Electric pole protection layer cushion block forming device and method and electric-pole centrifugal forming machine

A molding device and centrifugal molding technology, applied in ceramic molding machines, molds, manufacturing tools, etc., can solve the problems of waste of materials and labor, and achieve the effect of reducing production costs and solving waste of materials and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

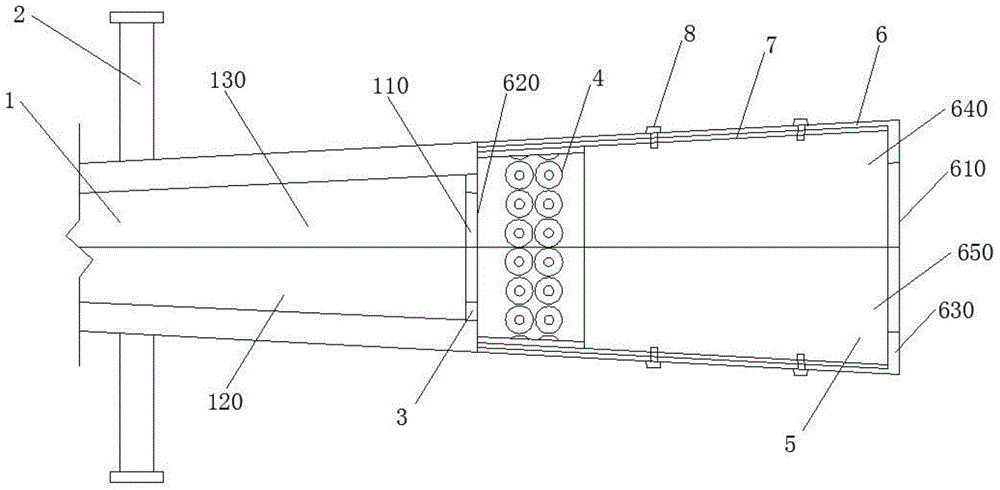

[0026] Such as figure 1 As shown, it shows a pole protective layer pad forming device, which includes a conical sleeve 6 connected to the big end 110 of the pole steel mold 1 . Pad block molds 4 are arranged on the inner surface of the conical sleeve 6 along the ring direction. The cushion block mold 4 utilizes the concrete mortar discharged during the centrifugal forming process of the electric pole to centrifugally form the protective layer cushion block and the electric pole together. The pad mold is used to collect concrete in the low-speed stage of the early stage of the pole centrifugal process so that it is covered with the groove of the pad mold, and is naturally densely formed under the action of centrifugal force.

[0027] The conical sleeve 6 includes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com