Patents

Literature

56results about How to "Solve material waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

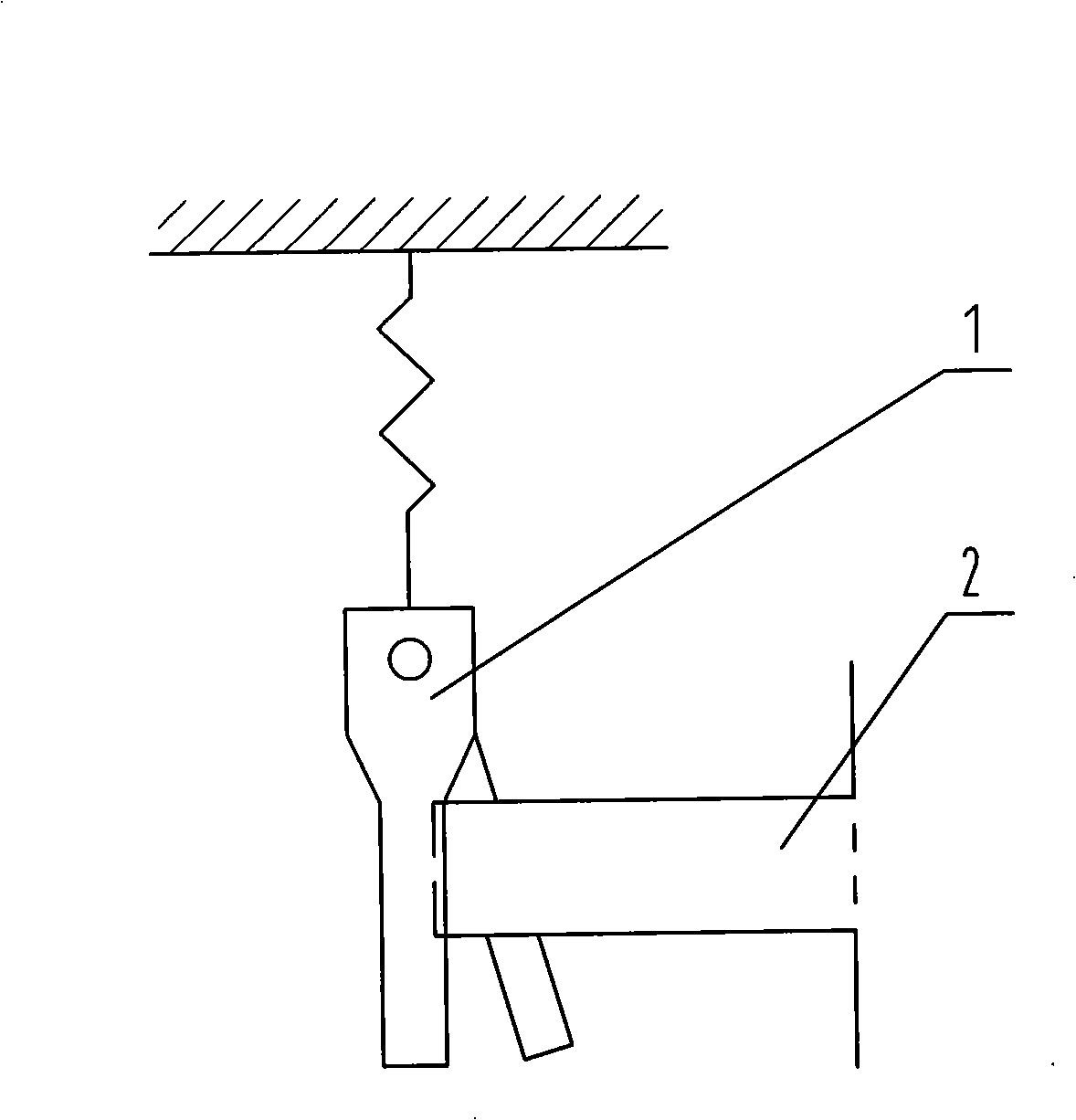

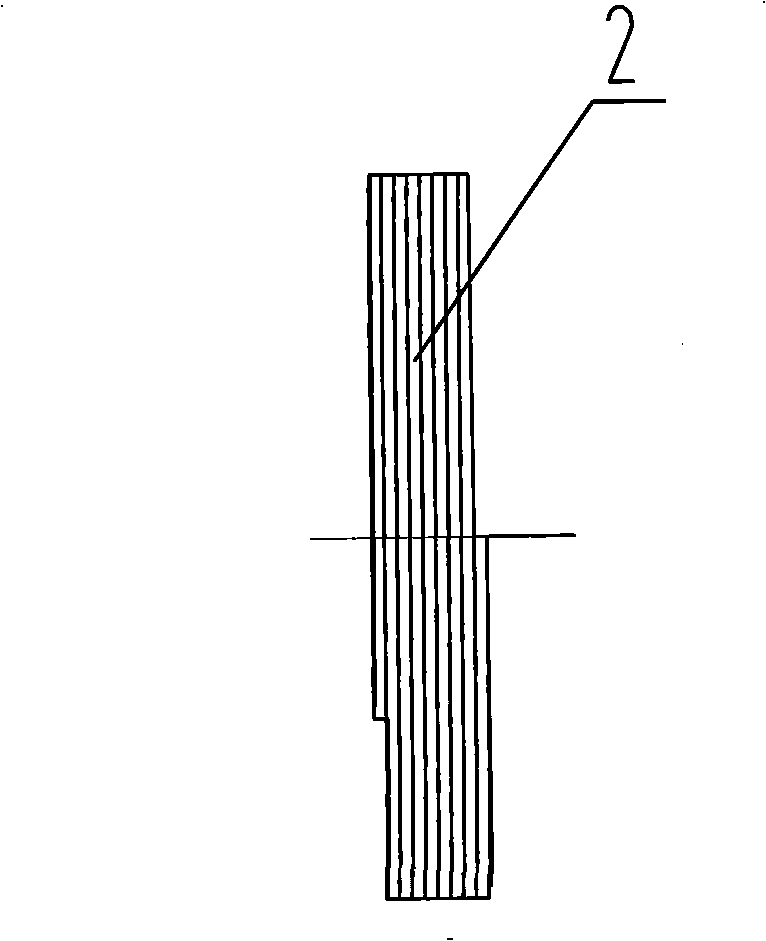

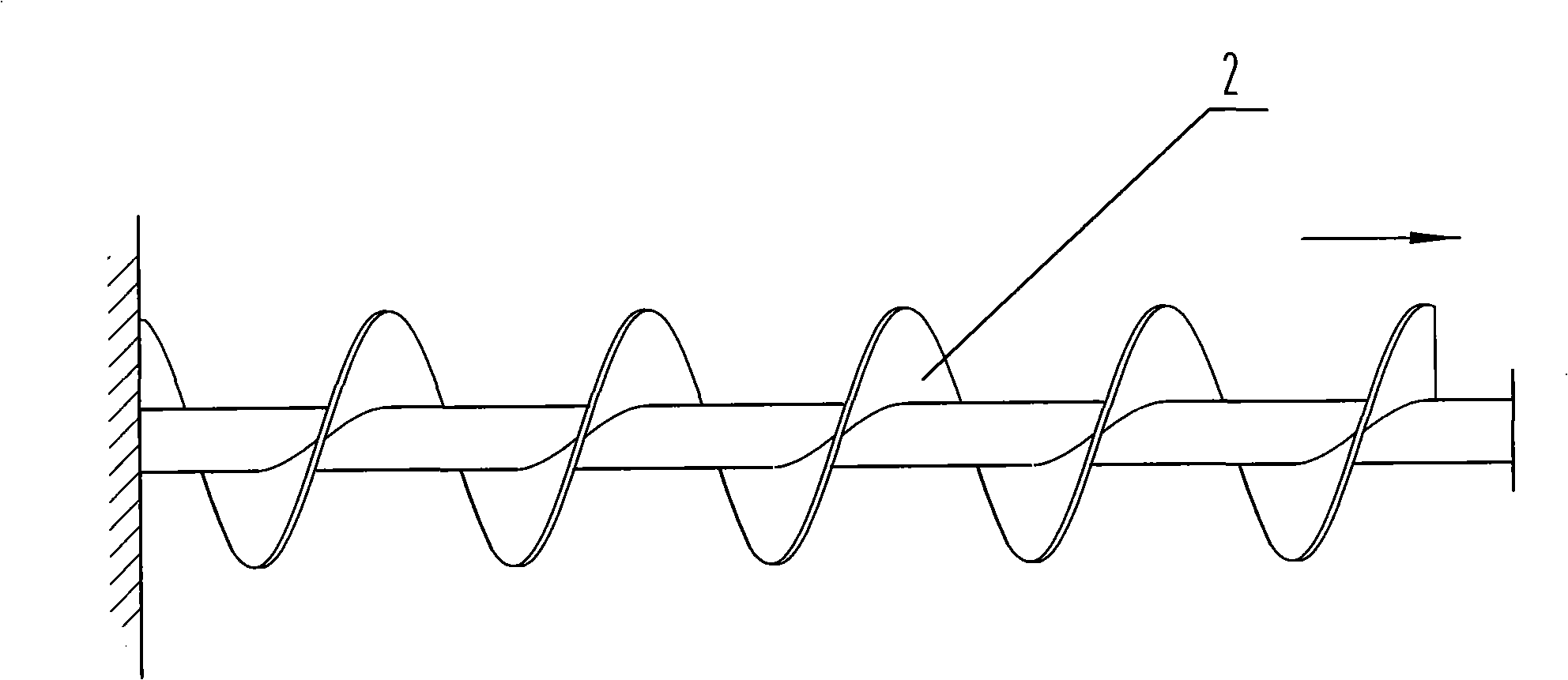

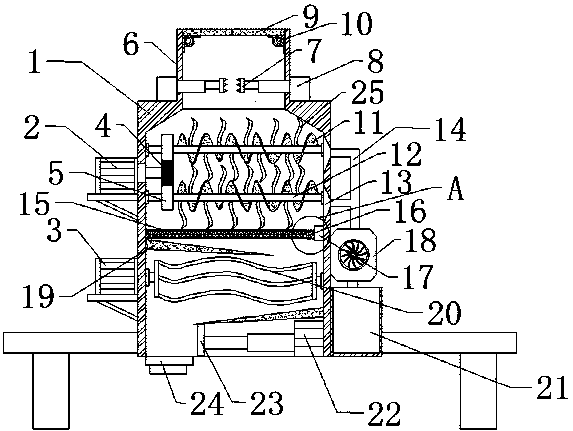

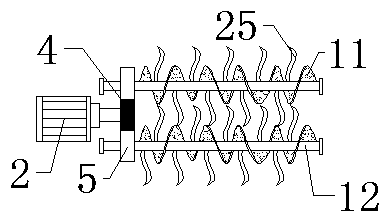

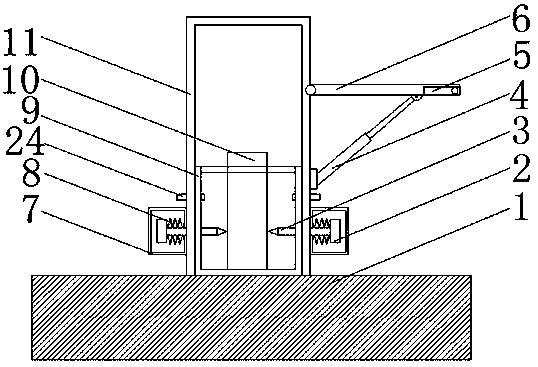

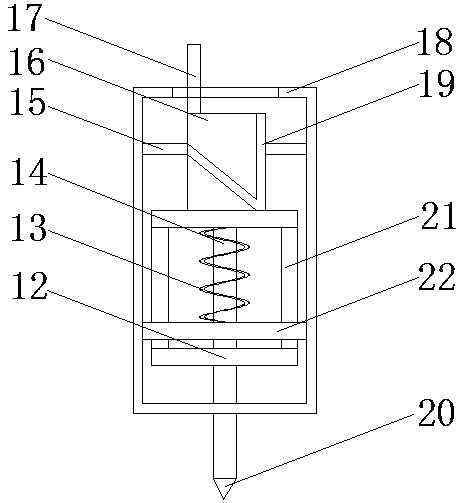

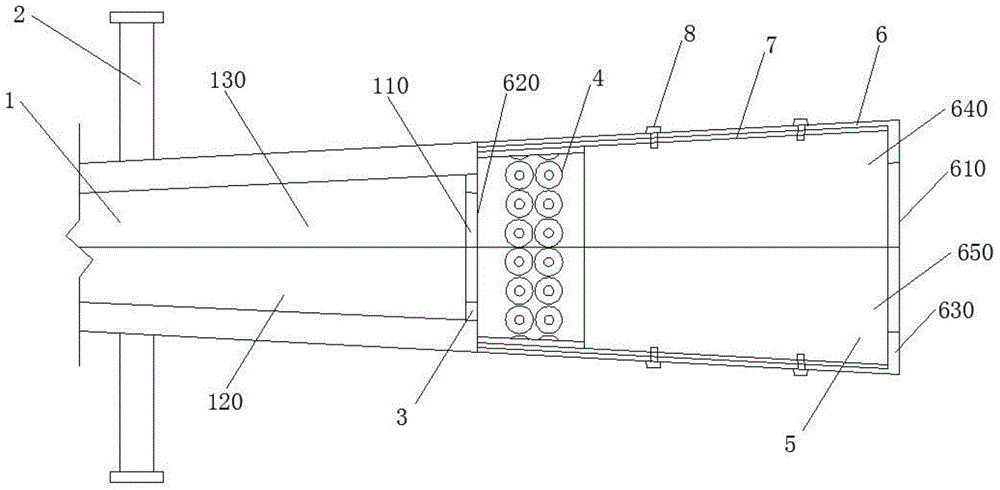

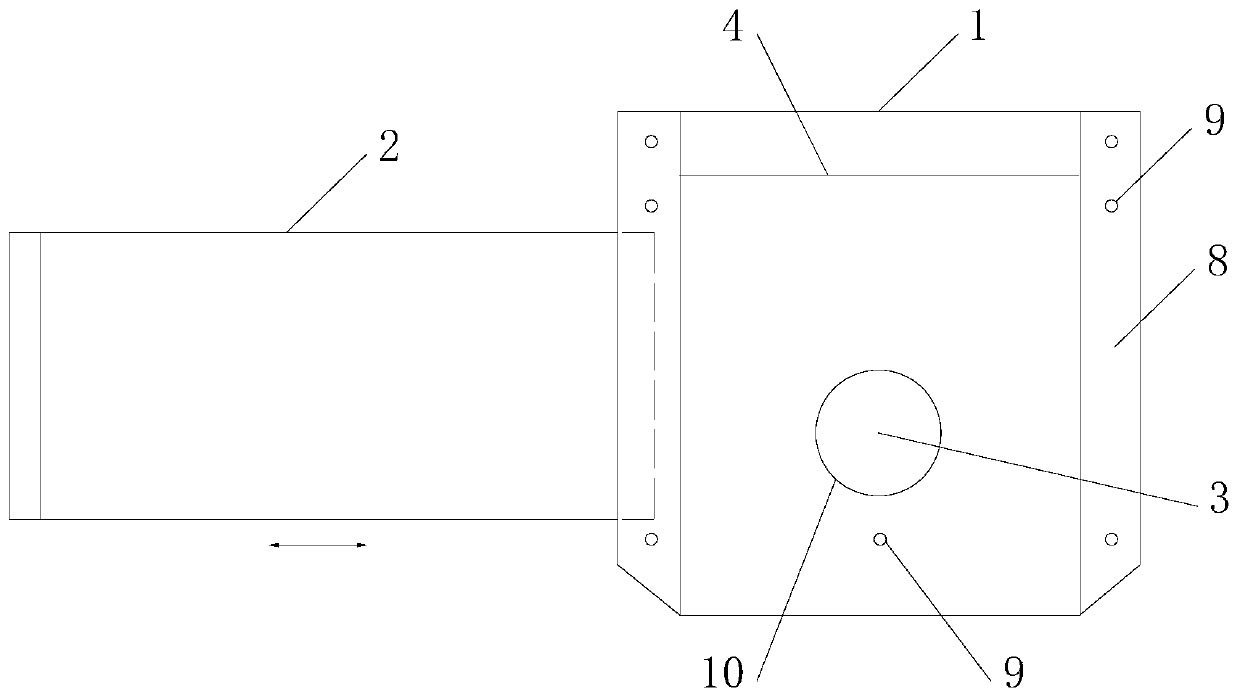

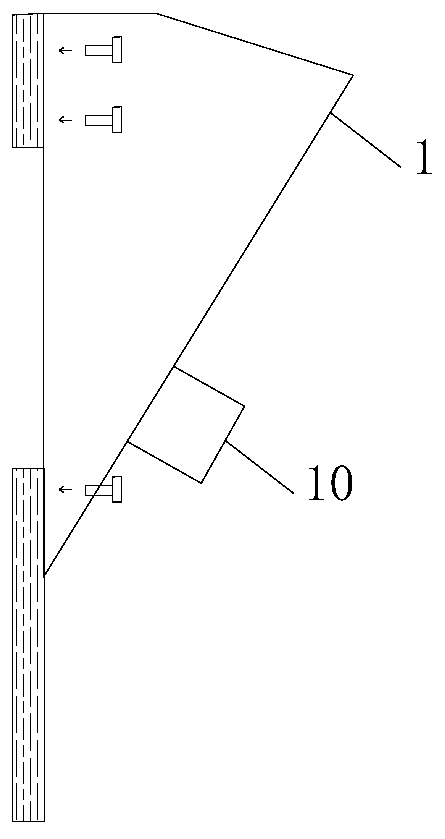

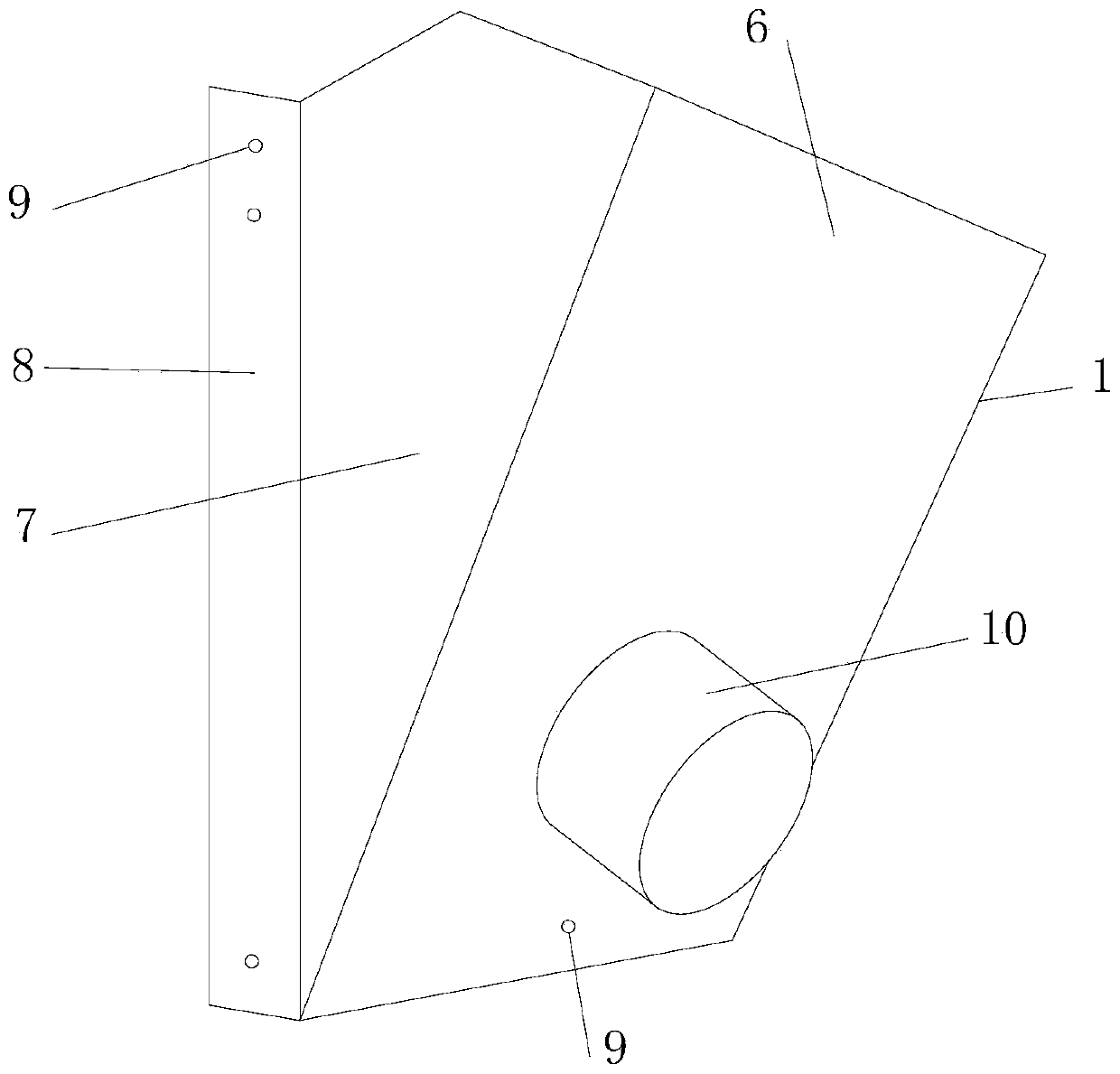

Screw blade coiling and molding method, and molding equipment thereof

ActiveCN101342562AIncrease profitIncrease productivityShaping toolsMetal-working feeding devicesDrive shaftHelical blade

The present invention relates to a convolution forming method of a helical blade and a forming device thereof. A steel belt is fixed on a fixing mould; the fixing mould and a dynamic mould are closed to hold the steel belt; the transmission shaft of a convolution machine rotates to drive the steel belt to vertically rotate along with the central mandril of the fixing mould, so that the helical blade with the helical surface being overlapped is produced; the helical blade is stretched by a professional stretching device to obtain the required helical distance. The present invention also relates to a convolution forming device of a helical blade; an output shaft of a reducer of the device is connected with a transmission shaft through a transmission element; one side of the fixing mould is firmly connected with one end of the transmission shaft, and the other side of the fixing mould is provided with a central mandril; the two sides of the dynamic mould are supported on a guiding device; the rear side of the guiding device is connected with a press-molding device. A material guiding device is arranged at the outer side of the working surface of the fixing mould and the dynamic mould. The convolution forming method of the present invention reduces the production procedures, and improves the material utilization rate and the production efficiency; the thickness of the produced helical blade is equal, and the mechanics performance is uniform.

