A Formwork Supporting System of Adjustable Elevation Combined Buckle Frame Using Micro-Bump Technology

A micro-bump and combined technology, which is applied to the accessories of scaffolding, building structure support, building structure support, etc., can solve the problems that are difficult to match with multi-variant building structures, the application limitations of ring-type scaffolding, and the modulus of ring-type scaffolding Fixing and other problems, to increase convenience and accuracy, prevent bolt loss, and improve bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

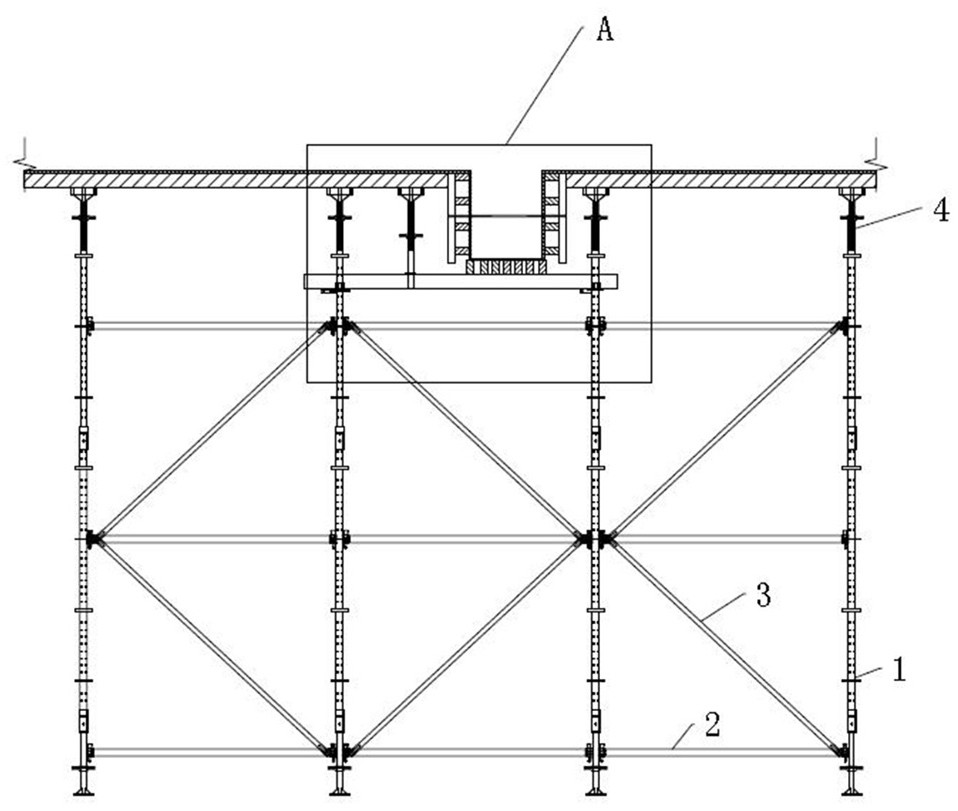

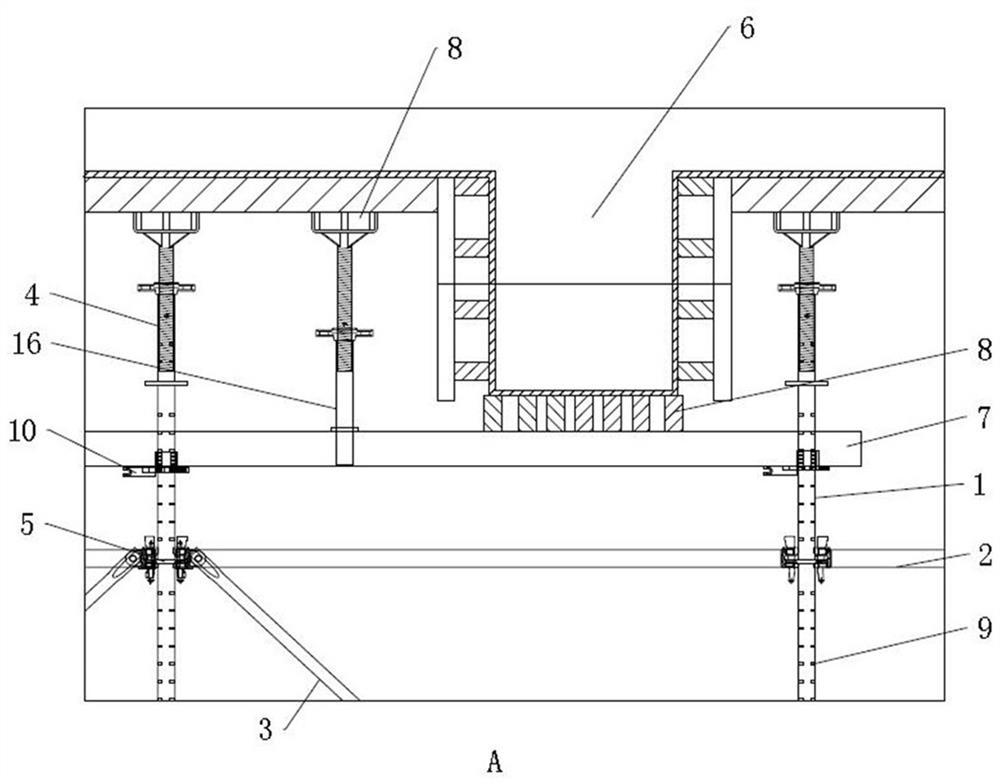

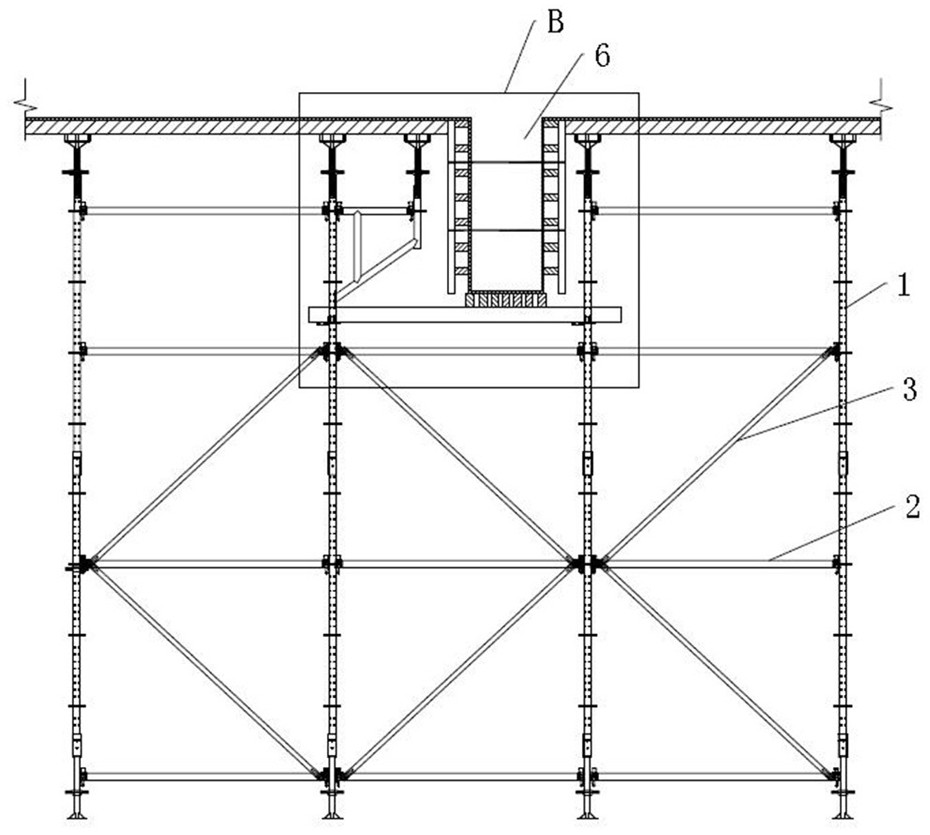

[0043] as Figure 1 and Figure 2 As shown, the present invention is an adjustable elevation combination disc buckle frame support system using micro-bump technique comprising a multi-row spacing uniformly set pole 1, connecting adjacent two rows of poles 1 crossbar 2, connecting each row of adjacent poles 1 longitudinal rod and connecting the vertical rod 1 and the bevel rod connected to the frame formed by the pole 1 and the crossbar 2, each row of pole 1 interval evenly arranged multiple roots, the upper end of the pole 1 is threaded with a top bracket 4, the top bracket 4 is used to install the keel 8 support template; the crossbar 2 and the longitudinal rod are set in multiple intervals along the height direction of the pole 1, Crossbar 2, longitudinal bar and diagonal bar 3 are fixed by latch connection with ordinary disc 5 fixed to pole 1, respectively.

[0044]Adjacent pole 1 at the bottom of the structural beam 6 is provided with a double C-beam 7 for supporting the structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com