Combined mask

A combined, masking technology, applied in the field of masking, can solve the problems of difficulty in manufacturing, waste of materials, and high cost, and achieve the effect of avoiding distortion of the coating pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to have a more complete and clear disclosure of the invention purpose, technical means and technical effects of the present invention, a detailed description is given below, and please also refer to the accompanying drawings and component numbers.

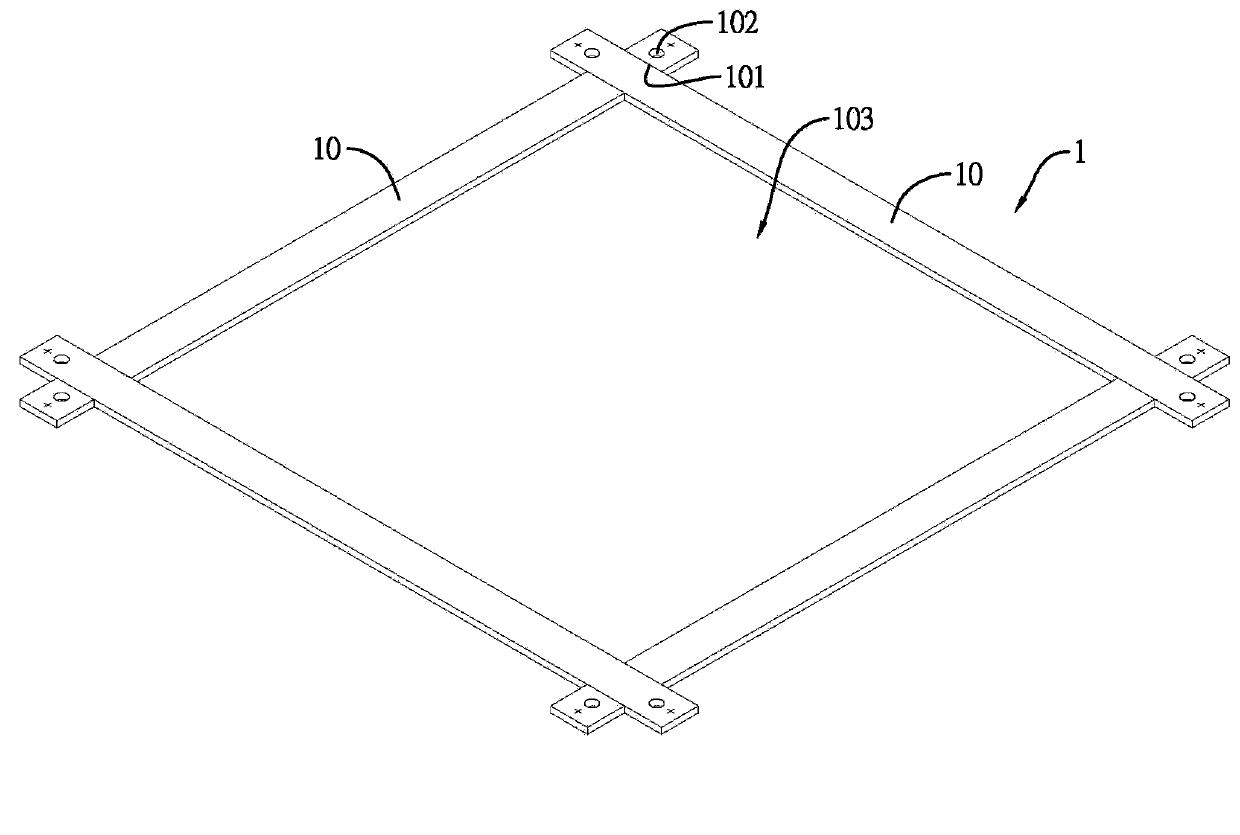

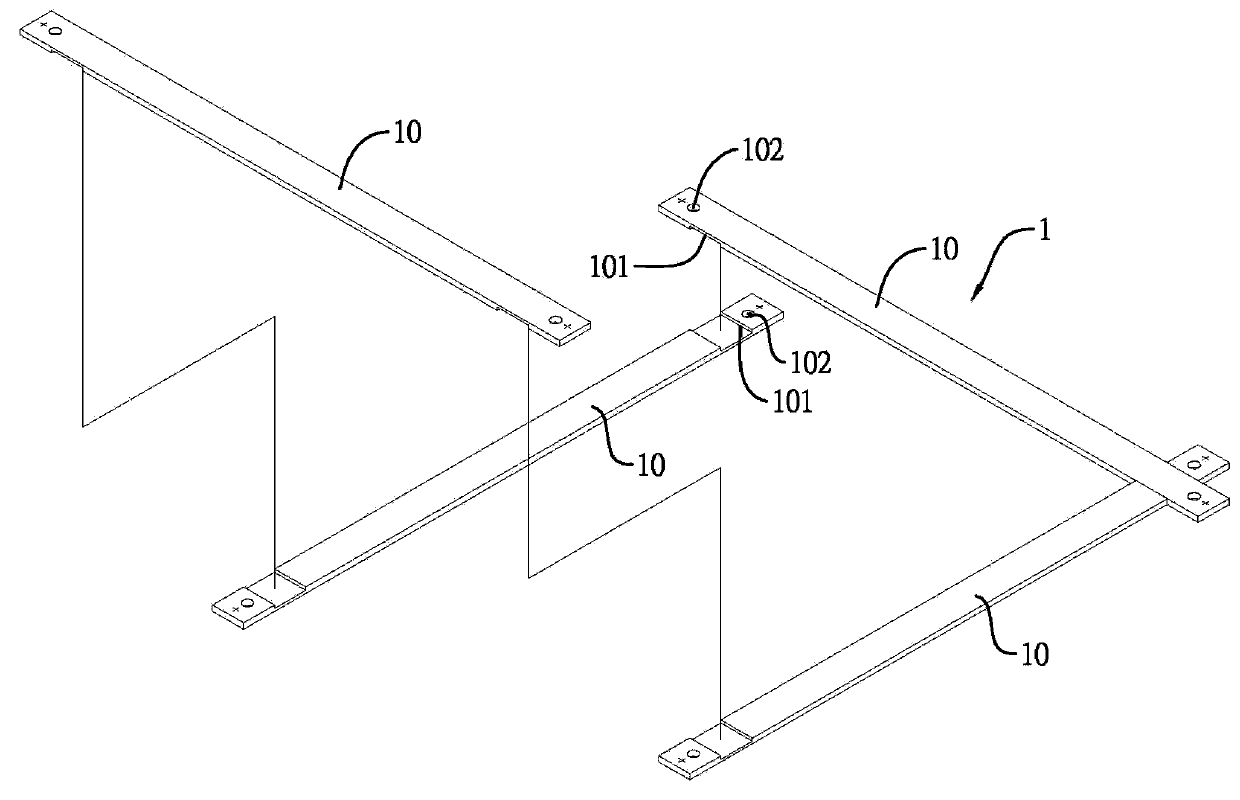

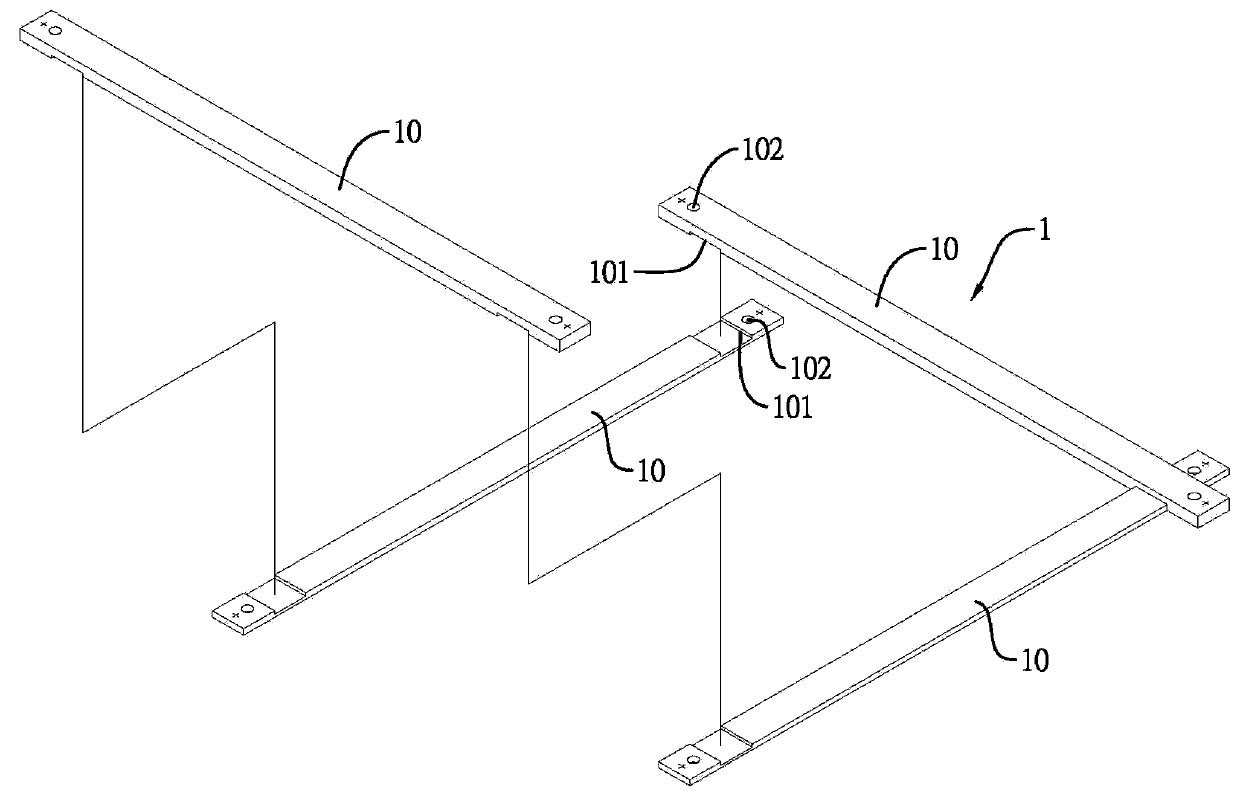

[0048] like figure 1 As shown, it discloses the first preferred embodiment of the combined cover of the present invention. The combined cover 1 includes four main frame plates 10, and the four main frame plates 10 are overlapped vertically and horizontally and enclose Form a rectangular frame with a main rectangular coating area 103 inside, and make one side of the assembled main frame plates 10 form a flat contact surface with the object to be plated.

[0049] Described main frame plate 10 is to select the material of low coefficient of expansion to make for good, as the nickel-iron alloy (Invar 36) that contains nickel 36%, the nickel-iron alloy (Invar 42) that contains nickel 42% etc.; Make these main frame plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com