Thermal forming method for rigid foam core material

A rigid foam and thermoforming technology, which is applied in the field of composite material manufacturing, can solve the problems of wasting materials and achieve the effect of solving waste materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

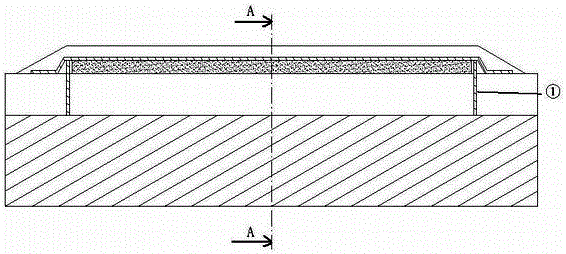

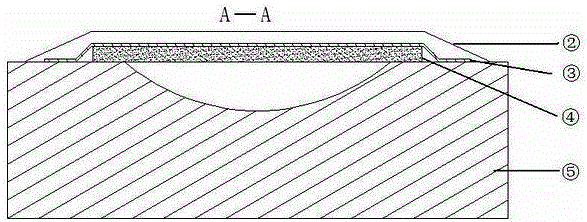

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

[0021] A method for thermoforming a rigid foam core material, the steps of the method are as follows:

[0022] 1) Place the PMI foam board on the molding die 5 according to the theoretical position;

[0023] 2) Stick Airpad rubber 1 on both ends of the PMI foam board with pressure-sensitive tape to prevent the vacuum bag 2 from being sucked between the PMI foam board 4 and the mold, resulting in poor molding of the PMI foam;

[0024] 3) Lay a layer of air felt 3 on the foam board, seal the PMI foam with a vacuum bag 2 and a putty strip, and place a thermocouple on the edge of the air felt;

[0025] 4) Install the quick release nozzle on the mold;

[0026] 5) Connect the quick release nozzle on the mold to the vacuum equipment of the curing furnace through the vacuum pipeline, and then connect the thermocouple to the curing furnace;

[0027] 6) Raise the temperature to 190°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com