Owner:ZHENJIANG BANGHE SPIRAL MFG

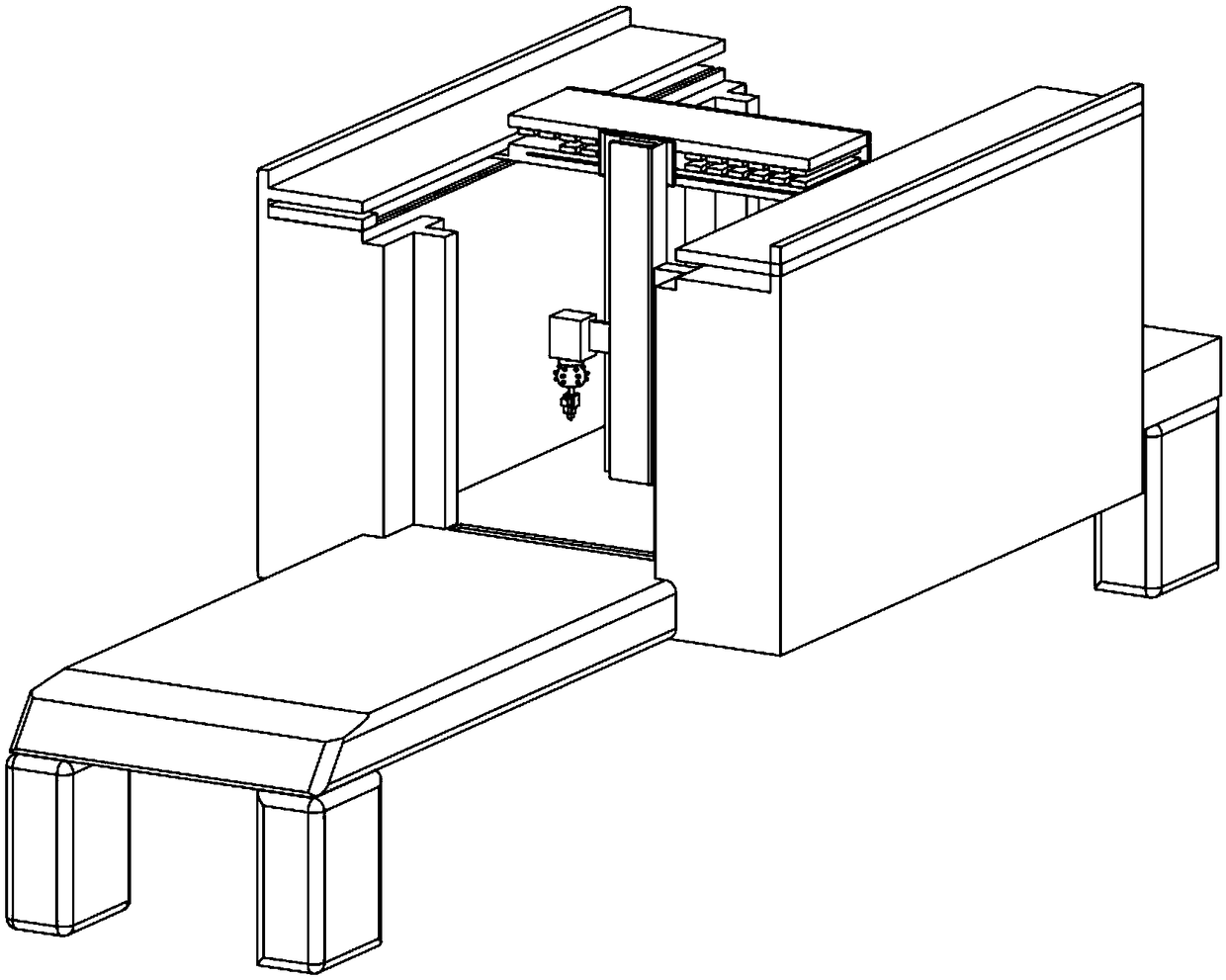

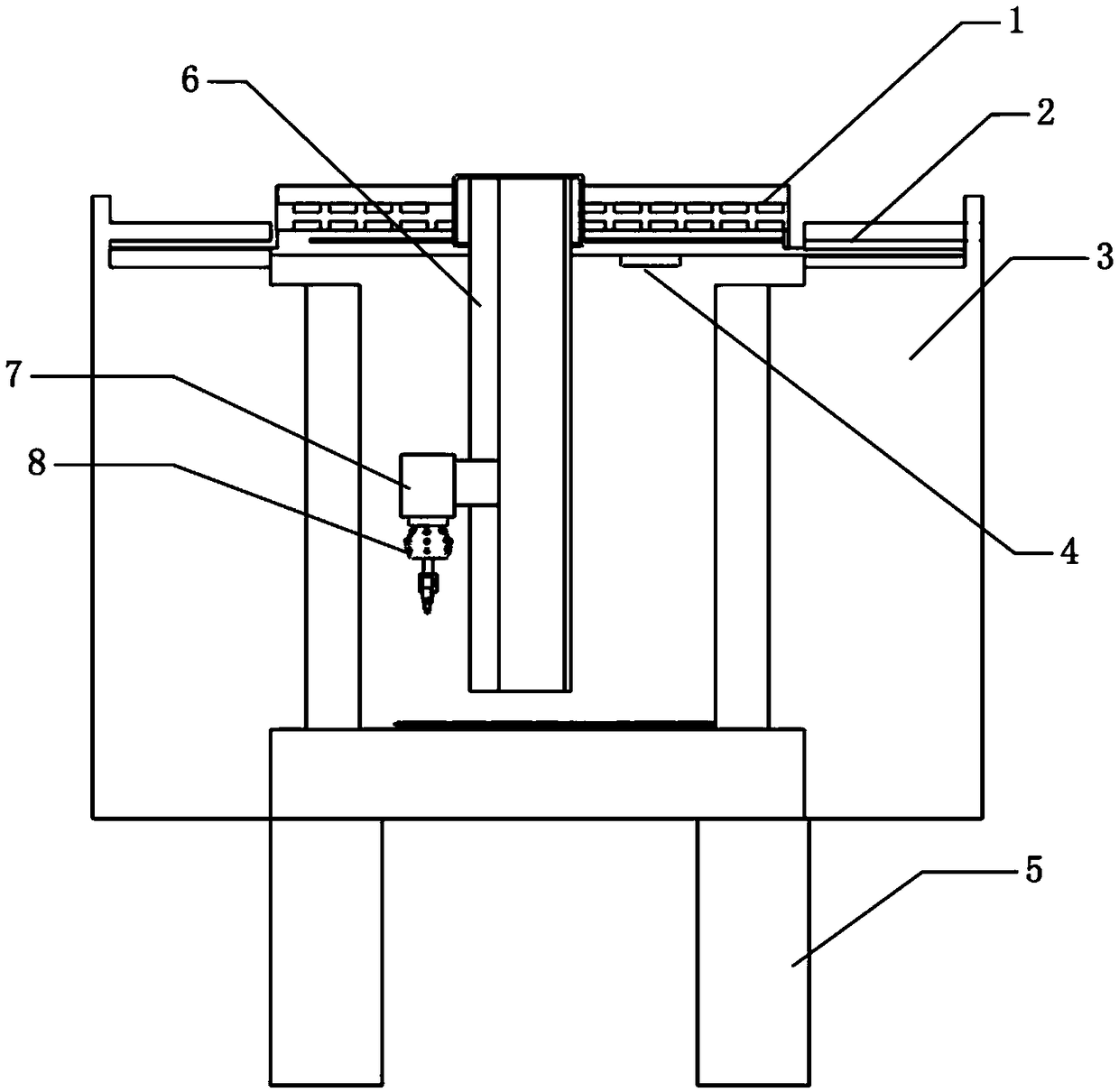

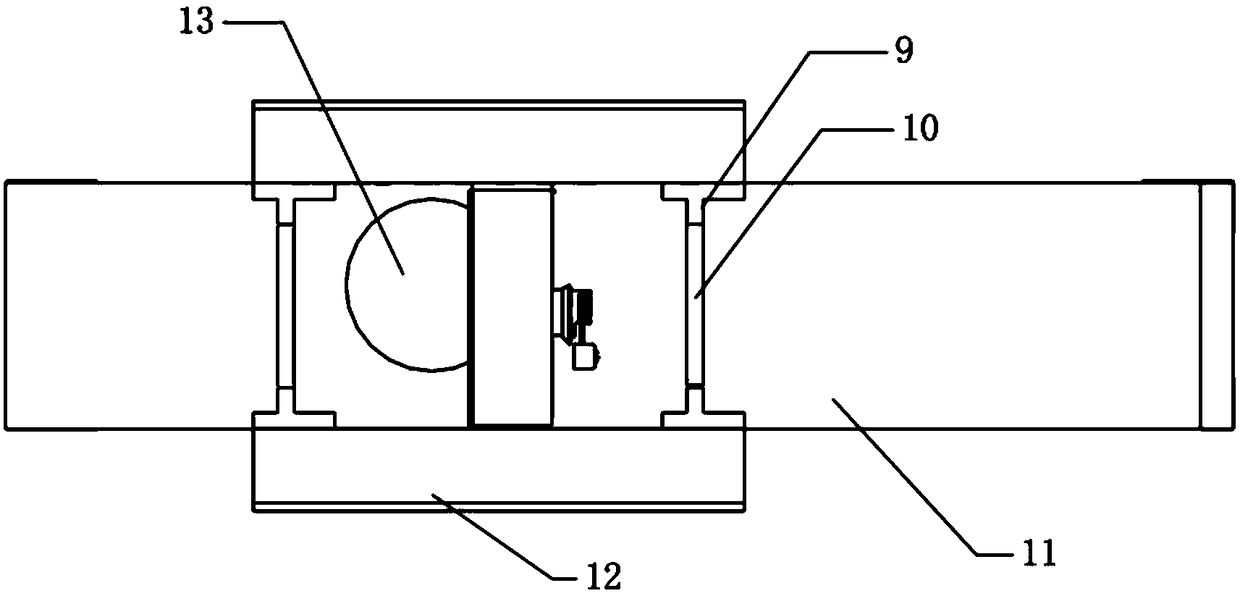

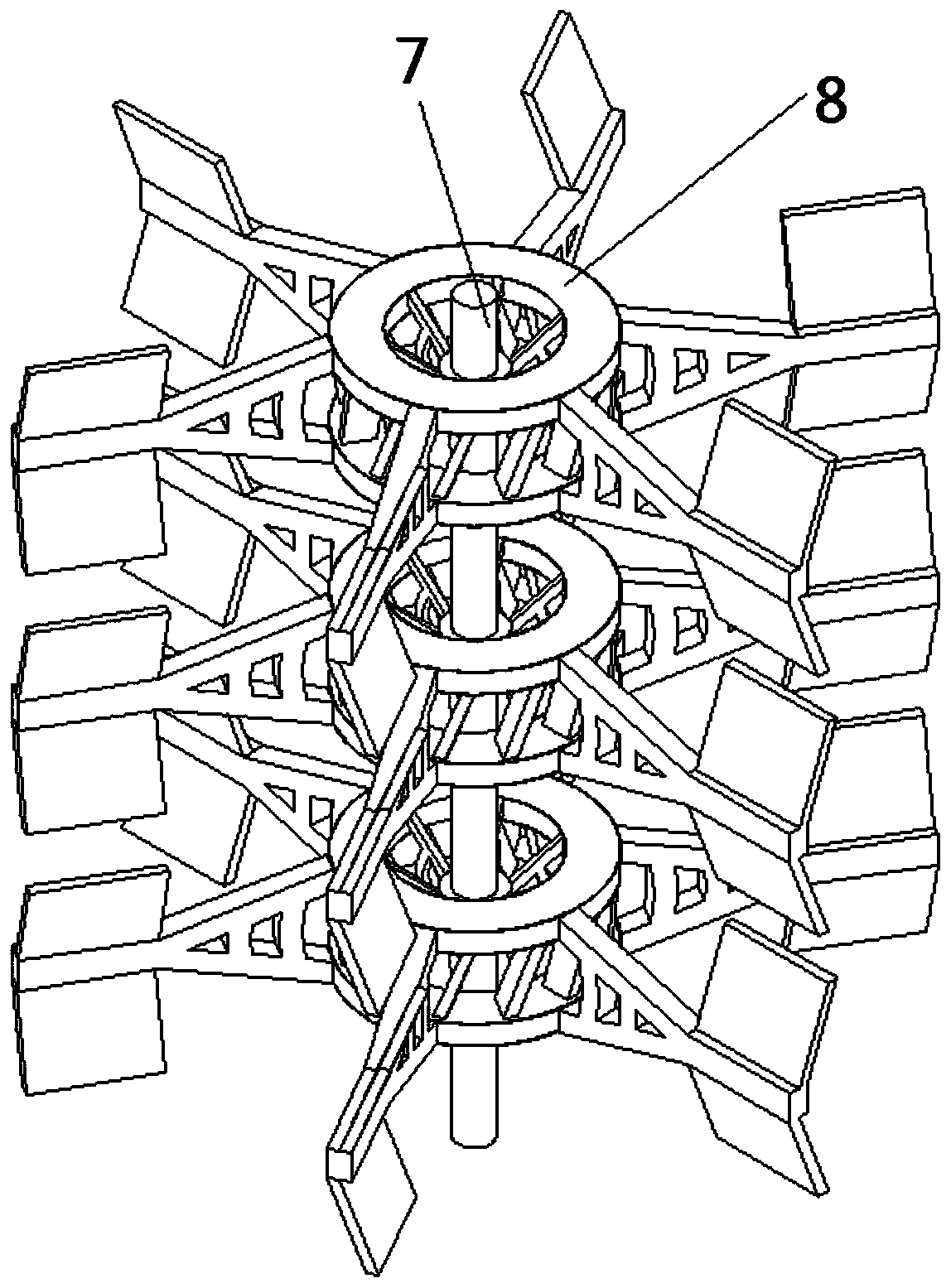

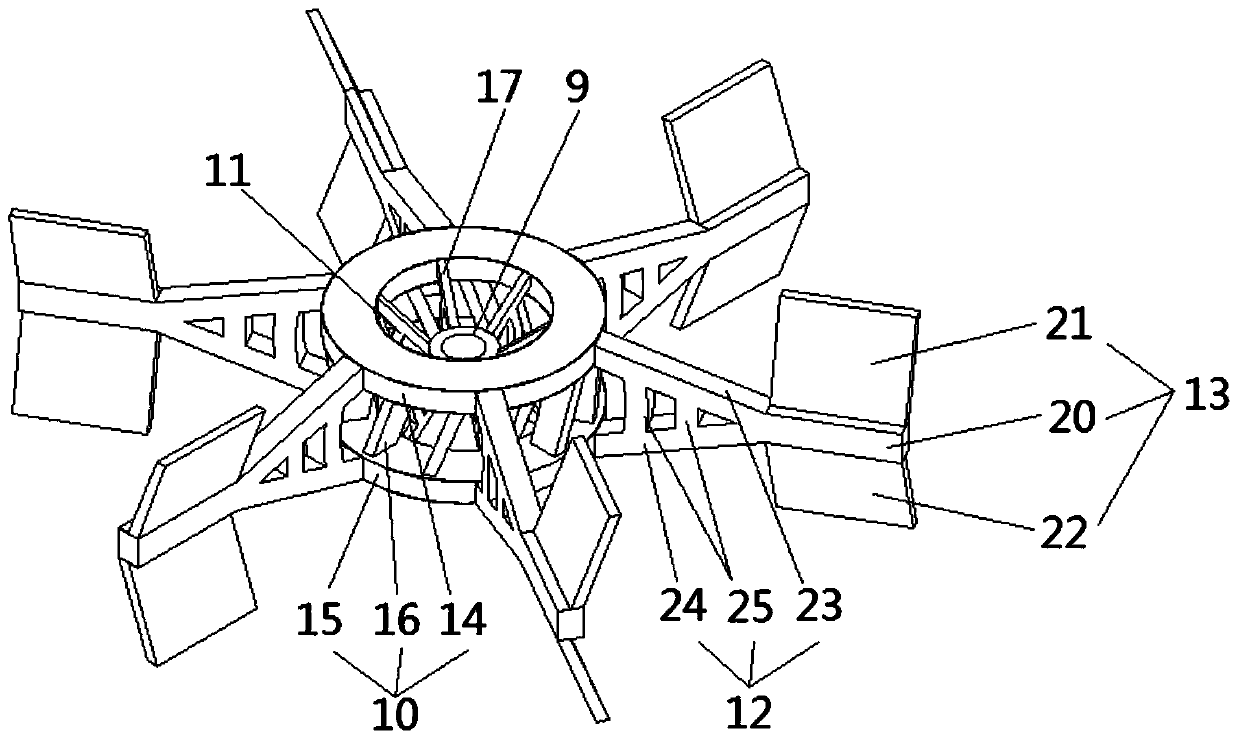

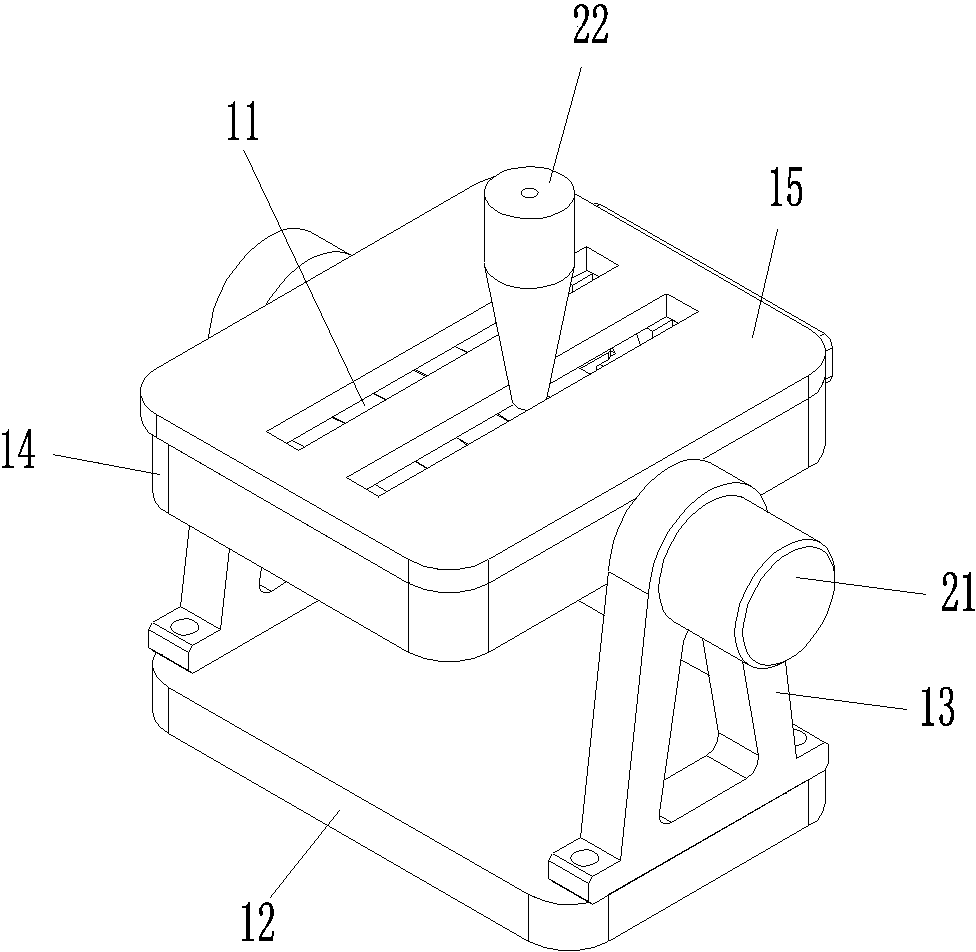

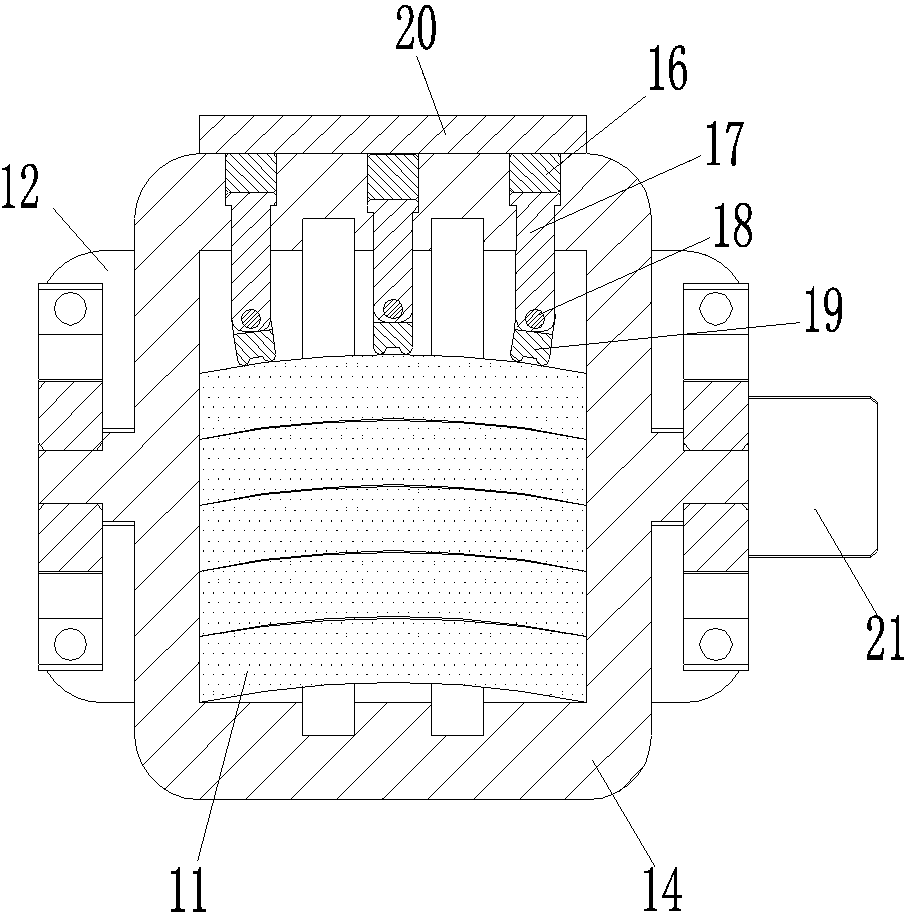

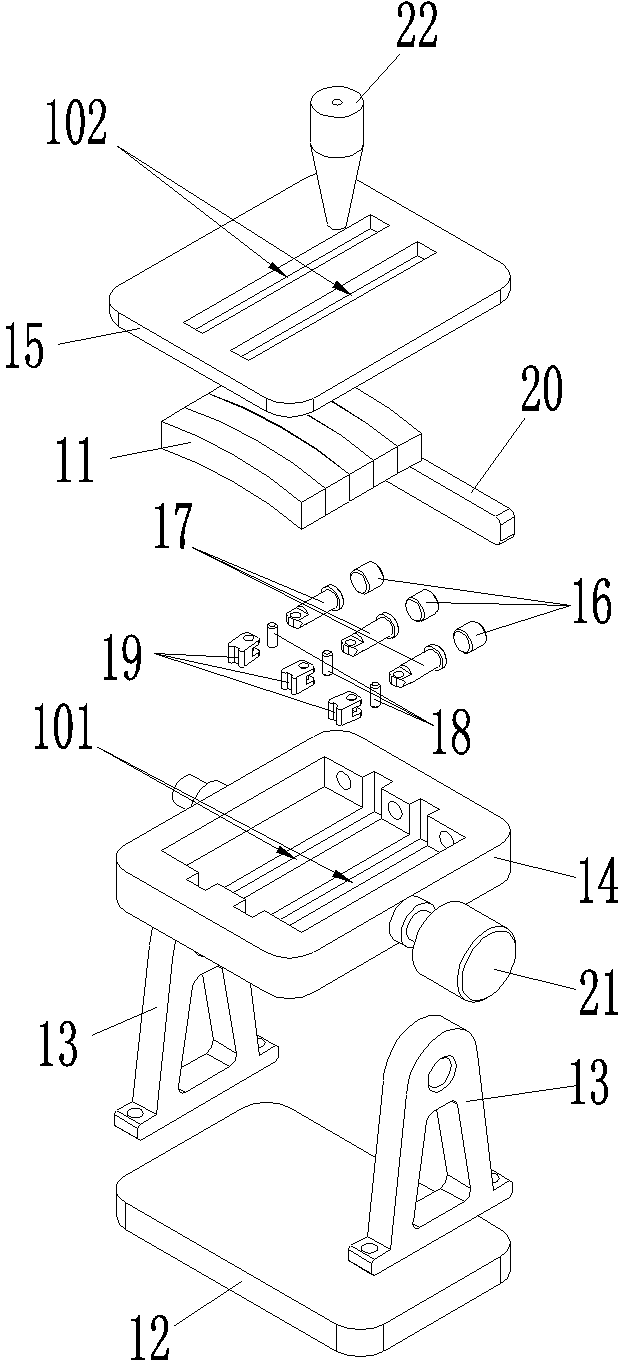

Spraying equipment based on multi-degree-of-freedom motor

InactiveCN109453928ASolve rough sprayingSolve the dead angle of sprayingSpraying apparatusMotor driveControl system

The invention provides spraying equipment based on a multi-degree-of-freedom motor, and relates to the technical field of spraying equipment. The spraying equipment based on the multi-degree-of-freedom motor mainly comprises a frame body, a three-dimensional movement mechanism, the multi-degree-of-freedom motor, a spray head, a rotary type working table and a control system, wherein the three-dimensional movement mechanism is connected with the multi-degree-of-freedom motor; the multi-degree-of-freedom motor is connected with the spray head; the controller comprises a camera; the three-dimensional movement mechanism drives the multi-degree-of-freedom motor; the multi-degree-of-freedom motor drives the spray head to spray multi-angularly in the space along a workpiece to be sprayed; a workpiece range is determined through image identification; and the angle of the spray head is adjusted according to the surface space radian of the workpiece so as to carry out spraying. The spraying equipment based on the multi-degree-of-freedom motor provided by the invention mainly solves the problems of spraying roughness, the existence of a spraying dead angle, material waste, a poor spraying effect, a big control error, low spraying accuracy and low spraying efficiency in the prior art, and has the characteristics of high spraying accuracy, good quality, high efficiency, saving in materialsand the like.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

