Fixedly-mounted waterproof socket

A waterproof socket, fixed technology, applied in the direction of coupling device, base/housing, connecting device parts, etc., can solve the problem of wasting materials, affecting the appearance of products, etc., and achieve the effect of good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

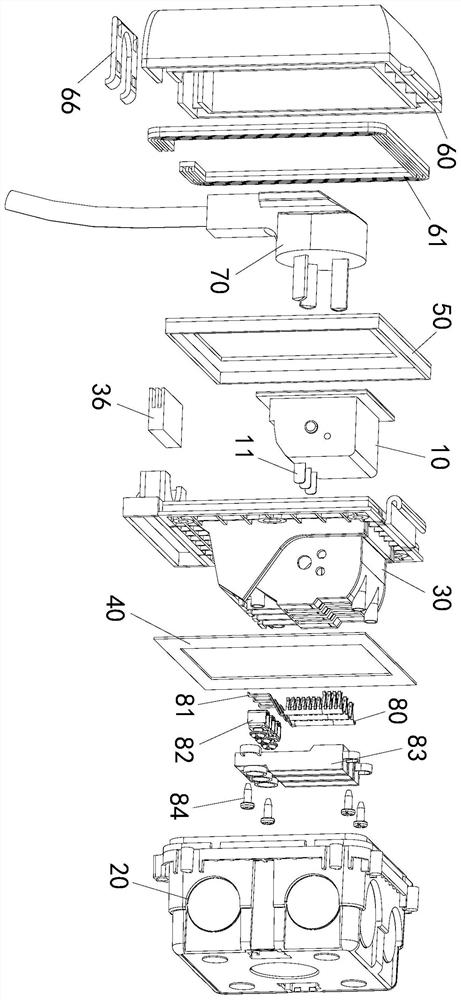

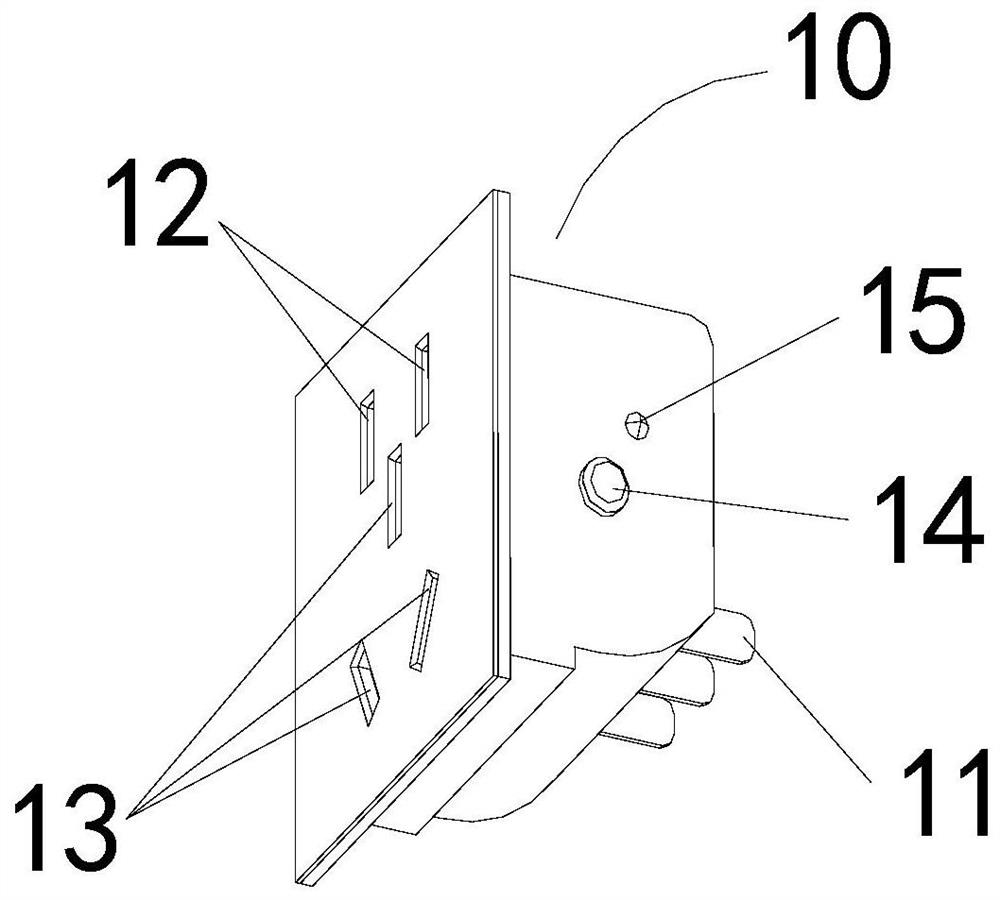

[0032] Embodiment 1: (This embodiment 1 is applicable to the usage scenario of a 90-degree outlet power plug)

