Metallographic detection sample preparation method after carbonitriding of high-carbon chromium bearing steel, as well as product

A technology of high-carbon chromium bearing steel and carbonitriding, which is applied in the preparation of test samples, metal material coating technology, coating, etc., can solve problems such as difficult to distinguish, batch scrapping of batch bearings, material waste, etc. achieve high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

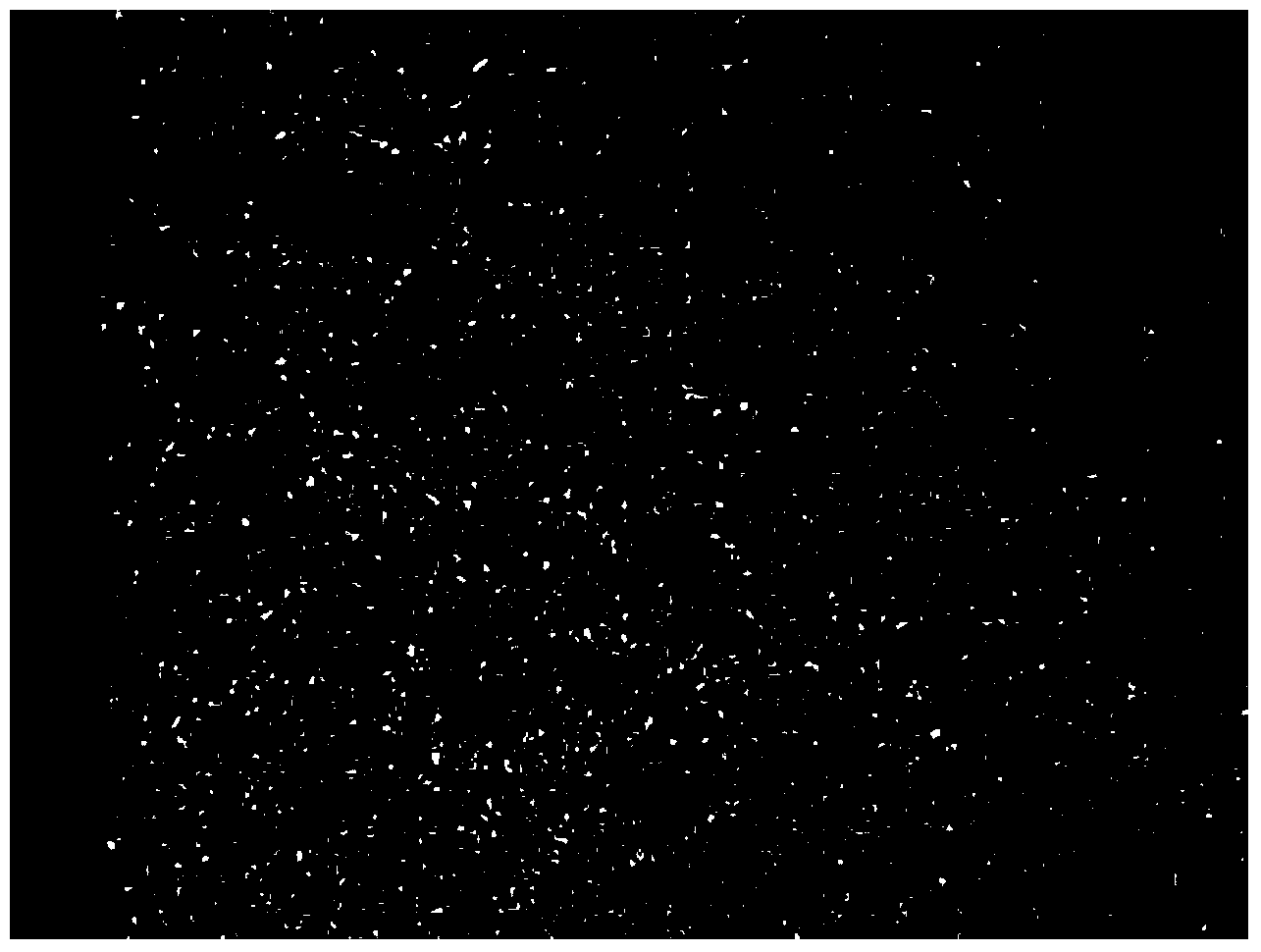

[0025] Specific embodiment 1: The ball bearing that has undergone carbonitriding heat treatment is subjected to high-temperature tempering for 2 hours, and the temperature is controlled at 300° C., so that the residual austenite and acicular martensite on the bearing surface are decomposed into Trotenite structure; After air-cooling to room temperature, it was cut, inlaid, polished, polished, etched in 5% picric acid alcohol solution for 1 minute, cleaned and dried after etching, and observed under a metallographic microscope, see figure 2 shown, with figure 1 In contrast, the morphology of carbonitride particles can be seen very clearly.