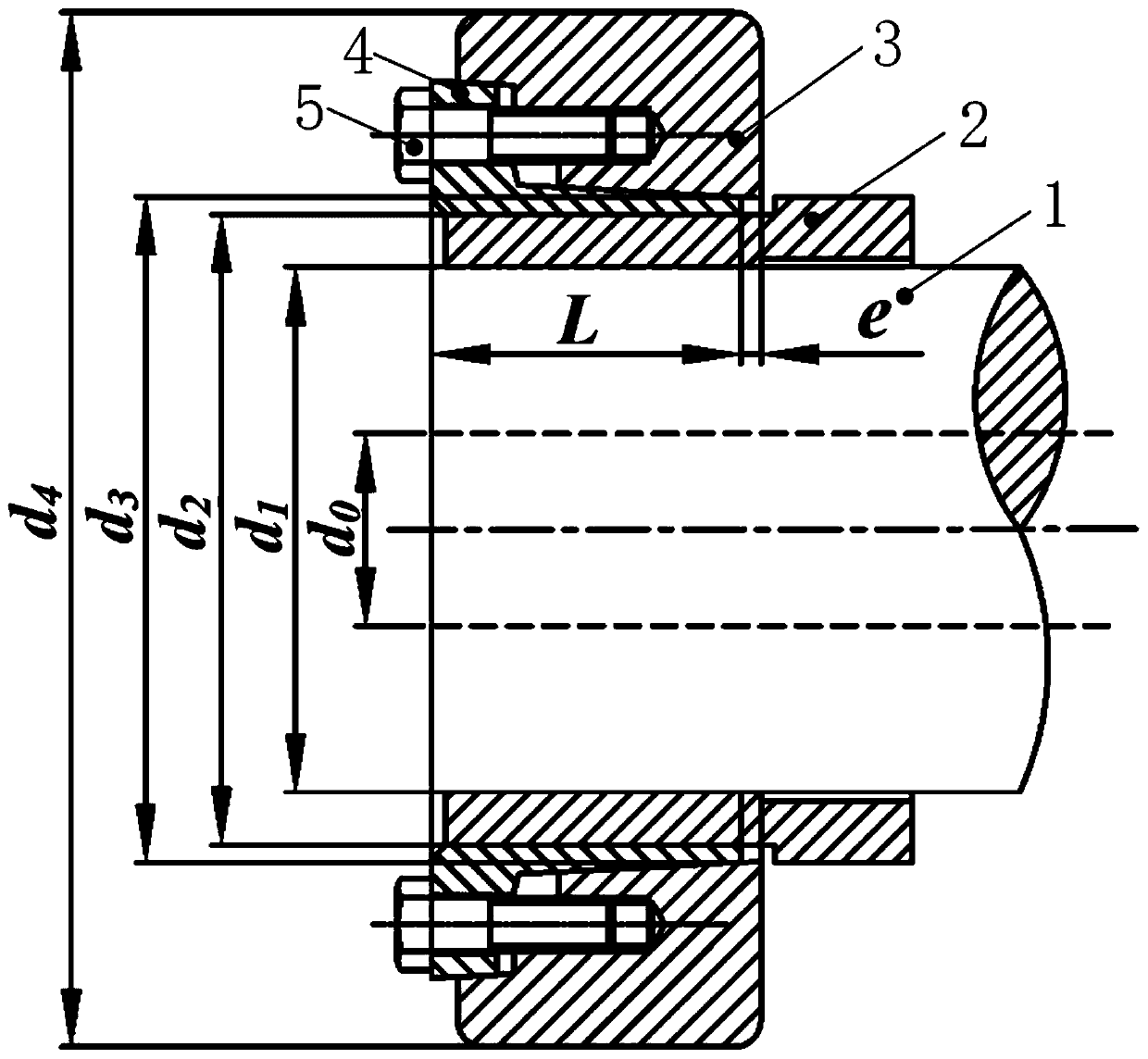

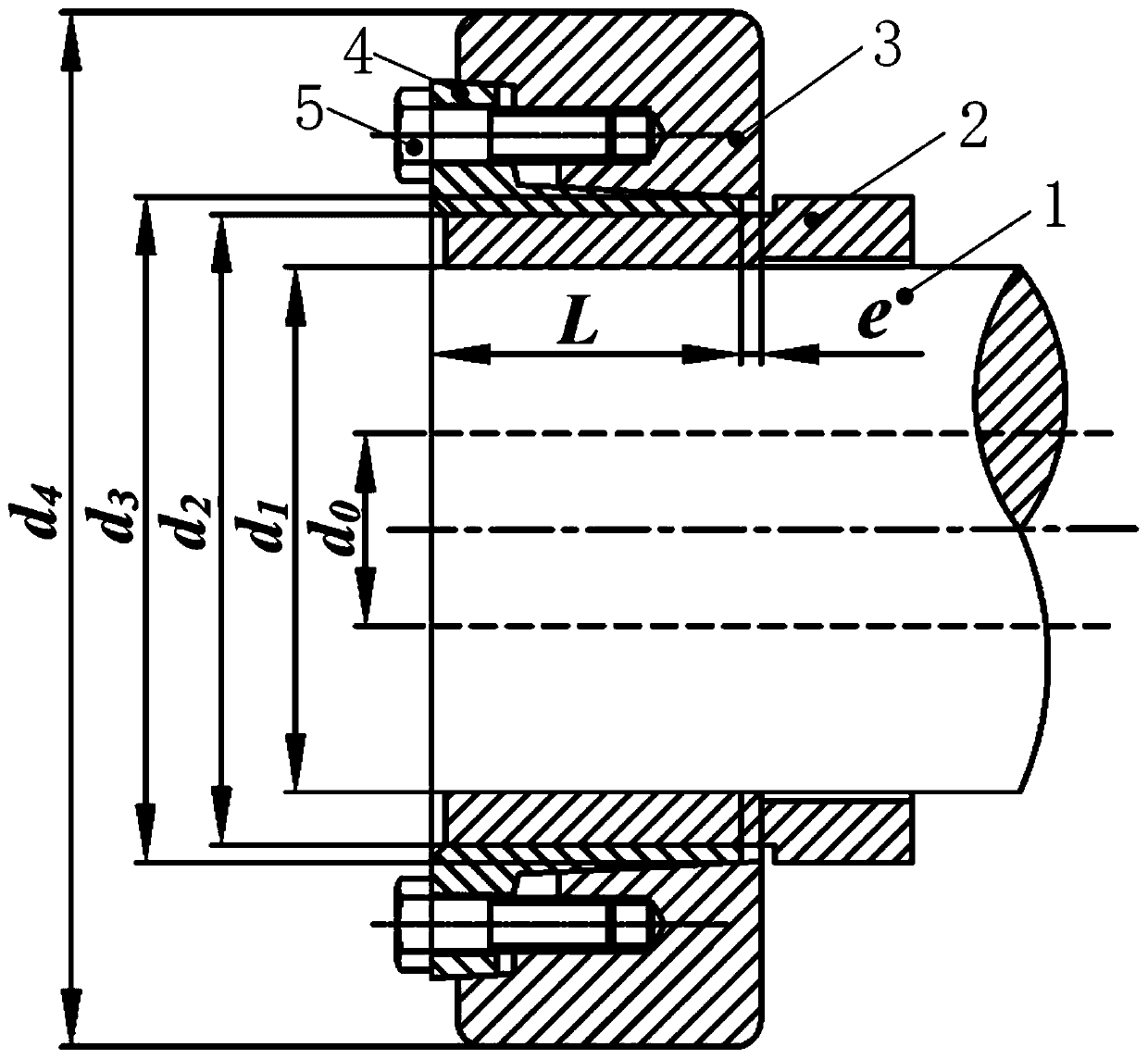

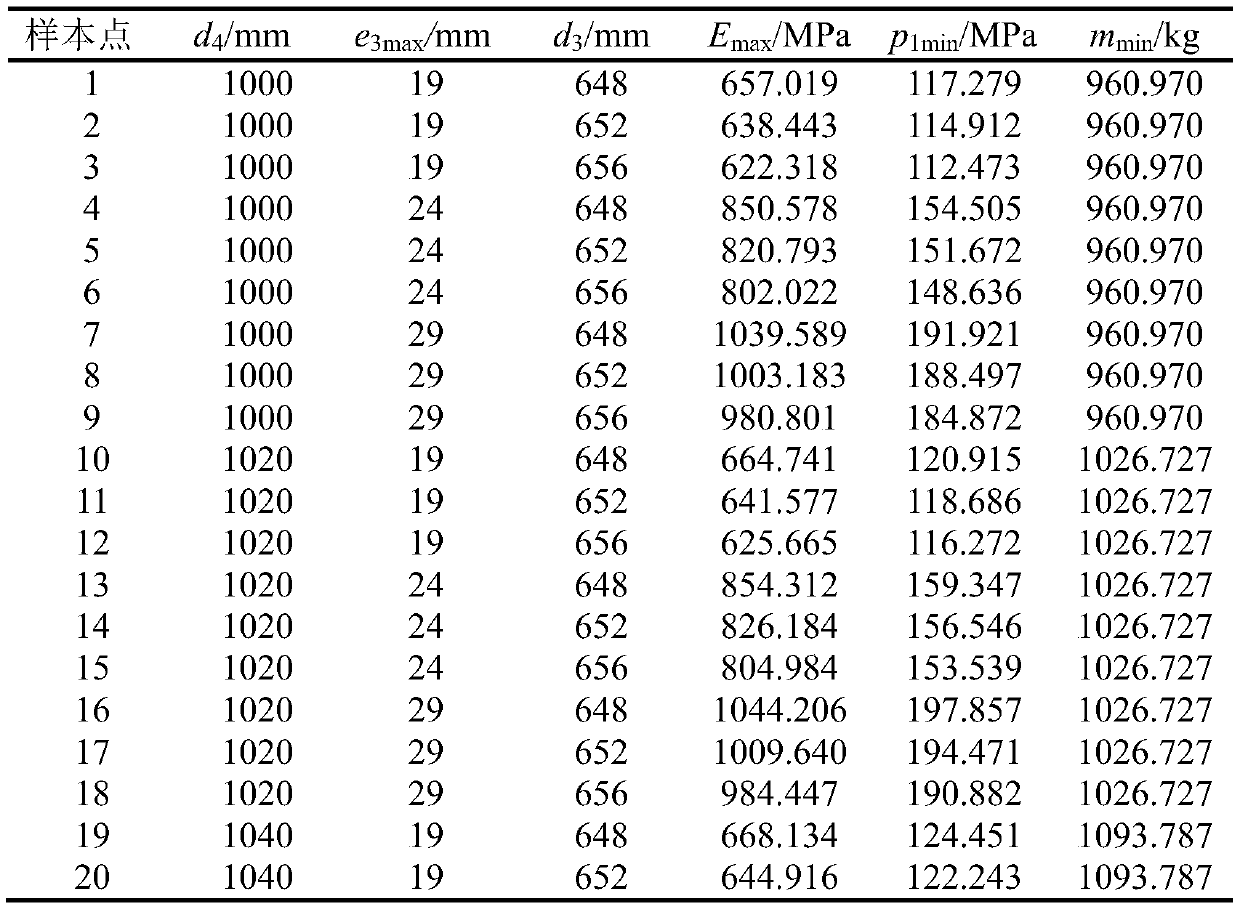

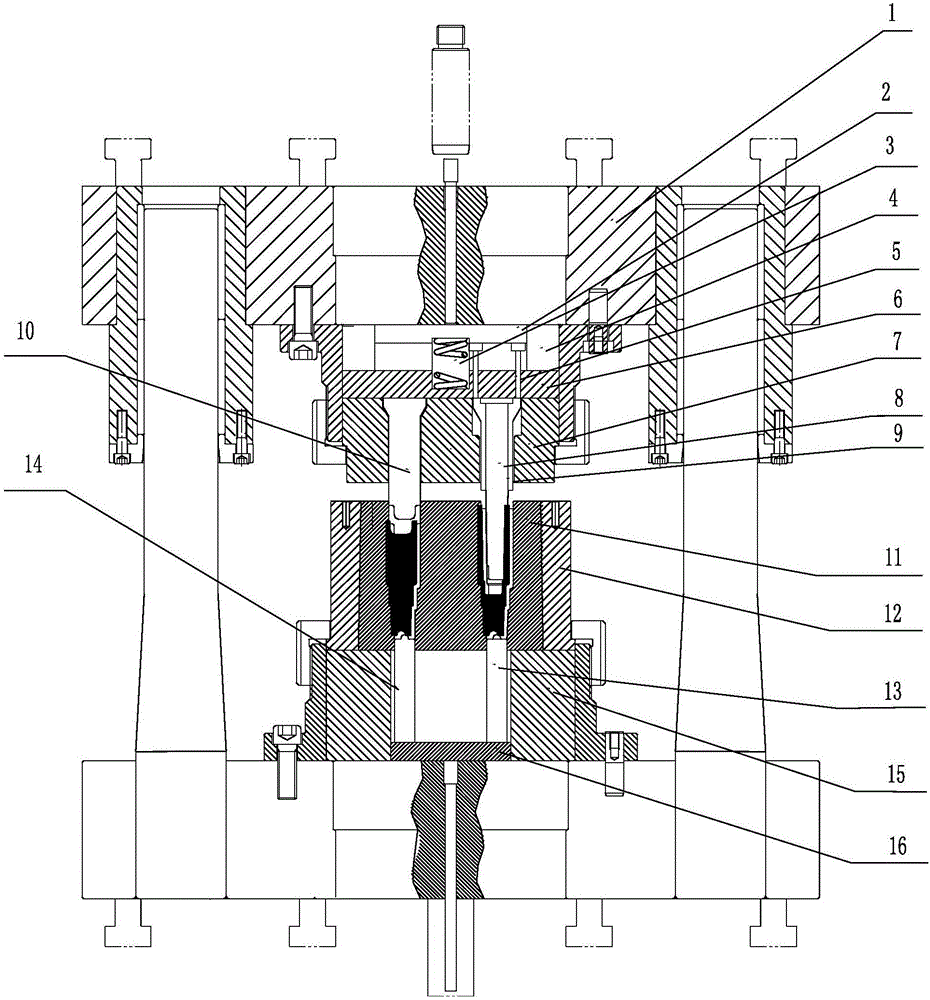

Design method of expansion coupling sleeve for solving stress concentration and light weight

ActiveCN109977562AAddress reliabilitySolve material wasteGeometric CADDesign optimisation/simulationStress concentrationContact pressure

The invention relates to a design method of an expansion coupling sleeve for solving stress concentration and light weight. The method mainly solves the technical problems that an existing expansion sleeve size design method is insufficient in reliability, materials are wasted and the like. The specific method comprises the following steps of 1) according to an expansion coupling sleeve transmission torque requirement, a material yield strength requirement and a light-weight minimum mass requirement, determining the design indexes as follows the minimum contact pressure p1min of the main shaftand the shaft sleeve, the maximum equivalent stress Emax of the whole machine and the minimum mass mmin; 2) determining the design parameters of the expansion sleeve according to the design indexes,and obtaining the sample data by utilizing orthogonal test design based on finite element simulation; 3) concluding the sample data, taking the design index as a function dependent variable, taking the design parameter as an independent variable, obtaining an objective function by utilizing a Kriging method, and constructing a prediction model which meets the requirements of torque, equivalent force and minimum mass; 4) obtaining a multi-objective optimization function through a simultaneous prediction model, and obtaining a final design parameter by solving a second-generation genetic algorithm (NSGA-II).

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Backward extrusion forming method of stepped hollow shaft part and die

ActiveCN105921671AProtection lifeIncrease profitForging/hammering/pressing machinesEngine componentsIntermediate frequencyContact time

The invention discloses a backward extrusion forming method of a stepped hollow shaft part and a die. The backward extrusion forming method comprises the following steps: adopting a cylindrical bar material for blanking; heating to 750 DEG C through an intermediate-frequency diathermanous stove, and then forming a formed inner cavity through backward extrusion through an extrusion forming shape; carrying out little machining on an extrusion piece; then carrying out surface shot blasting treatment, thus obtaining a qualified forging piece. According to the backward extrusion forming method disclosed by the invention, a one-die two-process way is adopted by the die, so that the forming speed is quickened, an extrusion force of a punch is well shared, and meanwhile, the production rhythm is greatly increased; during a forming process of the two-process die, the in-die time of blank is reduced, the contact time of the die and the blank is reduced, and the service life of the die is greatly ensured; the problems of forming complexity, material waste, low efficiency and poor quality of the stepped hollow shaft part are solved.

Owner:HUOSHAN HUINENG AUTO PARTS MFG

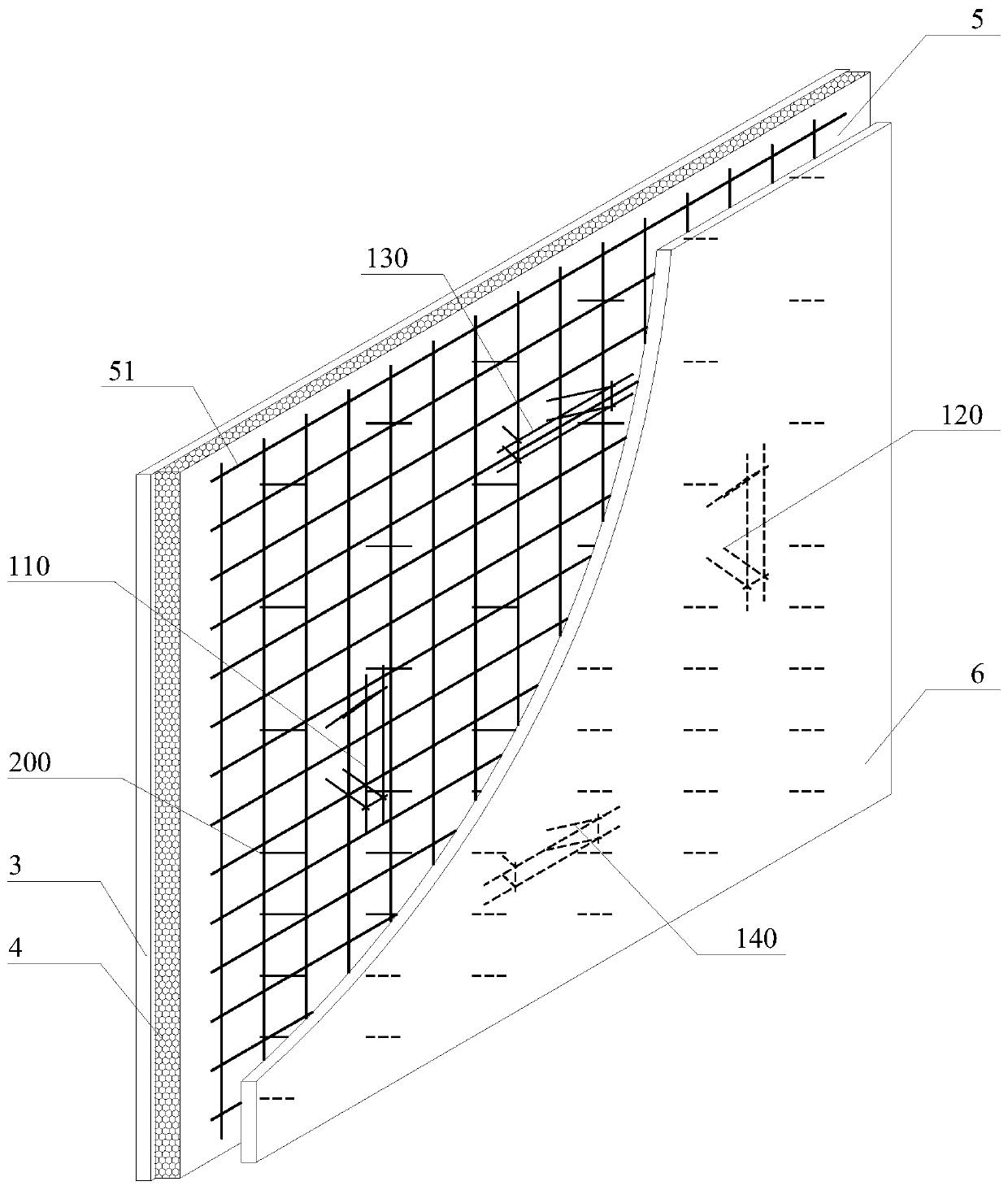

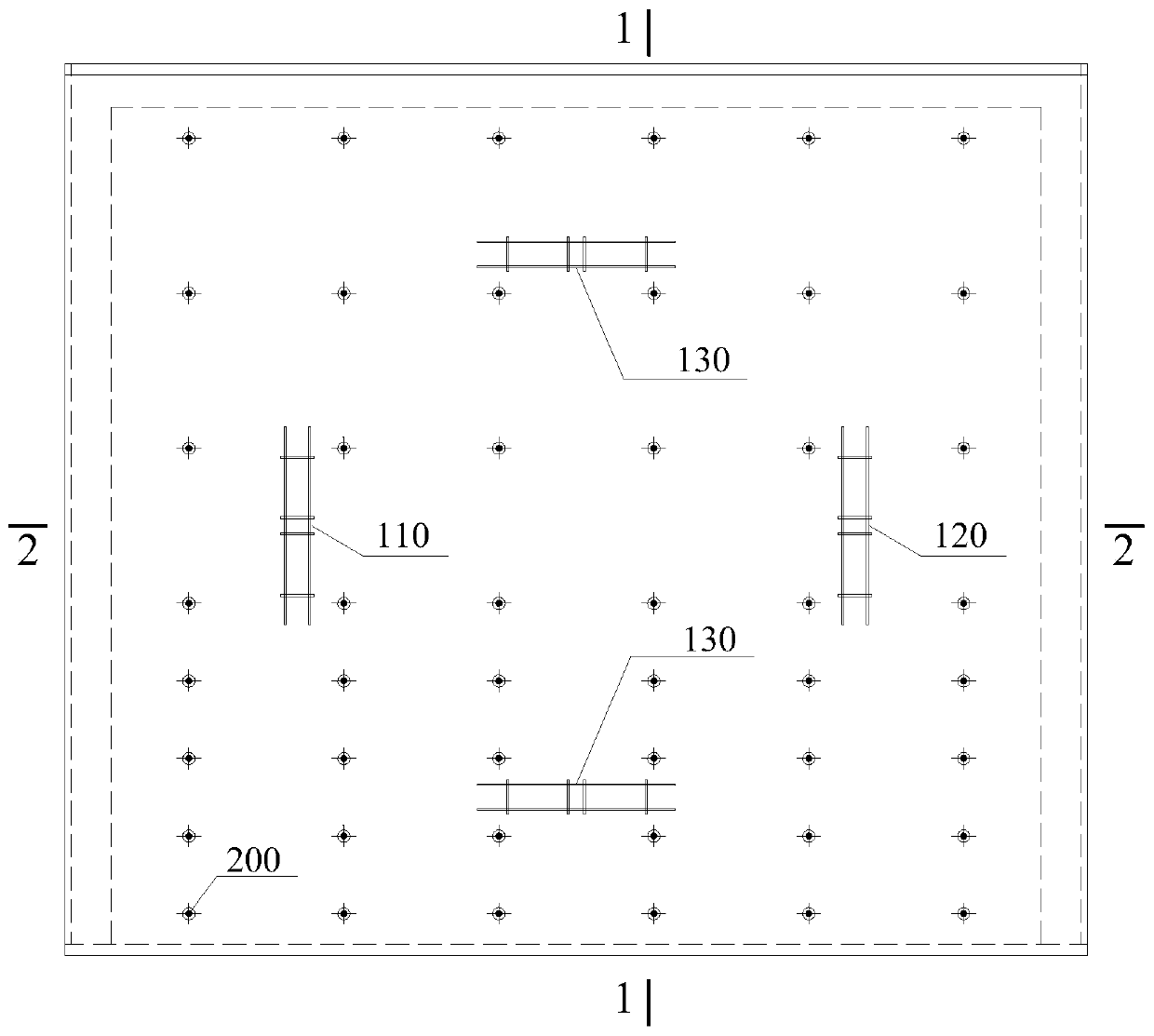

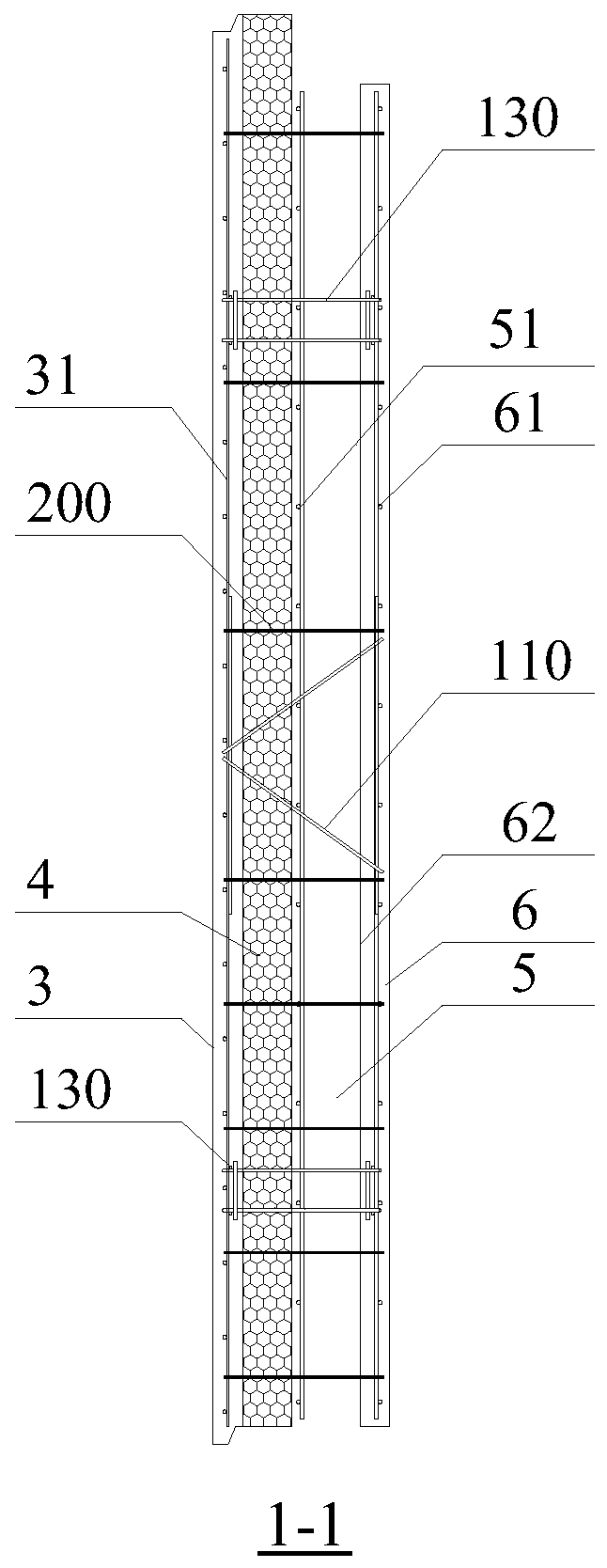

Sandwich heat preservation composite shear wall prefabricated part and manufacturing method thereof

PendingCN110978211AAvoid forceAvoid problems with unclear design calculationsWallsCeramic shaping apparatusInsulation layerMesh reinforcement

The invention discloses a sandwich heat preservation composite shear wall prefabricated part and a manufacturing method thereof. The prefabricated part comprises an inner concrete wallboard, an outerconcrete wallboard, a heat preservation layer, a cavity and a connecting piece system; the connecting piece system penetrates through the cavity and the heat preservation layer and extends into the inner concrete wallboard and the outer concrete wallboard; and the connecting piece system comprises at least four independent truss connecting pieces and a plurality of rod-shaped connecting pieces with the lengths distributed in a wall thickness direction. The manufacturing method comprises the following steps of: binding the reinforcing mesh of the outer concrete wallboard, and mounting the connecting piece system on the reinforcing mesh; pouring outer wallboard concrete, laying a heat insulation board, and mounting a reinforcing mesh in the cavity; binding and mounting the reinforcing mesh of the inner concrete wallboard, pouring concrete, keeping the inner concrete wallboard still, and integrally overturning other components by 180 degrees; and moving the overturned components towards the inner concrete wallboard, pressing the end portions of all the connecting pieces into the inner concrete wallboard and making the end portions of all the connecting pieces fully contact with the inner concrete wallboard. All components in the connecting piece system are stressed definitely, and the non-combined stress mode of a sandwich heat preservation composite shear wall is achieved.

Owner:CABR TECH CO LTD

Circuit board recycling treatment device

PendingCN109772561AImprove recycling ratesSolve material wasteGrain treatmentsElectric machineryMagnet

The invention discloses a circuit board recycling treatment device. The circuit board recycling treatment device comprises a machine body, the top of the machine body is provided with a material inletin a running through manner, the top of the material inlet is connected with moving plates through springs, the two sides of the material inlet are provided with first air cylinders, and the output ends of the first air cylinders run through the two sides of the material inlet and are connected with impact plates, the upper portion of one side of the machine body is provided with a first motor, the lower portion of one side of the machine body is provided with a second motor, and the circuit board recycling treatment device is further provided with a flow guide plate, the second motor and magnet rods. According to the circuit board recycling treatment device, circuit boards fall to the flow guide plate from a filter screen after being smashed, because the tilt angle of the flow guide plate is relatively gentle, the smashed circuit boards are made to fall slowly, the second motor rotates to make the magnet rods rotate, metal contained inside downward-falling broken blocks is adsorbed by the magnet rods, and the metal adsorbed on the magnet rods is collected manually, the recycling use ratio of the circuit boards is increased, generated dust is collected and treated by a dust remover, and pollution of the dust to the environment is prevented.

Owner:WUHAN POLYTECHNIC UNIVERSITY

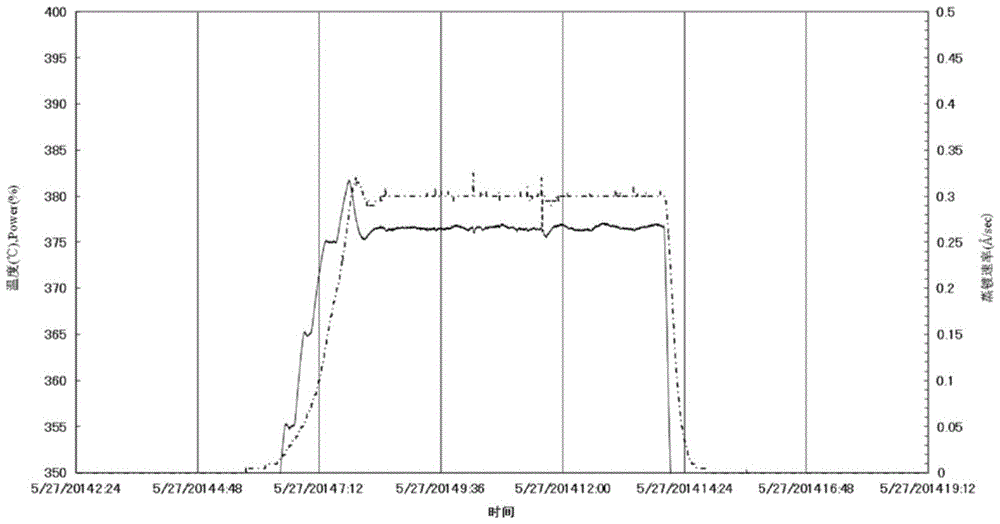

Metallographic detection sample preparation method after carbonitriding of high-carbon chromium bearing steel, as well as product

InactiveCN103938149AImprove detection accuracyEasy vertical measurementPreparing sample for investigationSolid state diffusion coatingNitrogenRoom temperature

The invention discloses a metallographic detection sample preparation method after the carbonitriding of high-carbon chromium bearing steel. The sample preparation method comprises the following steps: tempering for 2-3 hours at high temperature, cooling to room temperature, then cutting, inserting, grinding and polishing a bearing to obtain parts, putting the part in a 5%-6% picric acid alcoholic solution for etching for one minute, cleanly washing the parts and blow-drying to obtain samples. When the samples, prepared by adopting the method, are used for metallographic observation, the depth of carbo-nitride compound particles on the surface of the bearing can be more easily judged, and the detection accuracy can be improved. The invention further discloses samples prepared by adopting the method, the acicular martensite structures and retained austenite structures on the surfaces of the samples are decomposed into troostite structures after being prepared by adopting the method, so that the carbo-nitride compound particles can be more easily differentiated.