[0033] Such as Figures 1 to 7 As shown, the fixedly installed waterproof socket includes a socket function part 10 and a socket bottom box 20. The socket function part 10 is arranged in the socket fixing frame 30, and the angle of rotation (the angle of this embodiment 1 is 0, no rotation angle is required, For the rotation angle, refer to the content in the following embodiment 2), the back of the socket holder 30 is provided with a power connection mechanism, and the power connection mechanism is socketed with the conductive insert 11 that passes through the back of the socket holder 30 on the back of the socket function part 10. A first waterproof mechanism is provided between the socket fixing frame 30 and the socket bottom box 20, and the first waterproof mechanism is a rectangular waterproof rubber ring. The socket holder 30 is fastened to the socket bottom b...

Embodiment 2

[0040] Embodiment 2: (This embodiment 2 is applicable to the usage scenario of 180-degree outlet power plug)

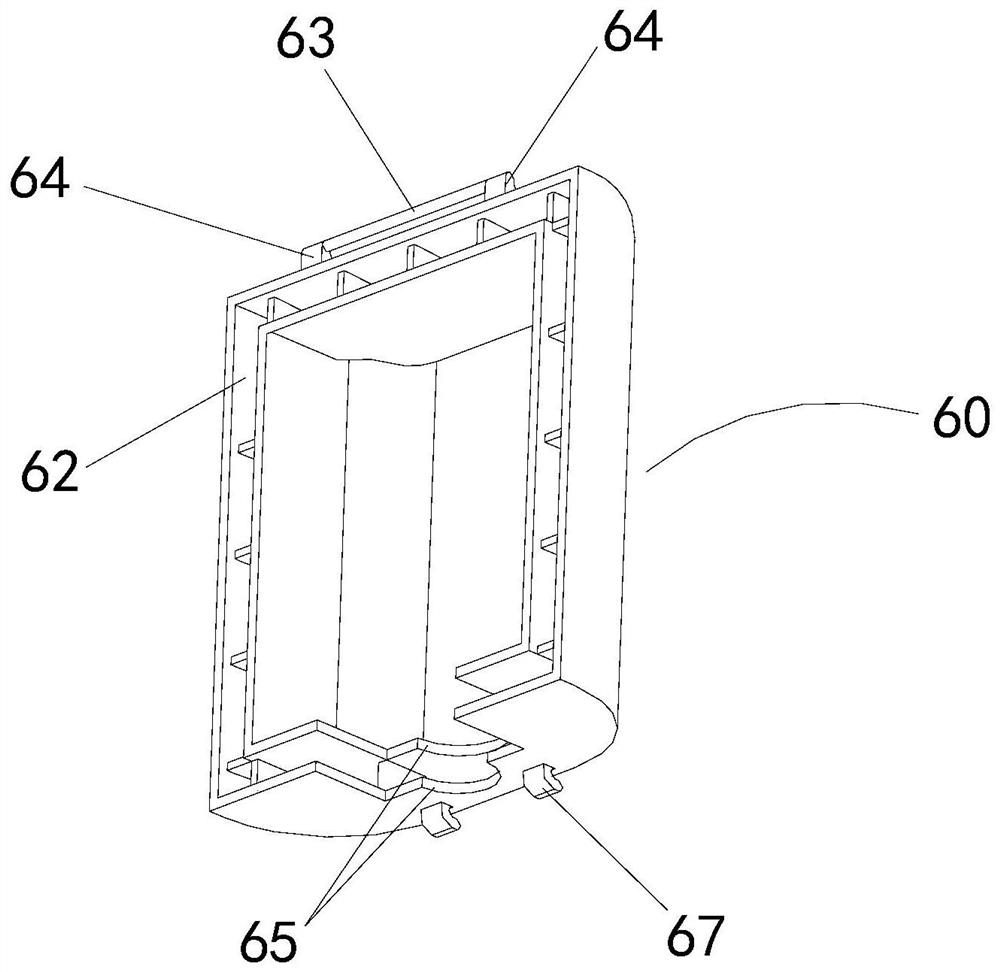

[0041] Such as Figure 8 As shown, the difference from Embodiment 1 is that the power plug of Embodiment 2 is a 180-degree outlet power plug (including a 180-degree outlet two-pin power plug 71 and a 180-degree outlet three-pin power plug 72), and the socket function part 10 can make two The socket surface of the pin power supply socket 12 and the three-pin power supply socket 13 forms an angle of α degree with the surface of the socket panel 50 (preferably α is an angle of 55 degrees), so that when the 180-degree outlet power plug is used, it can be completely covered in the waterproof cover 60 The inside is sealed and isolated from the outside to ensure effective waterproof and electric shock protection. The rest of the content is the same as that of Embodiment 1, and will not be repeated here.

[0042] The usage method of this embodiment 2 is as follows: first pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com