Spraying equipment based on multi-degree-of-freedom motor

A technology of spraying equipment and degree of freedom, which is applied in the direction of spraying devices, etc., which can solve the problems of waste material spraying effect, low spraying efficiency, and low spraying precision, and achieve good spraying effect, high spraying precision and material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

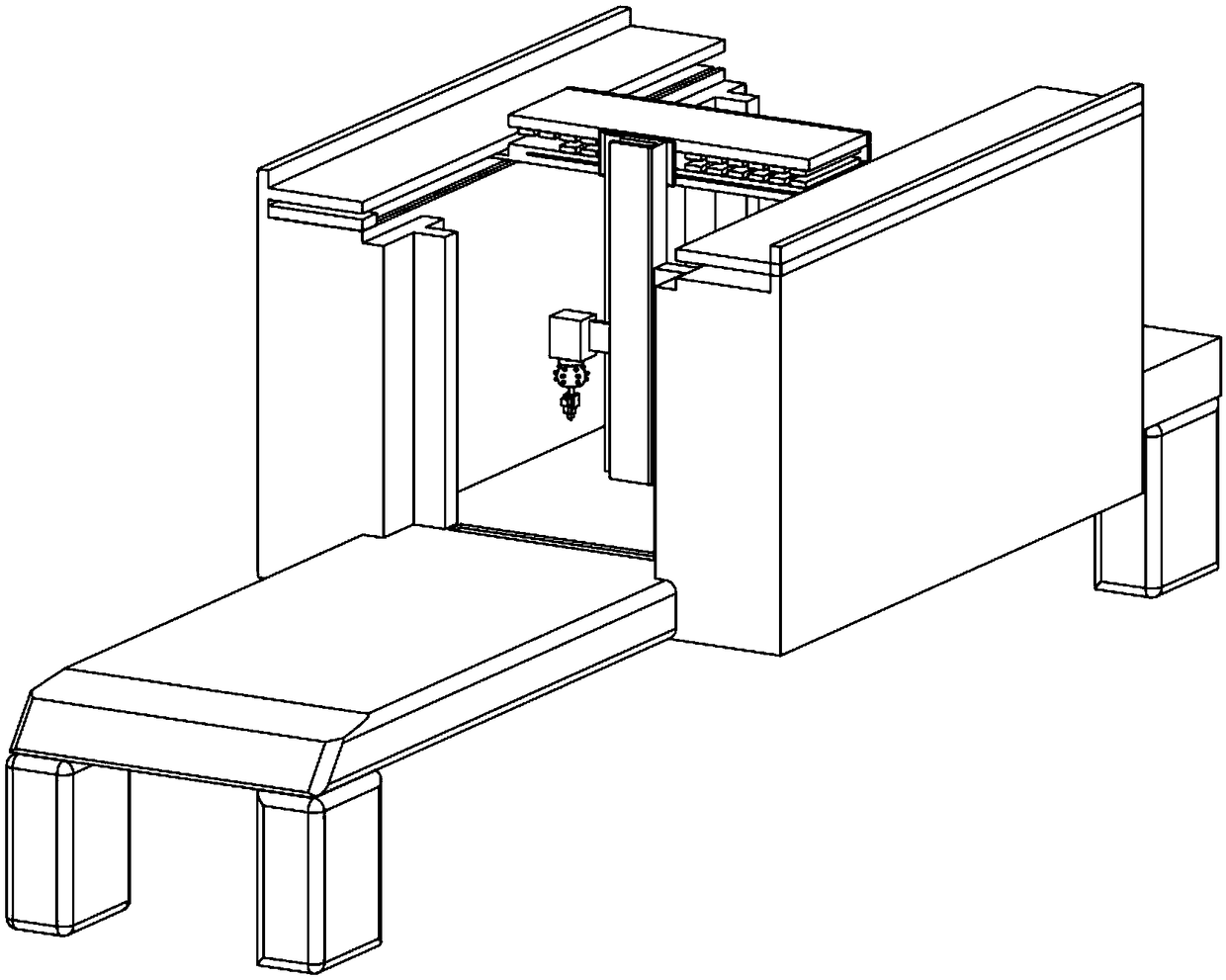

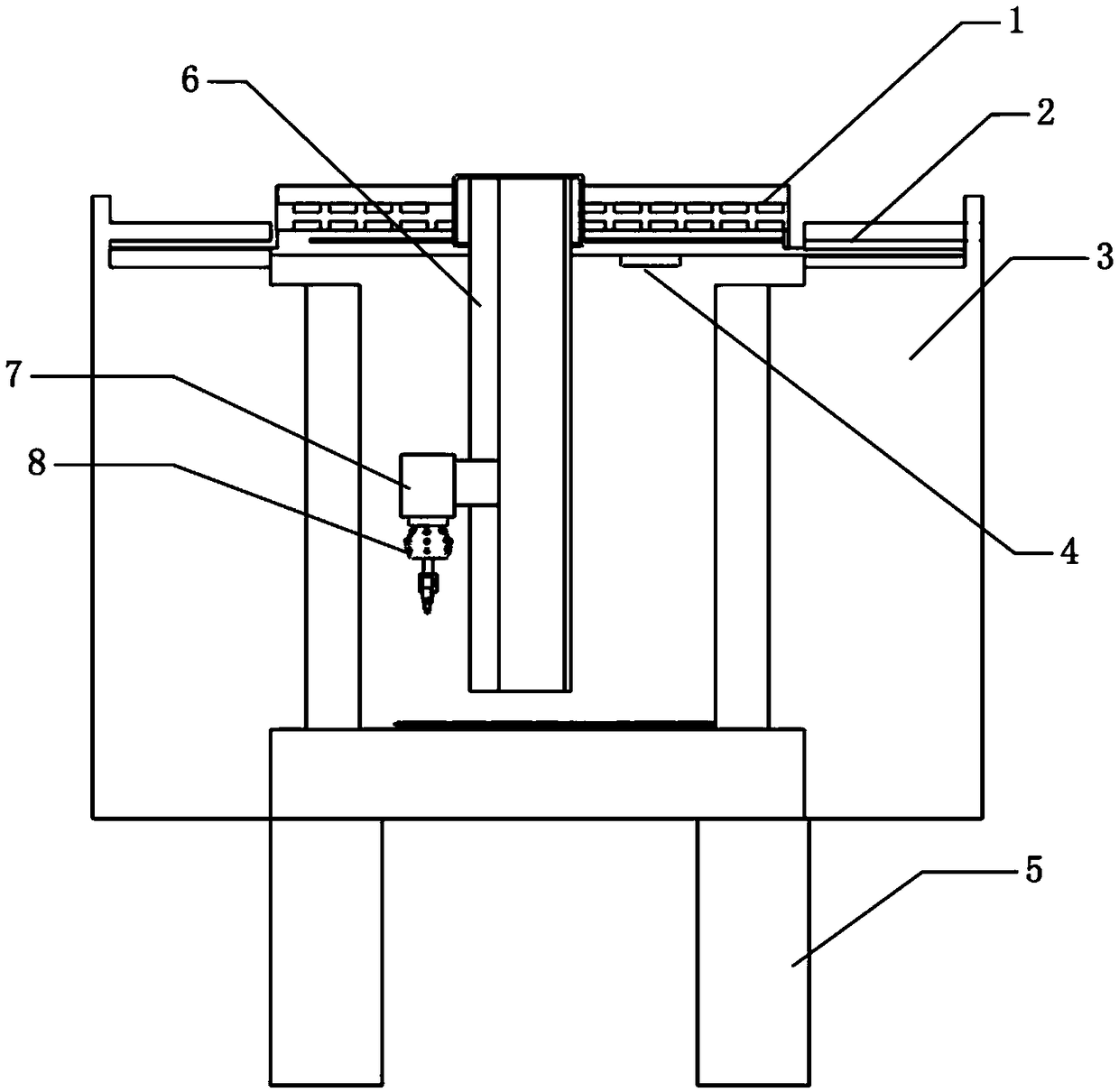

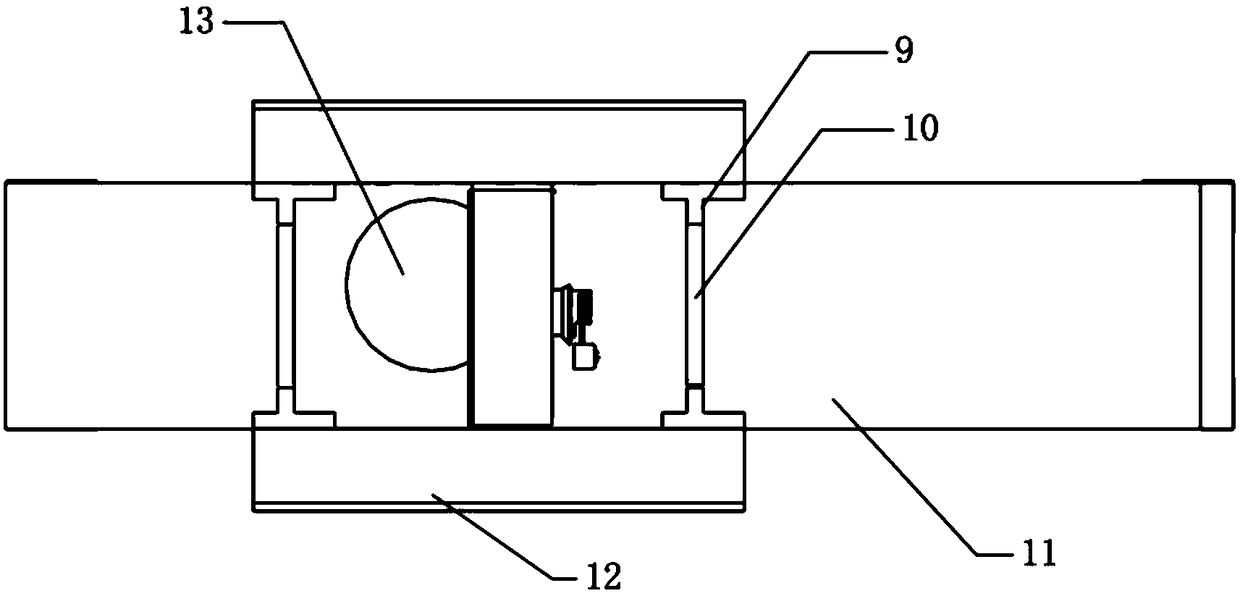

[0031] refer to Figure 1-Figure 10 . As a specific embodiment provided by the present invention, a spraying equipment based on a multi-degree-of-freedom motor is characterized in that it mainly includes a frame body, a three-axis motion mechanism, a multi-degree-of-freedom motor 8, a nozzle 81, a rotary (circular ) workbench 13 and control system; the three-dimensional motion mechanism is installed on the frame body, the three-dimensional motion mechanism is connected with the multi-degree-of-freedom motor 8, the multi-degree-of-freedom motor 8 is connected with the nozzle 81, and the controller includes a camera; the three-dimensional motion mechanism drives the multi-degree-of-freedom motor Motor 8, the multi-degree-of-freedom motor drives the nozzle to perform multi-angle spraying motion along the workpiece to be sprayed in space, determines the range of the workpiece through image recognition, and adjusts the angle of the nozzle according to the surface radian of the work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com