Owner:C&U CO LTD

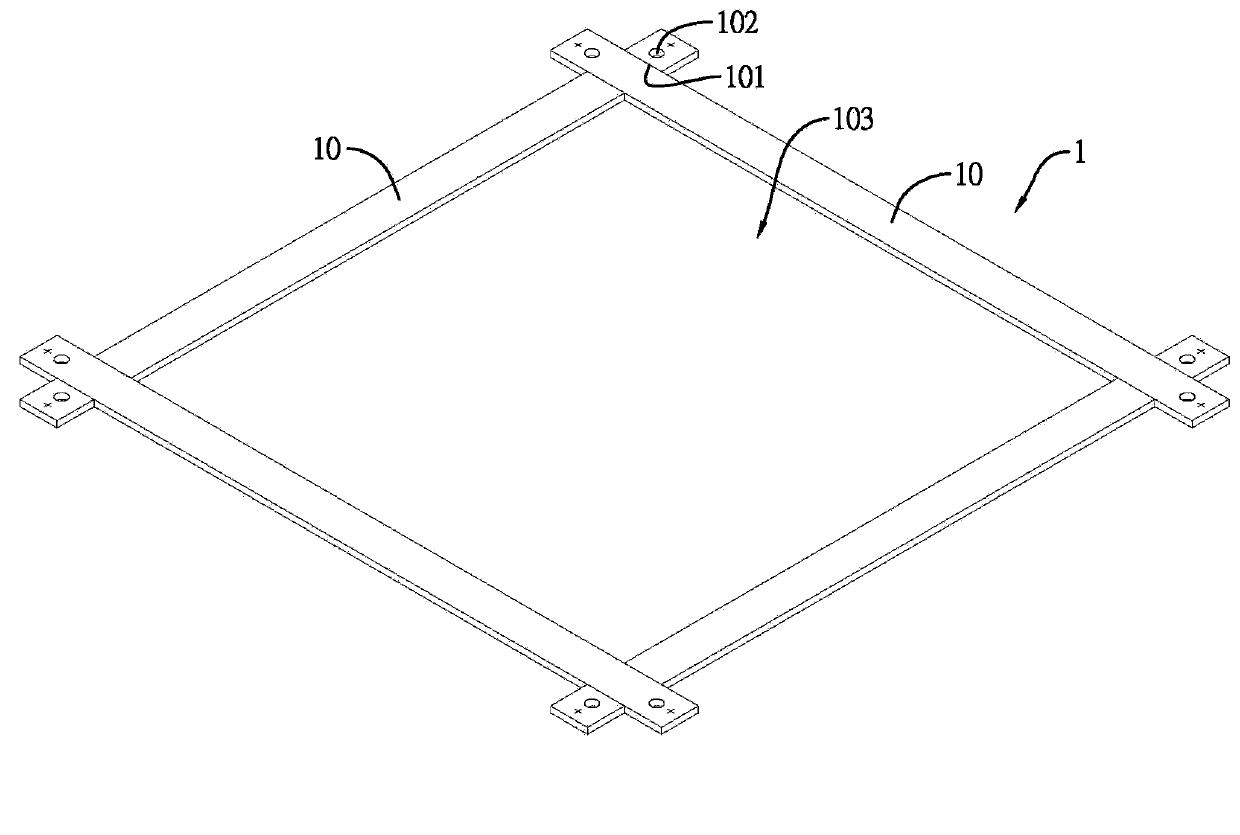

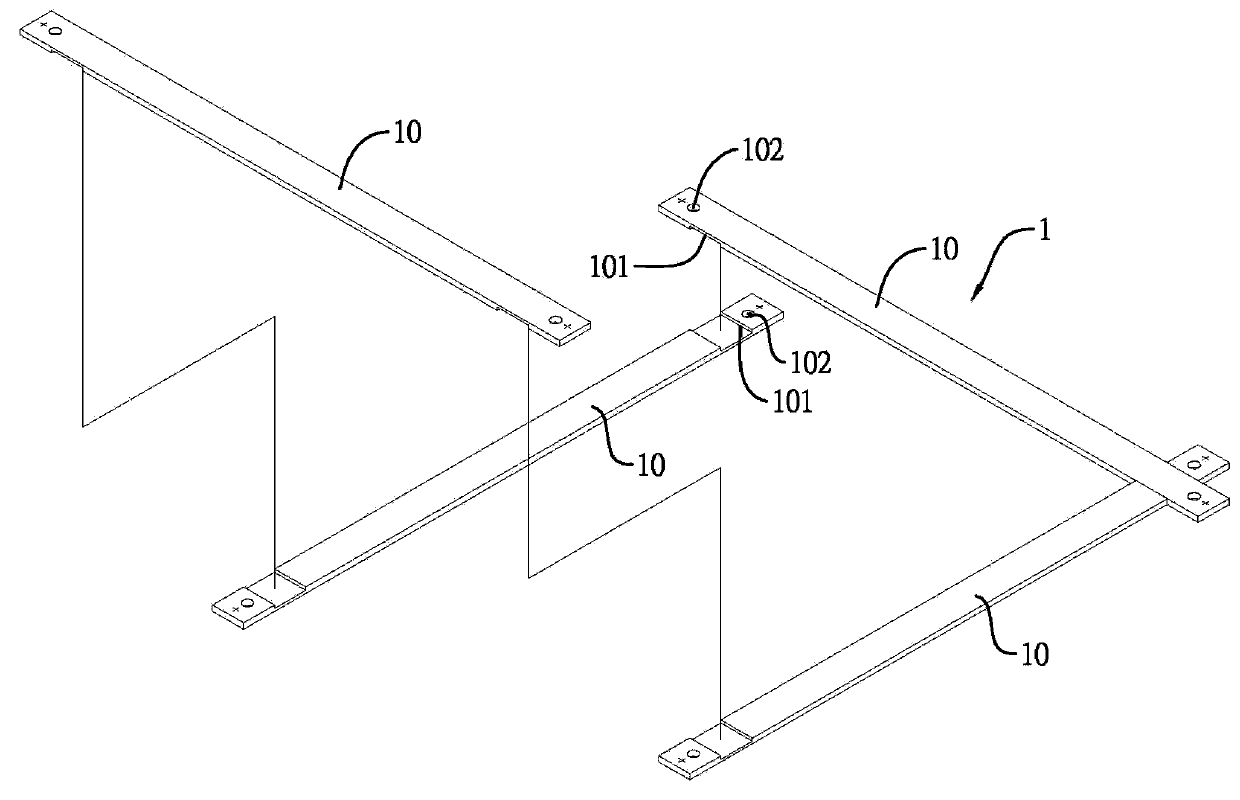

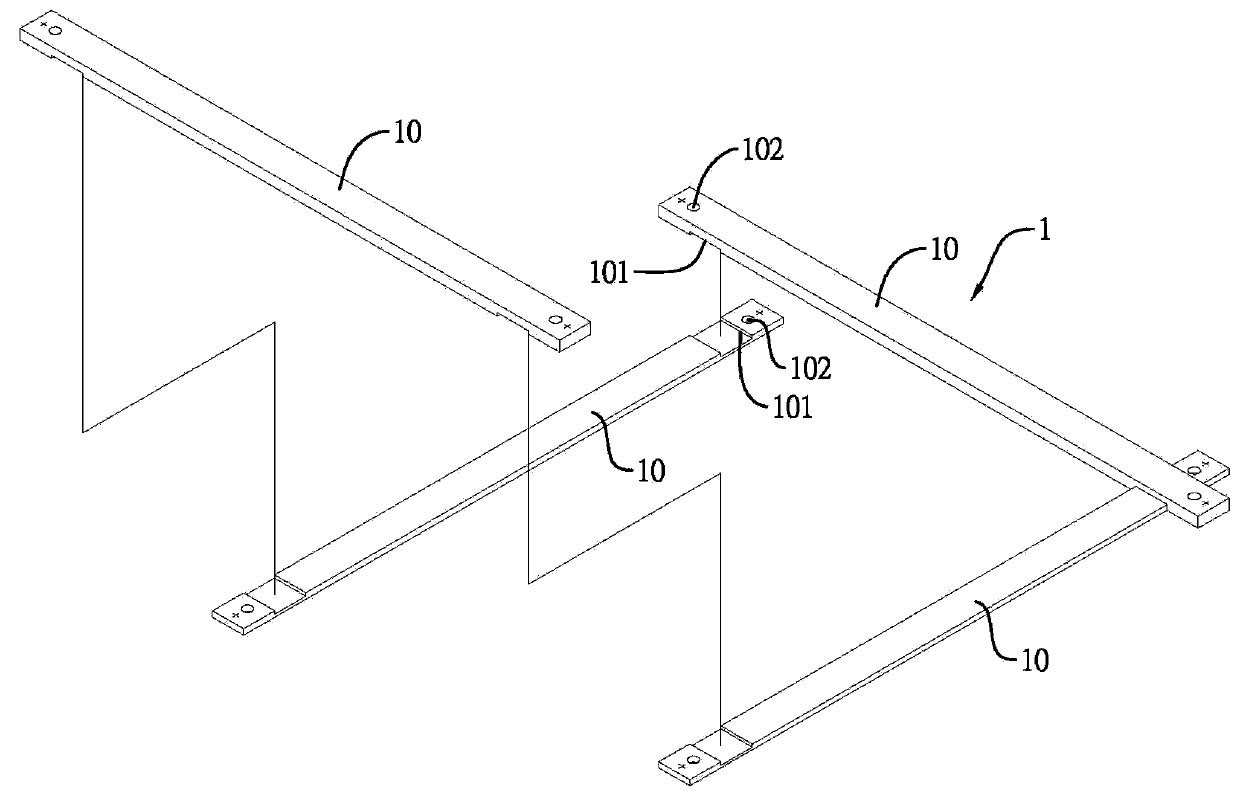

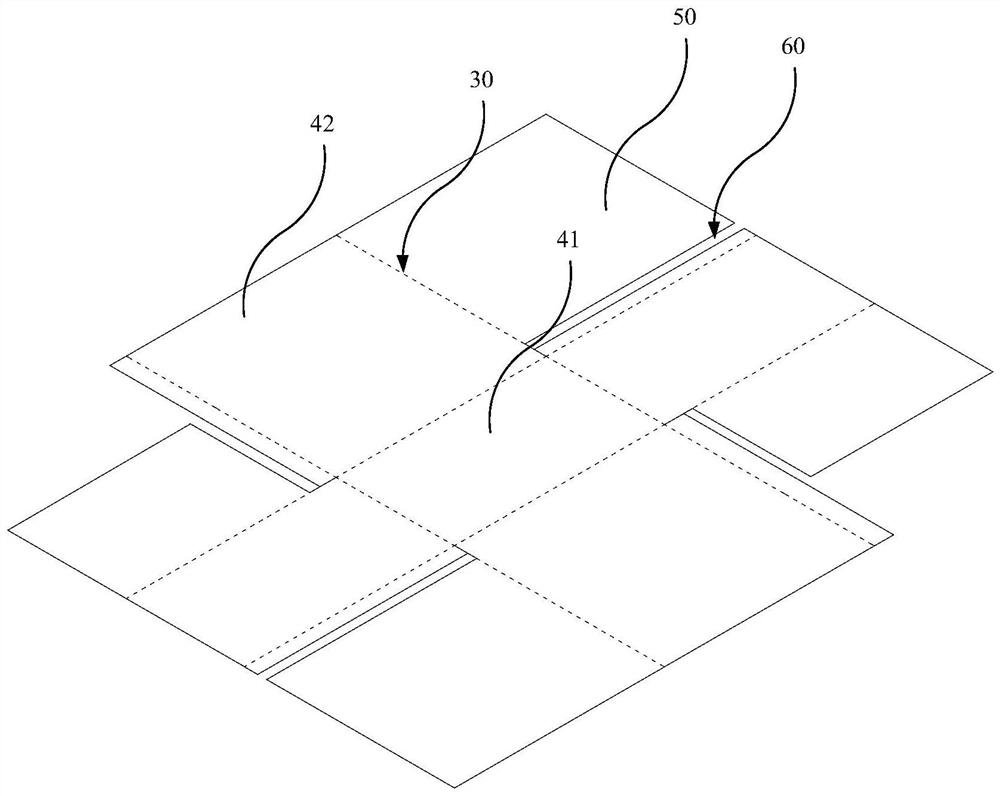

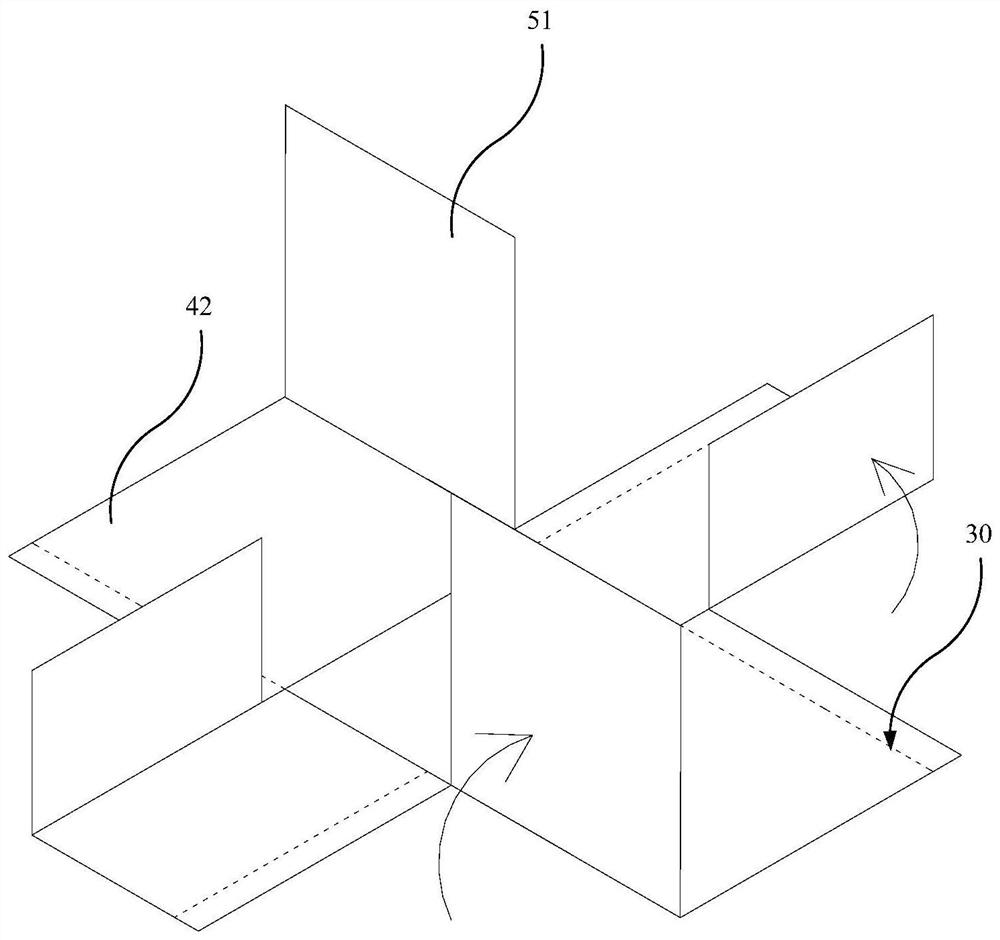

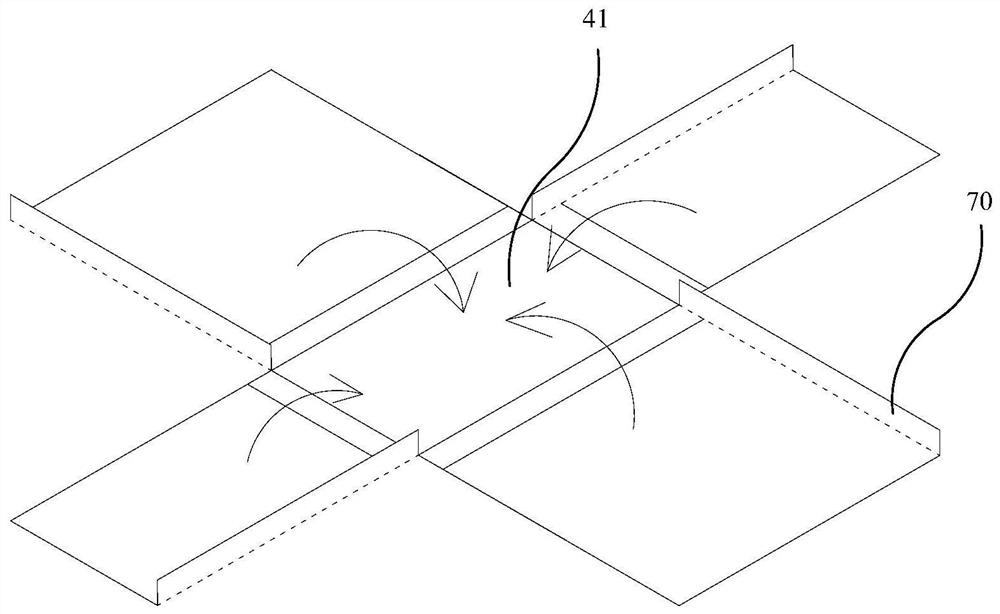

Combined mask

ActiveCN103993260AAvoid crossingAvoid distortionVacuum evaporation coatingSputtering coatingSputteringEvaporation

The invention relates to a combined mask. The combined mask comprises four main frame plates that are vertically and horizontally overlapped to form a rectangular frame internally provided with a main rectangular coating area, and ones sides of the main frame plates can form a flush coated object contact surface. Thereby, the mask with a large-area coating area can be formed. In addition, and the characteristics of easy manufacturing and no material waste of the strip-shaped main frame plates are utilized to reach the efficacy of saving manufacturing materials and reducing the cost. Also, the coated object contact surface of the combined mask is flush, can be attached to the coated object surface as far as possible. In a coating deposition process, the coating material for evaporation or sputtering can be effectively prevented from passing through the gap between the combined mask and the coated object, thus avoiding the circumstance of coating pattern distortion.

Owner:FINEMAT APPLIED MATERIALS

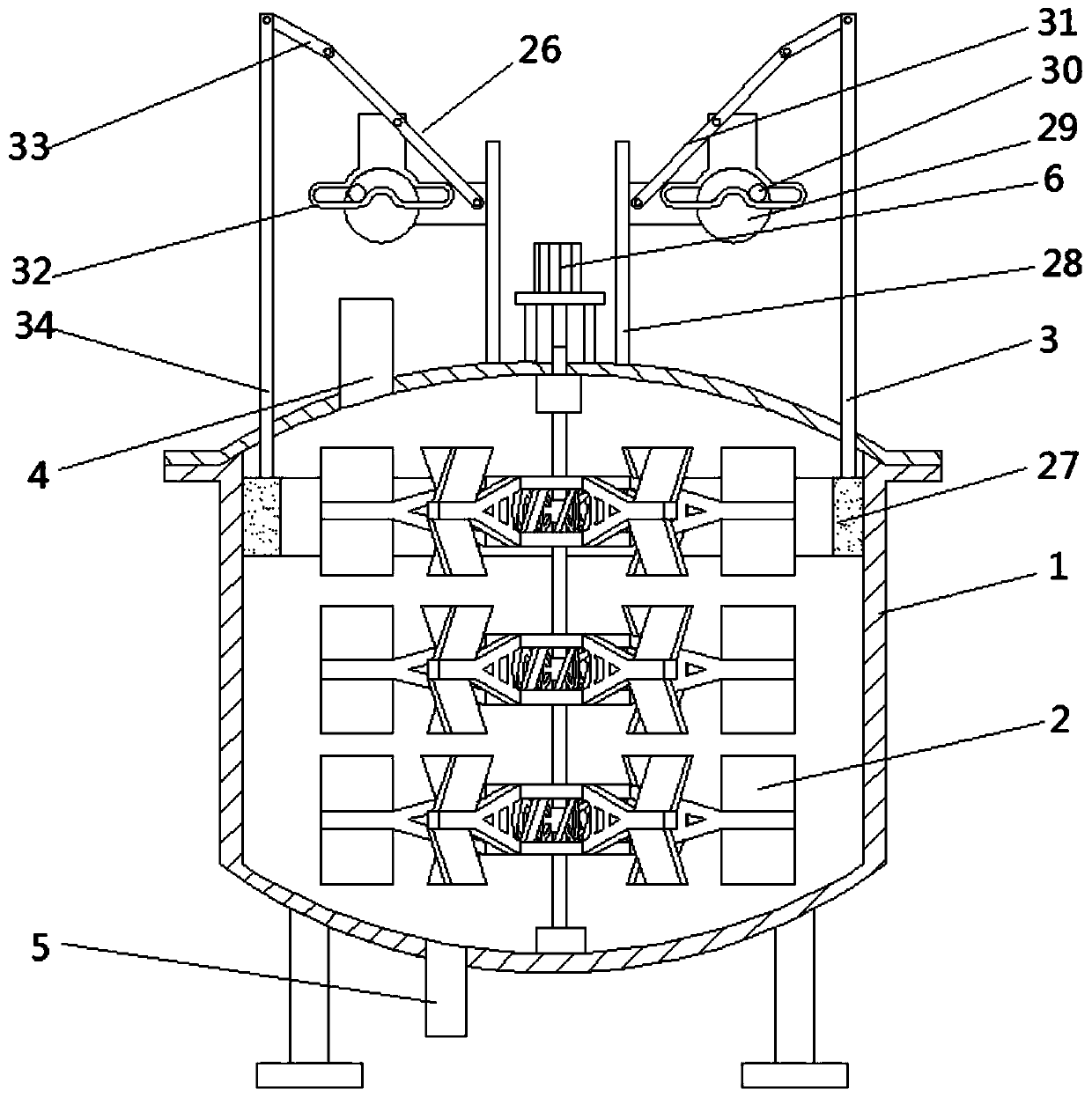

Stirring device for producing plastic products

The invention discloses a stirring device for producing plastic products. According to stirrers of the stirring device, the problems that an existing stirring device is long in stirring time and low in stirring efficiency in a stirring process is solved. Through distribution of the plurality of stirrers in an axial direction of a tank body, a plurality of layer flows are formed in the axial direction of the tank body, so that materials can be mixed up and down, layer flows distributed in a radial direction of the tank body are formed in each layer flow in the axial direction by utilizing a first stirring blade and a second stirring blade, so that the materials can be exchanged inside and outside, so that the stirring mixing effect and efficiency in the radial direction are improved. A material scraping structure solves the problems that materials are easy to adhere to the inside of a tank body in the existing stirring process, so that uneven stirring and material waste are caused. Through a connecting rod mechanism formed among a driving frame, a first connecting rod, a second connecting rod and a third connecting rod, the third connecting rod is driven to linearly move along a central axis direction of the tank body, a scraping ring moves along with the third connecting rod, so that the materials which adhere on the inner wall of the tank body are scraped into the tank body tobe stirred.

Owner:江苏东弘塑业有限公司

Thermal forming method for rigid foam core material

The invention relates to a thermal forming method for a rigid foam core material and belongs to the technical field of composite manufacturing. The thermal forming method mainly comprises the steps of putting a PMI foam board onto a female mold forming mold through a vacuum bag / curing oven forming technology; blocking the two ends of the PMI foam board with Airpad rubber; laying ventilated felt on the surface of the PMI foam board; then, pasting a vacuum bag; and forming the PMI board through bending by way of heating and vacuum extraction. According to the thermal forming method, the PMI foam core material is formed through the vacuum bag / curing oven forming technology, and the problem that when a machining forming mode is adopted, a great number of materials are wasted is solved.

Owner:JIANGXI HONGDU AVIATION IND GRP

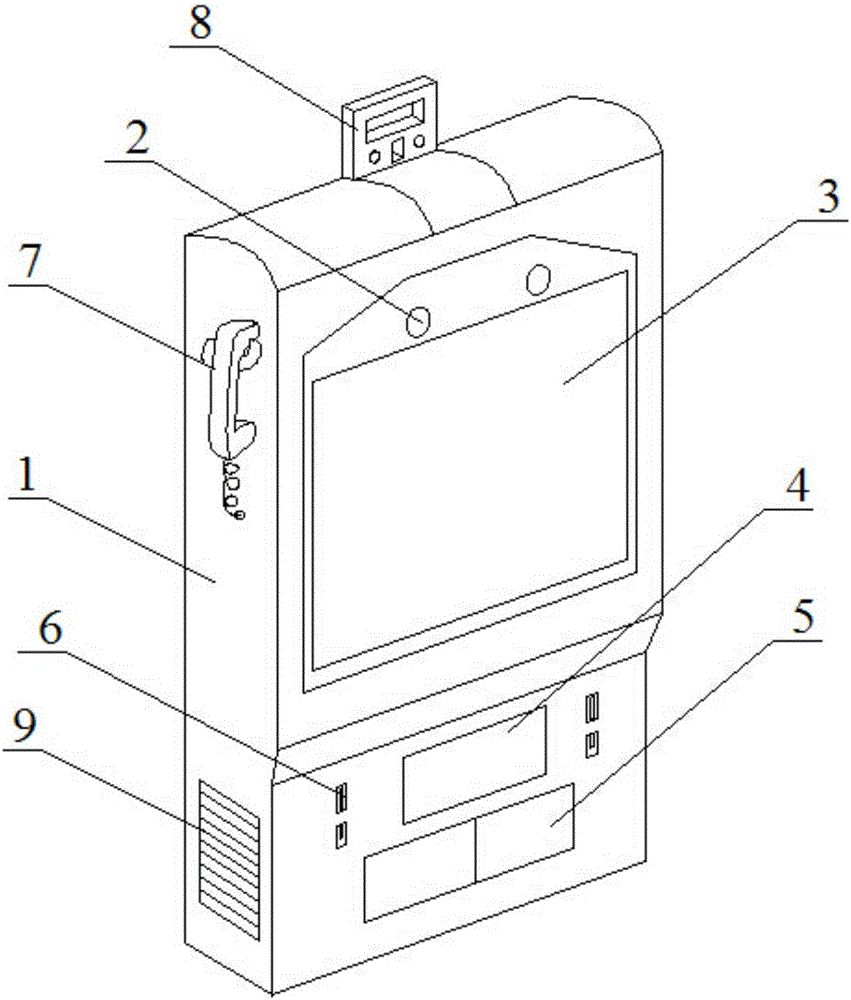

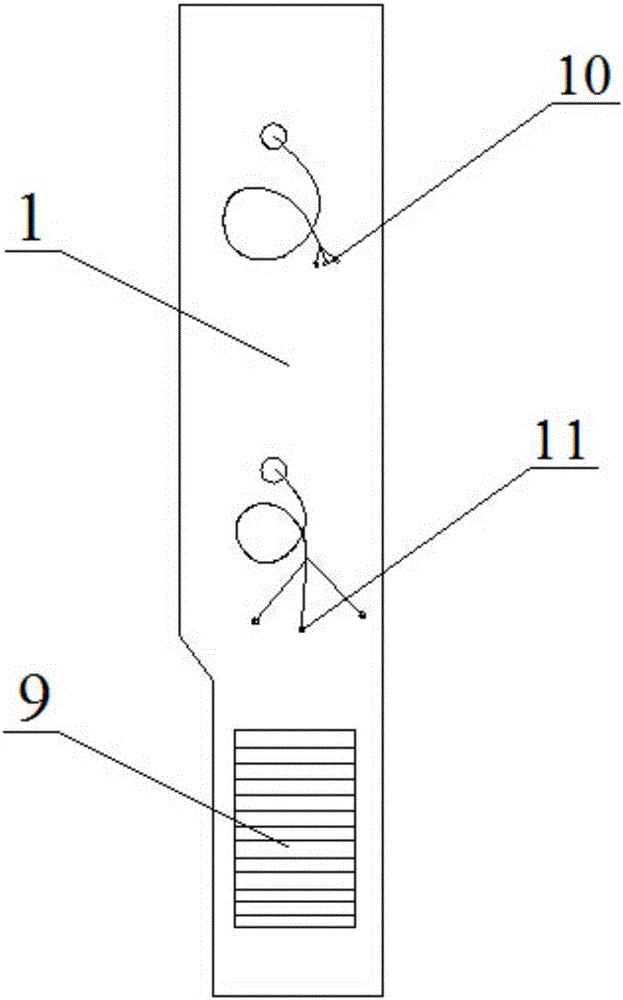

Mobile phone and electric vehicle dual-purpose networking intelligent charging integrated machine

InactiveCN106410911ARealization of networked smart chargingSolve space problemsCharging stationsMobile unit charging stationsInformation processingNetwork communication

The invention discloses a mobile phone and electric vehicle dual-purpose networking intelligent charging integrated machine which is an integrated wall-mounted intelligent charger and comprises a charger shell, a wall-mounted mounting assembly, a user identification system, a mobile Internet access system, a man machine operation system, an intelligent payment settlement system, a coin payment system, a charging capacity display system, a network communication system, an automatic charging system, an intelligent processing system, and connecting lines. The intelligent processing system comprises an information processing system, an intelligent motherboard, a wireless router, and a wireless network card, and the systems are connected through the connection lines. The mobile phone and electric vehicle dual-purpose networking intelligent charging integrated machine conforms to the development needs of the mobile Internet, Internet+, and smart cities and is connected to the mobile Internet, a new 'smart' way of life is formed, a mobile phone charger and an electric vehicle charger are integrated into one body, and the networking intelligent charging of a mobile phone and an electric vehicle is realized.