specific Embodiment 2

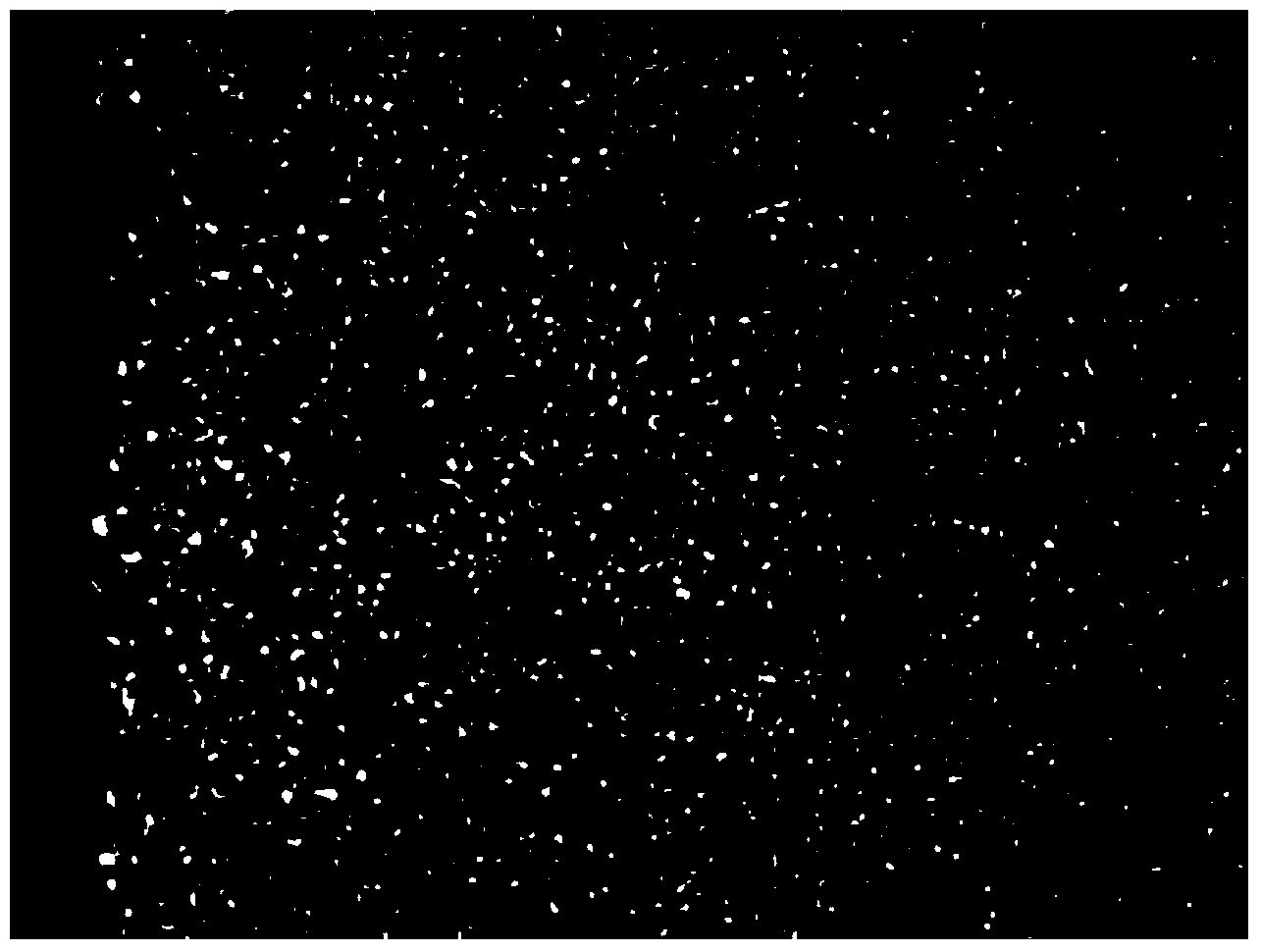

[0026] Specific embodiment two: the ball bearing that has passed carbonitriding heat treatment is subjected to high-temperature tempering for 2.5 hours, and the temperature is controlled at 350 ° C, so that the residual austenite and acicular martensite on the bearing surface are decomposed into troostite structure; After air-cooling to room temperature, it was cut, inlaid, polished, polished, etched in 6% picric acid alcohol solution for 1 minute, cleaned and dried after etching, and observed under a metallographic microscope, see image 3 shown, with figure 1 In contrast, the morphology of carbonitride particles can be seen very clearly.

