Robot system for spraying anti-pollution flashover coatings on substation insulators and spraying method

A technology of spraying robots and anti-fouling flashover coatings, which is applied in spraying devices and other directions, can solve problems such as difficulty in guaranteeing coating quality, inaccurate measurement, pollution, etc., and achieve the effect of improving operation efficiency and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

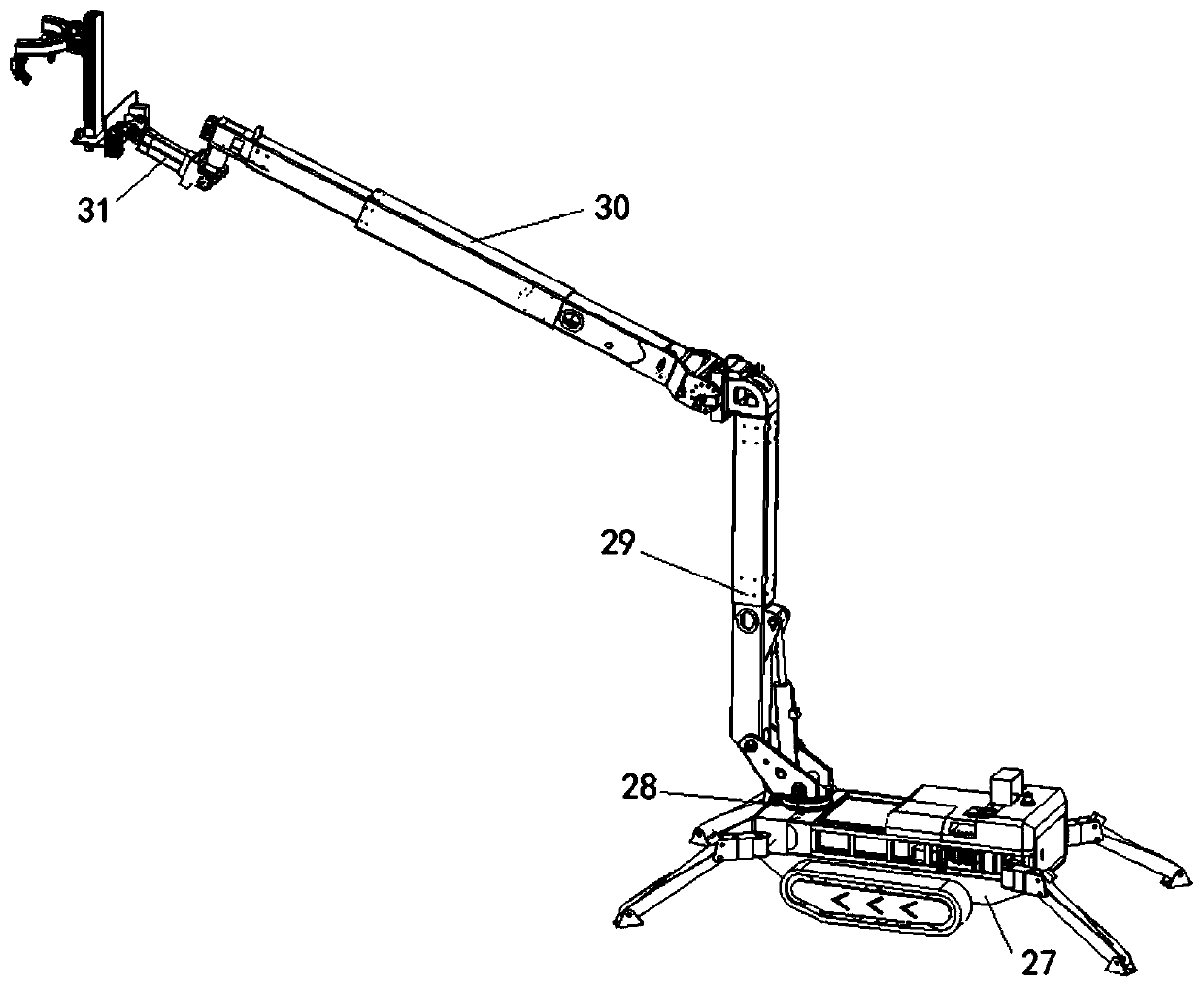

[0052] This embodiment discloses a live RTV spraying robot, which includes a moving mechanism 27, an insulating lifting mechanism arranged on the moving mechanism, and an operation terminal arranged at the end of the lifting mechanism, and the operation terminal is connected with an RTV spraying tool.