Owner:扬州亮点网络技术有限公司

Skin disinfection device

InactiveCN110152176AWill not delay the treatment timeTime-consuming and laborious to solveMedical devicesMedical applicatorsDisinfectantEngineering

The invention discloses a skin disinfection device. The device comprises a sponge, wherein a mounting block is fixed to the upper end of the sponge, a first handle is arranged at the upper end of thesponge, a first cavity is formed in the first handle, and the lower end of the first cavity is communicated; the two ends of the mounting block are fixed to the side walls at the two ends of the firstcavity, a second cavity is formed in the mounting block, a first opening is formed in the upper end of the second cavity, and a disinfectant capsule is fixed to the bottom of the second cavity; one end of the disinfectant capsule penetrates through the first opening and extends into the first cavity; the two ends of the first handle are both provided with a protection box; a third cavity is formed in each protection box, and a first fixing rod penetrates through the side wall of one end of each third cavity. Through transformation of the skin disinfection device, the problem that time, laborand materials are wasted is solved; moreover, the skin disinfection device is simple in structure and convenient to operate, can be taken and used immediately and cannot delay the treatment time of medical staff, so that the skin disinfection device is suitable for popularization.

Owner:赵琳

Suction bucket foundation with anti-pull steel pipe pile and mounting method thereof

The invention discloses a suction bucket foundation with an anti-pull steel pipe pile and a mounting method thereof. The suction bucket foundation comprises a bucket body and an anti-pull pile mechanism. The bucket body is of a bucket-shaped structure with an open bottom and a sealed top, and an inner bin is formed in the bucket body. The bucket body comprises an inner bucket wall and an outer bucket wall, and a hollow interlayer is formed between the inner bucket wall and the outer bucket wall. The anti-pull pile mechanism is arranged in the hollow interlayer and can vertically slide along the hollow interlayer. The anti-pull pile mechanism comprises a base and the anti-pull steel pipe pile. The use method comprises the following steps that (1) the bucket body sinks due to the dead weight; (2) water is extracted out of the inner bin, and the bucket body continues to sink; (3) the anti-pull steel pipe pile stretches out of the hollow interlayer and penetrates into a seabed; and (4) high-pressure water in the hollow interlayer is drained to underwater grouting liquid to fill the hollow interlayer, and after the underwater grouting liquid is solidified, the steel pipe pile and the bucket body form a whole. According to the suction bucket foundation with the anti-pull steel pipe pile and the mounting method thereof, the anti-pull steel pipe pile can penetrate into the seabed, theanti-pull bearing capacity of the suction bucket foundation is improved, and the problems of soil blocking and material waste caused by bucket length increase and bearing capacity improving are solved.

Owner:SUN YAT SEN UNIV

Electric pole protection layer cushion block forming device and method and electric-pole centrifugal forming machine

The invention discloses an electric pole protection layer cushion block forming device and method and an electric-pole centrifugal forming machine. The electric pole protection layer cushion block forming device comprises a conical sleeve connected to the large end of an electric-pole steel mold. A cushion block mold is arranged on the inner surface of the conical sleeve in the circumferential direction. A protective layer cushion block and an electric pole are integrally and centrifugally formed by the cushion block mold through concrete mortar discharged in the electric pole centrifugal forming process. According to the electric pole protection layer cushion block forming device and method and the electric-pole centrifugal forming machine, as the concrete electric pole protection layer cushion block is made of the mortar discharged in the electric pole centrifugal forming process, the problem that in the prior art, materials and labor are wasted during production of the electric pole protection layer cushion block is solved; meanwhile, the concrete protection layer cushion block can be conveniently and rapidly made, the residual concrete mortar discharged in the centrifuging process can be processed, and the production cost is reduced.

Owner:SICHUAN CHINA STRUCTURE RESIDENTIAL IND

Constructional column casting tool and method

PendingCN110067379ASolve material wasteGuarantee the pouring qualityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksChiselArchitectural engineering

The invention discloses a constructional column casting tool and method. The constructional column casting tool comprises a hopper and a first baffle, wherein the hopper is detachably mounted on a formwork of a constructional column and used for forming a casting opening; and the first baffle can move between the formwork of the constructional column and the hopper. In such arrangement, operatingpersonnel pours concrete into the inner side of the formwork of the constructional column through the hopper, the concrete is left to rest for some time after casting, the first baffle is inserted immediately into the concrete, the redundant concrete in the hopper is separated from the constructional column, the hopper is removed and transferred to a next construction site, at the same time, redundant concrete residue can be collected and reused, so that materials are not wasted, a bracket structure is also not formed, the construction efficiency is greatly accelerated, the quality of concretecasting is ensured, labor charge of later chisel away and repairing is reduced, the problems that in the prior art a bracket is produced and need to be dismantled later due to the fact that the constructional column and the casting opening are integrally casted and molded, the construction quality of the constructional column is affected, and materials and manpower are greatly wasted are avoided.

Owner:NANTONG SIJIAN CONSTR GRP

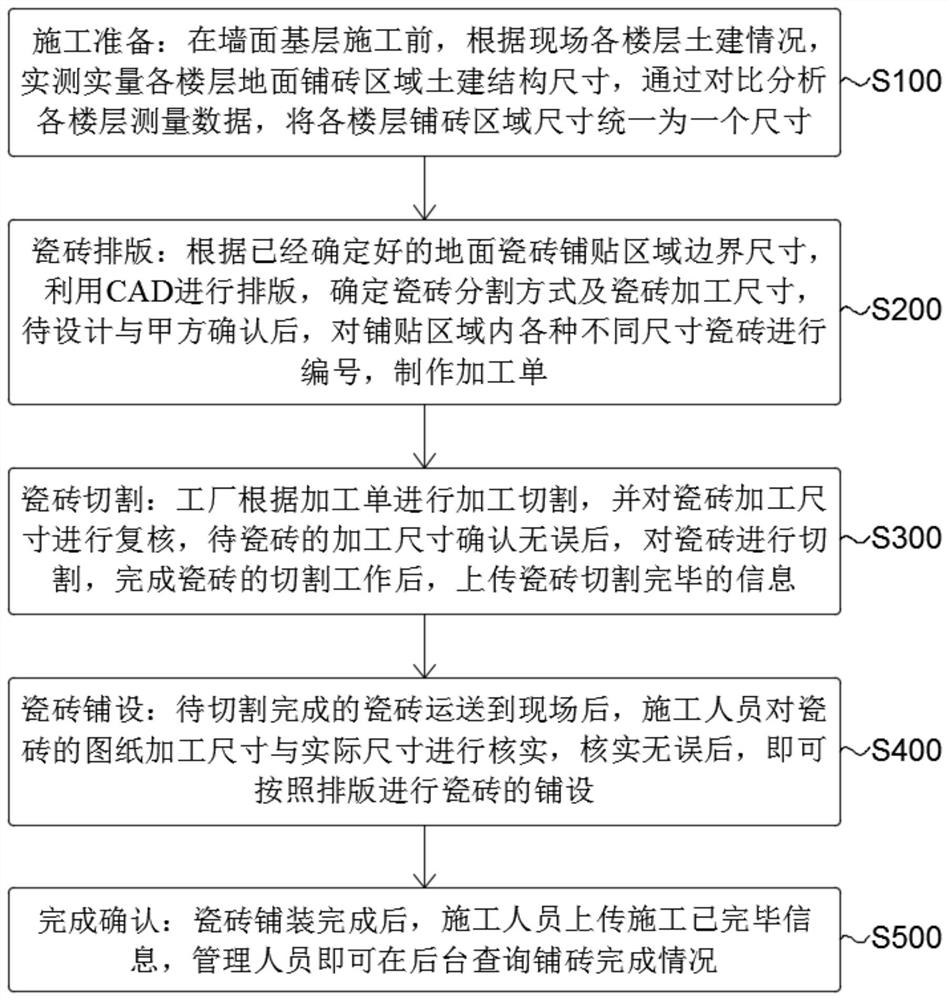

Ceramic tile batch processing accurate typesetting positioning construction process based on Internet of things

PendingCN112982913AFast and efficient pavingReal-time understanding of processing progressBuilding constructionsBrickConstruction engineering

The invention discloses a ceramic tile batch processing accurate typesetting positioning construction process based on the Internet of things. The construction process comprises the following steps that according to the civil engineering condition of each floor on site, the civil engineering structure size of the ground tile laying area of each floor is actually measured, and the sizes of the tile laying areas of all the floors are unified into one size; typesetting is carried out according to the boundary size of the ground tile laying area, and a processing list is manufactured; a factory carries out processing and cutting according to the processing list, and uploads the information of tile cutting completion; constructors verify the drawing processing size and the actual size, and after verification is correct, tiles can be laid; and after the tiles are laid, the constructors upload the construction completion information, and managers can inquire the tile laying completion condition in the background. The method is reasonable in design, ceramic tiles can be laid quickly and efficiently, meanwhile, the laying quality of the ceramic tiles can be guaranteed, and the ceramic tile laying cost and pollution generated in the ceramic tile cutting process are reduced.

Owner:中建八局装饰工程有限公司

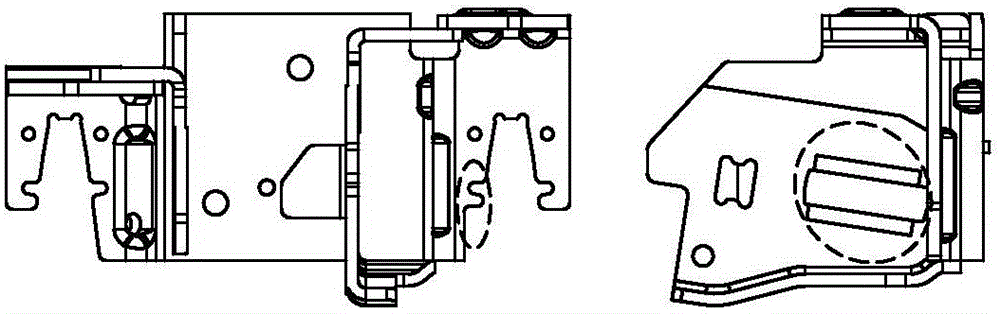

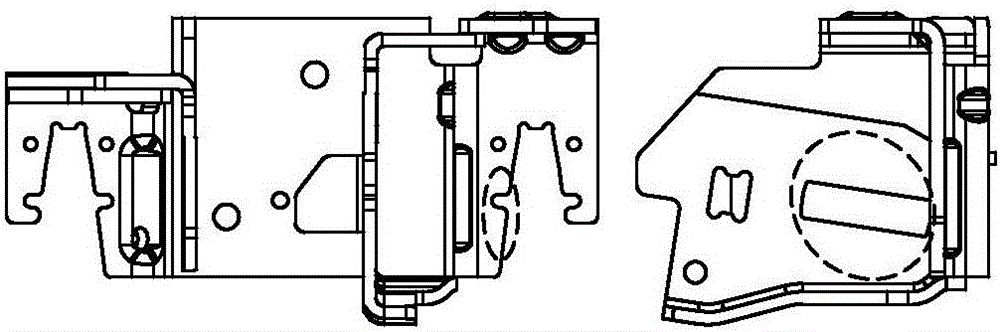

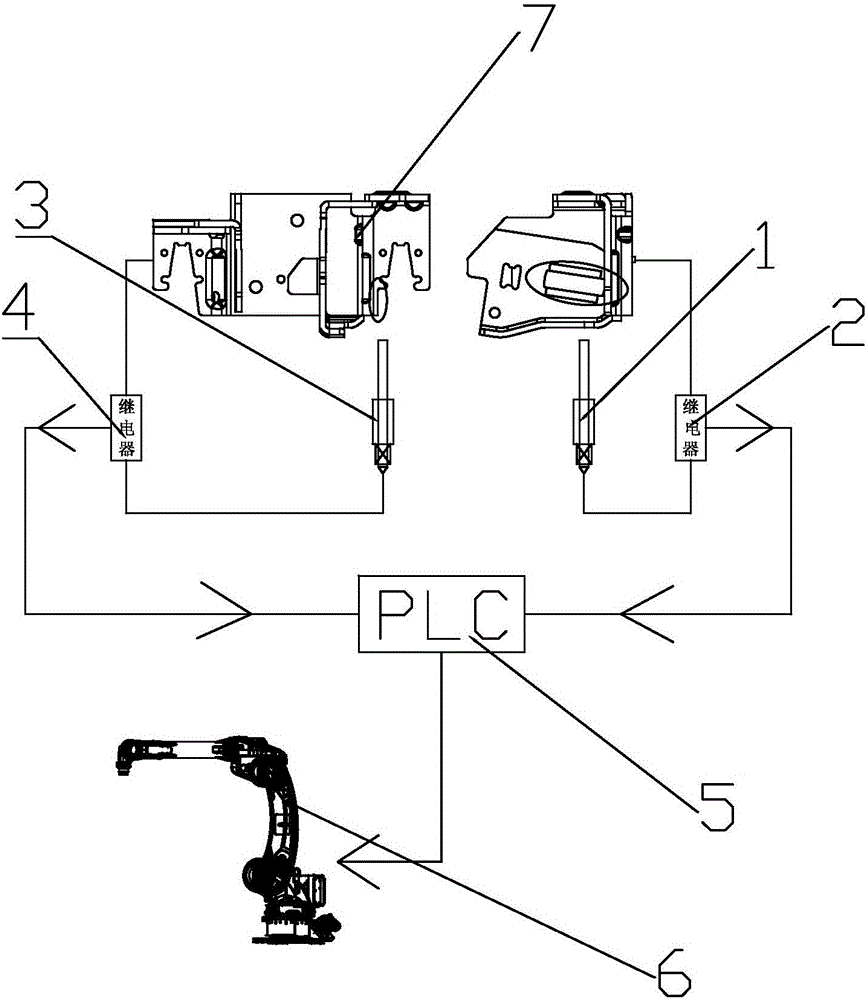

Welding recognition device for automobile parts

InactiveCN105911949ASolve scrapSolve material wasteWelding/cutting auxillary devicesAuxillary welding devicesWeldingScrap

The invention discloses a welding recognition device for automobile parts, and the device comprises a first tool and a second tool for placing to-be-detected products. A first sensor and a second sensor, which are used for detecting the to-be-detected products, are disposed outside the first and second tools. The first and second sensors are respectively connected with a first relay and a second relay. The first and second relays are respectively connected with a PLC control cabinet. The PLC control cabinet is connected with a welding robot. The device judges assembly products in the tools through the sensors, carries out the welding if the assembly products are qualified, cycles the unqualified assembly products, and solves problems of material waste and product scrap caused by assembly.

Owner:TAKAHASHI METAL MFG SUZHOU

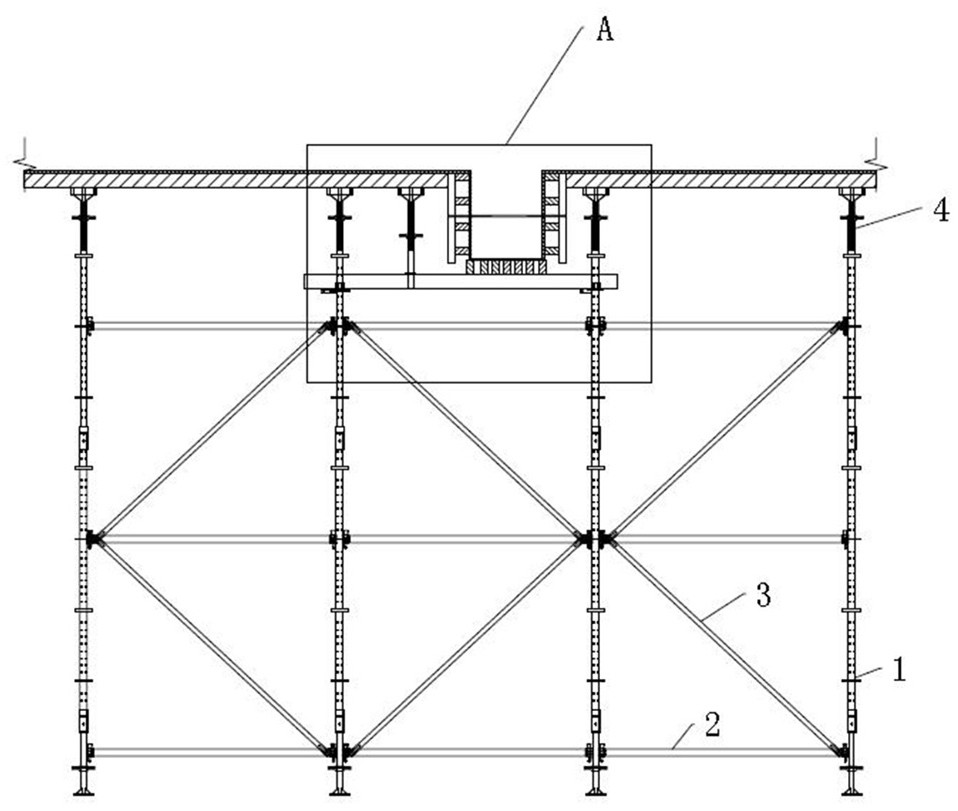

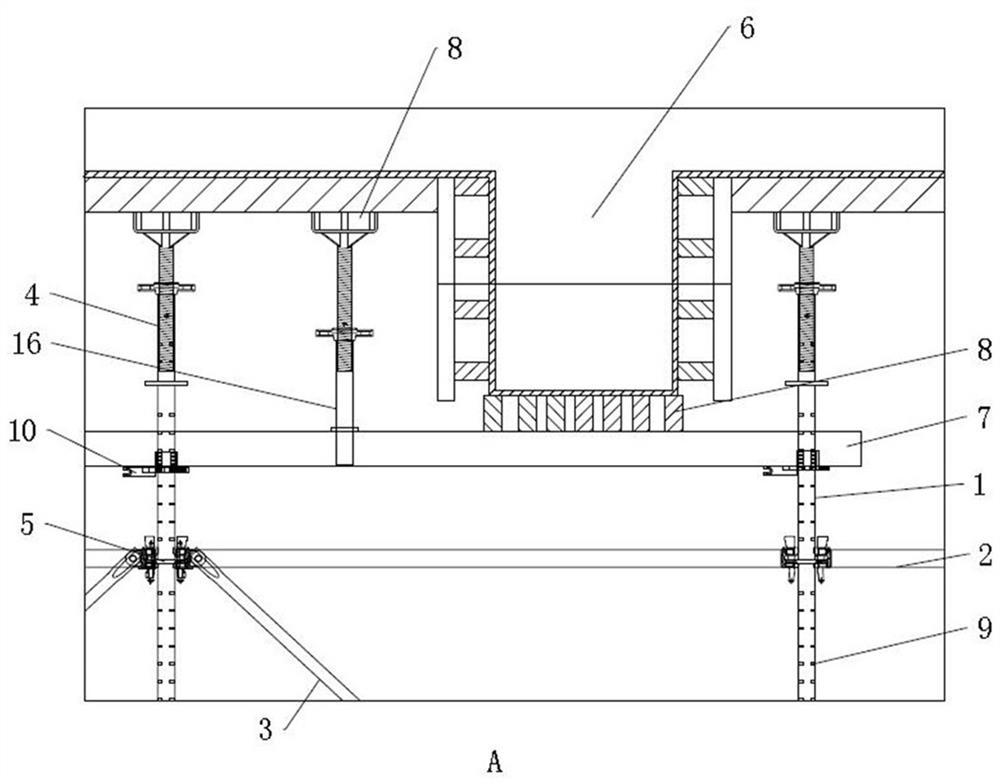

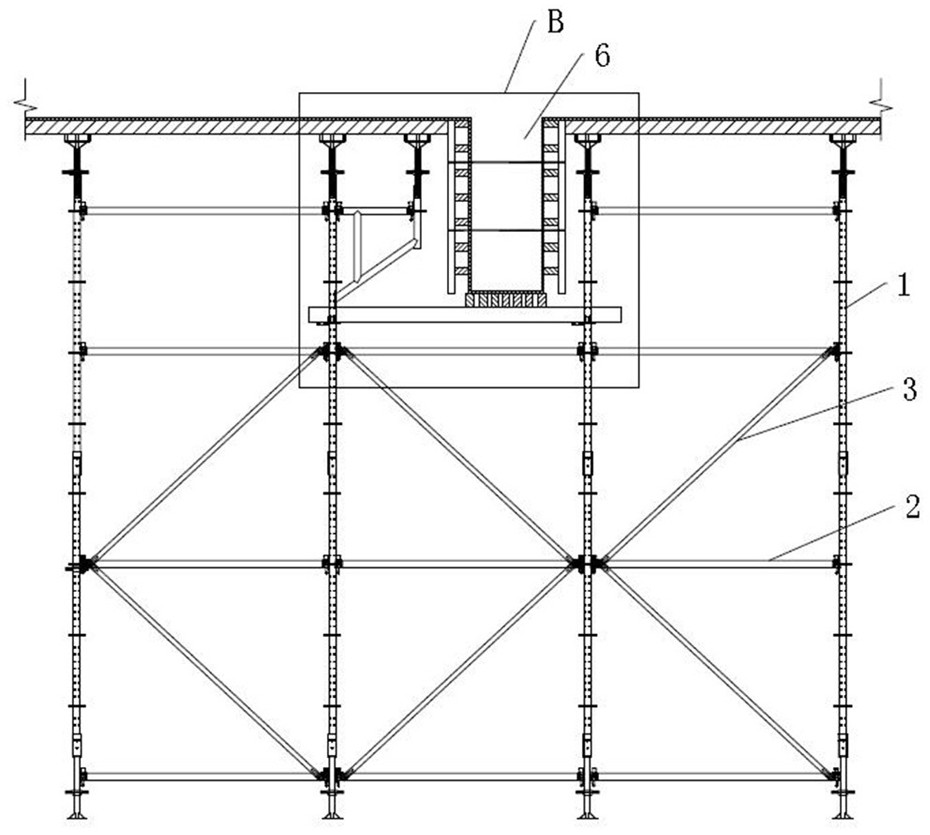

A Formwork Supporting System of Adjustable Elevation Combined Buckle Frame Using Micro-Bump Technology

ActiveCN114059752BHeight adjustableSolve material wasteScaffold connectionsScaffold accessoriesCircular discPhysics

The invention discloses an adjustable-elevation combined plate buckle frame formwork support system using micro-bump technology, which includes a plurality of rows of vertical rods arranged at intervals, a horizontal rod connecting two adjacent rows of vertical rods, and a horizontal rod connecting each row of adjacent vertical rods. The vertical rods of the rods and the oblique rods connected in the frame formed by the vertical rods and the horizontal rods, between the adjacent vertical rods, there are double C-shaped steels at the bottom of the structural beams for supporting the bottom mold of the structural beams, and multiple A group of protruding points arranged at intervals along its length direction, and each group of protruding points is arranged at intervals along the circumferential direction of the pole; a disc buckle frame disc is arranged at the installation position of the C-shaped steel on the pole, and the disc buckle frame disc is supported on the C The bottom of the section steel; the disk of the buckle rack includes an upper half disk and a lower half disk, one end of which is hinged, and the other end is detachably connected by a connecting component; the inner openings of the upper half disk and the lower half disk are formed with The cylinder wall is provided with concave points matching with the convex points on the vertical rod. The application has the advantages of adjustable height, strong applicability, material saving and matching with different building structures.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU

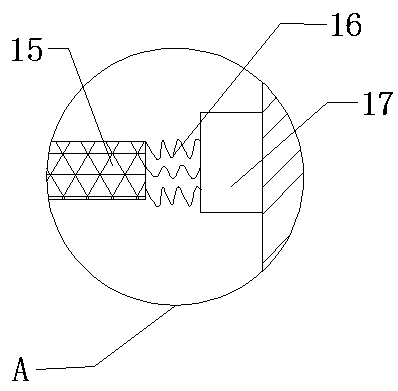

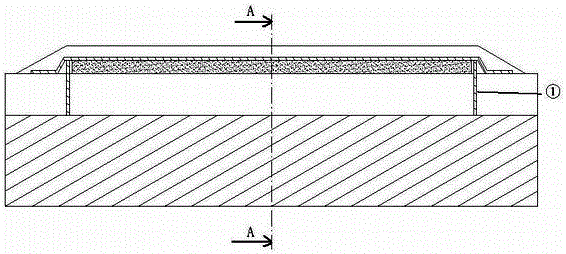

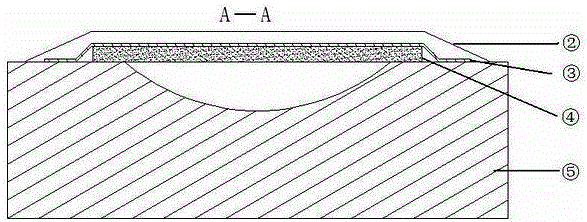

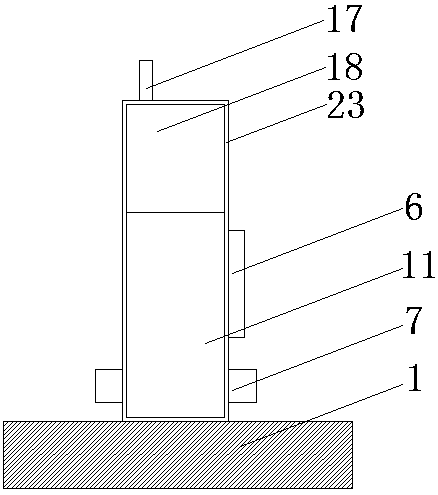

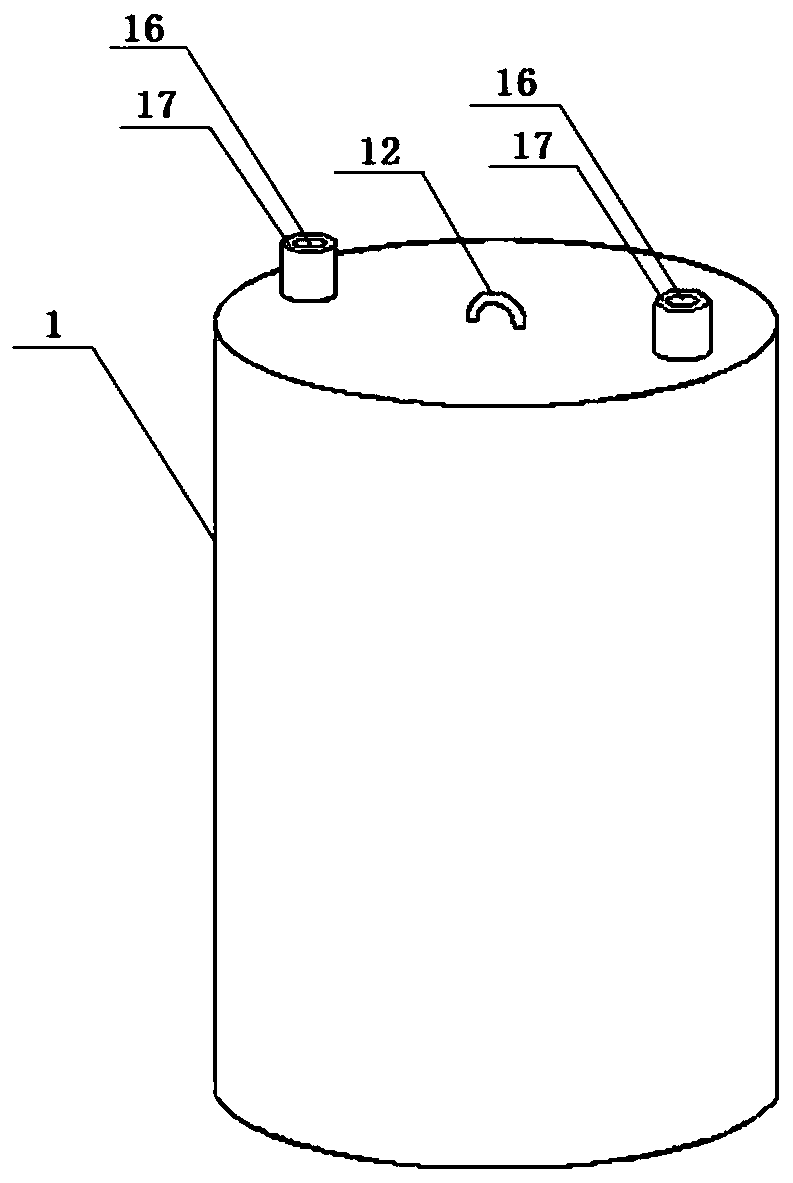

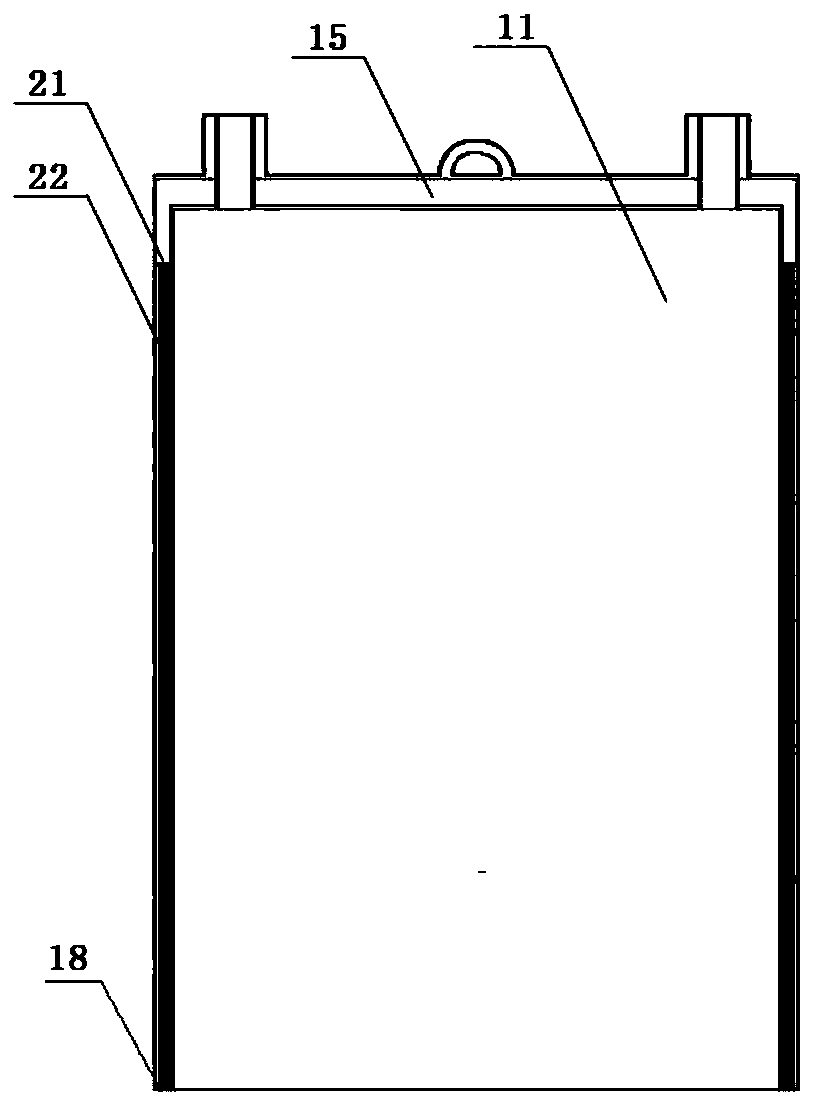

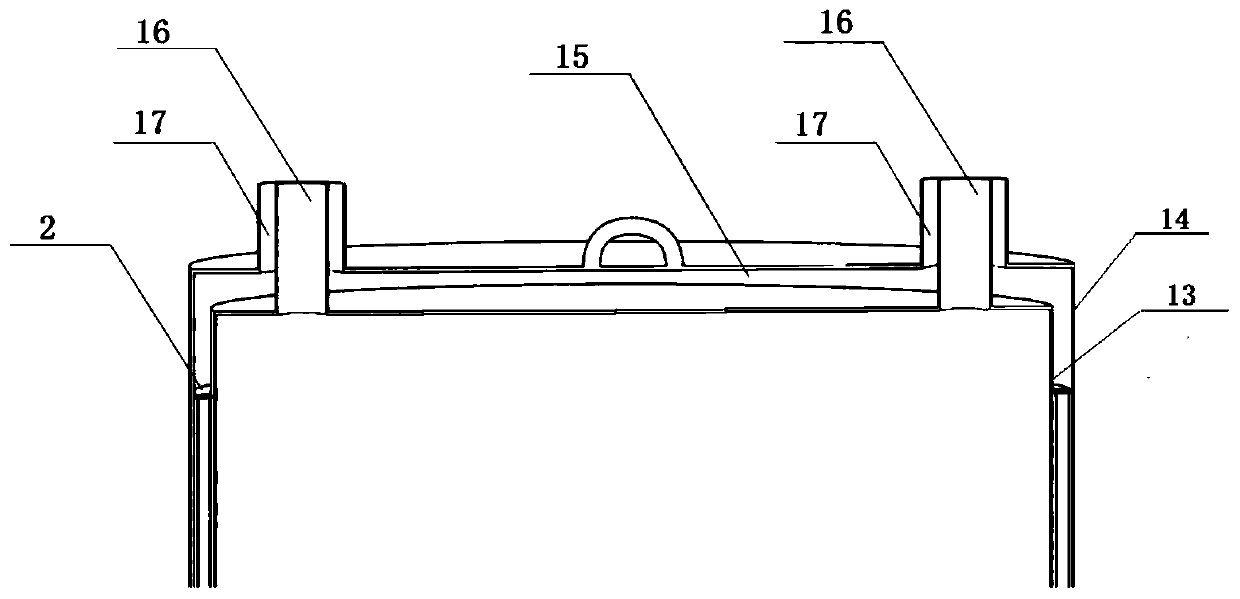

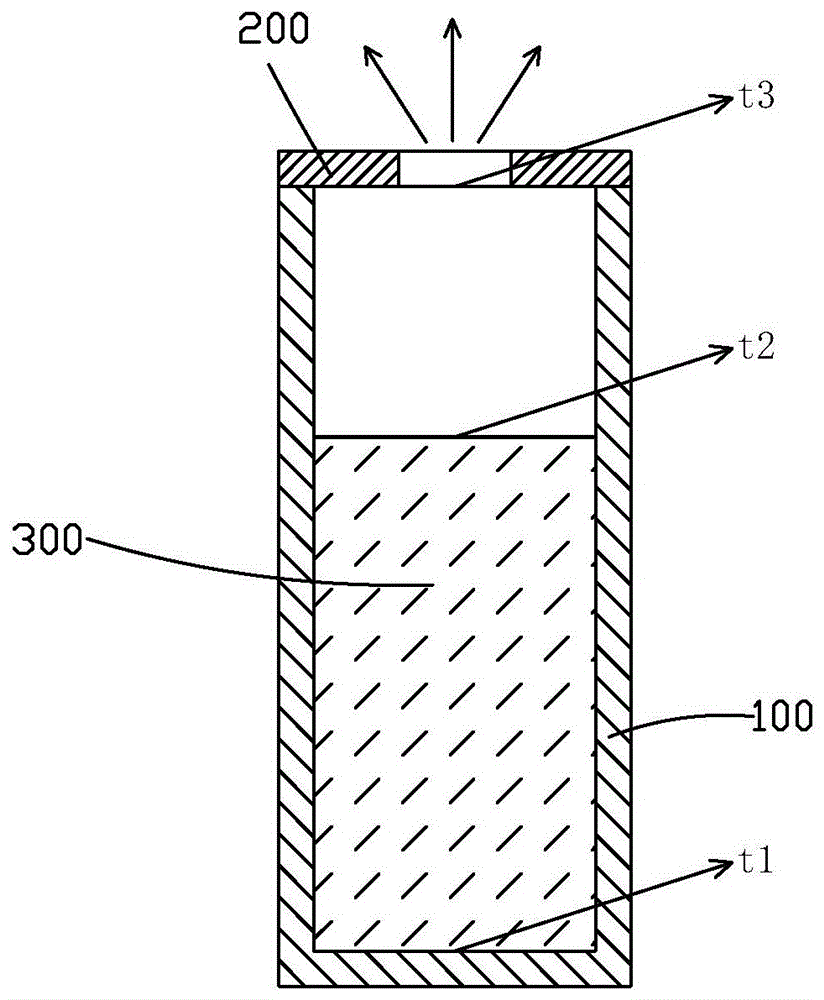

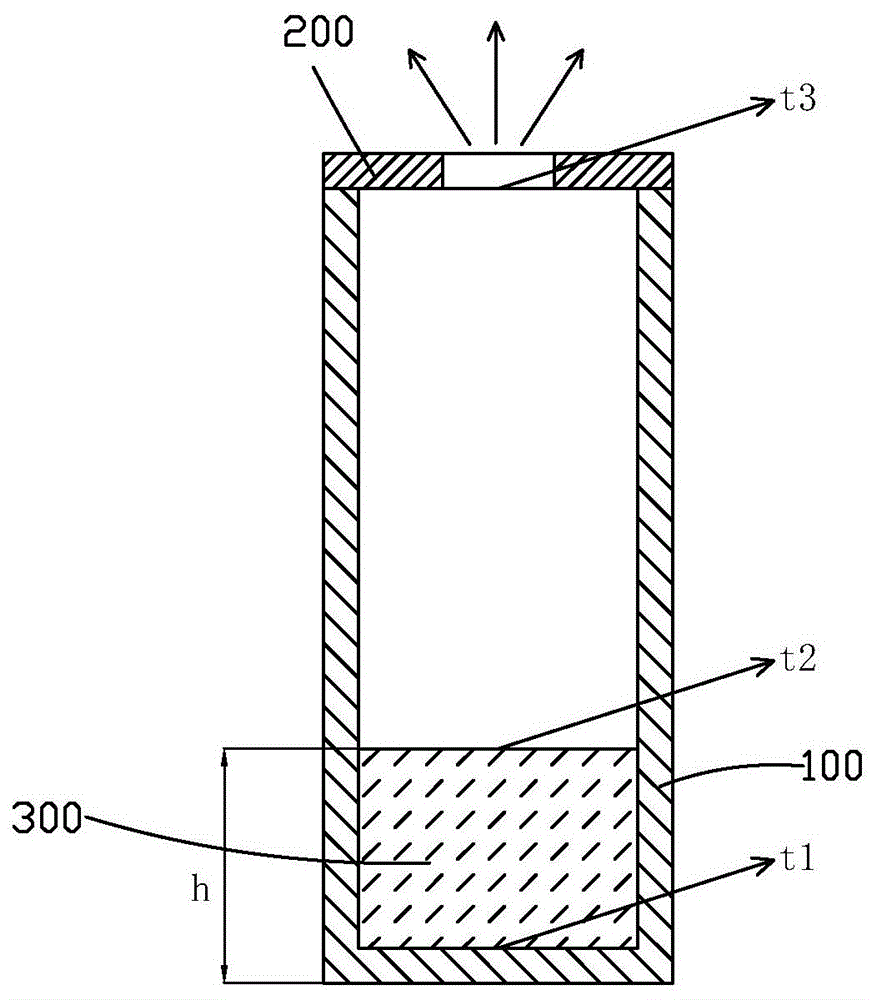

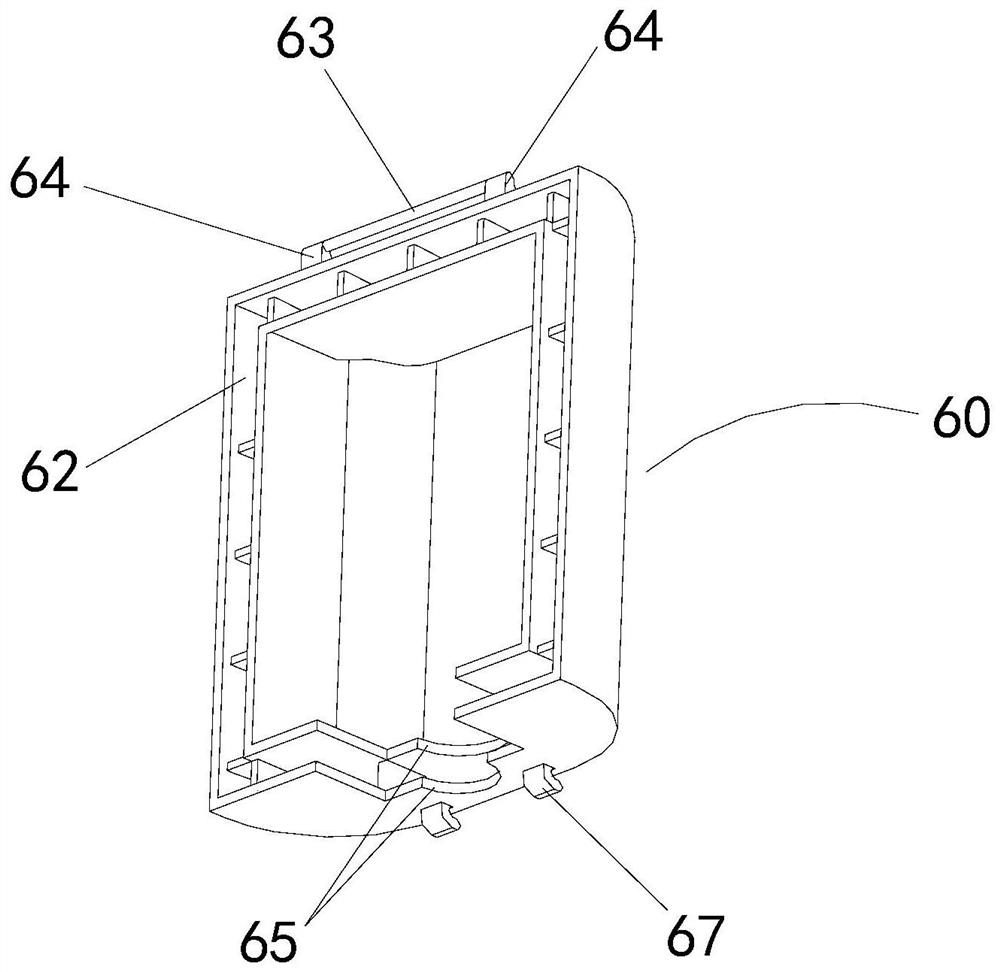

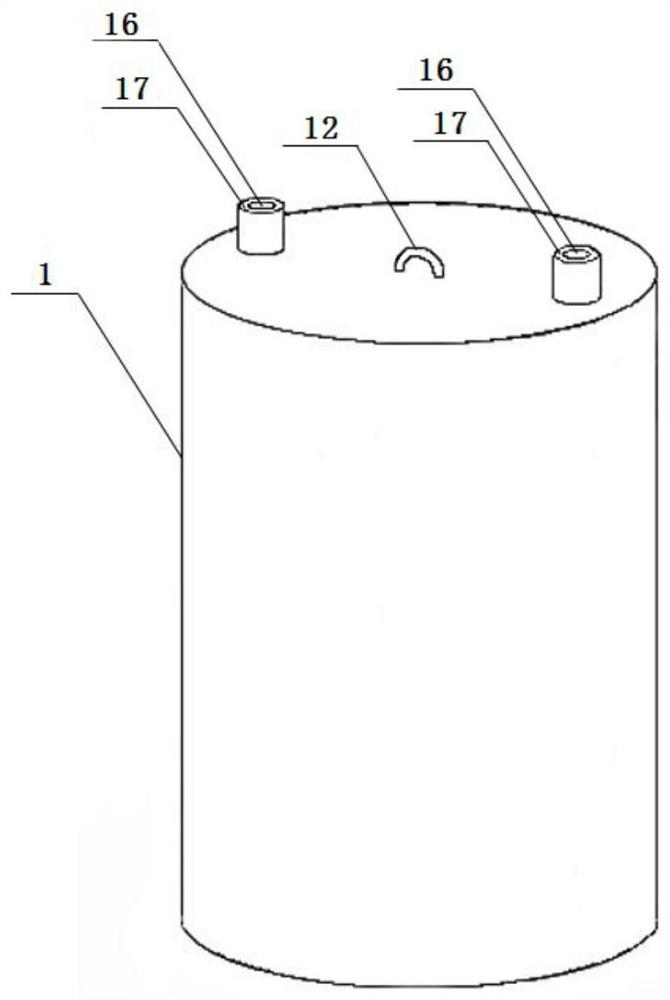

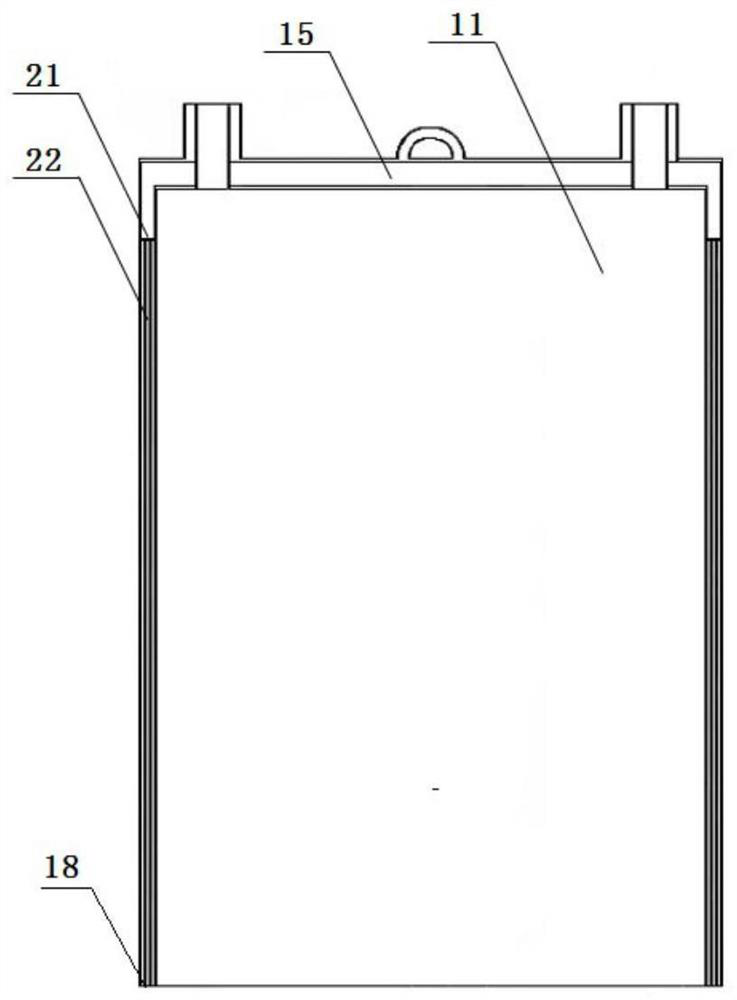

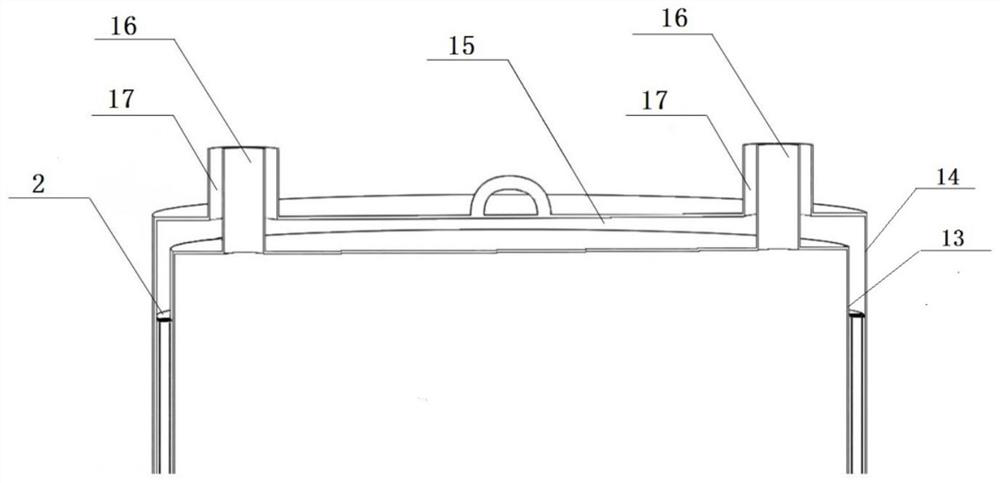

Crucible to prevent cracking of oled materials

ActiveCN104593730BSolve material wasteGuaranteed qualityVacuum evaporation coatingSputtering coatingCrucibleDisplay device

The invention provides a crucible for preventing cracking of OLED materials, comprising a crucible body (1) for containing OLED materials (3), and a cover (2) covering the opening end of the crucible body (1); the crucible There is a lifting structure (11) at the bottom of the body (1), through which the height of the lowest liquid level of the OLED material (3) in the crucible is raised through the lifting structure (11), so that the OLED material (3) is completely Steam out. The invention can solve the problem that the OLED material in the crucible is easily cracked and the material is wasted in the vapor deposition process, so that the vapor deposition process runs stably and ensures the quality of the OLED display device.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

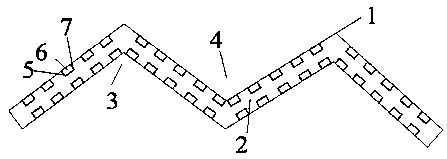

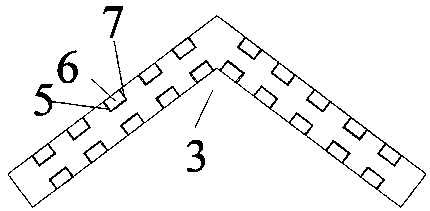

Weather-resistant angle steel for transmission tower

InactiveCN111058673ASolve material wasteAvoid pollutionTowersBuilding insulationsSteel platesCorrosion prevention

The invention discloses a weather-resistant angle steel for transmission tower. The weather-resistant angle steel comprises a weather-resistant angle steel body and a plurality of round grooves, the weather-resistant angle steel body is formed by sequentially connecting a plurality of V-shaped units, each V-shaped unit is composed of two steel plates, wherein a first included angle is formed at the joint of the two steel plates, and a second included angle is formed at the joint of every two adjacent V-shaped units; and the plurality of round grooves are formed in the surface of the steel plate body, and anti-corrosion blocks are installed in the round grooves and fixedly connected with the round grooves through adhesives. By means of the mode, the weather-resistant angle steel for the transmission tower can solve the problems of material waste, maintenance cost increase, environment pollution and the like caused by galvanizing corrosion prevention in the manufacturing process of the transmission tower.