specific Embodiment 3

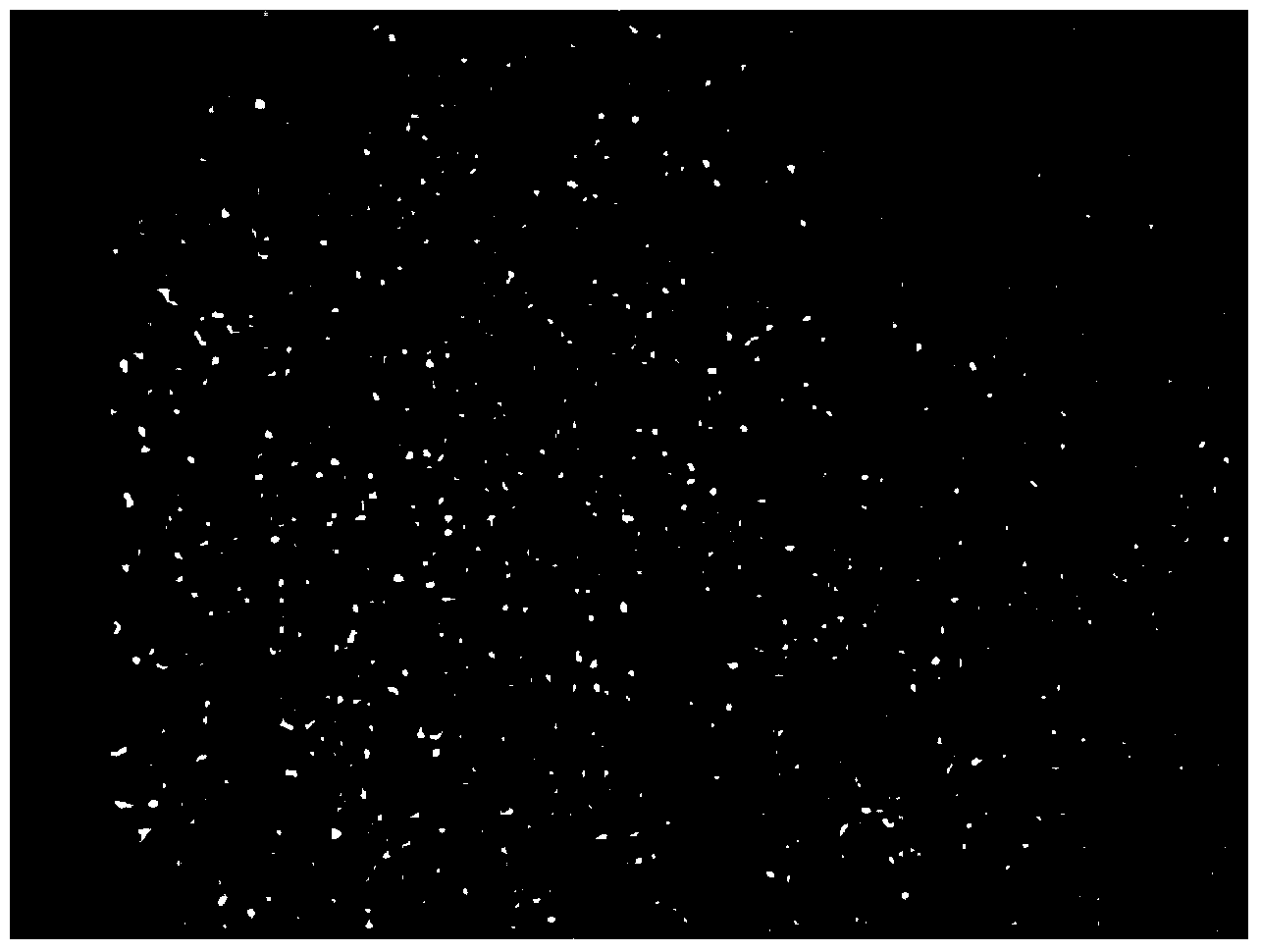

[0027] Specific embodiment three: the carbonitriding heat-treated ball bearing is subjected to high-temperature tempering for 3 hours, and the temperature is controlled at 400 ° C, so that the residual austenite and acicular martensite on the bearing surface are decomposed into troostite structures; After air-cooling to room temperature, it was cut, inlaid, polished, polished, etched in 5% picric acid alcohol solution for 1 minute, cleaned and dried after etching, and observed under a metallographic microscope, see Figure 4 shown, with figure 1 In contrast, the morphology of carbonitride particles can be seen very clearly.

[0028] By adopting the above scheme, the present invention decomposes the acicular martensite structure and residual austenite structure on the surface into troostite structure due to the high-temperature tempering of the bearing through the carbonitriding heat treatment, so that the carbonitride particles can be compared It is easy to be distinguished. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com