[0053] The insulating lifting system includes a rotary platform 28 and a multi-stage mechanical arm, and the multi-stage mechanical arm is arranged on the rotary platform, including a large arm 29, a telescopic arm 30 and a small flying arm 21 connected in sequence, such as figure 1 shown.

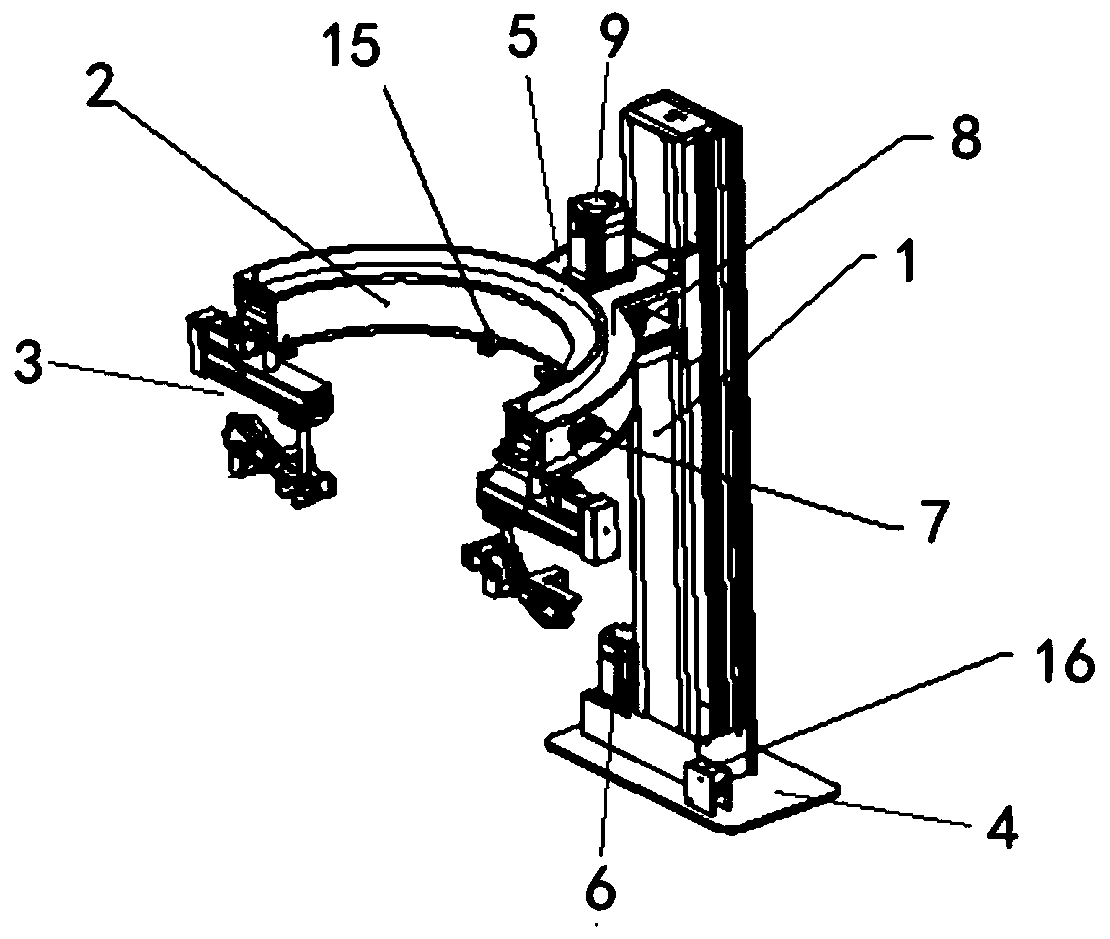

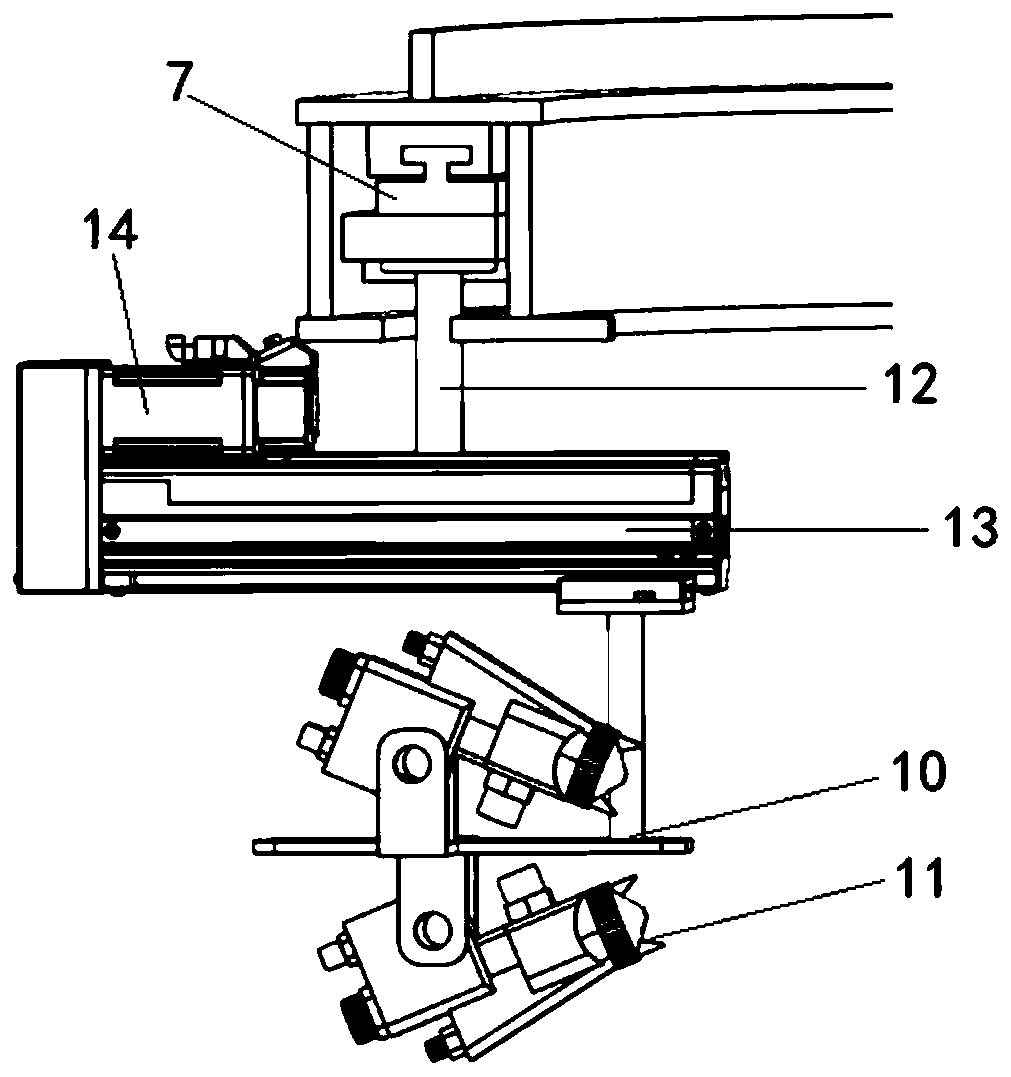

[0054] Such as figure 2 , the RTV spraying tool includes a supporting mechanism 1, an embracing mechanism 2 and at least one spraying mechanism 3, wherein the embracing mechanism 2 is arranged on the supporting mechanism 1 and can move up and down relative to the supporting mechanism 1; the at least one spraying mechanism The mechanism 3 is arranged on the surrounding mechanism 2, and can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com