Owner:CHANGSHU FENGFAN POWER EQUIP

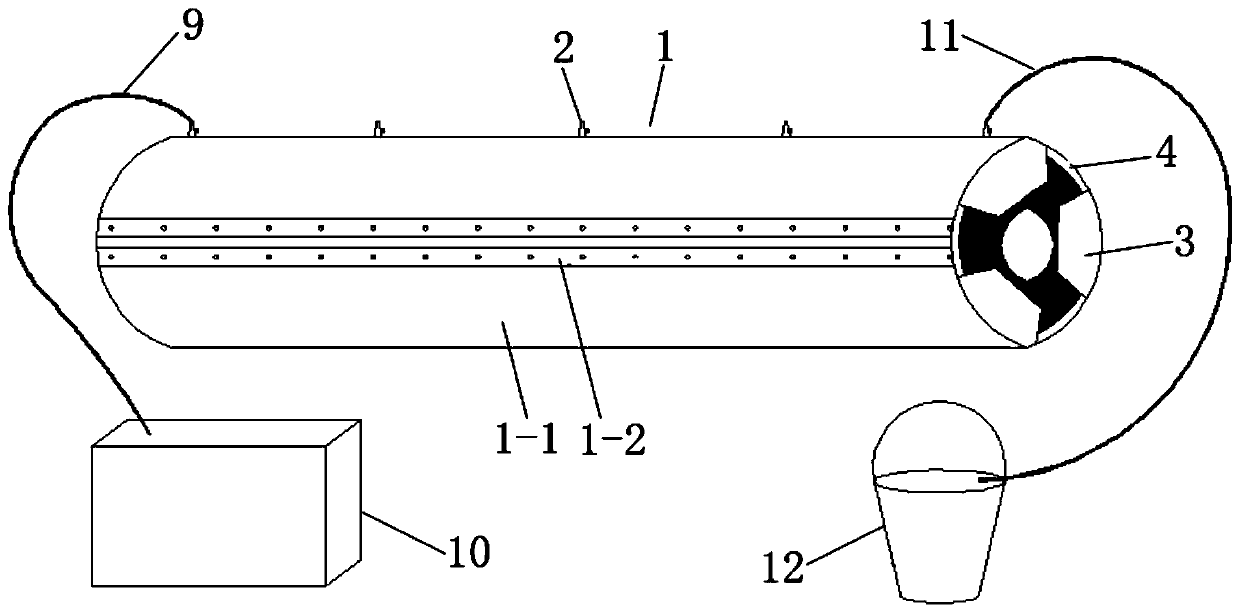

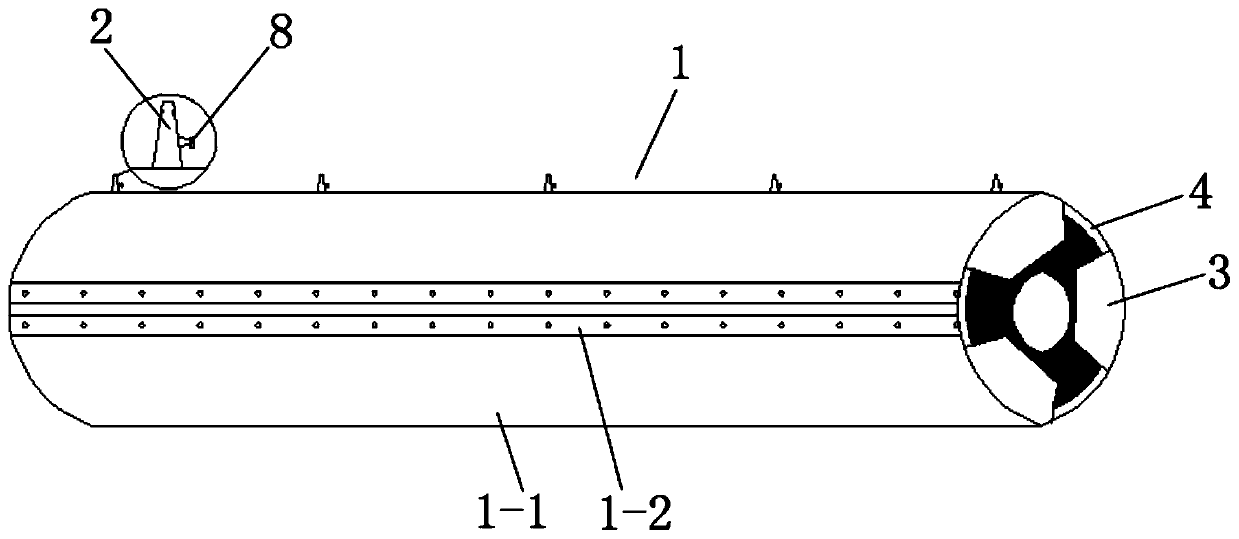

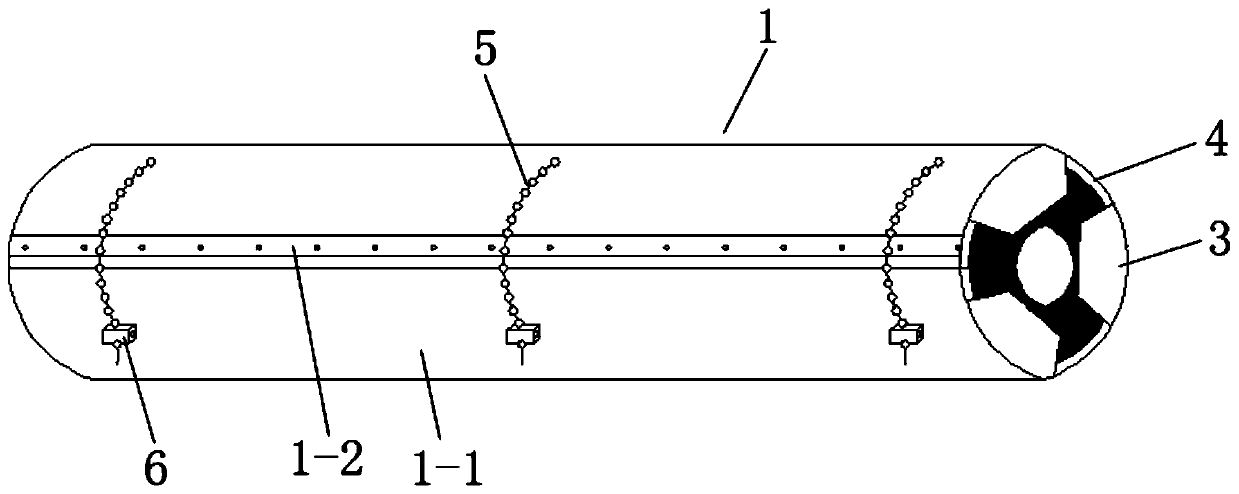

Thick fireproof coating construction device and construction method thereof

The invention relates to a thick fireproof coating construction device and a construction method thereof. The construction device comprises an integral coating template, wherein the integral coating template is of a cylinder structure capable of being circumferentially unfolded with two end openings, the shape of the cylinder structure is matched with the appearance structure of a preformed coating on the outer side of a steel structure; a plurality of material openings are arranged on an integral coating formwork at intervals in the length direction; valves are arranged in the openings, the integral coating formwork is provided with baffles at both ends and sealing strips that can match with gaskets at the ends of the fireproof coating. According to the invention, the fireproof coating onthe outer side of the steel structure is constructed and integrally formed by injecting the fireproof coating into the integral coating formwork, integral forming is achieved, so that the problems that thick fireproof coating is easy to crack, the forming difficulty is high, the material is wasted, the construction pollution is high, and the construction period loss is serious and the like in a traditional construction mode can be effectively solved, the construction quality of the thick fireproof coating is effectively improved, and the construction efficiency is improved.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Fixedly-mounted waterproof socket

PendingCN113036514AReduce use costSolve aestheticsCouplings bases/casesLive contact access preventionElectric shock effectFastener

The invention relates to a fixedly-mounted waterproof socket. The fixedly-mounted waterproof socket comprises a socket functional part and a socket bottom box, wherein the socket functional part is arranged in a socket fixing frame and can rotate by an angle; a power connection mechanism is arranged on the back of the socket fixing frame; the power connection mechanism is in sleeved connection with a conductive insertion piece which is arranged on the back of the socket functional part and penetrates out of the back of the socket fixing frame; a first waterproof mechanism is arranged between the socket fixing frame and the socket bottom box; the socket fixing frame is fastened with the socket bottom box through a fastener; a socket panel is arranged on the front portion of the socket fixing frame; a waterproof cover is arranged on the front side of the socket panel; the upper end of the waterproof cover is hinged to a hinge mechanism at the upper end of the socket fixing frame; a second waterproof mechanism is arranged on the contact surface of the waterproof cover and the socket panel; and a two-pin power jack and a three-pin power jack are formed in the front part of the socket functional part. After a power plug is inserted into the power jack, a third waterproof mechanism at the lower end of the waterproof cover wraps a power line of the power plug, and the waterproof cover covers the power plug, so the dual effects of waterproof effect and anti-electric shock effect are achieved. The fixedly-mounted waterproof socket of the invention is attractive in appearance and convenient to use.

Owner:温州瓯创电气科技有限公司

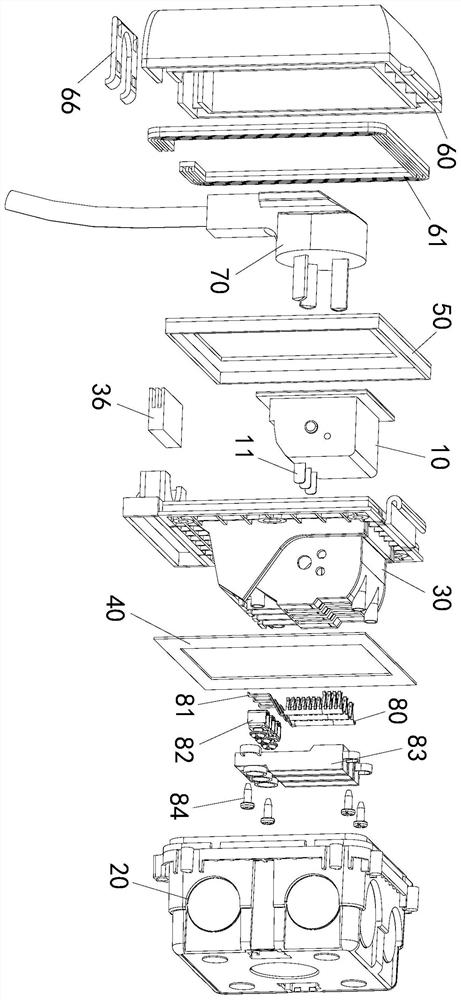

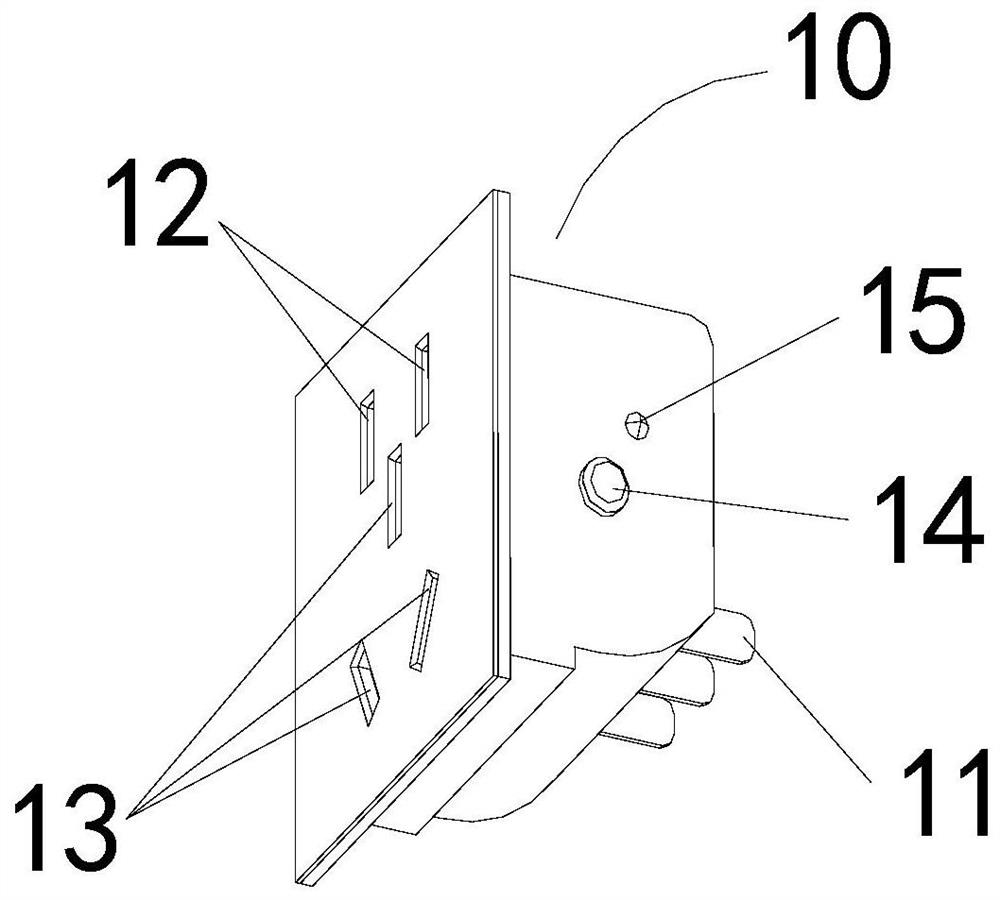

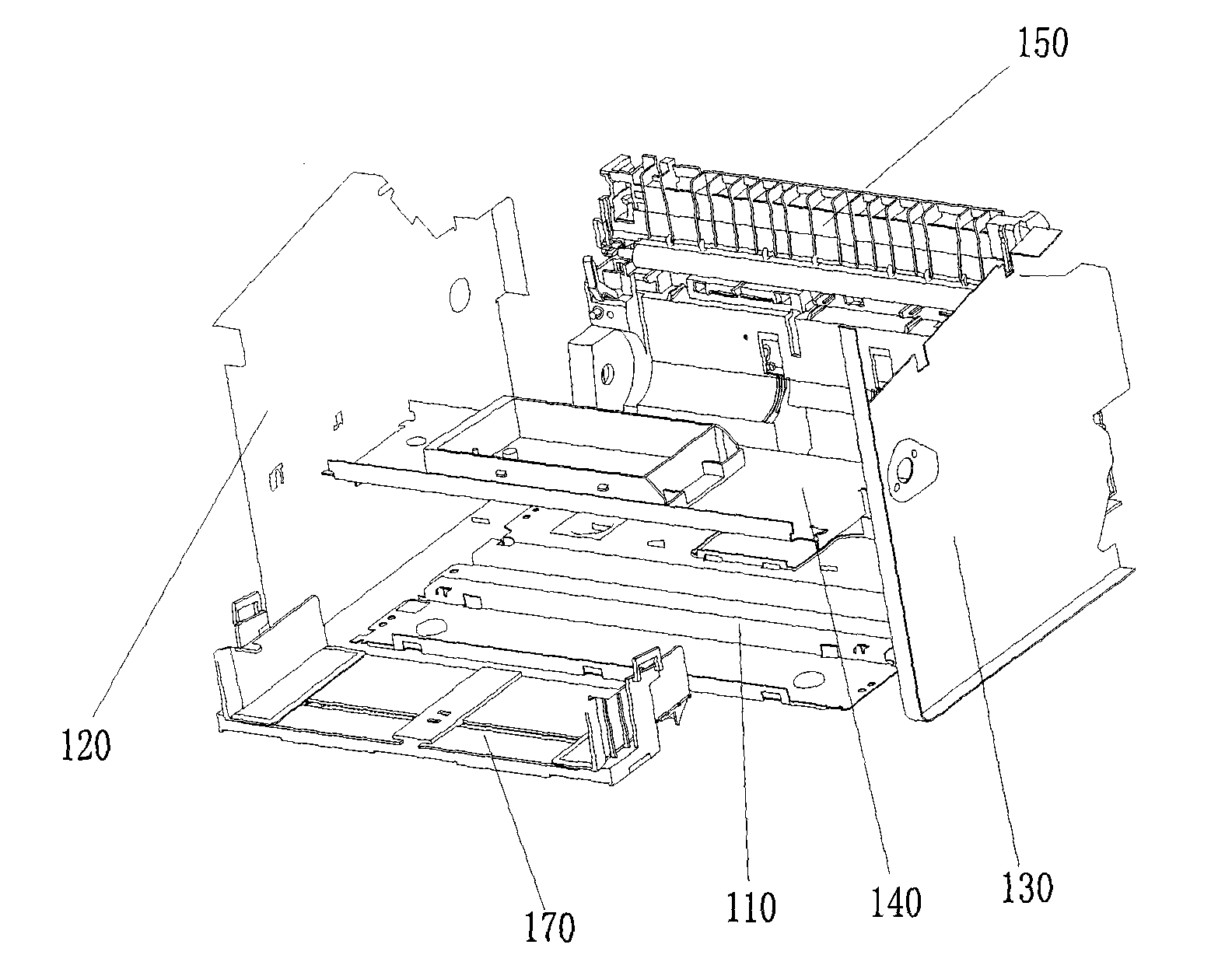

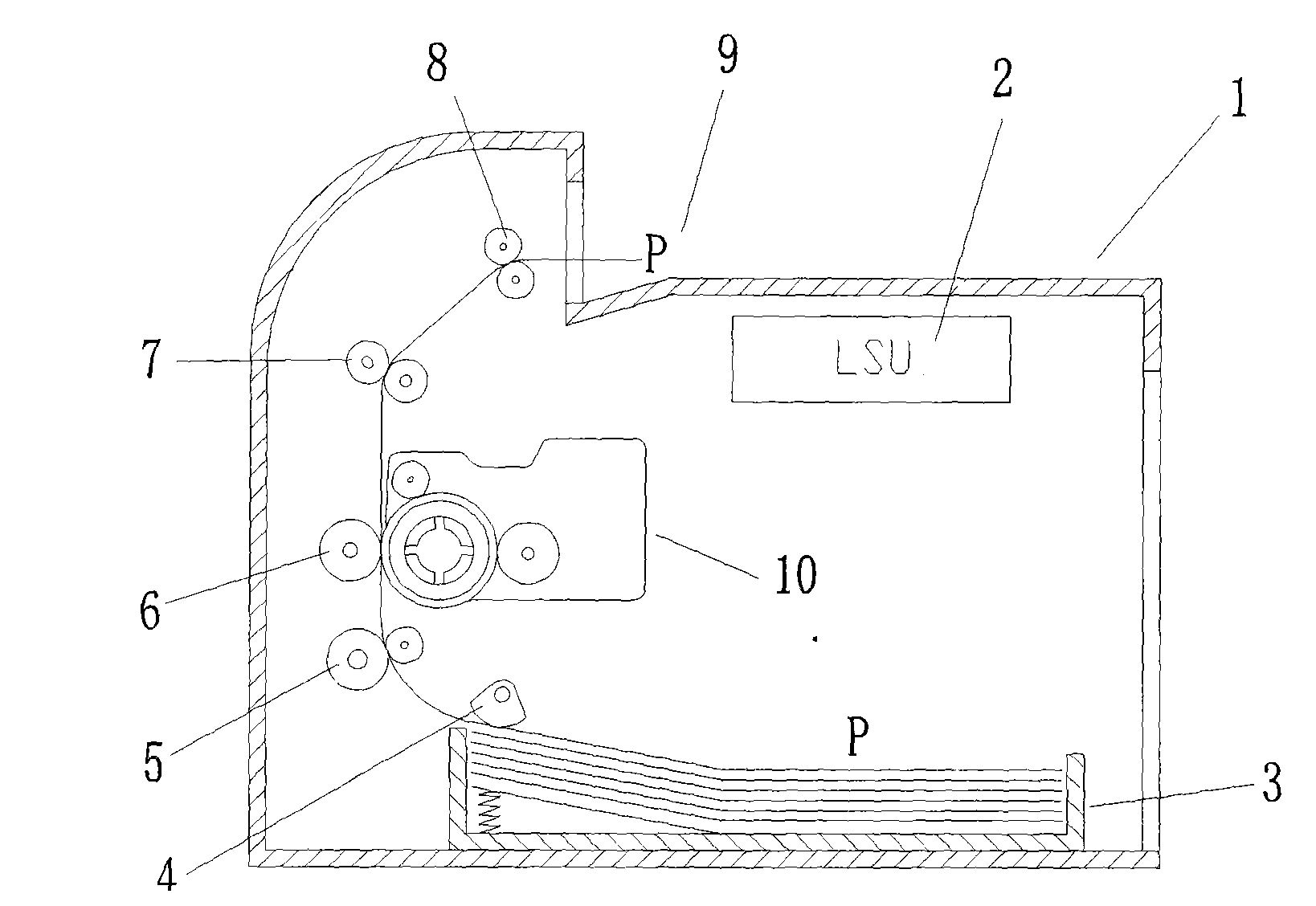

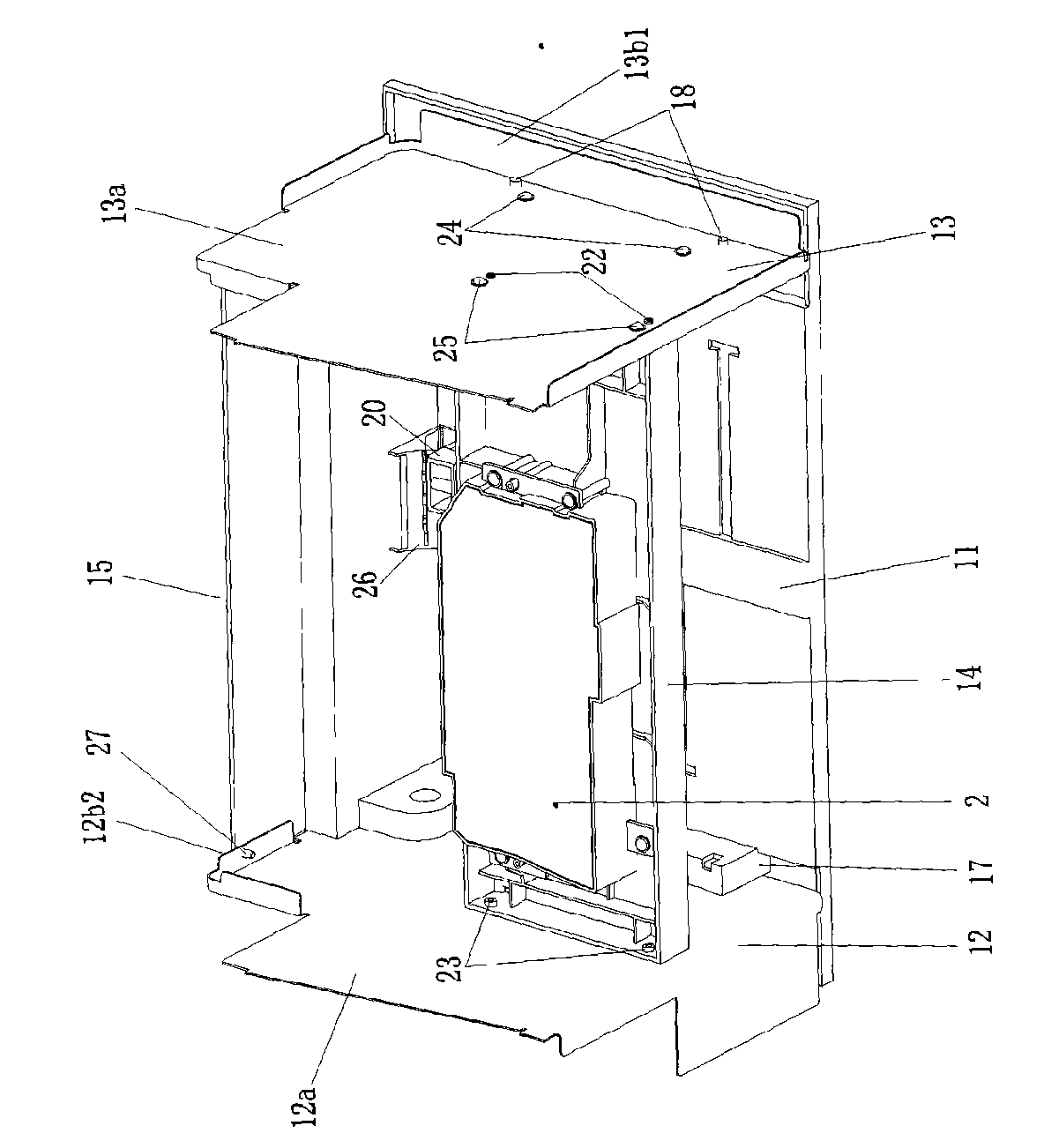

Frame of image forming device

ActiveCN101661243ASolve assembly problemsSolve the costElectrographic process apparatusImage formationEngineering

The invention relates to a frame of an image forming device, which comprises a base plate, a pair of lateral plates which are arranged mutually independently, and a conveying plate used for bearing conveyed elements, a pair of lateral plates and the conveying plate are all arranged on the base plate, a pair of lateral plates and the conveying plate are detachably connected with the base plate, thebase plate is an independent plastic member. A base plate molding mold can be a miniature mold so as to reduce the time for manufacturing the mold, reduce the cost of the mold and effectively save production cost. As detachable connection is used, any part going wrong is easily detached and maintained, and the rubber base plate is capable of reducing the weight of the whole image forming device so as to decrease the labor intensity of workers and users. The invention solves the technical problems that the assembly and maintenance of the frame of the prior image forming device are not convenient and the cost is high.

Owner:ZHUHAI PANTUM ELECTRONICS

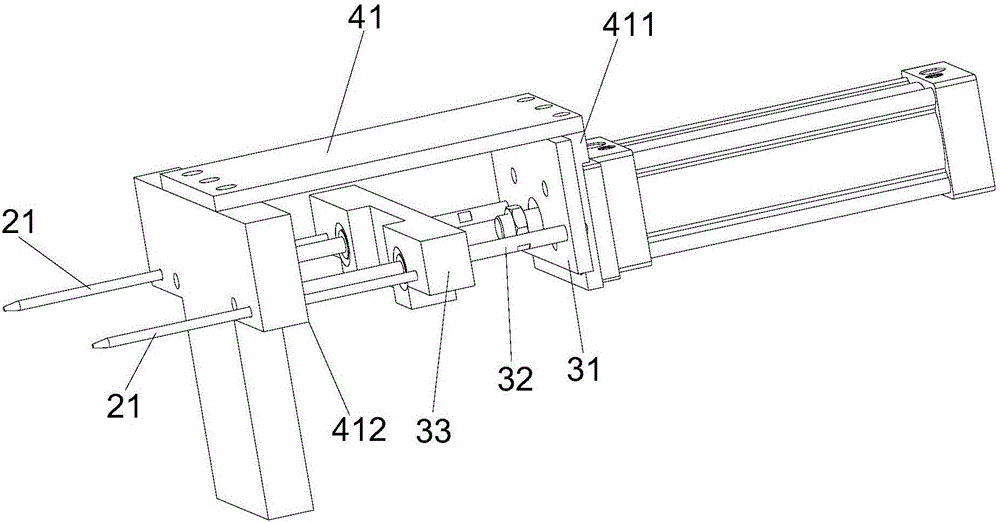

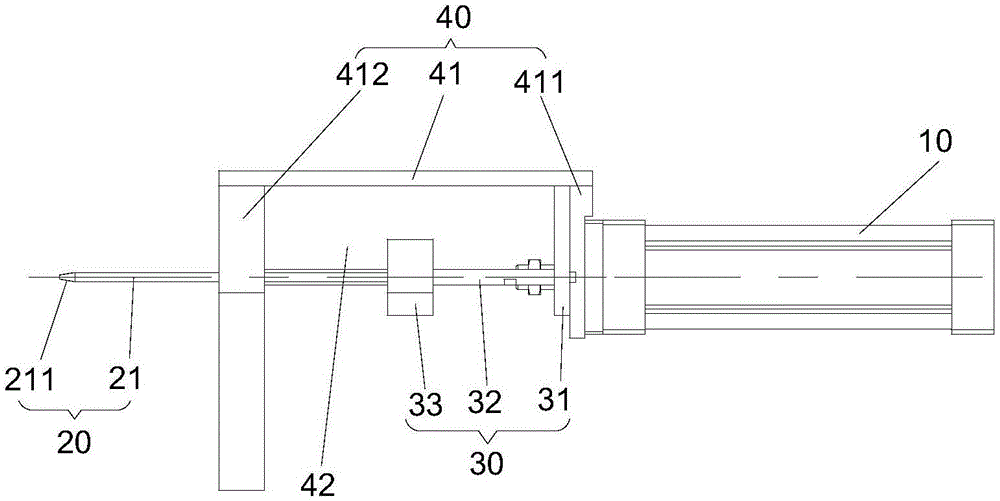

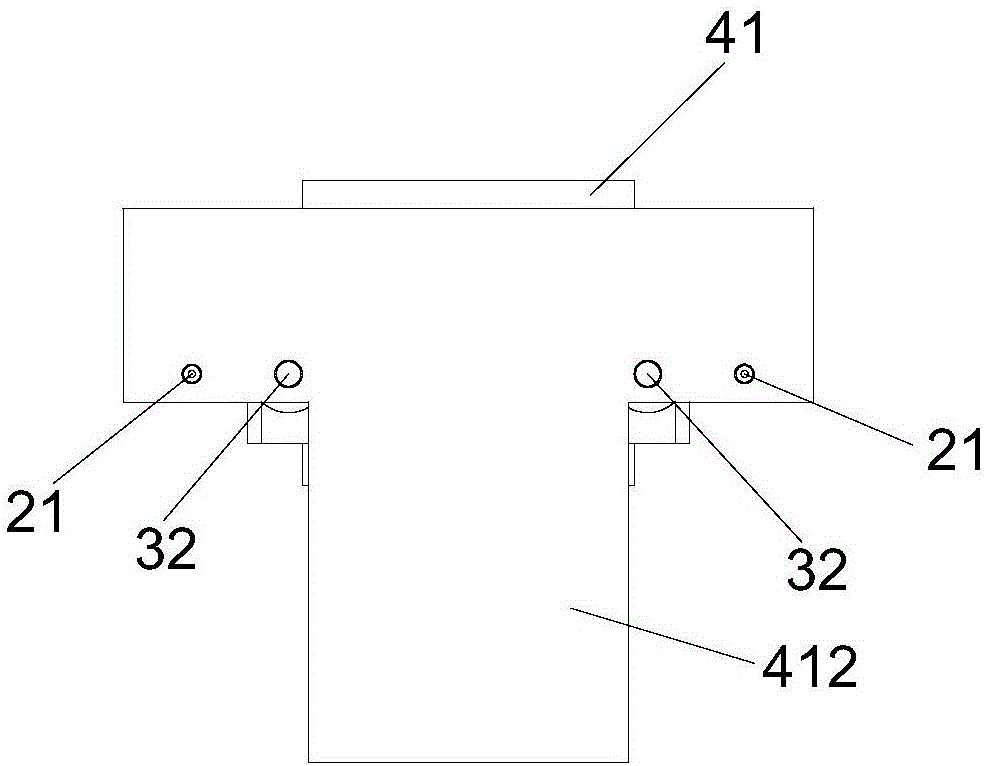

Pipe section unloading mechanism and pipe section processing device with same

InactiveCN106736807ASolve the waste of materialsImprove processing qualityTube shearing machinesMetal working apparatusScrapEngineering

The invention provides a pipe section unloading mechanism and a pipe section processing device with the same. The pipe section unloading mechanism comprises a drive part and a bearing part; the bearing part is connected with the drive part; and the drive part drives the bearing part to move so as to enable the bearing part to be provided with a connection position which is connected with a pipe section before being cut and an unloading position used for unloading the pipe section subjected to cutting. With adoption of the pipe section unloading mechanism, the cut pipe section can be unloaded timely, so that the problems of burr copper scraps at a pipe end and material waste caused by copper pipe cutting with scraps in the prior art are effectively solved, and the processing quality of the pipe section is improved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP TECH RES INST CO LTD +1

Suction bucket foundation with pull-out steel pipe piles and installation method thereof

The invention discloses a suction bucket foundation with uplift-resistant steel pipe piles and an installation method thereof, comprising a bucket body and an uplift-resistant pile mechanism. The body includes the inner barrel wall and the outer barrel wall. A hollow interlayer is formed between the inner barrel wall and the outer barrel wall. The uplift pile mechanism is arranged in the hollow interlayer and can slide up and down along the hollow interlayer. The uplift pile mechanism includes a base and an uplift steel pipe pile. ;The method of use is as follows: (1) the barrel body sinks under its own weight; (2) the inner cabin pumps water to make the barrel body continue to sink; (3) makes the pullout-resistant steel pipe pile protrude from the middle interlayer and penetrates into the seabed; (4) The high-pressure water in the hollow interlayer is discharged until the underwater grouting fluid fills the hollow interlayer, and the steel pipe pile and the bucket body are integrated after the underwater grouting fluid is solidified; the invention can penetrate the seabed through the anti-pull steel pipe pile and improve the resistance of the suction bucket foundation. Increase the bearing capacity, and solve the problem of soil plug and material waste caused by deepening the barrel length to increase the bearing capacity.

