Weather-resistant angle steel for transmission tower

A transmission tower, weather-resistant technology, applied in towers, building components, building insulation materials, etc., can solve the problems of increased maintenance costs, environmental pollution, material waste, etc., and achieve the effect of solving material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

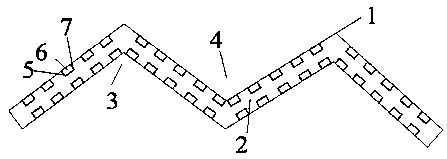

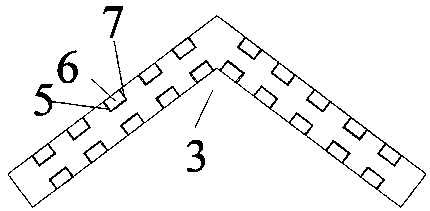

[0018] see figure 1 and figure 2 , a weather-resistant angle steel for transmission towers, including

[0019] A weather-resistant angle steel body, the weather-resistant angle steel body is formed by sequentially connecting several V-shaped units 1, the V-shaped unit 1 is composed of two steel plates 2 with a first angle 3 at the connection, and the two adjacent V There is a second included angle 4 at the joint of the type unit 1, and the first included angle 3 is the same as the second included angle 4, so that the structure of the weather-resistant angle steel body is more stable.

[0020] Several circular grooves 5, several described circu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com