Suction bucket foundation with anti-pull steel pipe pile and mounting method thereof

An anti-pulling steel pipe and suction bucket technology, applied in infrastructure engineering, sheet pile walls, buildings, etc., can solve problems such as material waste, and achieve the effect of avoiding rapid decline and reducing the risk of foundation failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are all simplified schematic diagrams, and only schematically illustrate the basic structure of the present invention.

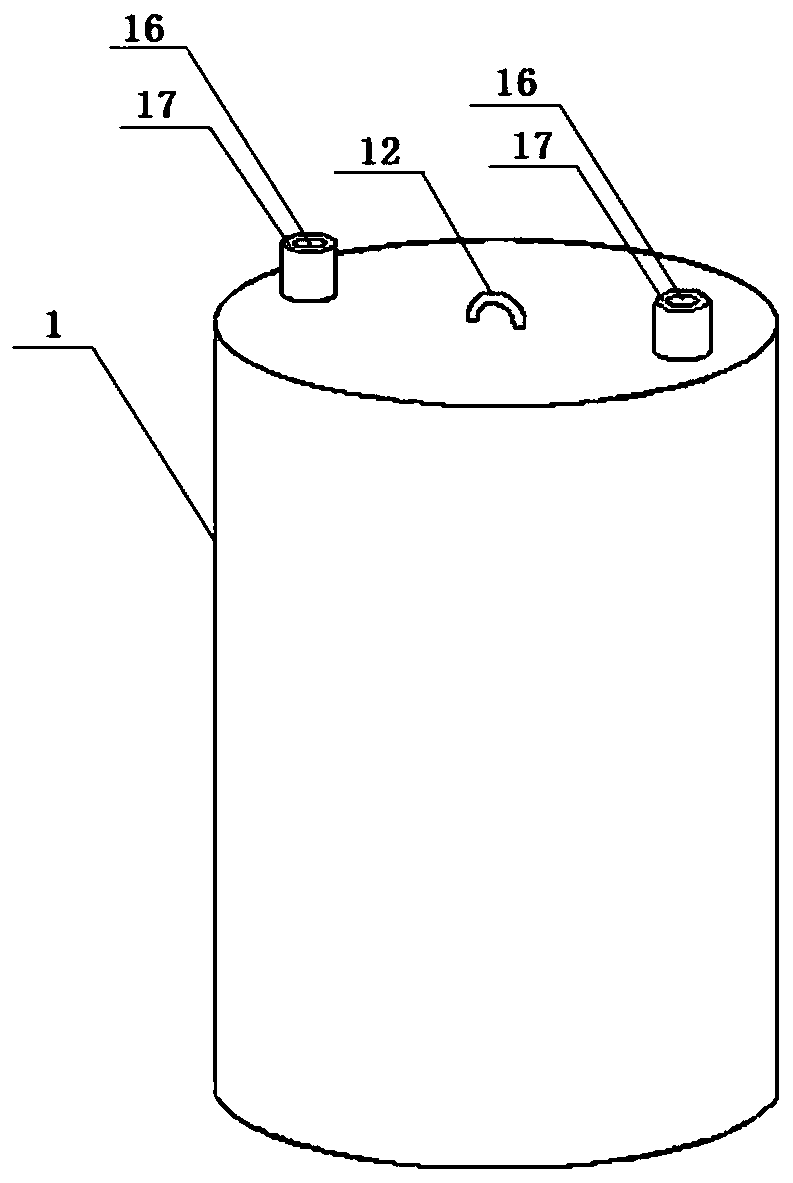

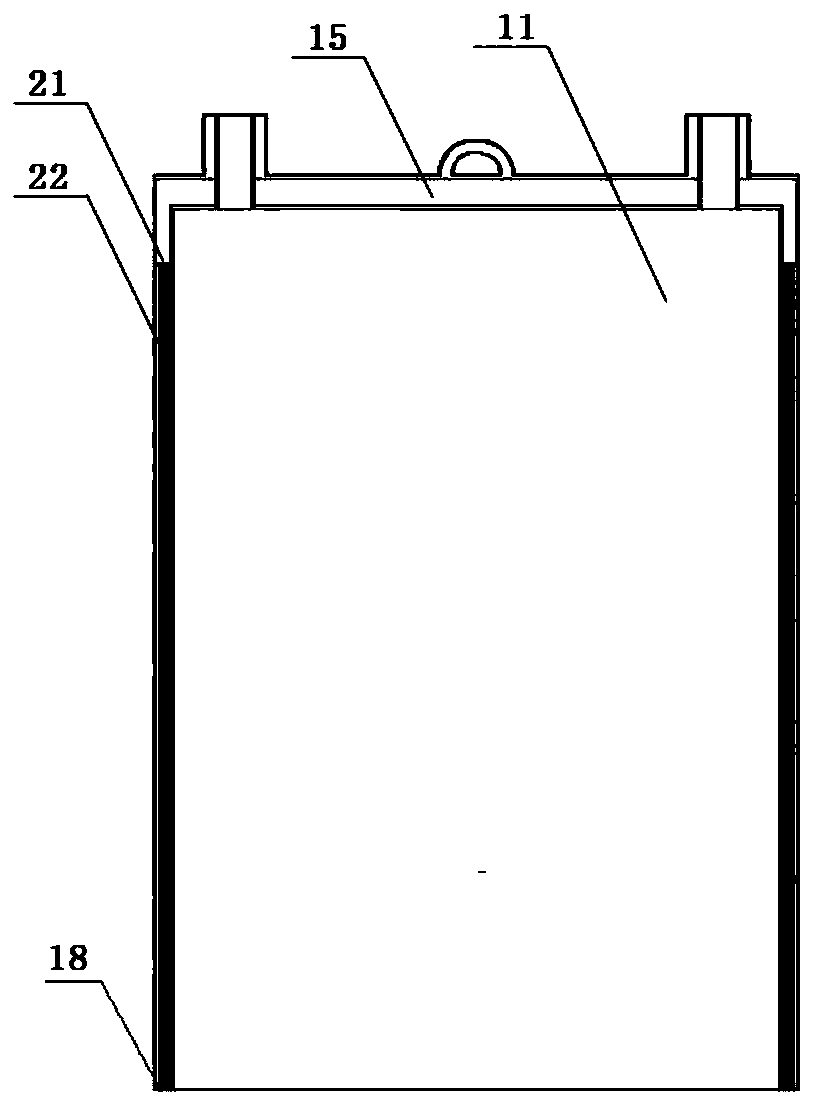

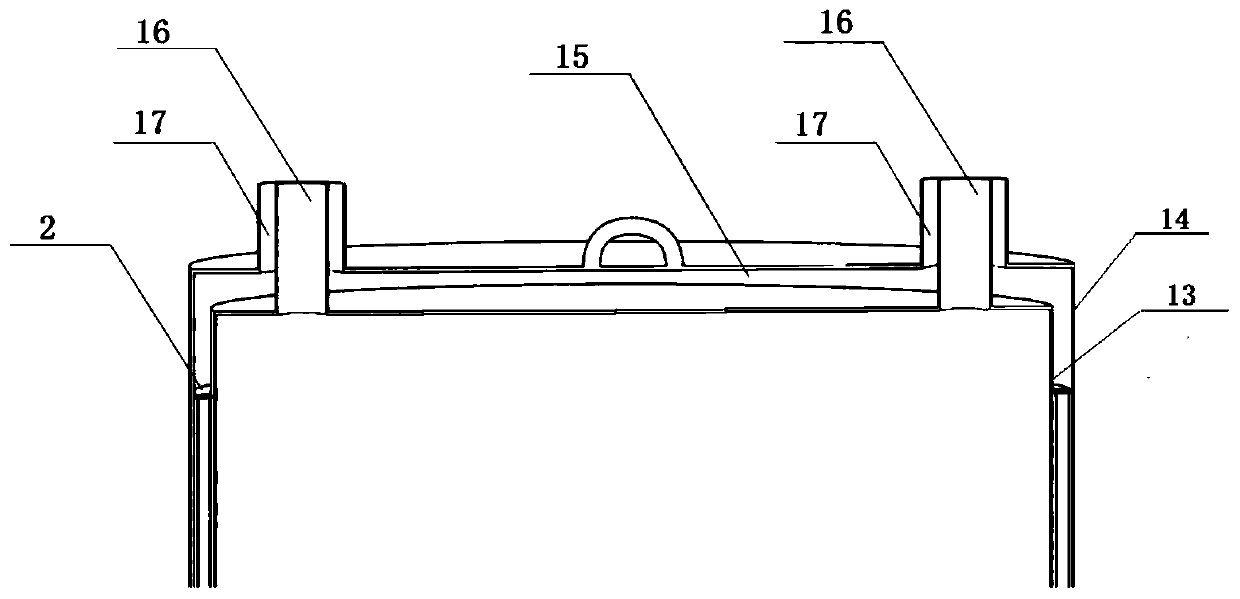

[0033] like Figure 1-Figure 10 As shown, the suction barrel foundation with uplift-resistant steel pipe piles of the present invention includes a barrel body 1 and an uplift-resistant pile mechanism 2, wherein:

[0034] refer to Figure 1-Figure 6 The barrel body 1 is a barrel-shaped structure with an open bottom and a sealed top, and an inner cabin 11 is formed inside it. A connecting piece 12 is arranged at the center of the top surface of the barrel body 1. The barrel body 1 includes an inner barrel wall 13 and an outer barrel wall 14. The inner barrel wall 13 and the outer barrel wall 14 to form a hollow interlayer 15, the top surface of the barrel body 1 is provided with two water pumping holes 16 that communicate with the outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com