Owner:SUN YAT SEN UNIV

Packaging box

PendingCN114455166ASolve material wasteReduce the chance of breakageRigid containersPackage recyclingClassical mechanicsPaperboard

The invention belongs to the technical field of packaging, and particularly relates to a packaging box which comprises a top plate formed by folding a paperboard and a surrounding plate assembly, an upper opening and a lower opening are defined by the surrounding plate assembly, the top plate is connected with the surrounding plate assembly and seals the upper opening, the surrounding plate assembly comprises four side plates connected in sequence, and the side plates are arranged to be of a double-layer stacked structure; according to the packaging box, the possibility that the packaging box is damaged is reduced through the arrangement of the side plates of the double-layer overlapping structure, and then it is guaranteed that packaged objects in the packaging box are not abraded; the packaging box is convenient to assemble, compared with the mode that two packaging boxes are connected together in a sleeved mode in the prior art, a large amount of materials are saved, and the problem that in the prior art, materials are wasted due to the fact that two layers of packaging boxes are connected together in a sleeved mode is solved.

Owner:HEFEI HUALING CO LTD +2

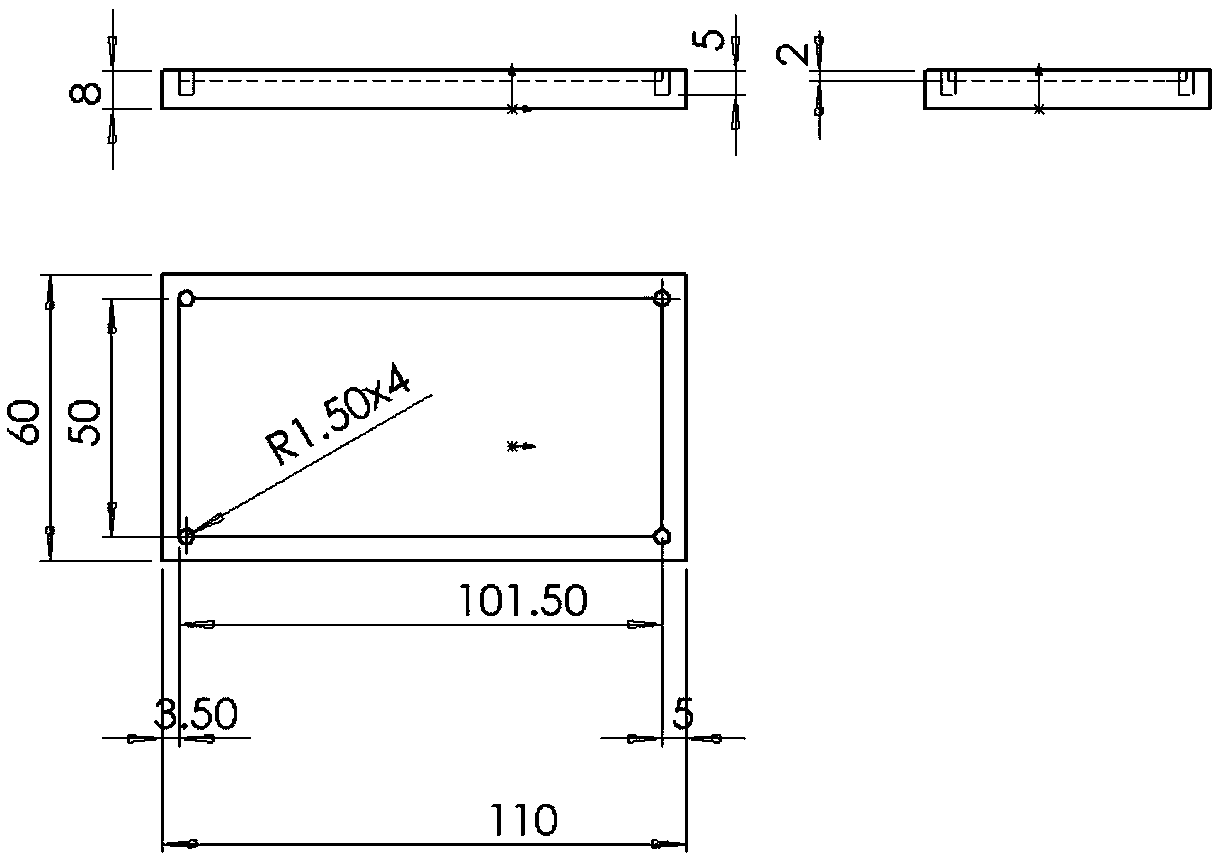

Clamp facilitating PDMS (Polydimethylsiloxane) die releasing and method for preparing PDMS layer thereby

The invention discloses a clamp facilitating PDMS (Polydimethylsiloxane) die releasing and a method for preparing a PDMS layer thereby, and belongs to the technical field of polymer films. The clamp facilitating the PDMS die releasing comprises a bottom plate, an intermediate plate and a permanent magnet, wherein the bottom plate is manufactured through a paramagnetic metal; a groove is formed inthe upper surface of the bottom plate, and the depth of the groove is more than the thickness of the intermediate plate; a plurality of die releasing holes which are uniformly distributed around the groove extend from the groove to the inner wall of the bottom plate; the shape of the intermediate plate fits that of the groove in the bottom plate; the intermediate plate is positioned into the groove in the bottom plate, and the intermediate plate can cover the bottom surface of the groove and can also be moved out from the groove; the intermediate plate is manufactured through a ferromagnetic substance; and the permanent magnet is positioned at the rear part of the bottom plate and is used for attracting the intermediate plate to cling to the bottom surface of the groove in the bottom platethrough the surface. The invention also provides a method for preparing the PDMS layer through the clamp. The clamp is good in forming effect, and hard to break during die releasing; and the clamp isapplicable to PDMS layer manufacturing.

Owner:HARBIN INST OF TECH

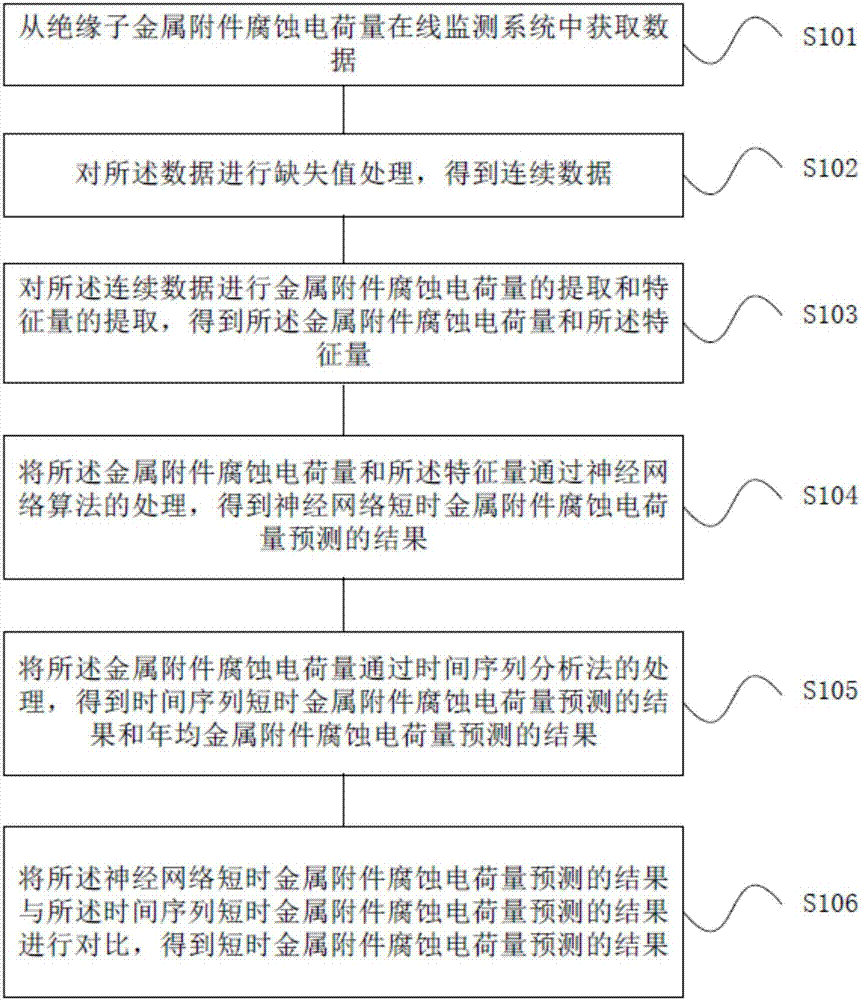

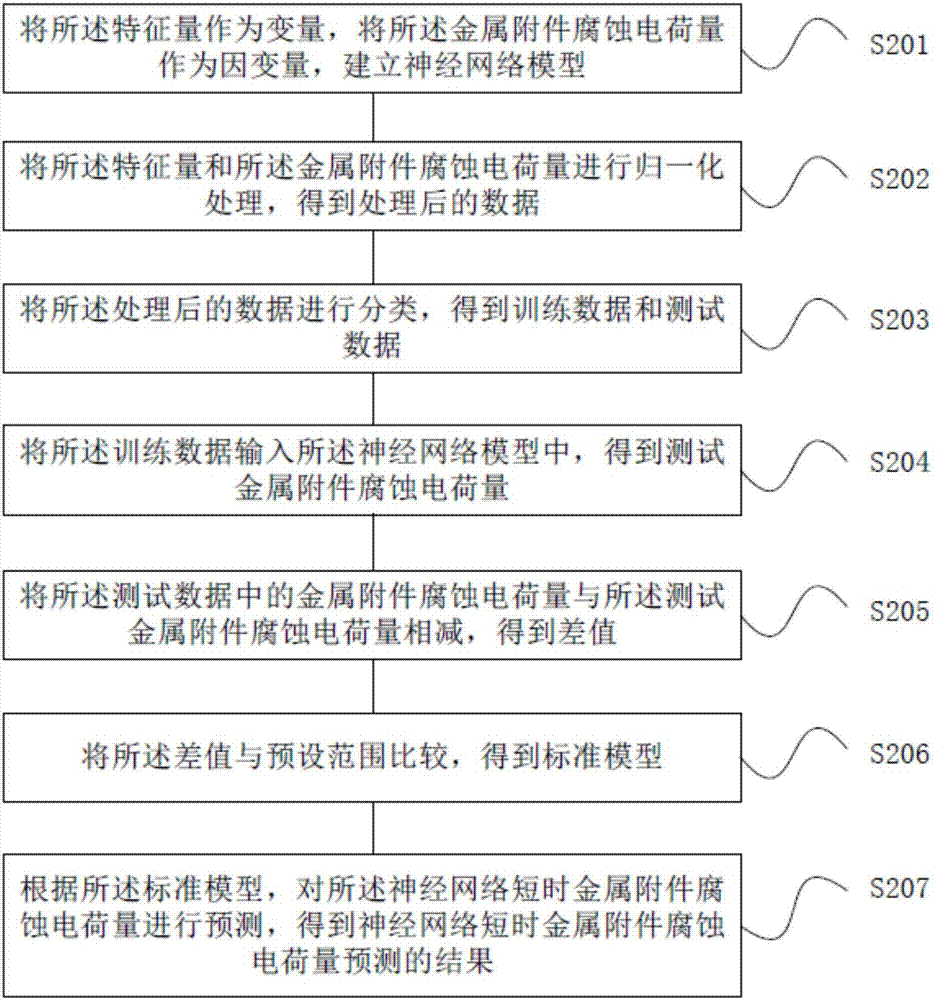

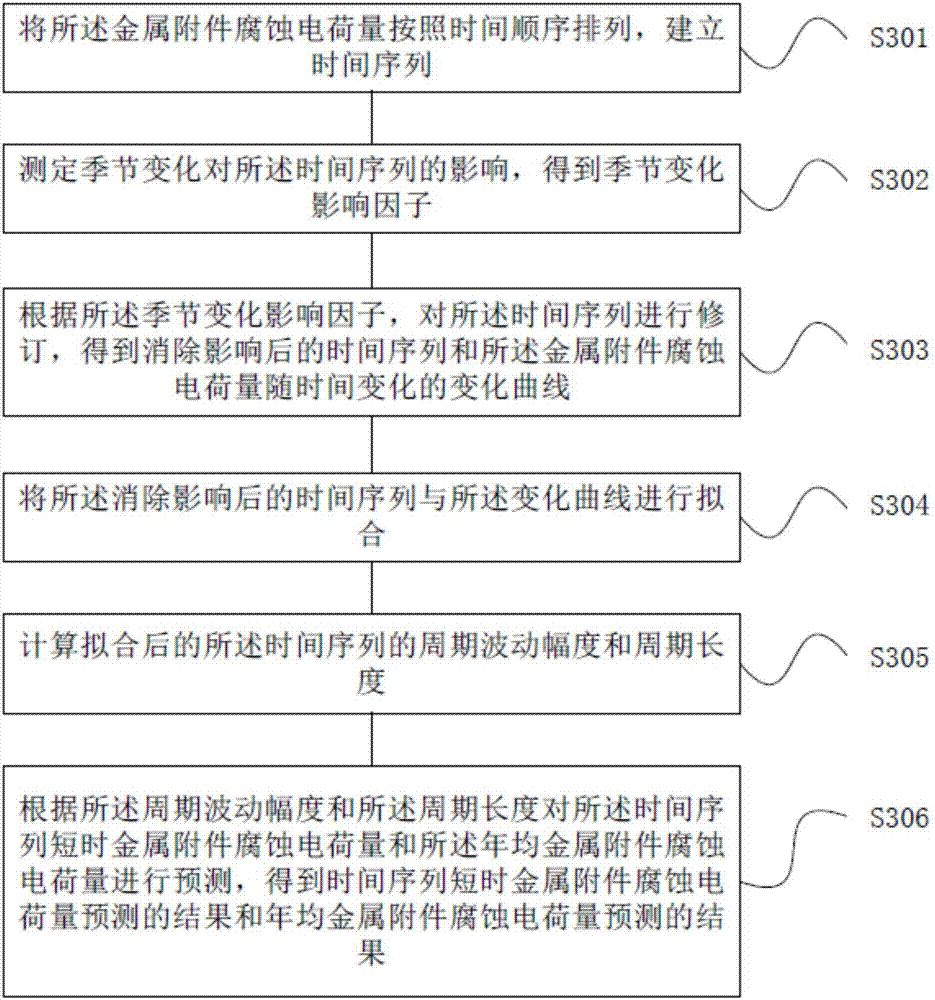

Insulator metal accessory corrosion charge quantity prediction method

ActiveCN106886651AContinuitySolve the problem of longevityForecastingDesign optimisation/simulationPredictive methodsShort terms

The invention discloses an insulator metal accessory corrosion charge quantity prediction method. The method comprises the steps that data is obtained in an on-line monitoring system, the obtained data is subjected to missing value handling and continuous data is obtained; the metal accessory corrosion charge quantity and the characteristic quantity are extracted from the continuous data; the metal accessory corrosion charge quantity and the characteristic quantity are processed by means of the neural network algorithm; the metal accessory corrosion charge quantity is processed by using the time series analysis method; a neural network short-term metal accessory corrosion charge quantity prediction result is compared with a time series short-term metal accessory corrosion charge quantity prediction result, and a short-term metal accessory corrosion charge quantity prediction result is obtained; finally, according to the short-term metal accessory corrosion charge quantity prediction result, the operation status of an insulator is evaluated. According to the annual average metal accessory corrosion charge quantity prediction result, a metal accessory protection device of the insulator is designed, and the problems that the metal accessory protection device is short in service life and wastes materials are solved.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Grinding wheel segment manufacturing method and cutting clamp for implementing same

InactiveCN104057405ASolve efficiency problemsSolve material wasteGrinding devicesLaser beam welding apparatusGrinding wheelLaser

The invention relates to the field of grinding wheel manufacturing, in particular to a grinding wheel segment manufacturing method and a cutting clamp for implementing the same. The grinding wheel segment manufacturing method comprises the following steps that (1) a lengthened grinding material block is loaded into the corresponding cutting clamp, the cutting clamp is provided with at least one lengthened grinding material block clamping position, the two opposite sides of the clamping position are provided with a front face cutting receding groove and a back face cutting receding groove respectively, and the front face cutting receding groove and the back face cutting receding groove which correspond to each other are arranged oppositely; (2) a laser cutting machine is used for cutting the lengthened grinding material block from the front face and the back face of the corresponding clamping position. The grinding wheel segment manufacturing method solves the problems that grinding wheel segment is low in manufacturing efficiency, materials are wasted, and the quality of a grinding wheel segment is poor.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

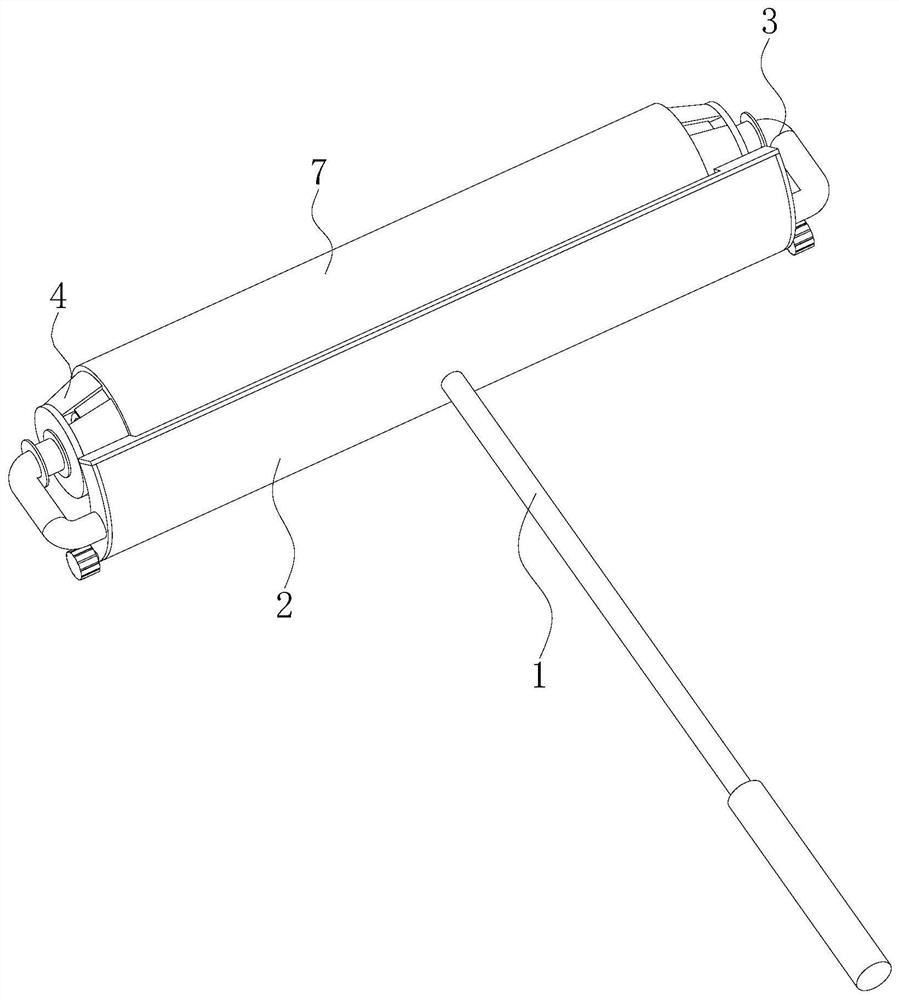

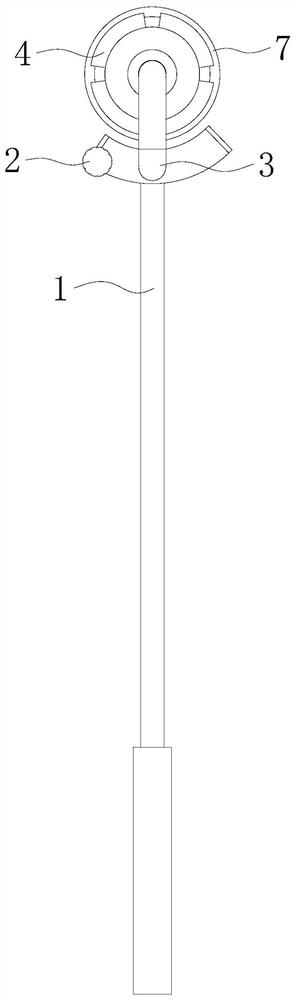

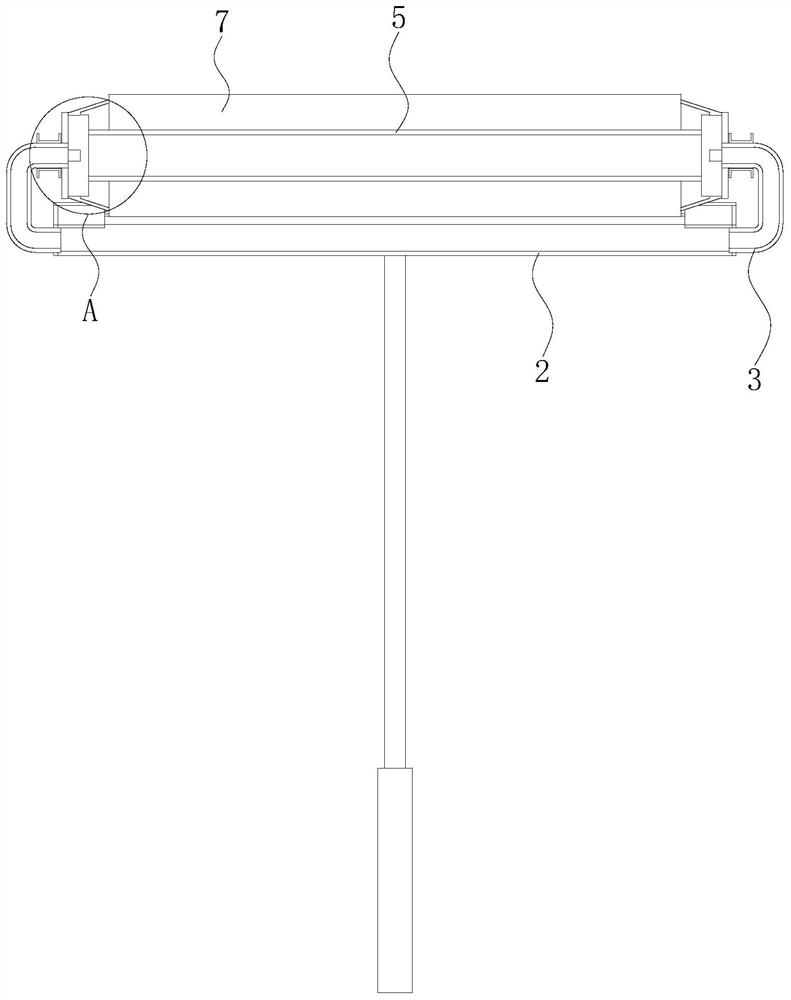

Roller brush for building decoration

PendingCN113309323AImprove efficiencyReduce wasteBuilding constructionsBuilding renovationMechanical engineering

The invention provides a roller brush for building decoration, and relates to the field of building painting. The roller brush for building decoration comprises a handle, a collecting mechanism is fixedly installed at one end of the handle, U-shaped pipelines are fixedly installed at the left end and the right end of the collecting mechanism correspondingly, the ends, close to the collecting mechanism, of the U-shaped pipelines communicate with the interior of the collecting mechanism, two releasing mechanisms are arranged above the collecting mechanism, the two releasing mechanisms are fixedly connected through a communicating pipe, a plurality of liquid outlets communicating with the interior of the communicating pipe are formed in the circumferential face of the communicating pipe, and the left end and the right end of the communicating pipe communicate with the two releasing mechanisms. According to the roller brush for building decoration, by arranging the collecting mechanism and the releasing mechanisms, liquid in two containing grooves can also be discharged through the liquid outlets in the communicating pipe to be used for better infiltrating the brush, the use efficiency of the liquid is improved, waste is reduced, and the problem that in a wall brush in the prior art, slurry drips, and materials are wasted is solved.

Owner:王腾飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com