Design method of expansion coupling sleeve for solving stress concentration and light weight

A technology of expansion and tightening coupling sleeves and design methods, which is applied in the field of expansion and tightening coupling sleeves, can solve problems such as insufficient reliability and waste of materials and manufacturing costs, and achieve the effects of improving product reliability, solving insufficient reliability, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

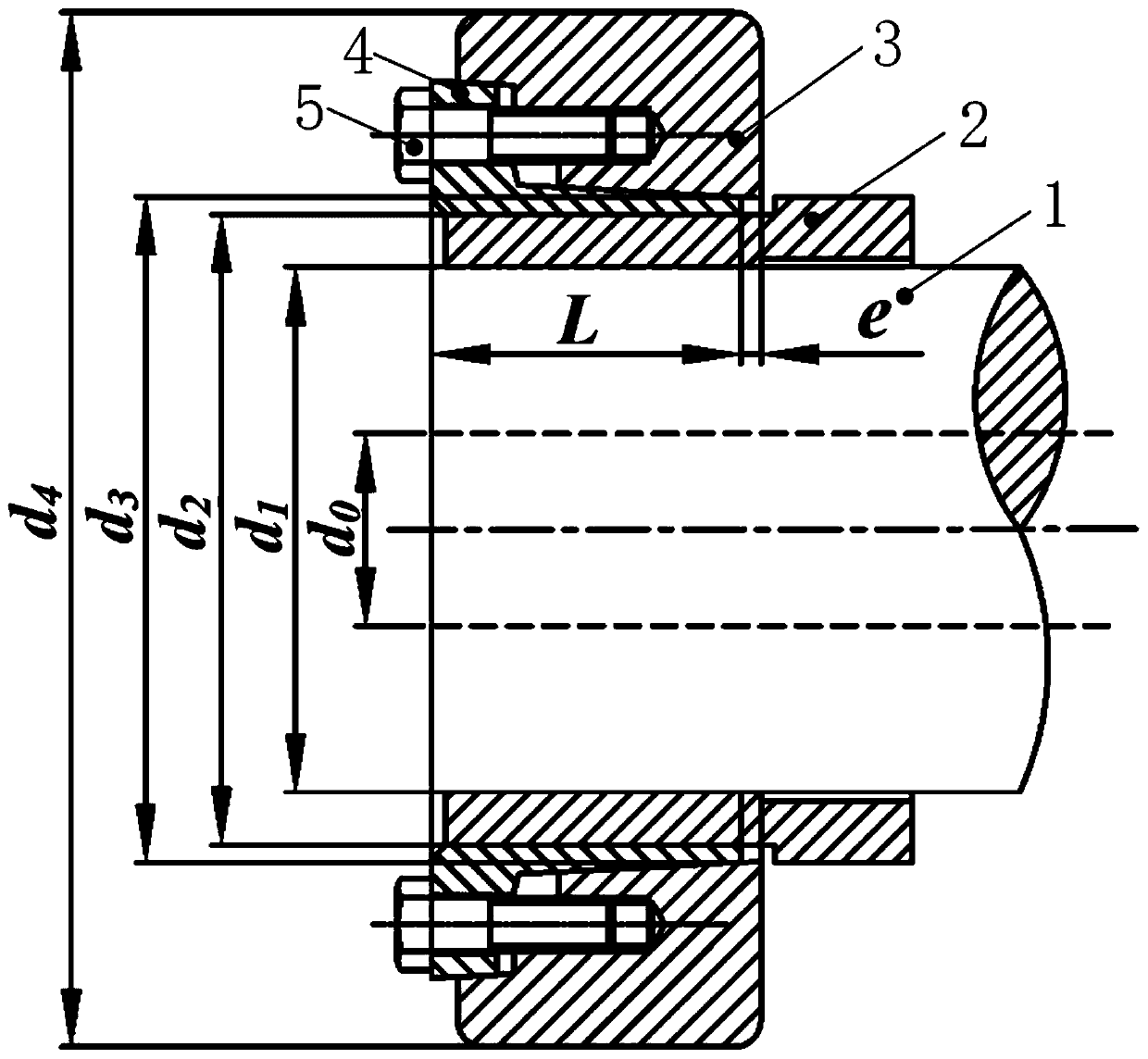

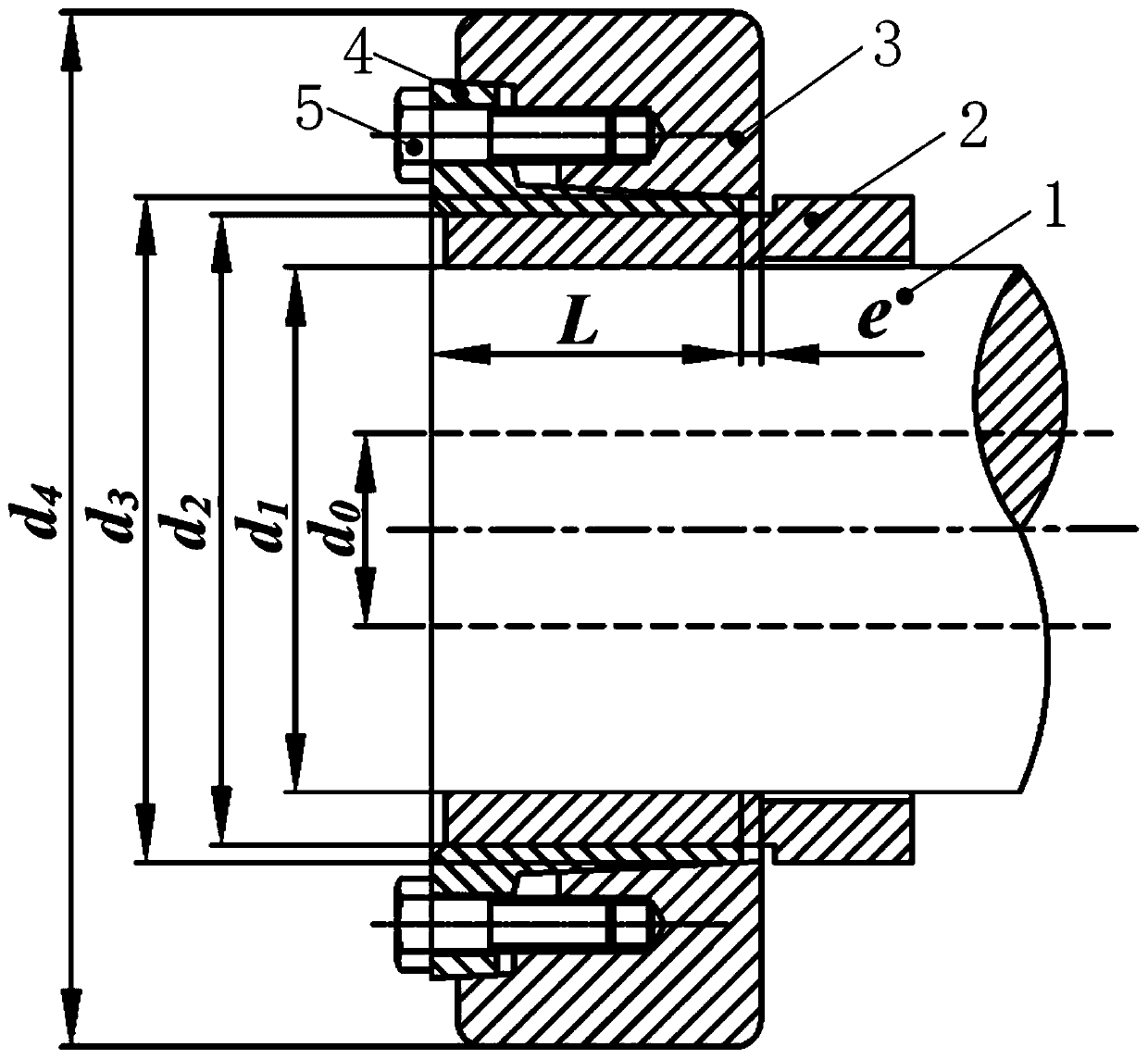

[0015] Such as figure 1 As shown, in this embodiment, a design method of an expansion coupling sleeve for solving stress concentration and light weight, the expansion coupling sleeve is composed of an inner ring, an outer ring and bolts, and is set on the shaft sleeve and the main shaft The design method includes the following steps:

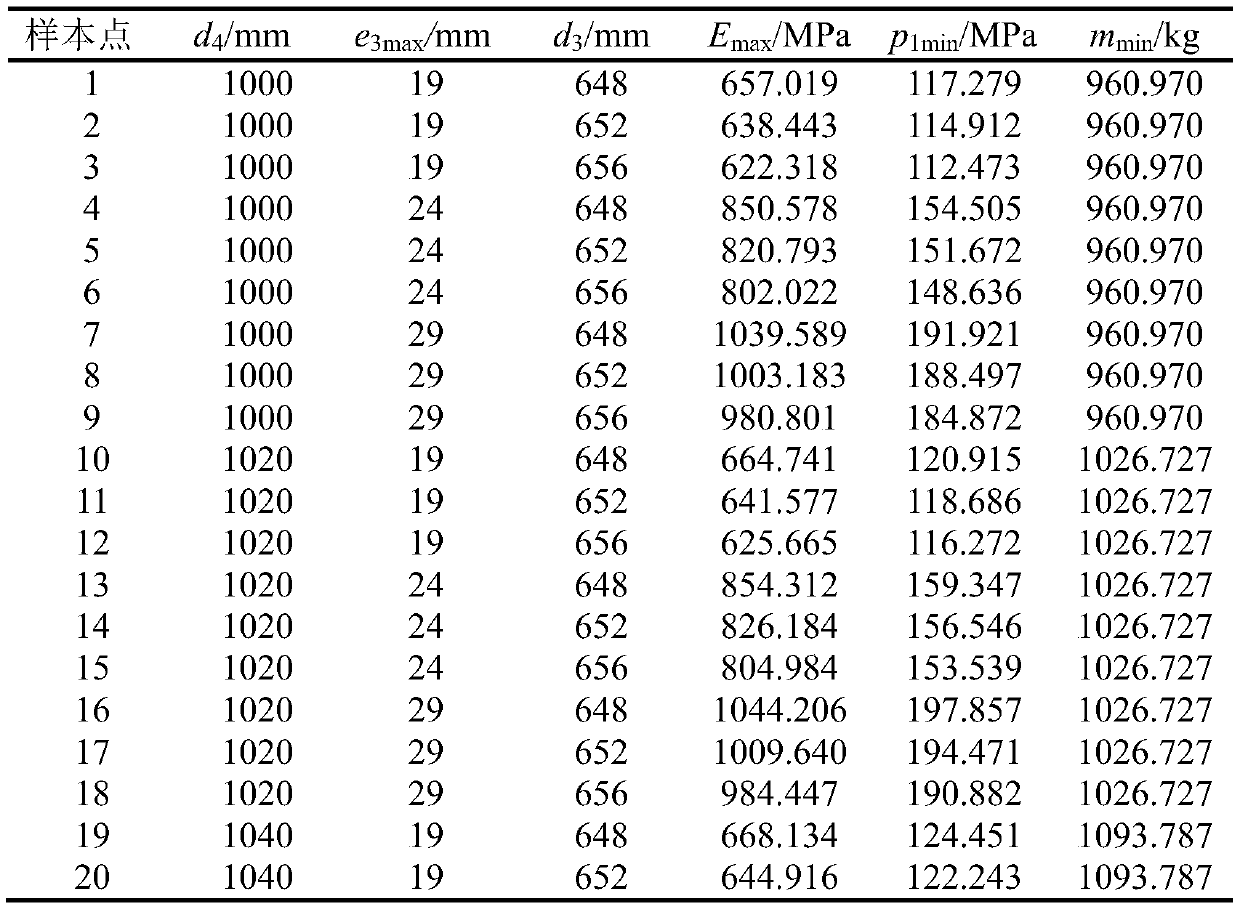

[0016] 1) According to the transmission torque requirements of the expansion and tightening coupling sleeve, the material yield strength requirements and the minimum weight requirements; the design index is determined as: the minimum contact pressure p between the main shaft and the shaft sleeve 1min , the maximum equivalent stress of the whole machine E max and minimum mass m min ;

[0017] 2) Combined with the structural characteristics of the expansion coupling sleeve, the determined design parameters are: the mini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com