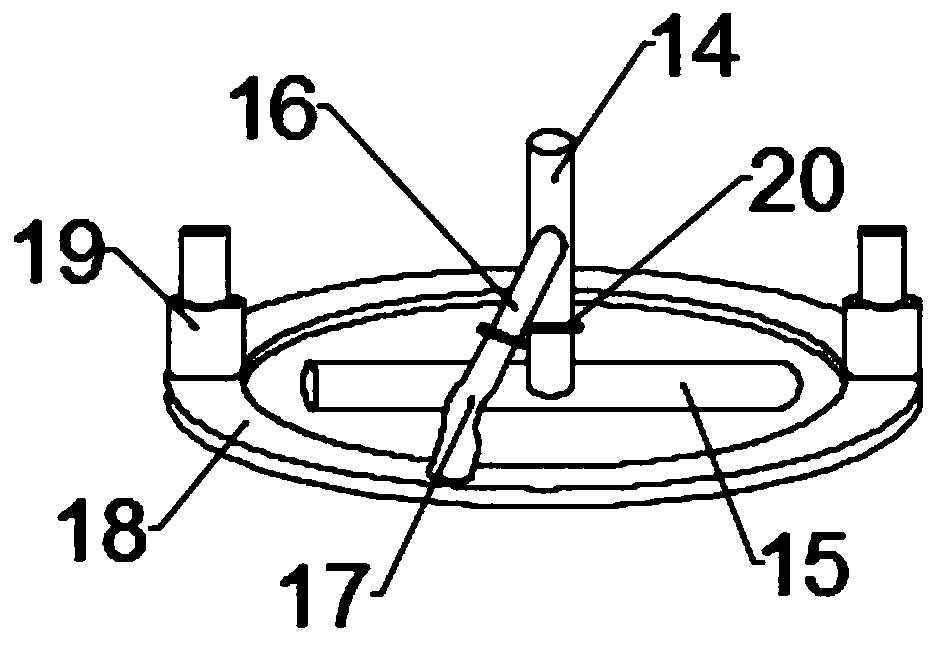

[0038] see Figure 1~2 In yet another embodiment provided by the present invention, the multi-angle spraying mechanism includes a paint box 12 and a paint pump 13 fixed on the top of the box body 1, and the paint box 12 is connected to the paint pump 13. The paint outlet is connected, the paint outlet of the paint pump 13 is connected with a paint outlet pipe 14, and the other end of the paint outlet pipe 14 is connected with a straight paint collection pipe 15;

[0039] The side wall of the paint outlet pipe 14 is provided with a branch pipe 16, and the other end of the branch pipe 16 is connected with a stretching hose 17, and the stretching hose 17 is connected to the annular paint collection pipe 18, and the annular collection pipe 18 The paint pipe 18 is installed inside the box body 1 through the second automatic telescopic rod 19 .

[0040] Specifically, the bottom end of the straight paint collecting pipe 15 is provided with a downward spraying head 21 , and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com